Patents

Literature

122results about How to "Guaranteed antistatic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

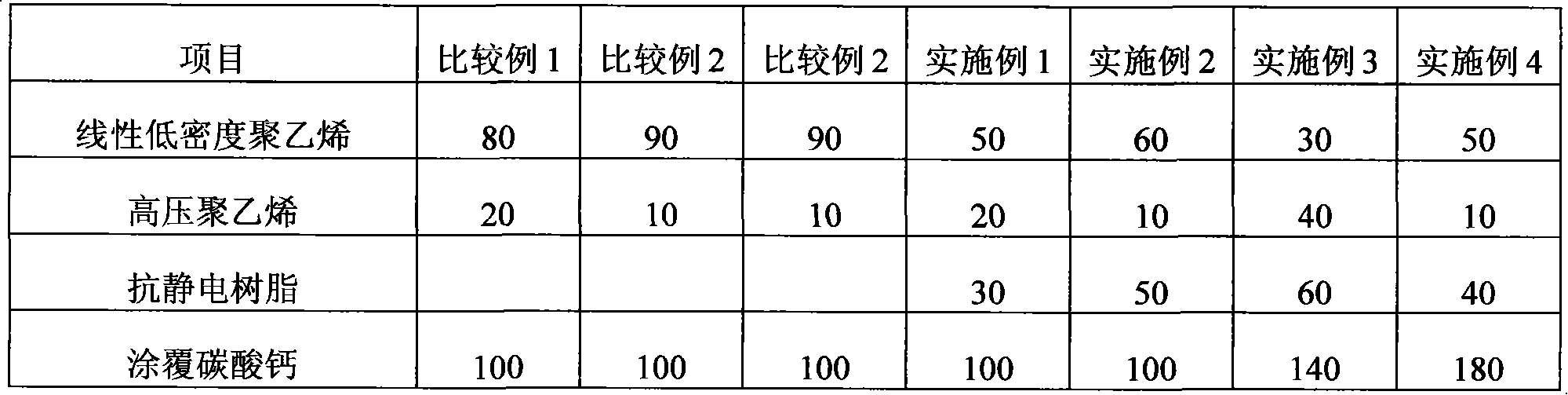

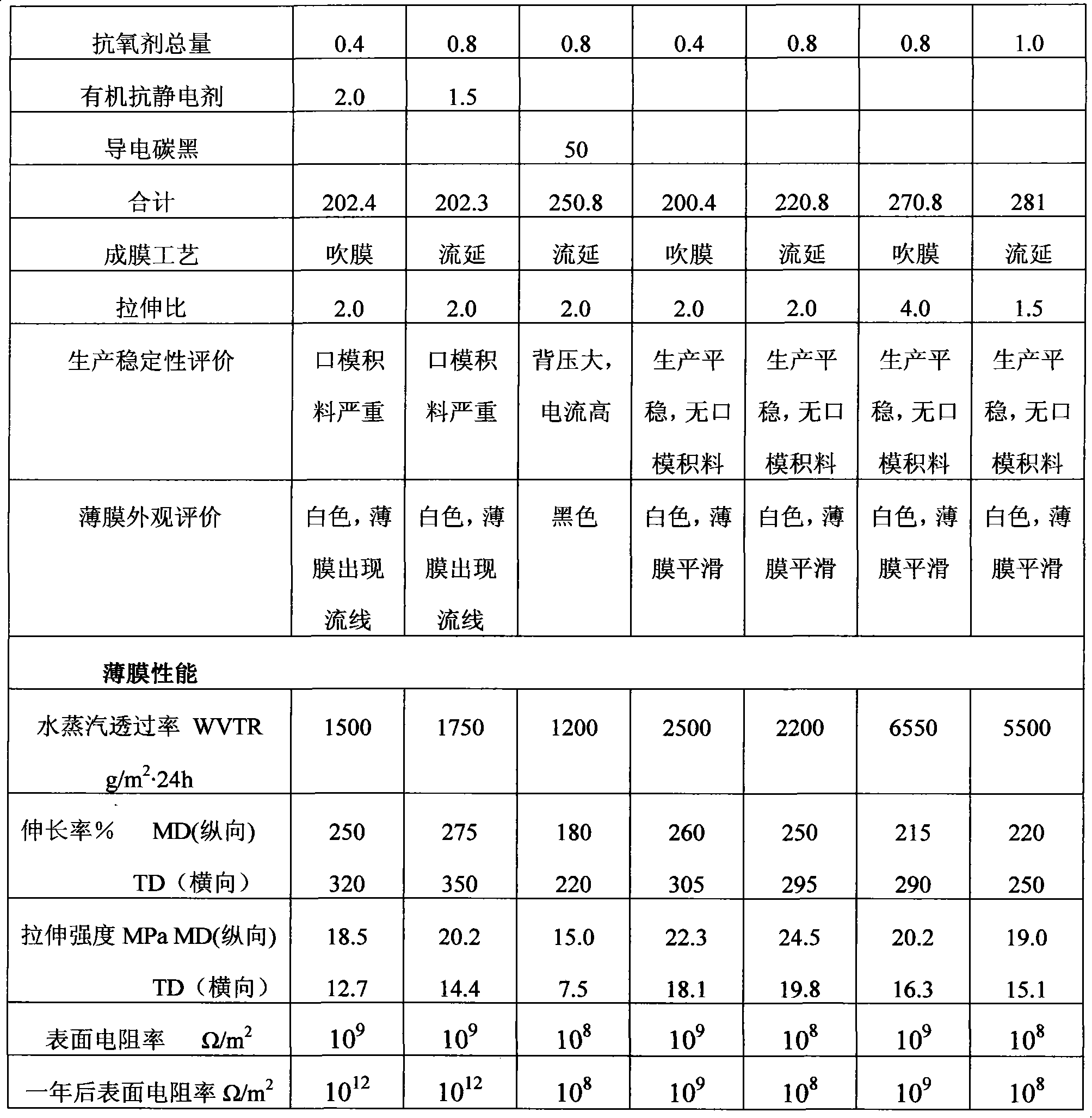

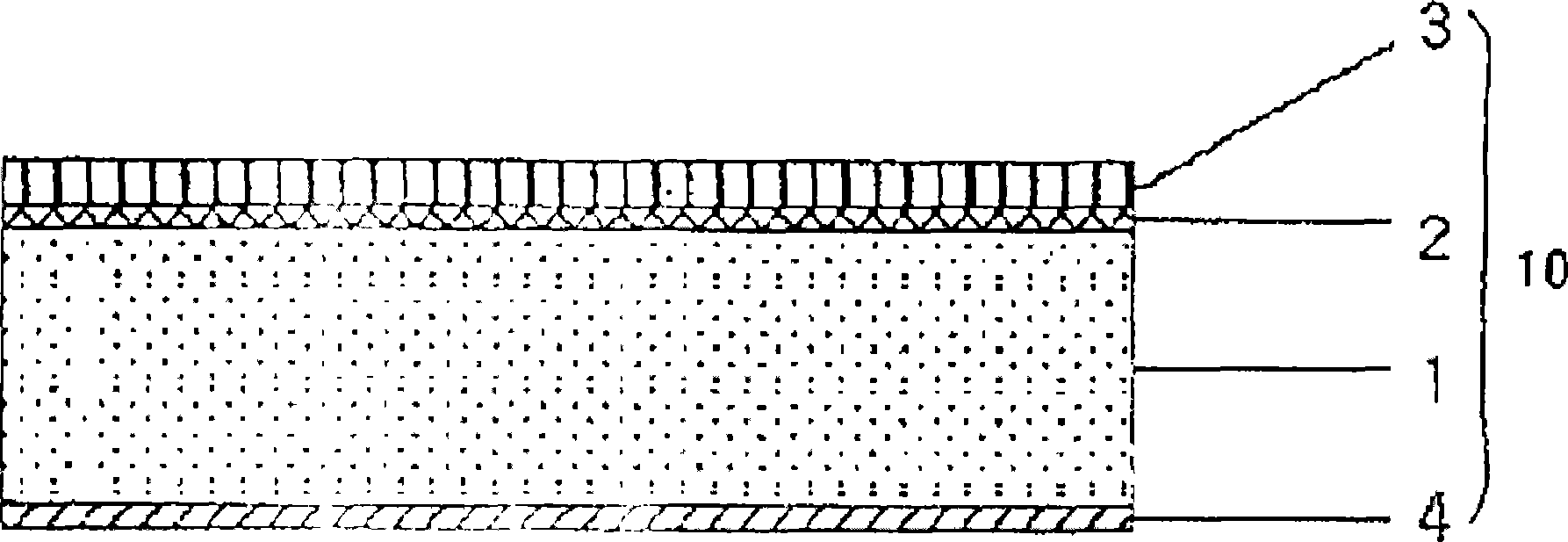

Anti-static polyolefin ventilated membrane composition and method for preparing the same

InactiveCN101250302APermanent antistaticGuaranteed antistatic effectCoatingsLinear low-density polyethylenePolyolefin

The invention discloses an antistatic polyolefin permeable film compound and a process for preparing the antistatic polyolefin permeable film. The compound comprises 30-60 parts by weight of linear low density polyethylene, 10-40 parts by weight of high-pressure polyethylene, 30-60 parts by weight of antistatic resin, 100-180 parts by weight of calcium carbonate and 0.4-1.0 parts by weight of anti-oxidant. The invention overcomes the weakness of traditional antistatic agent and antistatic filling, not only ensures the antistatic property of permeable film through adding antistatic resin, but also not affects the processing property, permeable property and the appearance of film. The processing flow-ability, the dispersing evenness of organic filling and processing stability of antistatic polyolefin permeable film compound in the invention can meet the production requirements of extrusion filmmaking. The water vapor permeable rate of the antistatic polyolefin permeable film which is prepared by the invention is not lower 2000g / m2 24h, and the surface electrical resistivity is no higher 10 9 omega / m2.

Owner:合诚技术股份有限公司

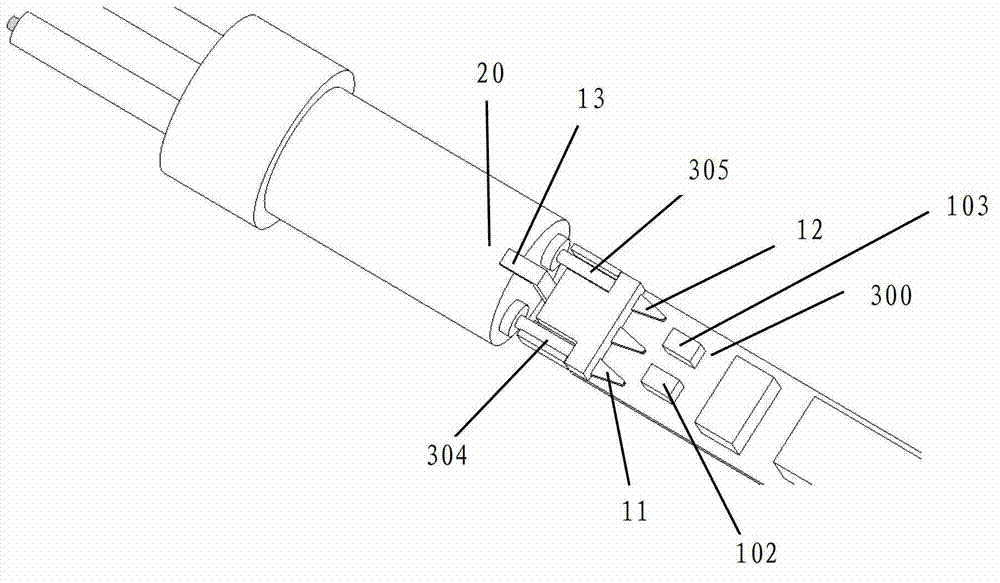

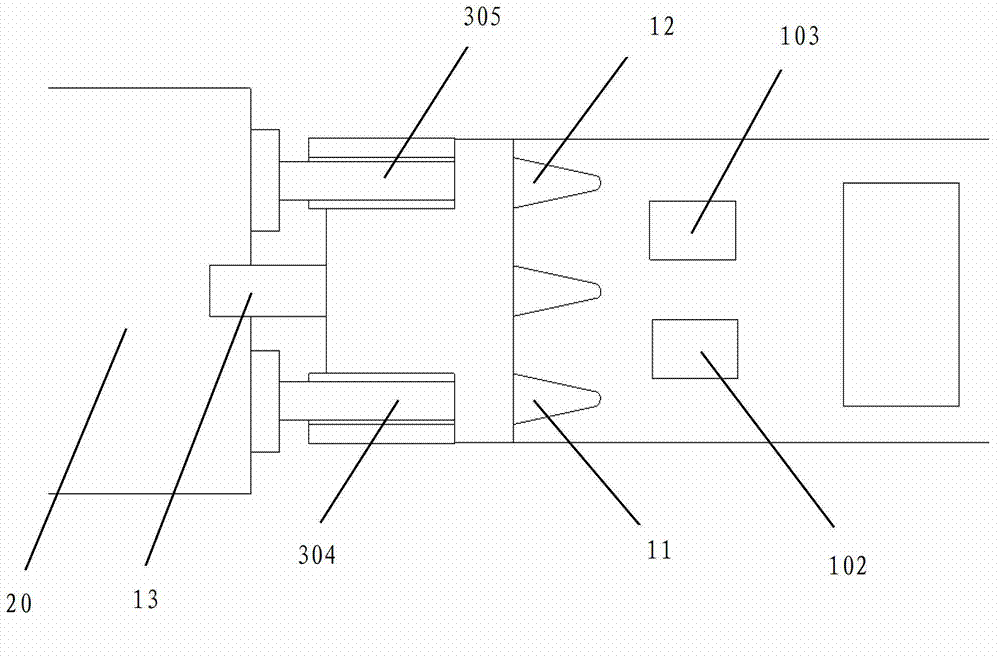

Anti-static structure of electronic detonator

ActiveCN103033100AAvoid damagePrevent accidental explosionAmmunition fuzesDetonatorElectrical resistance and conductance

The invention provides an anti-static structure of an electronic detonator, wherein two leg wires of the electronic detonator are electrically connected with a control circuit of a control circuit board. The anti-static structure of the electronic detonator is characterized by further comprising a discharge metal connecting piece; one end of the discharge metal connecting piece is electrically connected with a metal casing of the electronic detonator; two anti-static electronic devices are connected between the other end of the discharge metal connecting piece and one leg wire, as well as between the other end of the discharge metal connecting piece and the other leg wire respectively; and the anti-static electronic devices are transient suppression diodes, discharge tubes or voltage dependent resistors. By additionally arranging the anti-static structure on the electronic detonator, electricity can be preferentially discharged through the anti-static devices when the electronic detonator carries out electrostatic discharge, so that an error explosion can be prevented in the production and use processes; and moreover, one leg wire of the electronic detonator is connected with a first metal connecting piece and a second metal connecting piece in a manner of metal compression joint, the connecting operation is simple, tensile resistance is strong, and the electronic detonator can be prevented from being damaged by an external force in the production and use processes.

Owner:BEIJING QAML OF SCI & TECH CO LTD

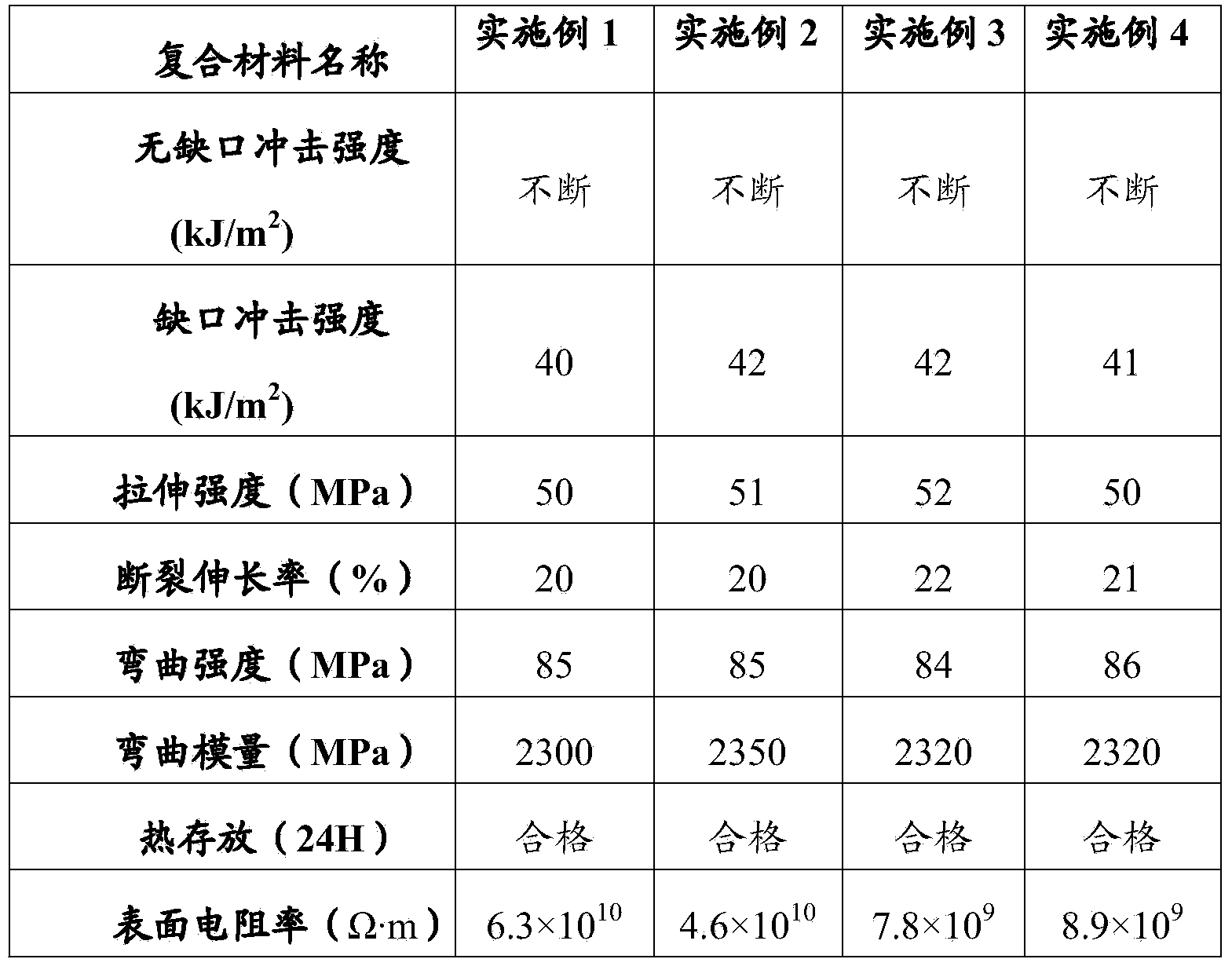

Antistatic polypropylene composite material and method for preparing same

The invention discloses an antistatic polypropylene composite material and a method for preparing the same and belongs to the technical field of modifying and processing polymers. The antistatic polypropylene composite material is prepared from the following raw materials in percentage by weight: 50 to 98 percent of polypropylene, 0 to 30 percent of inorganic filler, 0 to 20 percent of flexibilizer POE, 1 to 5 percent of antistatic agent, 0.1 to 1 percent of antioxidant and 0 to 1 percent of other auxiliary agents. The composite material and the method have the advantages that: 1, a proper amount of tin oxide is added in the composite material system, so that the prepared polypropylene composite material has better antistatic property; 2, under a condition of guaranteeing the antistatic property, the physical mechanical properties of the prepared polypropylene composite material are hardly affected; and 3, the method for improving the antistatic property of the polypropylene composite material is simple in preparation process and low in production cost.

Owner:SHANGHAI PRET COMPOSITES

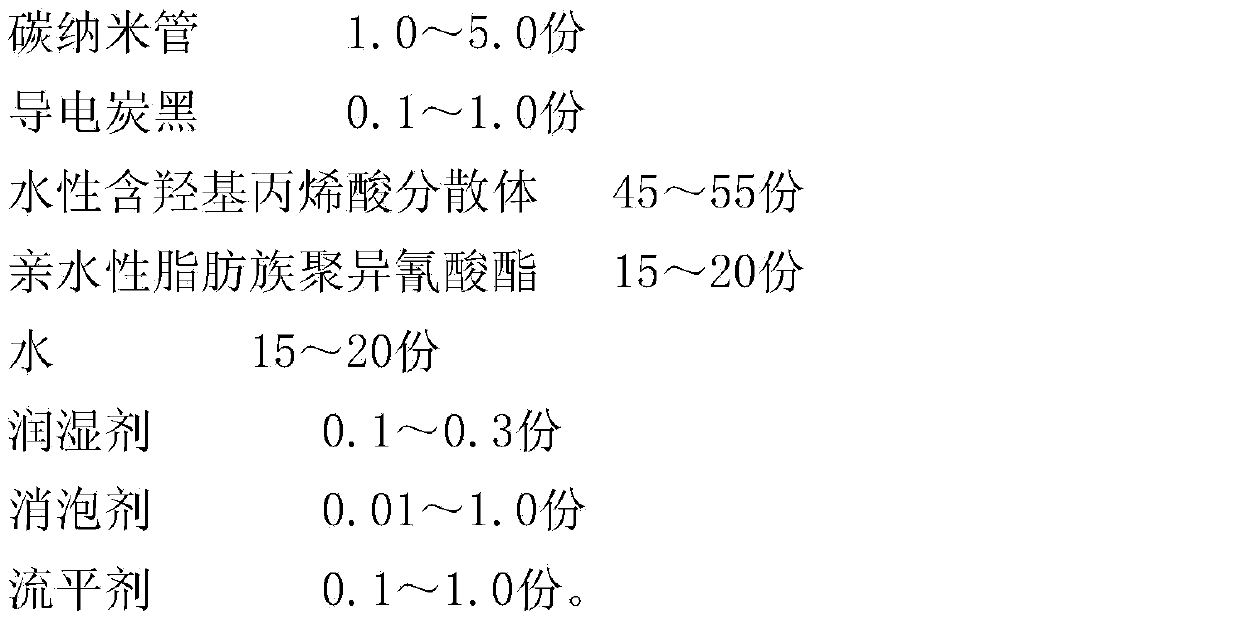

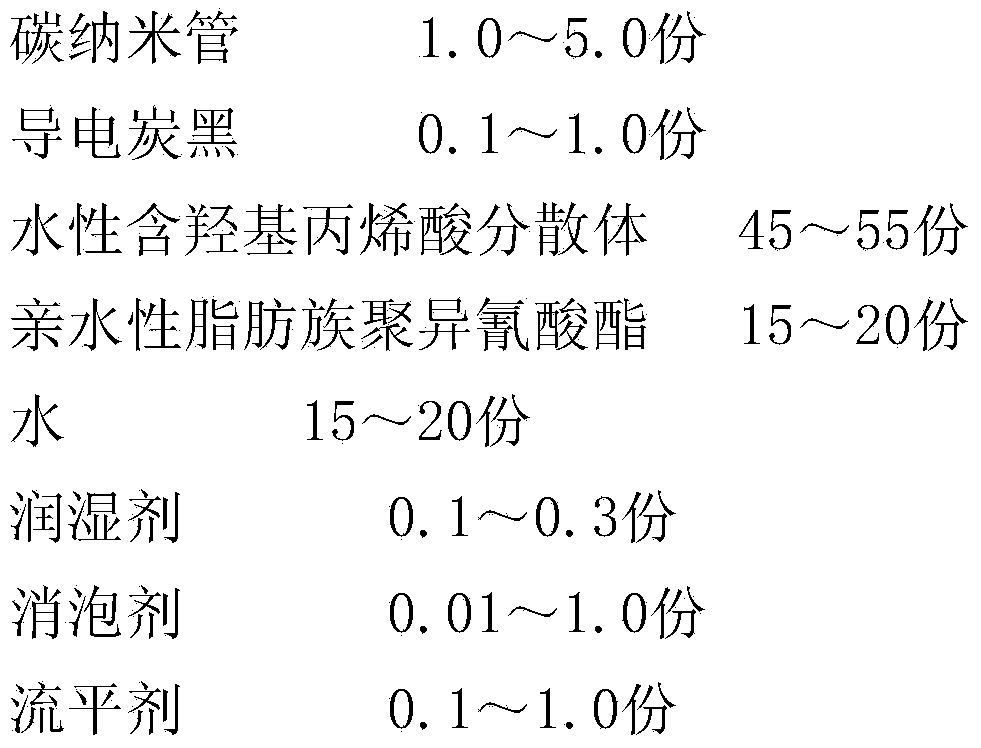

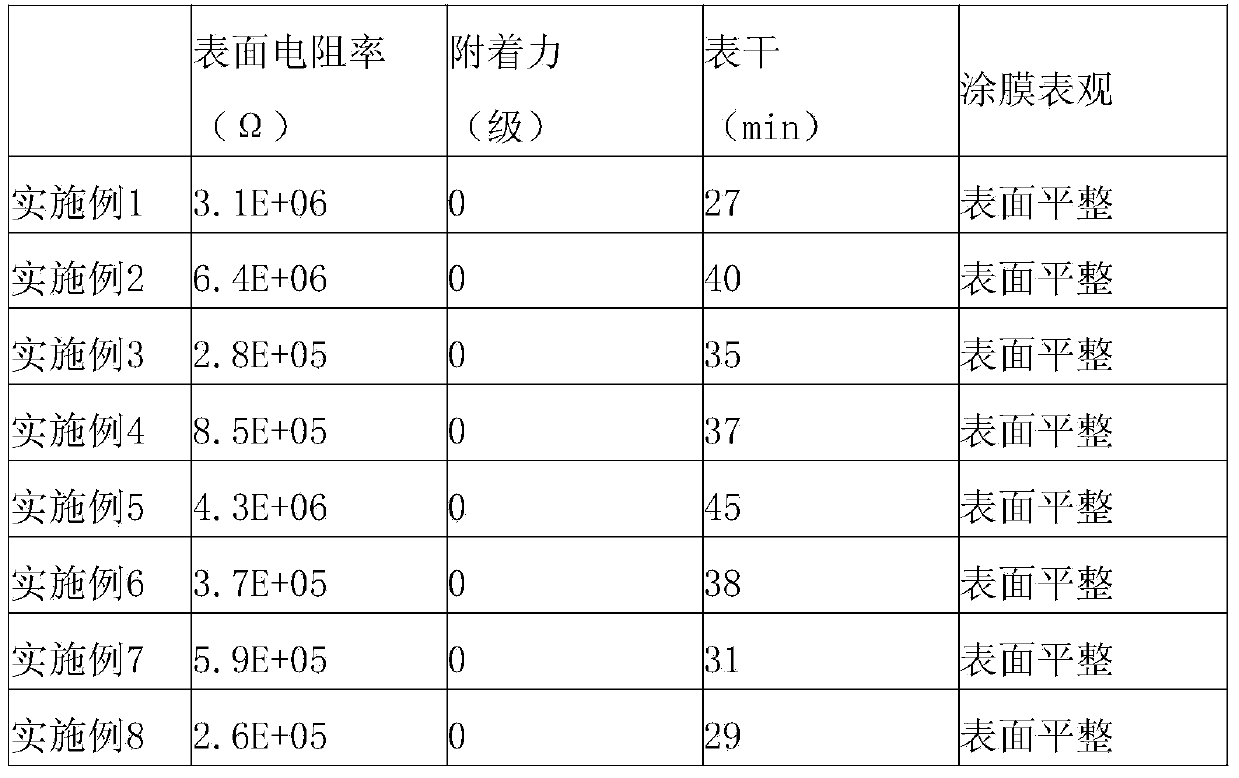

Antistatic waterborne polyurethane coating and preparation method thereof

ActiveCN103740252ASimple operation processReduced antistatic propertiesPolyurea/polyurethane coatingsElectrically-conductive paintsDefoamerChemistry

The invention belongs to the technical fields of a polymer composite material and a preparation method thereof, and particularly relates to an antistatic waterborne polyurethane coating and a preparation method thereof. The antistatic waterborne polyurethane coating comprises the following components in parts by weight: 1.0-5.0 parts of carbon nano tube, 0.1-1.0 part of conductive carbon black, 45-55 parts of waterborne hydroxyl-containing acrylic dispersion, 15-20 parts of hydrophilic aliphatic polyisocyanate, 15-20 parts of water, 0.1-0.3 part of wetting agent, 0.01-1.0 part of defoamer, and 0.1-1.0 part of flatting agent. The waterborne polyurethane coating prepared by the method has good anti-static performance, can be applied to a few of electronic equipment and elements, and effectively prevents electrostatic aggregation.

Owner:AODA KOALA PAINT HUIZHOU

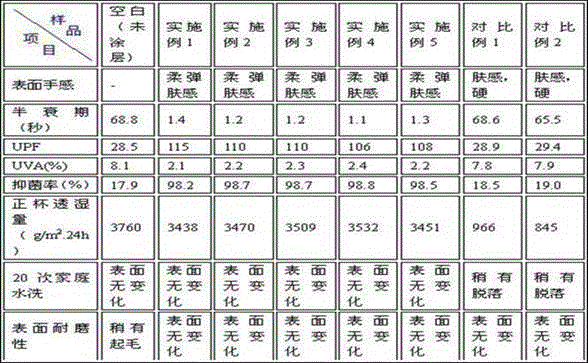

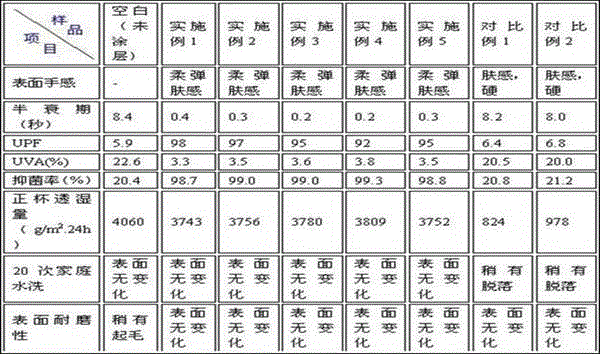

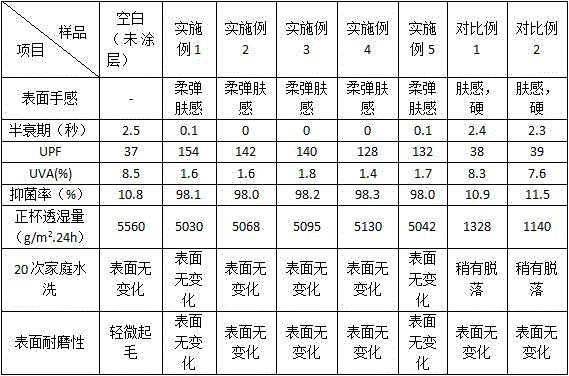

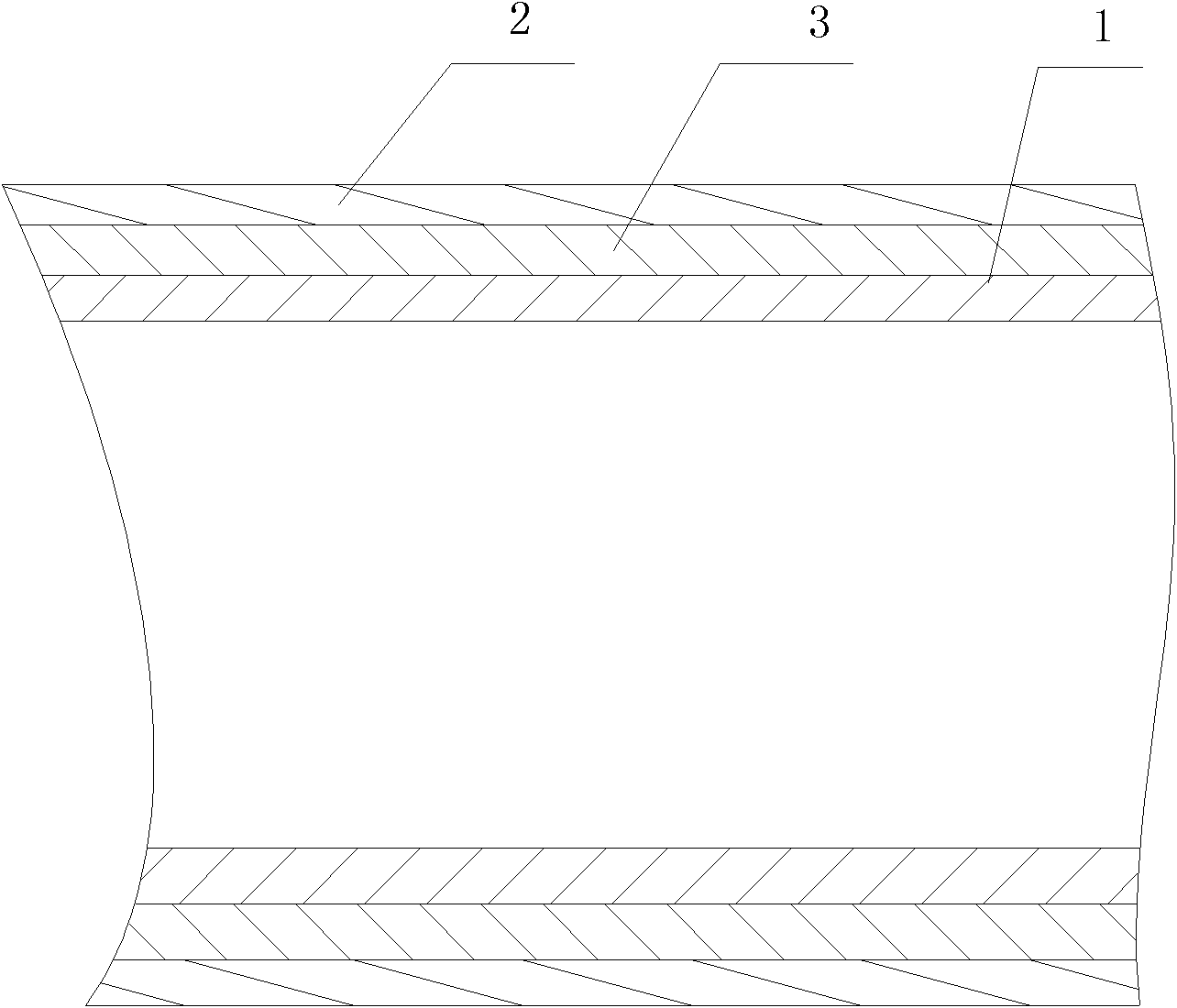

Antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive for textile and preparation method thereof

ActiveCN106436324AGuaranteed antistatic effectGuaranteed UV resistanceBiochemical fibre treatmentLight resistant fibresPolyesterPolymer science

The invention provides an antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive and a preparation method thereof. The coating adhesive is prepared from, by weight, 20-30 parts of deionized water, 0.5-3.0 parts of diisopropyl octadecanalkoxyl acetyl aluminum chelate, 5.0-15 parts of modified hemp lignocellulose powder, 3.0-5.0 parts of polyurethane elastic powder, 50-70 parts of polyurethane adhesive, 0.1-0.3 part of defoaming agent, 1.0-5.0 parts of associative polyurethane thickener, 2.0-5.0 parts of anti-static agent, 5.0-10 parts of organic silicon smooth handfeel agent, 2.0-5.0 parts of organic silicon anti-sticking agent and 1.0-3.0 parts of ultraviolet absorbent in a compounding mode. The coating adhesive is suitable for pure cotton, polyester, chinlon and various blended fabrics and good in wear resistance and washability.

Owner:LIAONING FIXED STAR FINE CHEM

Basic solution washable antistatic composition and polymer products manufactured by using the same

InactiveCN101379161AImprove adhesionImprove wettabilityOther chemical processesCoatingsPolymeric surfacePolymer science

The present invention provides an antistatic composition which can be used in washing processes using alkaline aqueous solution, that is, can be used to manufacture antistatic polymer products which can resist basic solvents, and antistatic polymer products manufactured by the same. The antistatic composition includes 0.1-20 parts by weight de metal oxides or carbon nanotubes; 0.5-20 parts by weight of a thermosetting resin; 0.02-5 parts by weight of a curing agent; and 55-99.38 by weight of a solvent, in which the antistatic composition is applied on a surface of a base polymer using a solution and can be reused without a change in surface resistance after a washing process using an alkaline aqueous solution.

Owner:徐光锡

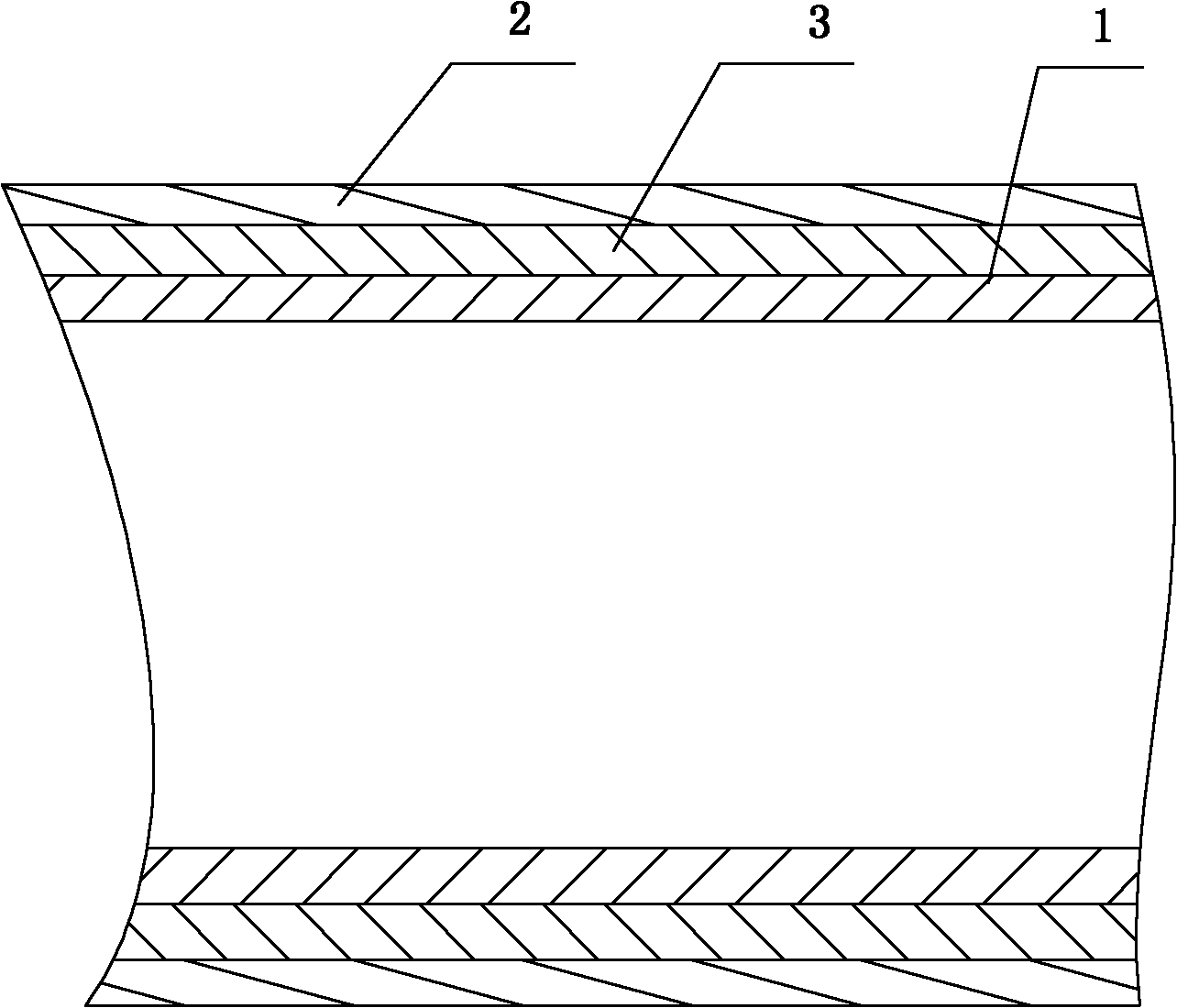

Fiber reinforced pipe for mine and production method thereof

InactiveCN102011897AImprove flame retardant performanceImprove antistatic performanceSynthetic resin layered productsRigid pipesFire resistanceMechanical engineering

The invention provides a fiber reinforced pipe for a mine and a production method thereof. The fiber reinforced pipe comprises a lined pipe, wherein the lined pipe is made of an antiflaming and antistatic special polyethylene material, so that the fire resistance and anti-static electricity performance of a pipe are improved; therefore, the safety of the pipe is improved; the weight of the polyethylene is light, so that the pipe can be conveniently installed and transported; moreover, the fiber reinforced pipe has a simple structure and can be processed conveniently; and the processing method of the fiber reinforced pipe is easy to operate, and can improve the fire resistance of the fiber reinforced pipe.

Owner:江苏金波新材料科技有限公司

Formulation of military sole

The invention relates to a formulation of a sole, in particular to formulation of a military sole, comprising the formulations for forming an outer bottom and a middle layer of the sole, wherein the formulation of the outer bottom based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.7-0.9 part of vulcanizing agent S-80, 2.4-2.6 parts of accelerating agent, 1.9-2.1 parts of magnesium oxide, 4.5-5.5 parts of zinc oxide, 4.5-5.5 parts of antimony oxide, 1.9-2.1 parts of stearic acid, 1.9-2.1 parts of zinc stearate, 20-24 parts of high wear resistance carbon black, 2-4 parts of engine oil 46#, 6-8 parts of dibutyl ester, 1.4-1.6 parts of anti-aging agent, 0.8-1.2 parts of paraffin wax and the like; and the formulation of the middle layer based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.9-1.1 parts of sulphur, 2.5-2.7 parts of accelerating agent, 4.5-5.5 parts of zinc oxide, 1.9-2.1 parts of magnesium oxide, 3.8-4 parts of antimony oxide, 6.3-6.7 parts of decabromodiphenyl oxide, 1.9-2.1 parts of stearic acid and the like. The sole prepared by the formulation has good wear resistance and folding resistance, and has the performances of oil resistance, acid-base resistance, inflaming retarding, static electricity prevention and the like, thus meeting the military requirements.

Owner:JIHUA 3513 IND

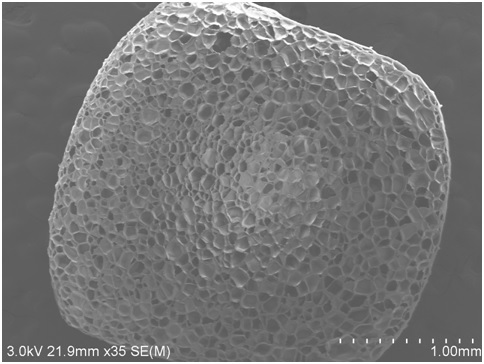

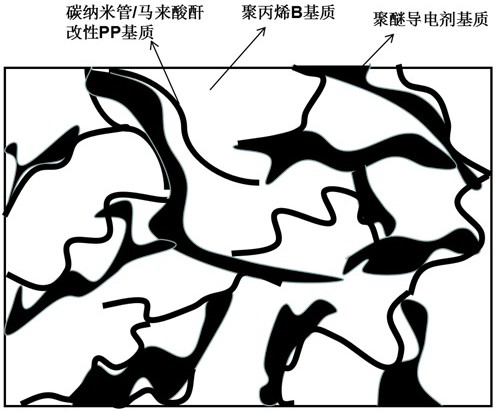

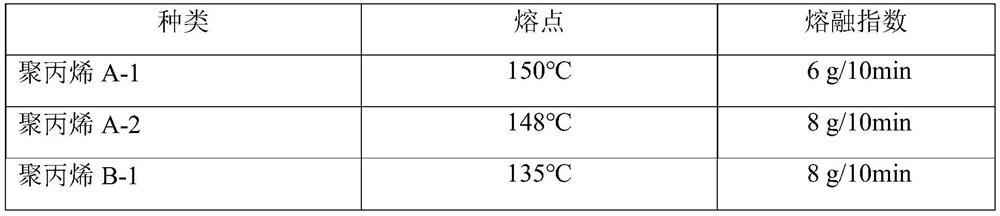

Gray antistatic polypropylene composite foamed beads with skin-core structure and molded product thereof

The invention discloses gray antistatic polypropylene composite foamed beads with a skin-core structure, which are composed of a foamed core layer and a non-foamed skin layer, and the foamed core layer is composed of polypropylene, a cell nucleating agent, an antioxidant, colored carbon black and a lubricant. The skin layer is prepared from polypropylene, a polyether block copolymer antistatic agent, maleic anhydride grafted modified polypropylene and multi-walled carbon nanotube; the composite foamed beads are obtained by extruding and granulating through a co-extrusion extruder and then foaming through a high-pressure foaming kettle. The skin layer contains the composite antistatic agent and the low-melting-point polypropylene, so that good fusion bonding, apparent quality and stable permanent antistatic property of the molded product are guaranteed; the foaming effect of the core layer is excellent, and the foaming ratio adjustability and the excellent mechanical property of a molded product are guaranteed. The molded product not only has permanent antistatic property, but also has good rigidity.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

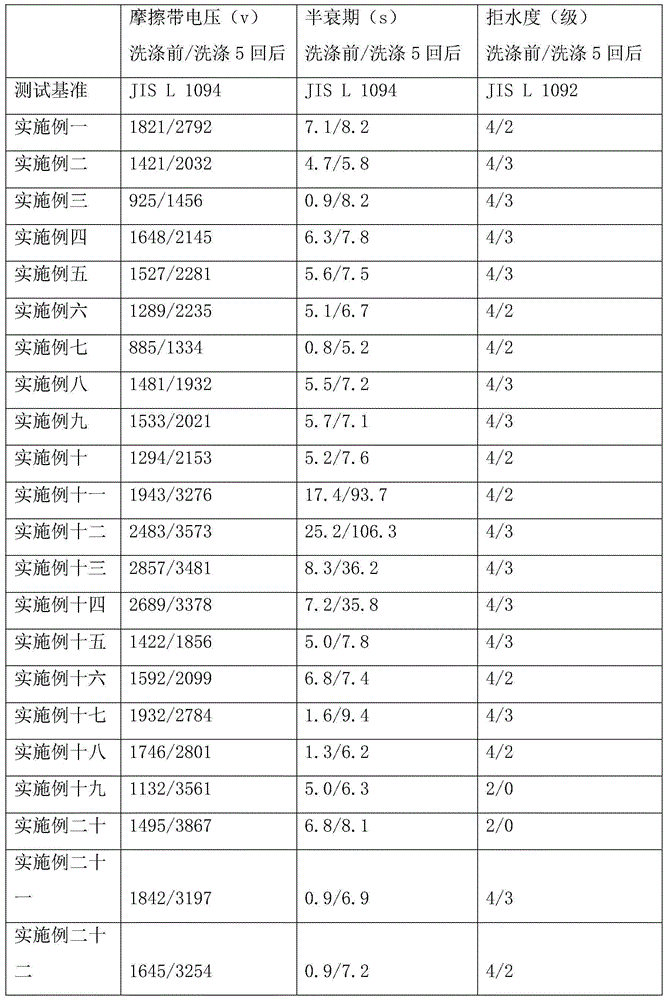

Manufacturing method of durable antistatic water-repellent fabric

ActiveCN105178029AImprove antistatic performanceImprove long-lasting antistatic performanceFibre typesPolyesterYarn

The invention discloses a manufacturing method of durable antistatic water-repellent fabric. The method includes the following steps of firstly, selecting fabric woven from polyester fiber or nylon fiber with yarn fineness of 7 D to 70 D as base cloth; secondly, conducting antistatic processing on the base cloth in the first step through antistatic finishing liquid, adjusting pH through citric acid, conducting twice immersing and once rolling, conducting non-contact type infrared pre-drying, conducting drying through a direct-contact type roller, and conducting cooling so that continuous antistatic resin film can be formed on surfaces of fiber; thirdly, conducting water-repellent processing on the fabric obtained in the second step through water-repellent finishing liquid, conducting once immersing and once rolling, conducting baking so that an insoluble water-repellent thin film can be formed on the surface of the antistatic resin film, and obtaining the durable antistatic fabric. The method has the advantages that through the cooperation of an antistatic agent and a water-repellent agent, emulsified siloxane quaternary ammonium is evenly distributed in the antistatic agent with waterborne polyurethane resin as carriers, and the optimal antistatic effect and water-repellent effect are achieved.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Antistatic tapes and method for producing thereof

InactiveCN1867643AGuaranteed antistatic effectImprove toleranceOpticsThin material handlingElectrical resistance and conductancePolymer science

The invention relates to a manufacturing method of an antistatic adhesive tape. More specifically, the present invention relates to an adhesive tape, wherein one surface of the tape has a resistance of 108-1011 ohm / square by forming a conductive polymer-based antistatic layer on the surface and forming an adhesive layer thereon. Surface resistivity, the other surface has a controllable surface resistivity of 103-1010 ohms / square meter by forming a conductive polymer-based surface hardening layer on it, and has good resistance to various solvents. The adhesive tape produced by the method of the present invention does not generate static electricity even when it is removed from the surface of the electronic component or film to which the tape is attached. Also, the tape has good antistatic properties on its surface when adhered or attached to the surface of an electronic component or film. In addition, the tape has good resistance to various solvents.

Owner:徐光锡

Flame-retardant anti-static two-faced plush cloth

ActiveCN105019119APermanent Flame RetardancyImprove thermal protection performanceWeft knittingYarnModacrylic

The invention discloses flame-retardant anti-static two-faced plush cloth which is formed by blending the following components in parts by weight: 50-60 parts of modacrylic, 30-40 parts of cotton, 5-15 parts of nylon and 1-3 parts of conductive wires. The two-faced plush cloth includes a first surface and a second surface, wherein both the first surface and the second surface are formed by blending and weaving modacrylic fibers and cotton fibers; the first surface and the second surface are connected with each other through polyamide yarns and the conductive wires; the polyamide yarns are arranged parallel to the conductive wires, the distance between adjacent polyamide yarns is 0.08-0.15 cm, and the distance between adjacent conductive wires is 0.8-1.2 cm. The two-faced plush cloth is knitted fabric and has the characteristics that the cloth is resistant to high temperature, non-combustible, free of molten drops, soft, comfortable and good in heat retention property, and does not lose plush.

Owner:上海俊首安防科技有限公司 +1

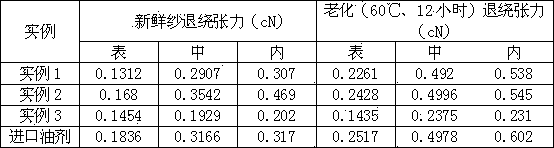

Polyurethane oil preparation with general applicability

The invention relates to a polyurethane oil preparation with general applicability. The oil preparation comprises the following components in percentage by weight: 50-67% of mineral oil, 10-20% of dimethicone, 20-40% of modified silicon oil, 1-3% of an antistatic agent, 1-5% of a dispersing agent and 1-10% of a spreading agent, wherein the modified silicon oil is high-carbon alkyl silicon oil of which the carbon number is 12-20 and the molecular weight is 500-3000, wherein the spreading agent is nanometer silicon oil, and the kinematic viscosity of the polyurethane oil preparation at the temperature of 40 DEG C is 7-20 mm2 / s. The spreading agent is added into the oil preparation and is directly acted on the surfaces of polyurethane silks, a uniform spreading effect can be achieved while oiling, the usage effect of the oil preparation is improved, the oil preparation has better applicability for the polyurethane silks with different specifications, and the silks are smooth and astringent but not sticky; at the same time, the spreading agent form a protective isolating layer on the surfaces of the silks, the oil preparation is prevented from being permeated into the inner parts of the silks, and the possibility of breakage and adhesion of the silks in the process of silk returning is reduced.

Owner:江阴市澄江化工有限公司

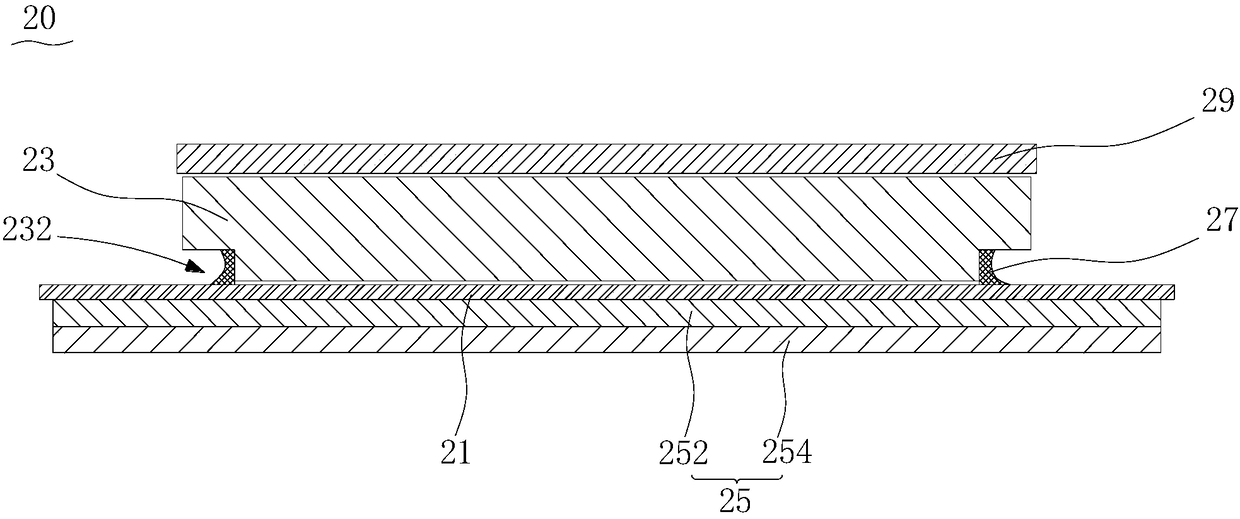

A fingerprint module and a fingerprint identification panel provided with the fingerprint module

InactiveCN109299637ASimple structureReduce volumeDigital data authenticationPrint image acquisitionFingerprintStatic electricity

The invention relates to a fingerprint module and a fingerprint identification panel provided with the fingerprint module. The fingerprint module comprises a substrate, comprising a laminated conductive layer and a cover layer, wherein the cover layer is partially covered with the conductive layer. A fingerprint chip arranged on the cover layer of the substrate; at that side of the substrate awayfrom the fingerprint chip, an electrically conductive support structure is arrange; the conductive layer is exposed to an area outside the capping layer to form a conductive region, and the conductivelayer not covered with the capping layer to form a conductive region, and the conductive region is wound around the fingerprint chip and electrically connected to the conductive support structure. The aforementioned fingerprint module. As that substrate is provided with a conductive region electrically connected to the conductive support structure. As such, during use of that fingerprint module,the static electricity striking on the fingerprint module is introduced into the conductive support structure through the conductive area, and then into the whole intelligent device installed with thefingerprint module through the conductive support structure, so that the anti-static effect can be achieved without installing components such as an anti-static metal ring and the like, and the volume of the fingerprint module can be reduced.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

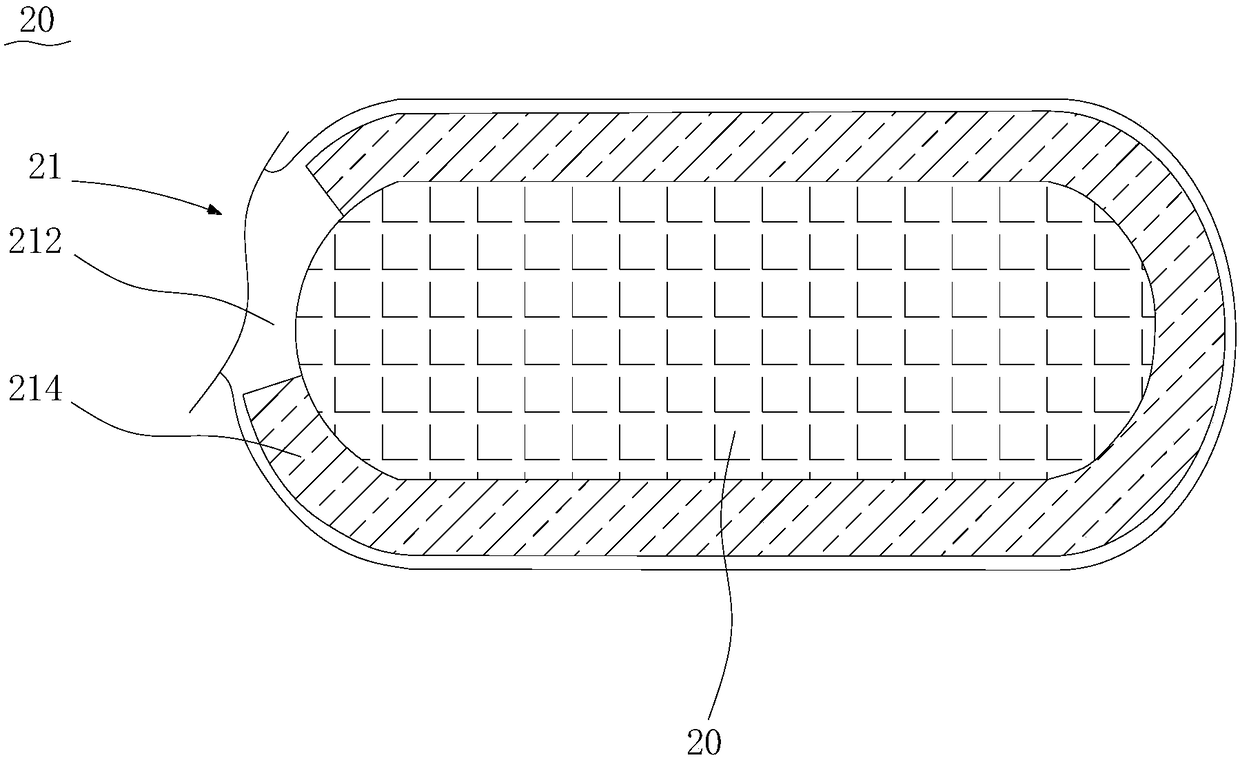

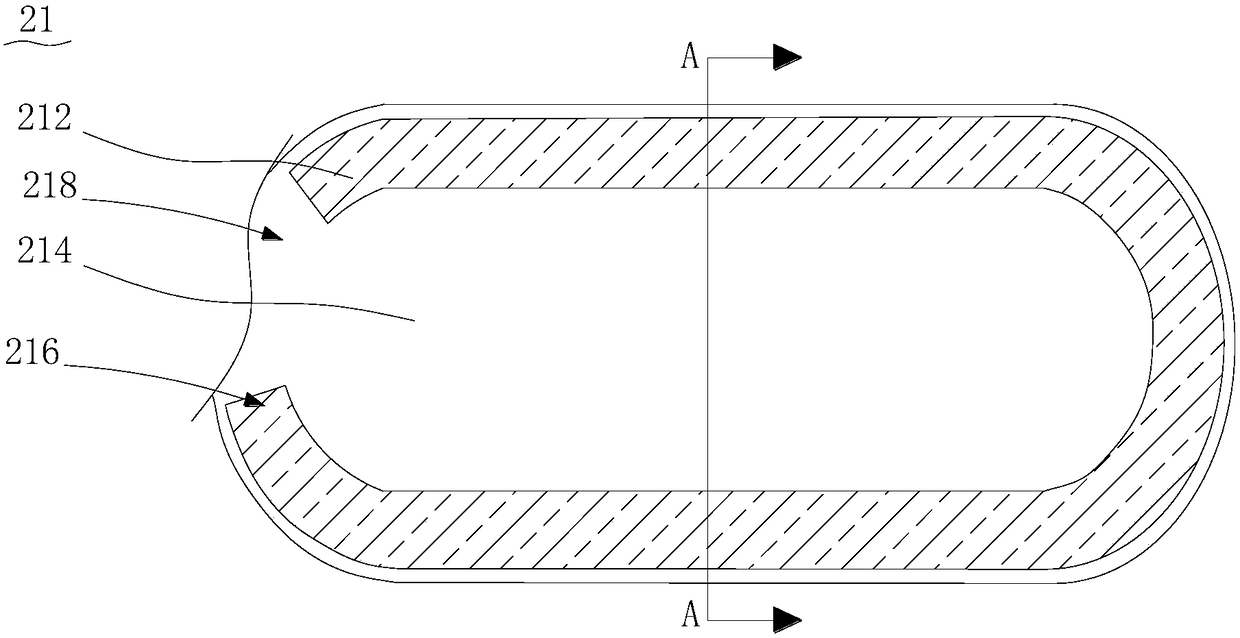

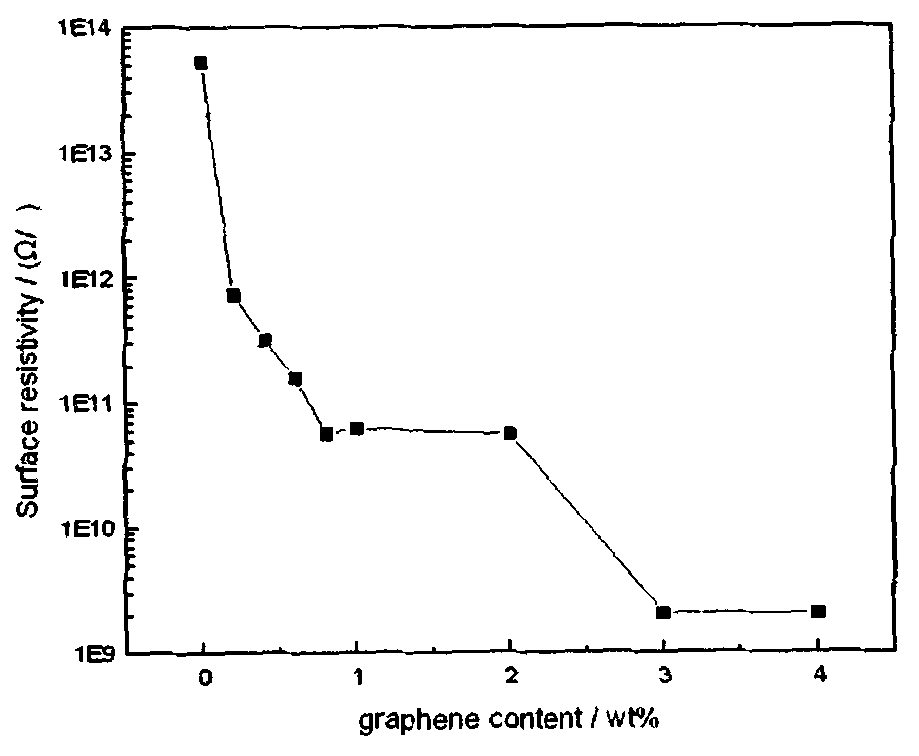

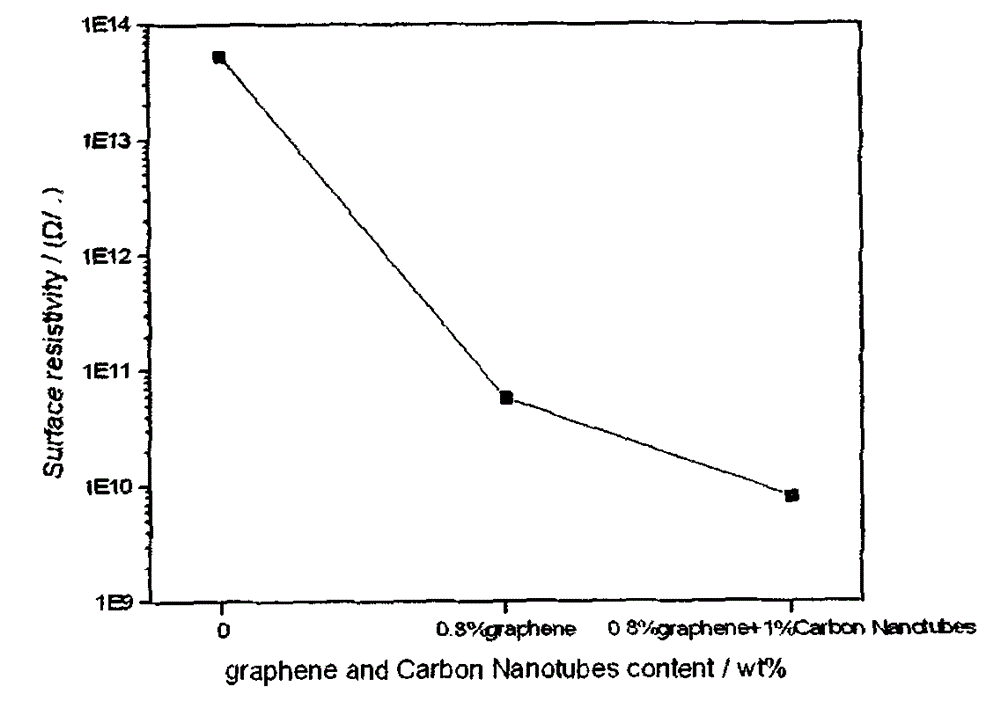

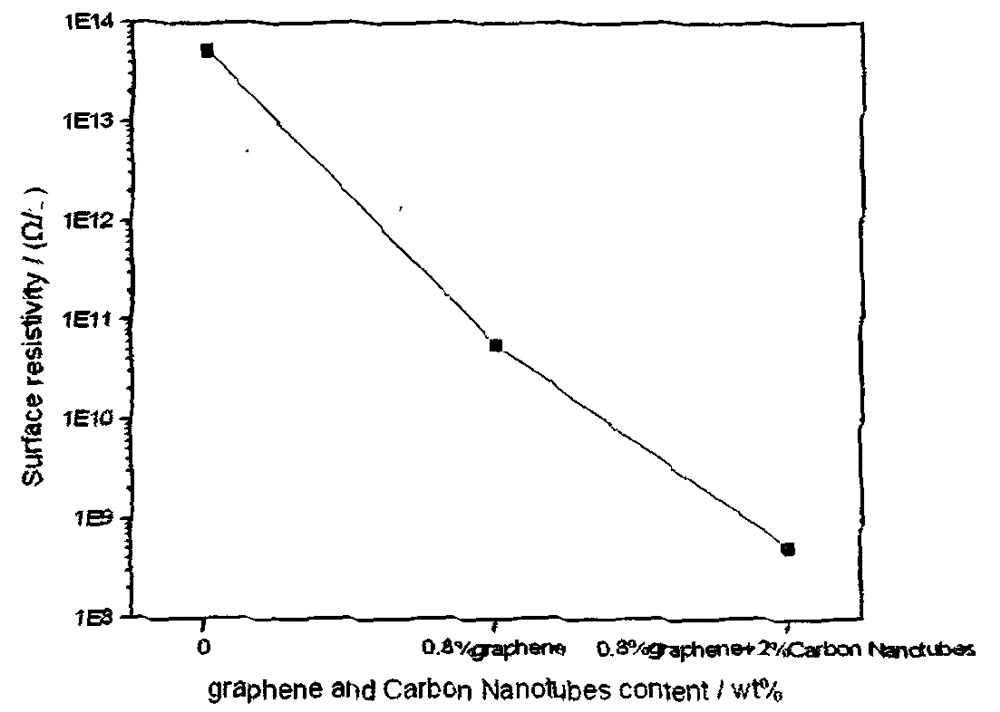

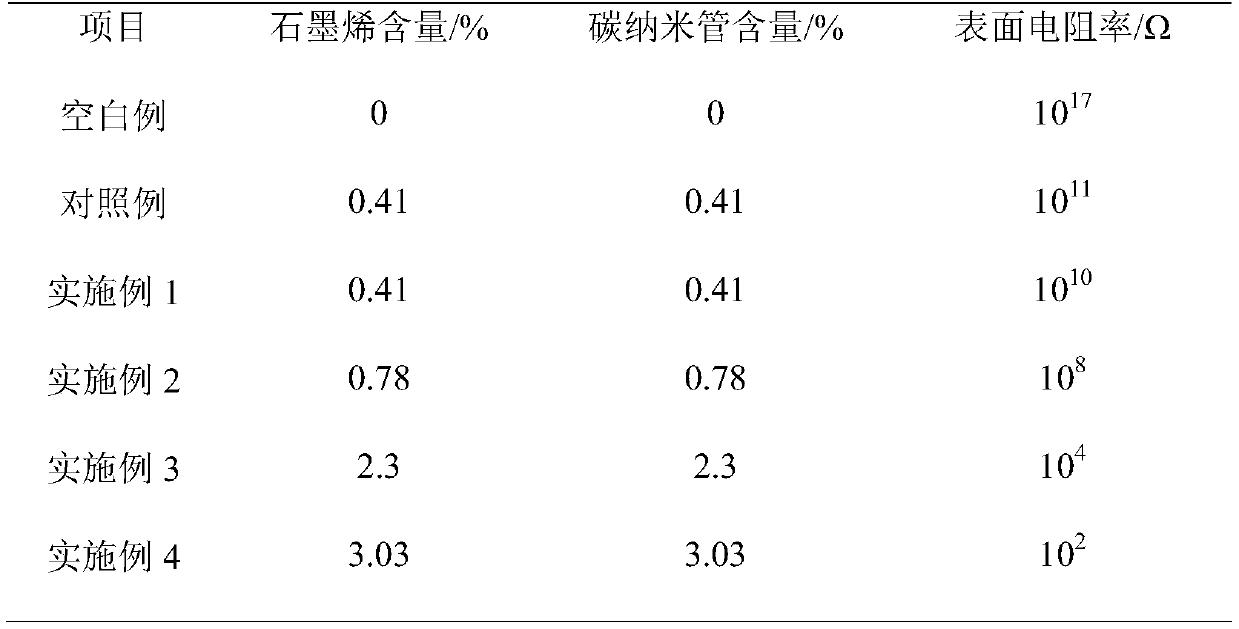

Synthesis of carbon material-polyimide composite film

The invention discloses synthesis of a carbon material-polyimide composite film, relates to synthesis of composite film, and especially relates to synthesis of a novel polyimide composite film. Polyimide film belongs to the insulation materials, has a high resistivity, and can easily generate a large amount of static charges during the process of large-scale production; while the accumulated charges can easily trigger accidents such as combustion, explosion, and the like. The invention aims to eliminate the static charges, which are generated during the processes of production and application of polyimide films. In the production technology of polyimide film, DMAC is taken as the solvent, graphene and acidified carbon nanotubes are added according to different ratios, and in-situ polymerization reactions are carried out to generate a series of novel polyimide composite films. The method has the characteristics of novelty, simple operation, short time, and environment-friendliness. At the same time, the composite film has excellent comprehensive properties, and can be applied to many antistatic facilities.

Owner:TIANJIN POLYTECHNIC UNIV

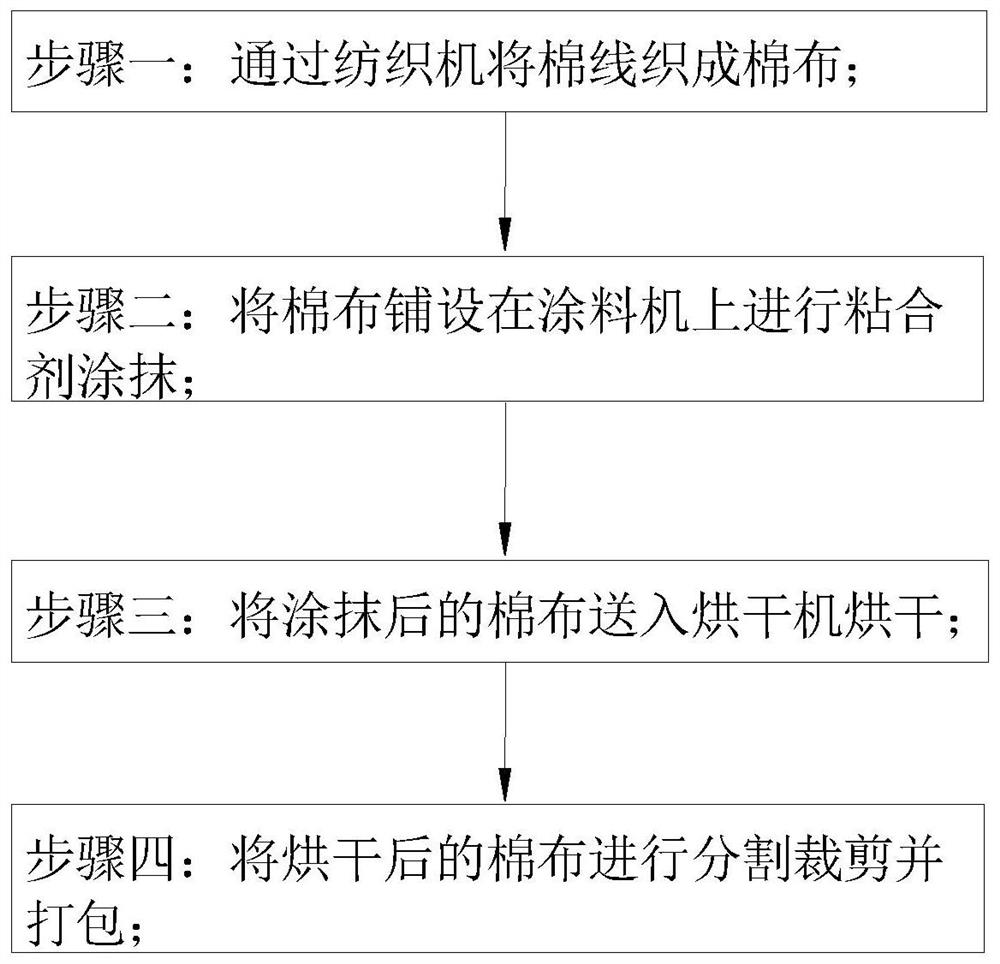

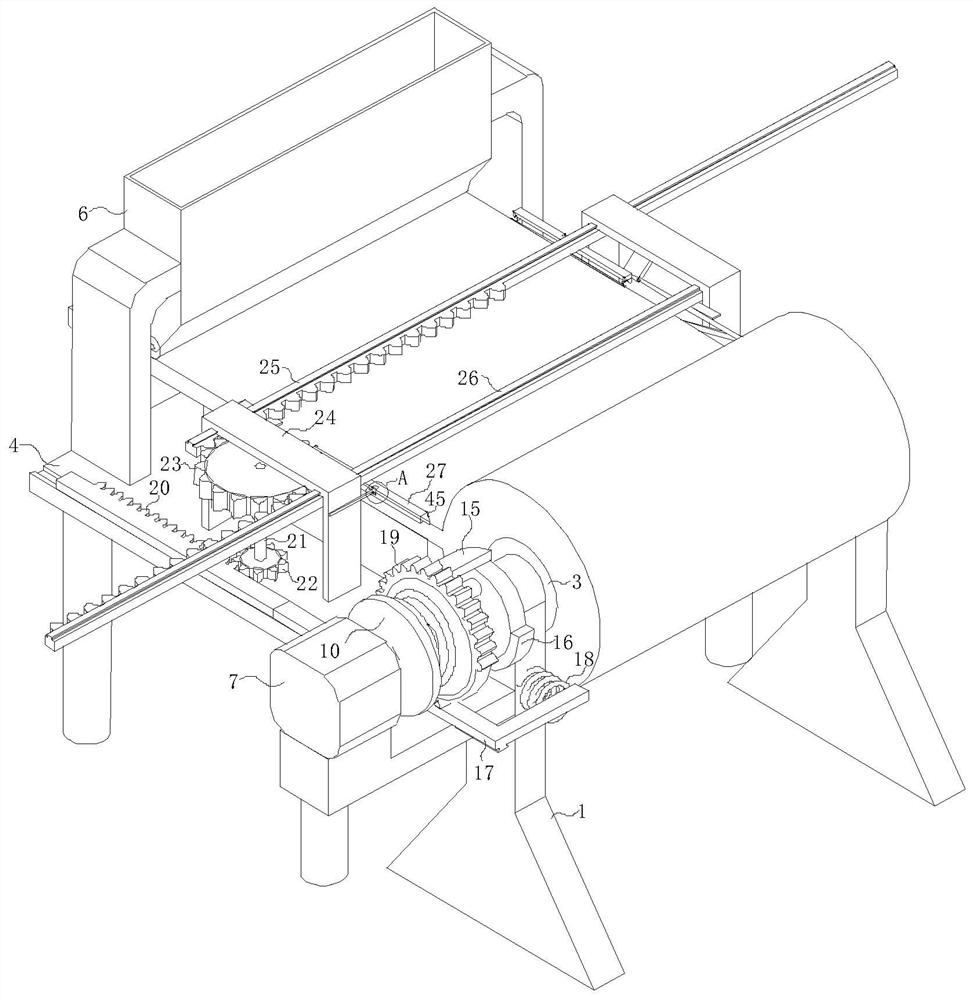

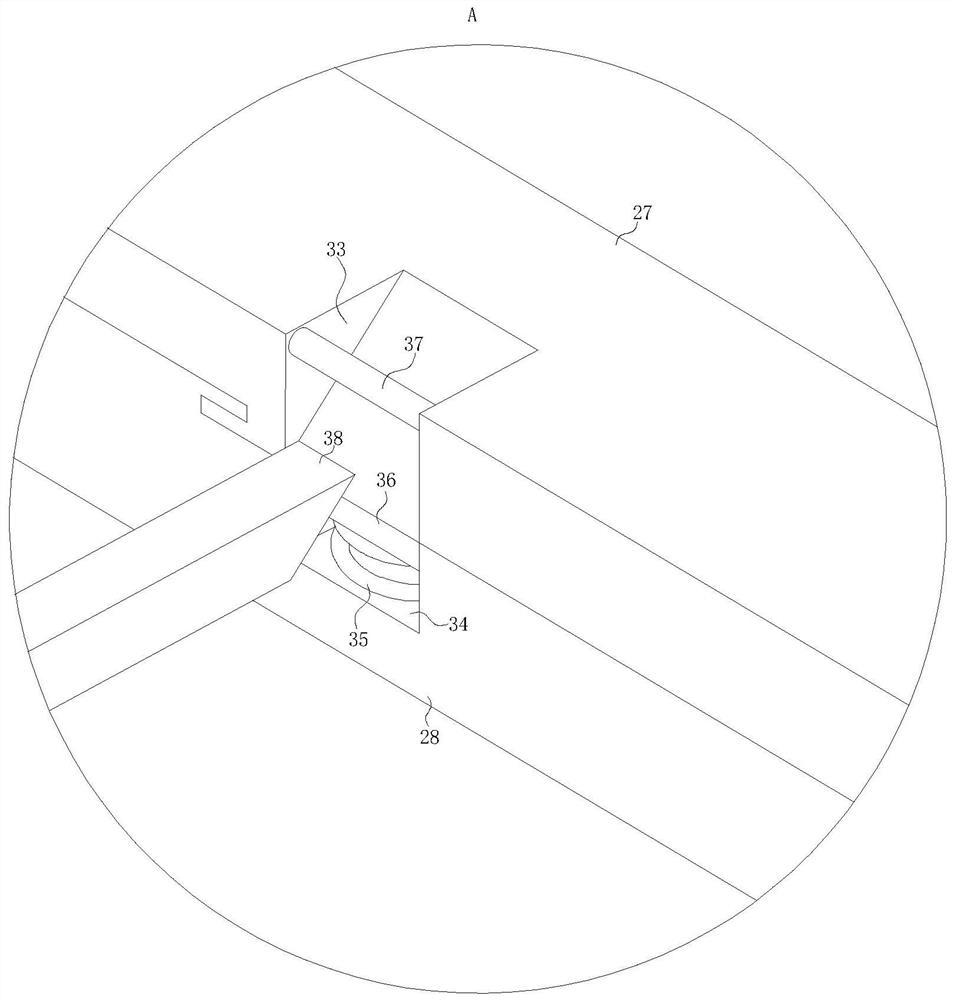

Antistatic textile material production and preparation process

InactiveCN113102190AAvoid Insufficient Antistatic PropertiesGuaranteed antistatic effectLiquid surface applicatorsCleaning using toolsCotton clothAdhesive

The invention discloses an antistatic textile material production and preparation process in the technical field of textile material production. The process comprises the following specific steps: step 1, weaving cotton threads into cotton cloth through a textile machine, step 2, laying the cotton cloth on a coating machine for coating an adhesive, step 3, feeding the coated cotton cloth into a drying machine for drying, and step 4, cutting and packaging the dried cotton cloth. An arc-shaped block is arranged and rotates along with a first transmission disc, when the highest point of the arc-shaped block does not make contact with an arc plate, a second transmission disc rotates, the cotton cloth on a workbench moves rightwards, when the highest point of the arc-shaped block makes contact with the arc plate, the second transmission disc is disengaged from a first elastic telescopic rod and does not rotate any more, and a gear ring drives an L-shaped rack to move, so that a second rack and a third rack move, the adhesive on the cotton cloth is evenly coated, and in cooperation with front-back reciprocating movement of a material pushing mechanism, the adhesive can make full contact with the cotton cloth.

Owner:北京深核智能科技有限公司

Antistatic master batch for polyester

The invention discloses an antistatic master batch for polyester. The antistatic master batch comprises, by mass, 20-80% of polyester, 15-40% of an antistatic agent, 0.5-2% of a nucleating agent, 3-5% of a dispersant and 0.5-3% of a coupling agent. The antistatic master batch prepared in the invention has the characteristics of good processability, efficient and lasting antistatic performance, good compatibility, good thermal stability, low cost, use convenience and the like when the antistatic master batch is used in the antistatic modification of the polyester, and polyester prepared by using the antistatic master batch has a guaranteed antistatic performance and allows the surface resistivity of a product to reduce to 10<8>-10<10>omega.cm, so the antistatic master batch has a wide development prospect.

Owner:QINGDAO XINZHAN PLASTIC

Fireproof mud used for power cable and preparation method thereof

The invention discloses fireproof mud used for installation of a power cable, and belongs to the technical field of fireproof mud. The fireproof mud is composed of, by weight, the raw materials of 25-28 parts of condensed polycyclic aromatic hydrocarbon resin, 15-20 parts of epoxy resin, 8-10 parts of chlorinated paraffin, 14-18 parts of clay, 11-13 parts of porcelain clay powder, 7-9 parts of perlite, 6-9 parts of quartz sand, 5-7 parts of bauxite chamotte, 2-4 parts of magnesium hydroxide, 6-8 parts of tributyl citrate, 4-6 parts of ethylene glycol, 7-9 parts of ammonium phosphate, 2-4 parts of antioxidant, 1-2 parts of anti-corrosion agent and 1-3 parts of antistatic agent. The invention further discloses a preparation method of the fireproof mud used for installation of the power cable. The fireproof mud is easy to prepare, environmentally friendly, low in pollution and good in durability, and has the effects of good fire resistance, corrosion resistance, water resistance and static resistance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Antistatic epoxy resin composite material and preparation method thereof

The invention relates to the field of polymer composite materials, and particularly relates to an antistatic epoxy resin composite material and a preparation method thereof. The antistatic epoxy resin composite material comprises the following components by mass: 0.1-3.0 parts of carbon nanotubes; 0.1-1.0 part of conductive mica; 0.1-1.0 part of coupling agents; 60-80 parts of epoxy resin; and 8-30 parts of curing agents. The method of the invention adopts amino-functionalized carbon nanotubes and conductive mica as compounding fillers, disperses the compounding fillers in epoxy resin to prepare the epoxy resin composite material with antistatic performance, and is simple in operation process; the adoption of the compounding fillers can, on one hand, ensure the antistatic performance of the material, and on the other hand, reduce the cost. According to the method, the adding amount of the functional fillers is less, and the product is good in stability, and is applicable to electric appliances, electrons, and the like.

Owner:HUIZHOU UNIV

Halogen-free, flame-retardant and antistatic master batch for modifying polybutylene telephthalate

InactiveCN103709620AGood flame retardant and antistatic modification effectSimple production processPolytetramethylene terephthalateChemistry

The invention discloses a halogen-free, flame-retardant and antistatic master batch for modifying polybutylene telephthalate. The master batch comprises components by mass: 50-80% of a halogen-free flame retardant, 10%-30% of an anti-static agent, 10%-20% of a carrier, 3%-5% of a lubricating dispersant, 1%-3% of a coupling agent and 1%-2% of an antioxidant. The prepared master batch has the characteristics of high concentration, low cost and convenient use. Due to the adoption of the halogen-free flame retardant, the master batch has secure, smoke-suppressing, non-toxic and environment-friendly high flame-retardant property; and the anti-static agent reduces surface resistivity to 10<8>-10<10> ohms.cm while guaranteeing anti-static property, so that good flame-retardant and anti-static modification effects can be achieved by using the master batch in producing polybutylene telephthalate. Besides, a production process can be simplified; cost is reduced; use is convenient; production efficiency is increased; environment pollution can be prevented; clean production is facilitated; and mixing quality can be increased.

Owner:QINGDAO XINZHAN PLASTIC

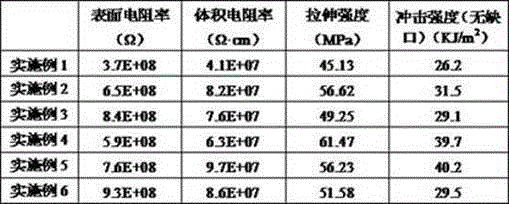

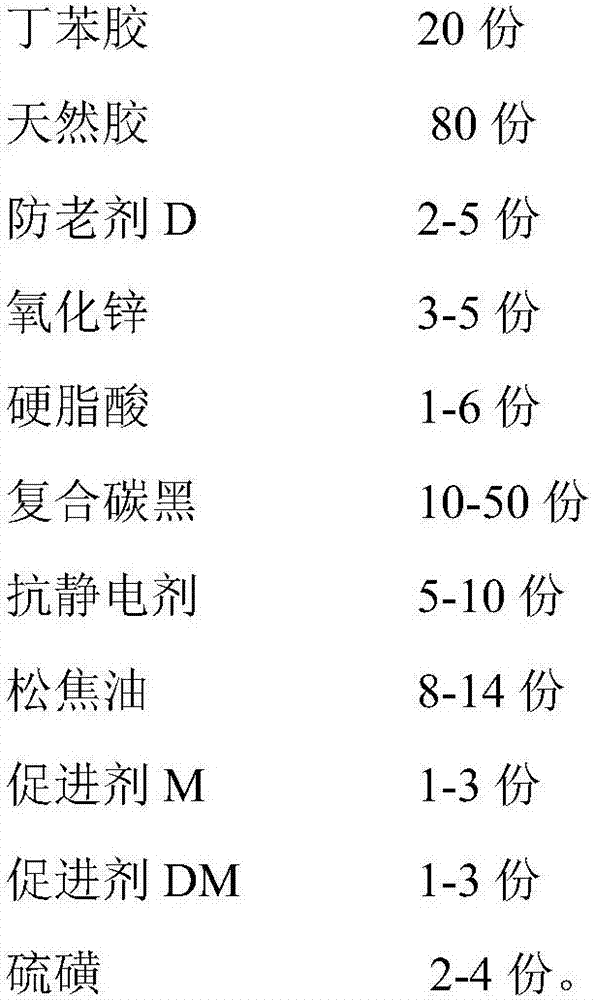

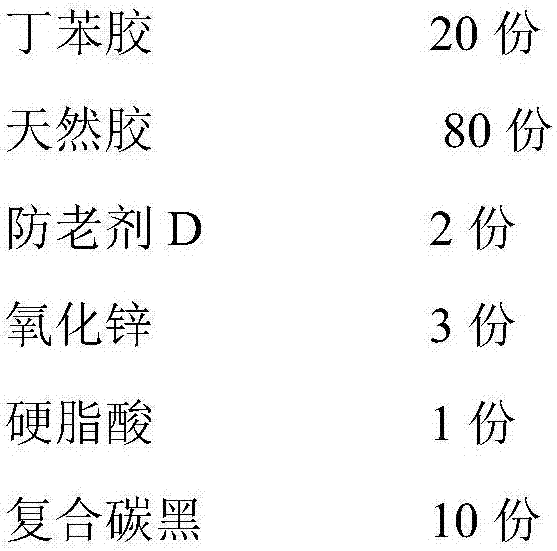

Anti-static rubber and preparation method thereof

InactiveCN107417991AEasy to processImprove wear resistanceBuilding insulationsAntistatic agentHardness

The invention discloses an anti-static rubber and a preparation method thereof and belongs to the field of rubber manufacturing. The anti-static rubber and the preparation method thereof aim at solving the problems of anti-static deficiency, poor physical performance and low heat generation rate in the prior art. The anti-static rubber is a compound conductive carbon black composition combined with anti-static agent, thereby effectively guaranteeing anti-static effects, improving wear resistance; compounded carbon black is low in heat value during operation and can ensure hardness and ductility of the anti-static rubber. By means of a two-section plastifying manner and through synergistic effects of the compounded carbon black and the anti-static agent, the anti-static rubber achieves good anti-static effects, excellent physical performance, good hardness and tensile strength, low heat value and simple production processes.

Owner:MAANSHAN TIANXIN ROLL IND

Antistatic bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556280ASignificant far infrared health functionSignificant UV shielding rateArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceMoisture absorption

The invention provides an antistatic bamboo charcoal viscose fiber and a preparation method thereof, which fill up the blank of the conventional antistatic bamboo charcoal viscose fiber and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antistatic bamboo charcoal viscose fiber is characterized by comprising 1-10 percent of graphite and 0.1-10 percent of bamboo charcoal, wherein the volume resistivity is lower than 1,010 ohm.cm, the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The antistatic bamboo charcoal viscose fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption and has soft handfeel; the antistatic effect is obvious and lasting.

Owner:YIBIN HIEST FIBER +1

Plant extract nutrient bath cream and preparation method thereof

InactiveCN107233249AWettabilityGuaranteed wettabilityCosmetic preparationsToilet preparationsWater balanceSkin clean

The invention provides plant extract nutrient bath cream comprising the following raw materials in percentage by weight: 1-5% of wormwood extract and 0.4-10% of fat agent, wherein the fat agent is at least one of glyceryl oleate, dodecyl lactate, tridecanyl lactate, olive oil PEG-7 ester and PEG-7 glyceryl cocoate. The invention also provides a preparation method of the plant extract nutrient bath cream. The bath cream provided by the invention adopts the wormwood extract has the effect of sterilizing and relieving itching and the fat agent capable of effectively maintaining water balance of human skin as the raw materials, so that the effects of sterilizing, relieving itching and nourishing skin are provided while the requirement of cleaning the skin is met, the materials such as a non-irritant preservative substituent, a skin conditioner providing skin nutrition and a mild and high foaming surfactant are cooperated to use, and thus the effects of deeply cleaning the skin, nourishing the skin and maintaining the skin smooth and soft are achieved.

Owner:曾万祥

Antistatic coating and preparation method thereof, and application of antistatic coating

InactiveCN110938327AImprove mechanical propertiesImprove antistatic performanceElectrically-conductive paintsPolymer sciencePlasticizer

The invention discloses an antistatic coating and a preparation method thereof, and application of antistatic coating. The antistatic coating comprises the following component in parts by weight: 100parts of PVC paste resin, 0-50 parts of vinyl chloride-vinyl acetate paste resin, 2-8 parts of a stabilizer, 2-10 parts of calcium carbonate, 1-5 parts of stearic acid and 80-400 parts of graphene slurry, wherein the graphene slurry comprises the following components in parts by weight: 1-5 parts of graphene, 1-5 parts of carbon nanotubes, 100 parts of a plasticizer and 0.5-5 parts of polyvinylpyrrolidone, and the antistatic coating does not contain a solvent. The antistatic coating provided by the embodiment of the invention can effectively enhance the mechanical properties of the PVC base material on the premise of ensuring the antistatic effect of the PVC base material; and moreover, a coating formed by the antistatic coating is thin, so that the production cost can be effectively reduced.

Owner:上海烯古能源科技有限公司

Calcium carbonate/nickel composite conductive material matrix antistatic coating and preparation method thereof

ActiveCN101921528AEasy to obtainGuaranteed antistatic effectEpoxy resin coatingsElectrically-conductive paintsMetallic materialsEconomic benefits

The invention discloses a calcium carbonate / nickel composite conductive material matrix antistatic coating and a preparation method thereof. The antistatic coating comprises the following main components in percentage by weight: 10-70 percent of composite conductive material, 0.5-3.0 percent of dispersant, 0.5-3.0 percent of wetting dispersant, 0.1-2.0 percent of deformer, 0.1-2.0 percent of leveling agent, 10.0-50.0 percent of resin and the balance of mixed thinner. In the invention, the antistatic coating is prepared by adding the calcium carbonate / nickel composite conductive material with favorable conductivity so that the antistatic effect of the antistatic coating is equivalent to that of a metal matrix antistatic coating and is stable and unchanged along with the changes of temperature, time, moisture, and the like. Compared with the metal matrix antistatic coating, the prepared antistatic coating greatly decreases the production cost, improves the economic benefits of enterprises, simultaneously solves the problems of excessive metal material consumption, and the like, accords with the sustainable development strategy and can be widely applied to the fields of electronic equipment, container pipelines, indoor decoration, furniture finishing, and the like.

Owner:池州市贵兴非矿新材料有限公司

High-flame-retardancy soft PVC antistatic material and preparation method thereof

The invention discloses a soft PVC antistatic material with high flame retardancy and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing graphene, carbon nanotubes, oxidized polyethylene wax, polyethylene wax, EBS wax and stearic acid to form a graphene master batch material; and uniformly mixing the graphene master batch material, PVC resin, a plasticizer, a heat stabilizer, an impact modifier and a flame retardant, and carrying out a melting treatment to obtain the soft PVC antistatic material with high flame retardancy. According to the preparation method, the multi-element space synergistic flame-retardant effect among graphene, carbon nanotubes, a flame retardant and PVC is fully exerted, the dosage of the flame retardant is greatly reduced, and the flame-retardant effect is improved. In addition, due to the synergistic conductive effect of graphene and carbon nanotubes, on the basis of achieving an antistatic effect, the use amount of a conductive filler can be greatly reduced, the material hardness is reduced, the use amount of the plasticizer is further reduced, the use amount of the flame retardant is further reduced, the flame retardance is improved, and the application range is expanded.

Owner:上海烯古能源科技有限公司

A graphene-containing static-electricity-conducting polystyrene foaming material and a preparing method thereof

A graphene-containing static-electricity-conducting polystyrene foaming material and a preparing method thereof are disclosed. The weight of graphene in the material is 0.4-1 wt% of the total weight of a styrene monomer and graphene before polymerization. Prepared graphene / polystyrene beads are subjected to foaming, plate pressing and molding to obtain a foam plate. The surface resistance of the foam plate is 10<6>-10<8> [omega], the antistatic requirement is met, the flame retardance grade of the foam plate can be the B1 grade, the heat conductivity decreases from original 0.039-0.042 W / (m.K) to 0.030-0.034 W / (m.K), and the drawing performance increases from original 90 KPa to 220-260 KPa.

Owner:无锡兴达泡塑新材料股份有限公司 +1

Processing technology of biodegradable medical high-moisture absorption fiber

ActiveCN110230149AGood hygroscopicityImprove antistatic performanceFibre treatmentNon-woven fabricsFiberMedical product

The invention discloses a processing technology of biodegradable medical high-moisture absorption fiber, and relates to the technical field of fiber processing. The processing technology comprises thefollowing steps: (1), modifying chitin fiber, (2), opening, (3), carding, (4), lapping, (5), drafting, (6), reeling. By the processing technology, control condition parameters are clear, the technology is good in repeatability, and the processed fiber is soft in hand feel and excellent in moisture absorption performance and antistatic performance and can be biodegraded after being discarded; theprocessing technology is applicable to processing of various medical products.

Owner:安徽柯林医疗用品科技股份有限公司

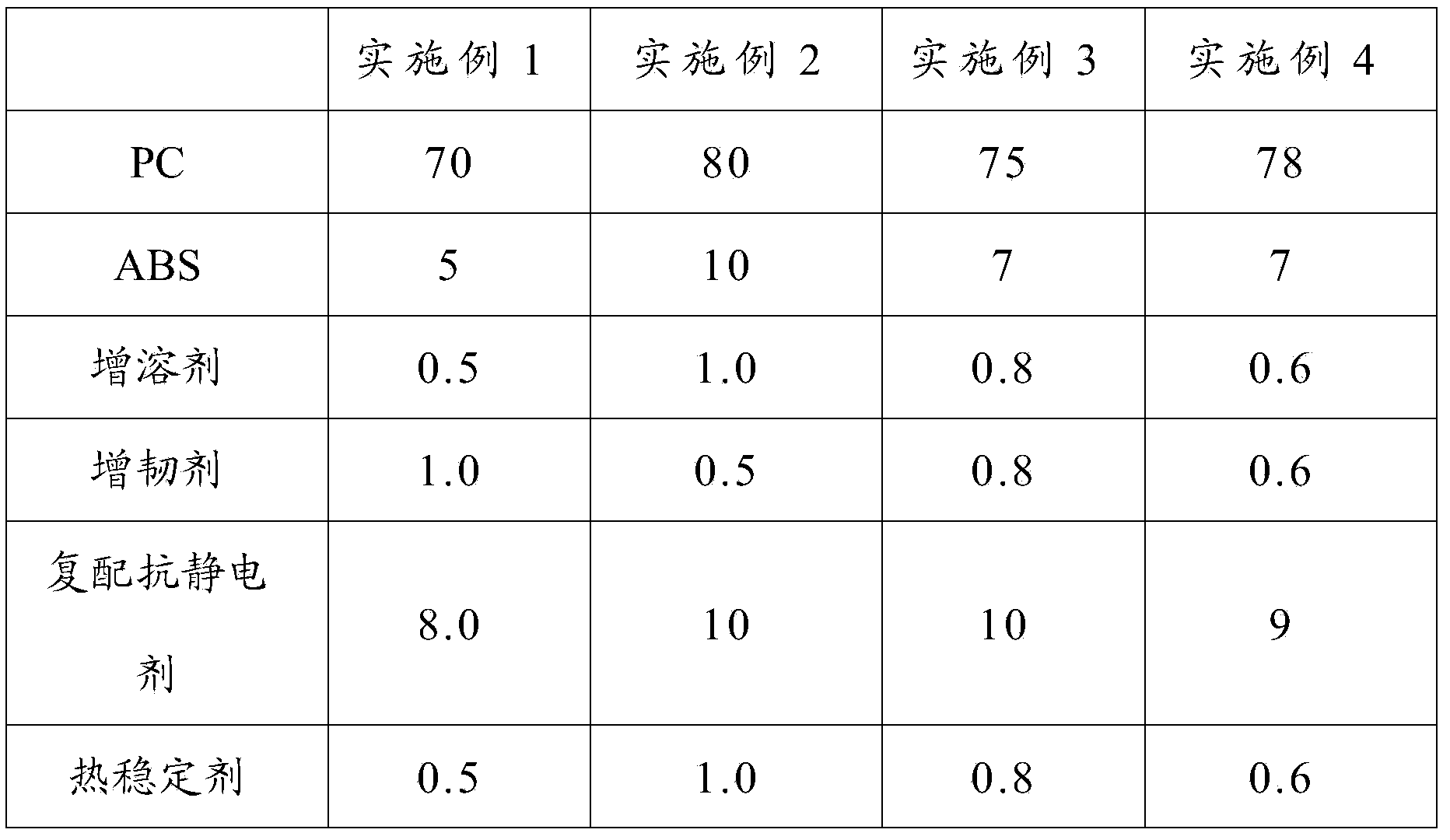

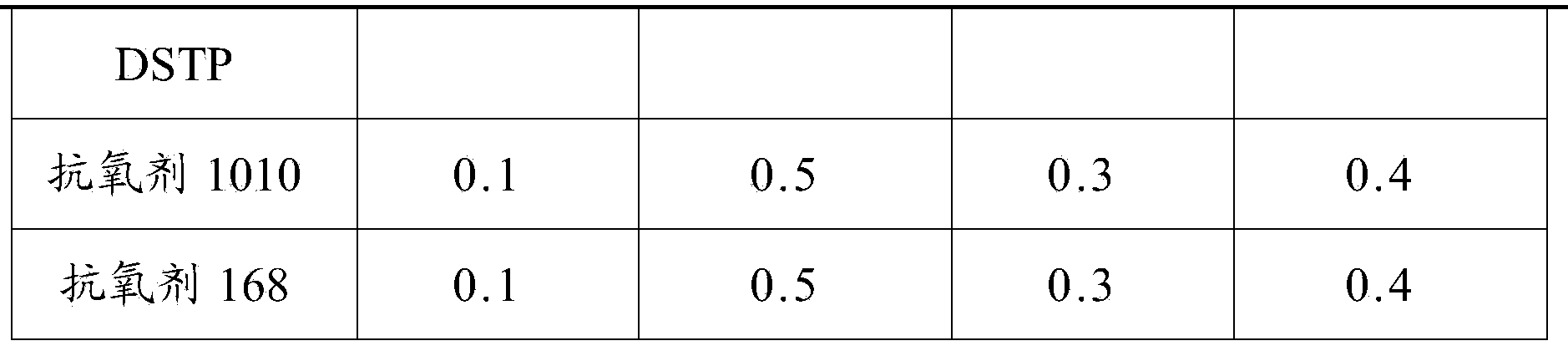

Antistatic PC/ABS alloy material and preparation method thereof

The invention discloses an antistatic PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) alloy material which comprises 70 to 80 parts of PC, 5 to 10 parts of ABS, 0.5 to 1.0 part of a solubilizer, 3 to 5 parts of a flexibilizer, 8 to 12 parts of a compound antistatic agent, 0.5 to 1.0 part of a heat stabilizer DSTP (disteaxyl thiodipropionate), 0.1 to 0.5 part of an antioxidant 1010, and 0.1-0.5 part of an antioxidant 168, wherein the compound antistatic agent is formed by compounding ABS and siloxane. According to the invention, the PC / ABS alloy material is used as a base material; by compounding the ABS and the siloxane, the static elimination is carried out, so that the antistatic performance of the material is ensured and meanwhile, the impact resistance, the mechanical property and transparency of the material are all well reinforced; the solubilizer promotes compatibility between the compound antioxidant and the alloy material; the flexibilizer enhances the toughness of the material.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

High-performance anti-static PP (Propene Polymer) polymer as well as preparation method and application thereof

InactiveCN103554661AImprove antistatic performanceStrong toughnessElectrical resistance and conductanceAntioxidant

The invention discloses a high-performance conductive PP (Propene Polymer) polymer which is prepared from the following raw materials: an antioxidant, a toughening agent, PP, an anti-static agent 1 and an anti-static agent 2. The high-performance conductive PP polymer disclosed by the invention has high impact resistance and wear resistance properties, is especially good in anti-static property, and is especially applicable to applications in manufacturing precise instrument and meter shells and panels, military special boxes, aerospace craft trims, automobile trims, vessel trims, electric appliance shells, component and panels, and anti-static package, and the resistance on the surface of a product is as low as 1*10<10>omega.

Owner:HUIZHOU CHANGYI NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com