Antistatic epoxy resin composite material and preparation method thereof

An epoxy resin and composite material technology, applied in the field of polymer composite materials, can solve the problems of complex steps and no industrialization prospects, and achieve the effects of good stability, less addition, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

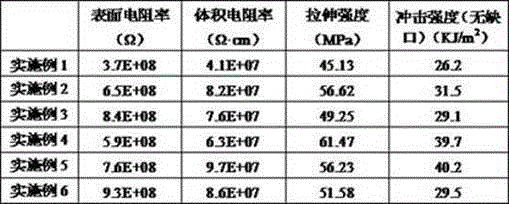

Examples

Embodiment 1

[0030] An antistatic epoxy resin composite material, according to the parts by mass, the preparation method is as follows:

[0031] 1 Put 0.2 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio: 3:1) was treated for 3 hours under the action of ultrasonic vibration and mechanical stirring, and then washed with a large amount of deionized water until neutral.

[0032] 2 Add the obtained carbon nanotubes into thionyl chloride, heat to 60° C. under ultrasonic vibration, reflux for 24 hours, and then distill off excess thionyl chloride under reduced pressure.

[0033] 3 Add the obtained carbon nanotubes and 10 parts of 1,6-hexamethylenediamine into dimethylformamide, stir the reaction with magnetic force at room temperature for 48 hours, filter, and wash away the unreacted 1,6-hexamethylenediamine with deionized water , Aminated carbon nanotubes were obtained after vacuum drying at 70°C.

[0034] 4 Heat 60 parts of E-44 epoxy resin to...

Embodiment 2

[0036] An antistatic epoxy resin composite material, according to the parts by mass, the preparation method is as follows:

[0037] 1 Put 0.5 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio is 3:1), under the action of ultrasonic vibration and mechanical stirring, treated for 4h, and then washed with a large amount of deionized water until neutral.

[0038] 2. Add the obtained carbon nanotubes into oxalyl chloride, heat to 60°C under ultrasonic vibration, reflux for 24 hours, and then distill off excess oxalyl chloride under reduced pressure.

[0039] 3. Add the obtained carbon nanotubes and 15 parts of ethylenediamine into dimethylformamide, stir the reaction with magnetic force at room temperature for 48 hours, filter, wash off the unreacted ethylenediamine with deionized water, and obtain the amino group after vacuum drying at 70°C. carbon nanotubes.

[0040] 4 Heat 70 parts of E-54 epoxy resin to 100°C, then add 0.1 parts...

Embodiment 3

[0042] An antistatic epoxy resin composite material, according to the parts by mass, the preparation method is as follows:

[0043] 1 Put 2.0 parts of carbon nanotubes into concentrated H 2 SO 4 and HNO 3 The mixed solution (volume ratio: 3:1) was treated with ultrasonic vibration and mechanical stirring for 5 hours, and then washed with a large amount of deionized water until neutral.

[0044] 2 Add the obtained carbon nanotubes into thionyl chloride, heat to 60° C. under ultrasonic vibration, reflux for 24 hours, and then distill off excess thionyl chloride under reduced pressure.

[0045] 3 Add the obtained carbon nanotubes and 20 parts of diethylenetriamine into dimethylformamide, stir the reaction with magnetic force at room temperature for 48 hours, filter, wash off the unreacted diethylenetriamine with deionized water, and vacuum dry at 70°C Aminated carbon nanotubes were obtained.

[0046]4 Heat 80 parts of E-51 epoxy resin to 100°C, then add 1.0 parts of conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com