Antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive for textile and preparation method thereof

A water-based polyurethane and anti-ultraviolet technology, which is applied in the fields of antistatic, water-based polyurethane coating adhesives for textiles, antibacterial, skin feel, anti-ultraviolet, and vapor permeability. It can solve the problems of polyurethane coating adhesives and achieve high Elasticity, fine and soft film formation, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

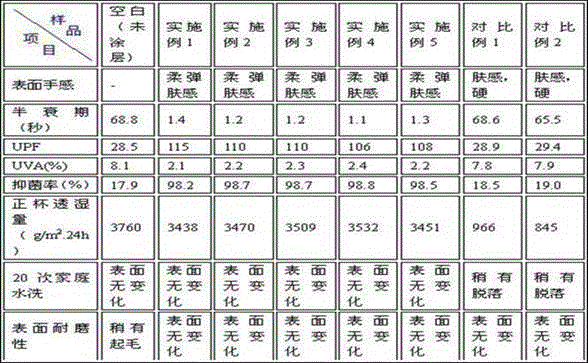

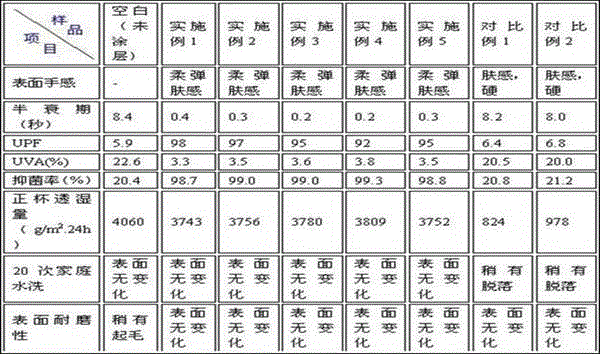

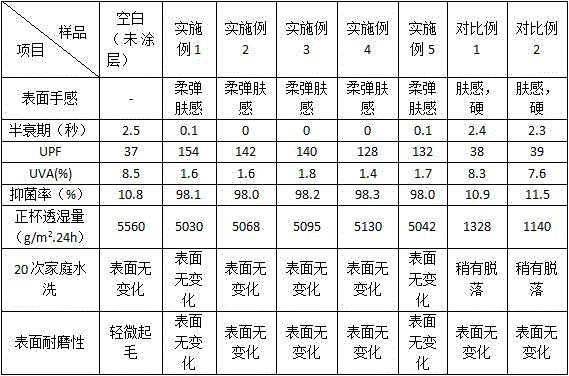

Examples

Embodiment 1

[0058] (1) Add 20% of deionized water and 0.7% of diisopropyl octadecyloxyacetyl aluminum chelate into the stainless steel reaction kettle, stir evenly, add 5.0% of modified hemp lignocellulose powder, and disperse for 35 minutes until completely uniform , add polyurethane elastic powder 3.0, continue to disperse for 15 minutes until completely uniform;

[0059] (2) Add polyurethane adhesive 65, defoamer 0.1, associative polyurethane thickener 3.0, stir for 40 minutes until completely uniform, continue to add antistatic agent 2.5, silicone smooth hand agent 8.0, silicone anti-sticking agent 2.8, ultraviolet absorber 2.8, then stir for 40 minutes until completely uniform, filter and discharge to obtain the product.

Embodiment 2

[0061] (1) Add deionized water 24, diisopropyloctadecyloxyacetyl aluminum chelate 1.2 to the stainless steel reaction kettle, stir evenly, add modified hemp lignocellulose powder 9.0, disperse for 40 minutes until completely uniform , add polyurethane elastic powder 4.5, disperse for 20 minutes until completely uniform;

[0062] (2) Add polyurethane adhesive 60, defoamer 0.15, associative polyurethane thickener 4.0, stir for 50 minutes until completely uniform, continue to add antistatic agent 4.0, silicone smooth hand agent 6.0, silicone anti-sticking agent 4.0, ultraviolet absorber 2.5, then stir for 35 minutes until completely uniform, filter and discharge to obtain the product.

Embodiment 3

[0064] (1) Add 25% of deionized water and 1.8% of diisopropyl octadecyloxyacetyl aluminum chelate into the stainless steel reaction kettle, stir evenly, add 12% of modified hemp lignocellulose powder, and disperse for 50 minutes until completely uniform , add polyurethane elastic powder 5.0, continue to disperse for 20 minutes until completely uniform;

[0065] (2) Add polyurethane adhesive 60, defoamer 0.15, associative polyurethane thickener 4.2, stir for 40 minutes until completely uniform, continue to add antistatic agent 4.5, silicone smooth hand agent 10, silicone anti-sticking agent 2.5, UV absorber 2.0, then stirred for 35 minutes until completely uniform, filtered out to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com