Antistatic PC/ABS alloy material and preparation method thereof

An alloy material and antistatic technology, which is applied in the field of chemical materials, can solve the problems of color limitation, influence on physical properties, poor timeliness, etc., achieve the effects of enhanced mechanical properties and transparency, guaranteed antistatic performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

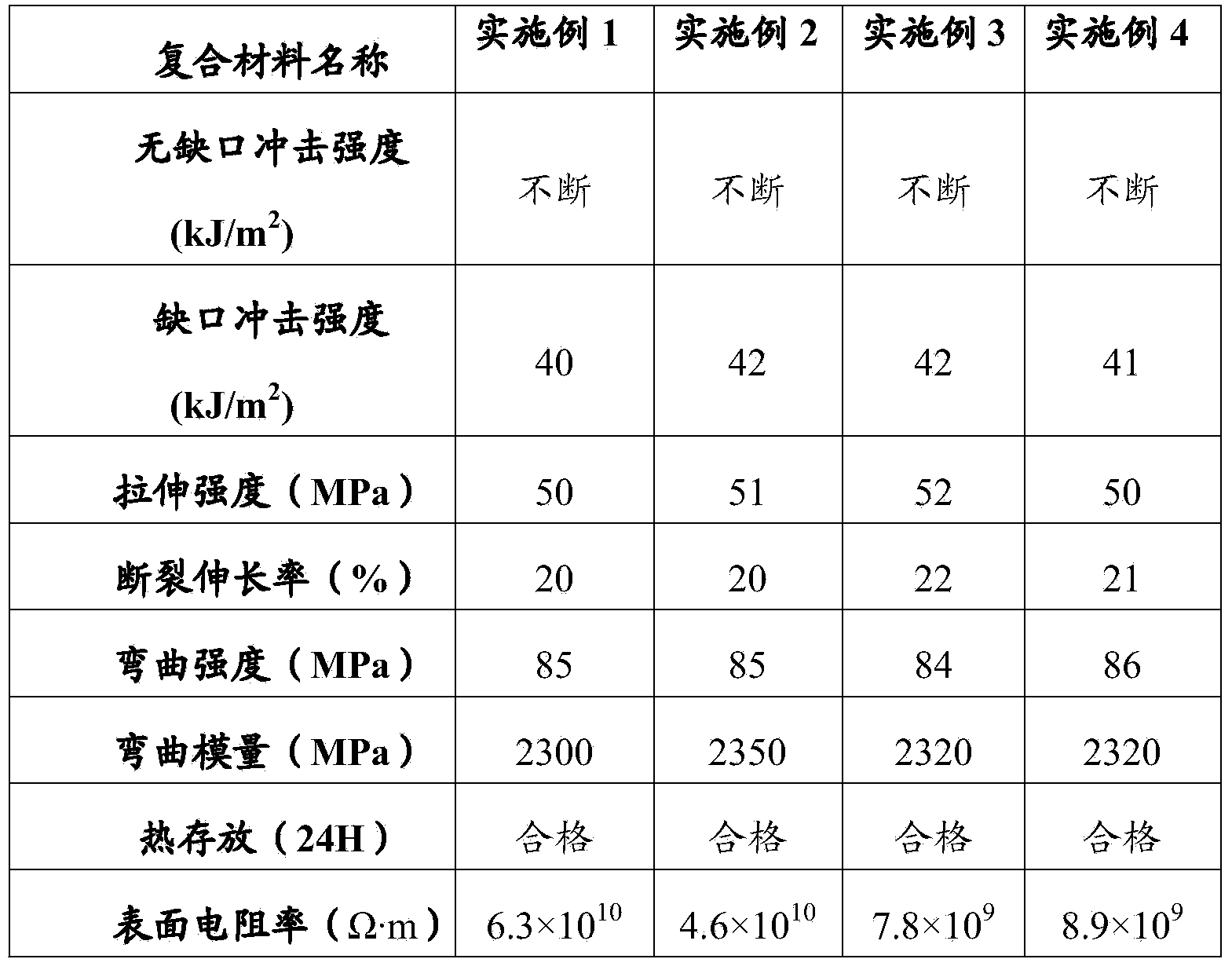

Examples

Embodiment Construction

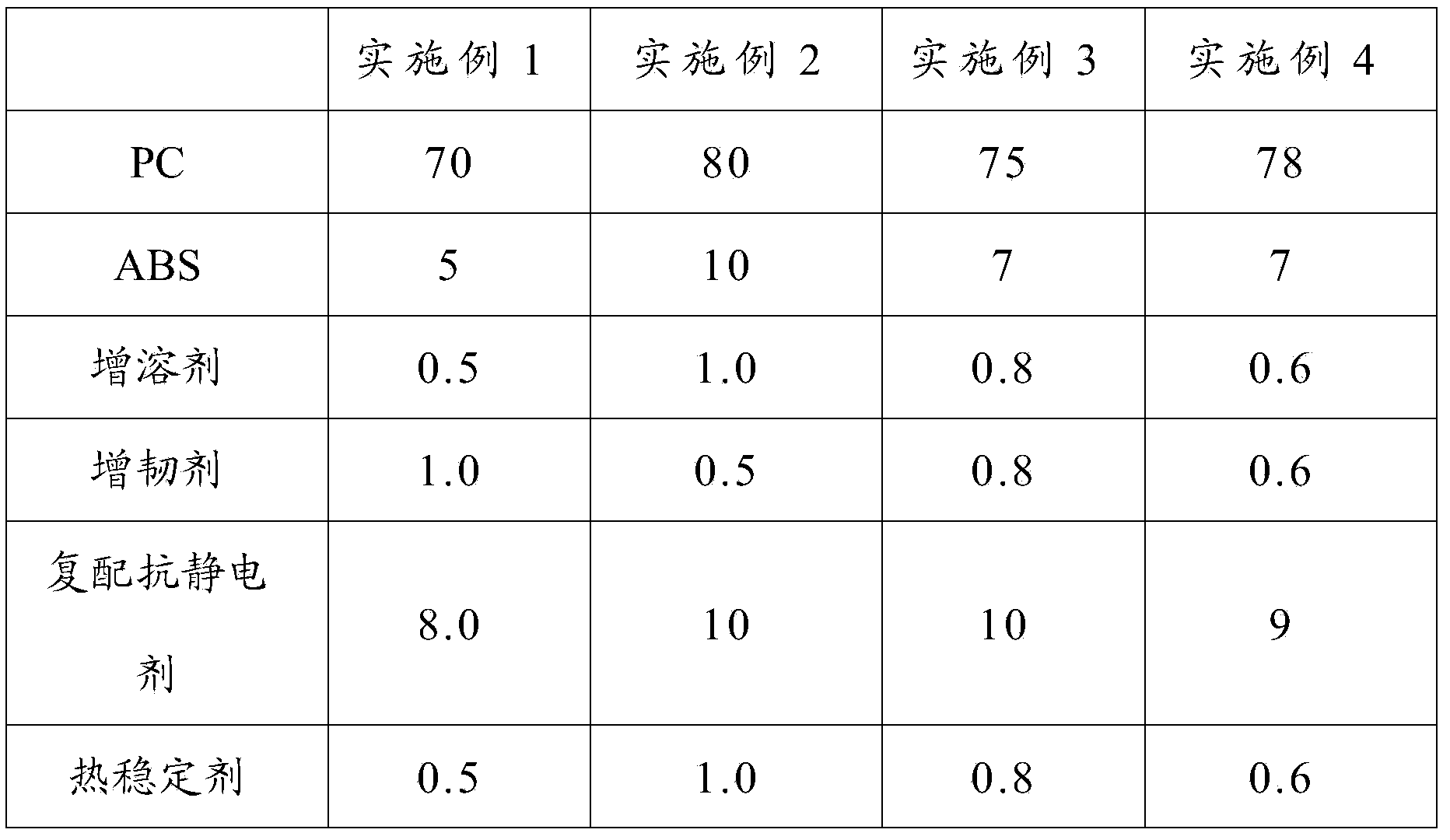

[0024] Below in conjunction with embodiment the present invention is described in further detail:

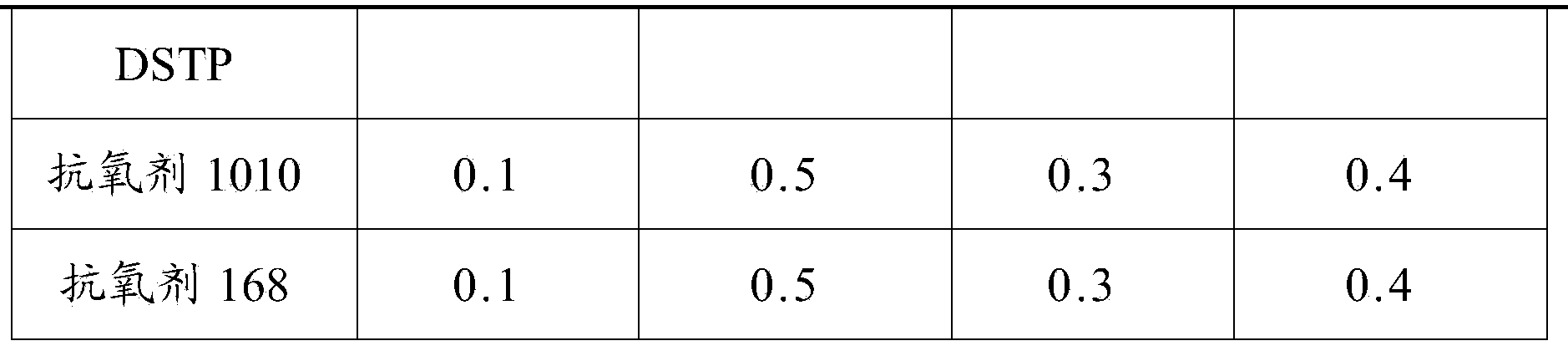

[0025] Material selection: In the following examples, PC (polycarbonate), chemical name: 2,2'-bis(4-hydroxyphenyl)propane polycarbonate, density 1.2g / mL (25°C); ABS: chemical name: Acrylonitrile-butadiene-styrene plastic, the solubilizer is maleic anhydride, the toughening agent is MBS, and the antistatic auxiliary agent is a compound product of alkylbenzene sulfonate and siloxane; the heat The stabilizer DSTP is produced by a certain company with a trade name of Negonox DSTP; the antioxidant 1010 is produced by a certain company with a trade name of Irganox 1010; the antioxidant 168 is produced by a certain company with a trade name of Irgafos 168.

[0026] The preparation methods of all the following experiments are: (1) Weigh raw materials according to parts by weight: weigh PC, ABS, solubilizer, toughening agent, compound antistatic agent, heat stabilizer DSTP, antioxidant 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com