Patents

Literature

305results about How to "Guaranteed antimicrobial properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex antibacterial fiber, fabric and preparation method thereof

ActiveCN101597860AMeet surface modificationUniform surface modificationFibre treatmentFiberIrradiation

The invention relates to a complex antibacterial fiber, a fabric and a preparation method thereof, in particular to an irradiation grafting coordination group on the surface of the fiber and on the surface of the fabric, the complex antibacterial fiber loading antibacterial components Ag, Cu and Zn and the composition thereof, the fabric and the preparation method thereof. The method improves the mobility of the antibacterial components in a fiber surface liquid film, has favorable sterilization effect and antibacterial effect, is suitable for modification of organic polymer fibers and fabrics of various types and preparation of corresponding broad-spectrum antibacterial fibers and fabrics, does not generate negative influences on the hygroscopicity, the air permeability and the mechanical properties of the fibers and the fabrics, has simple preparation technology, and is convenient to realize industrialization and lower the production cost.

Owner:王家君

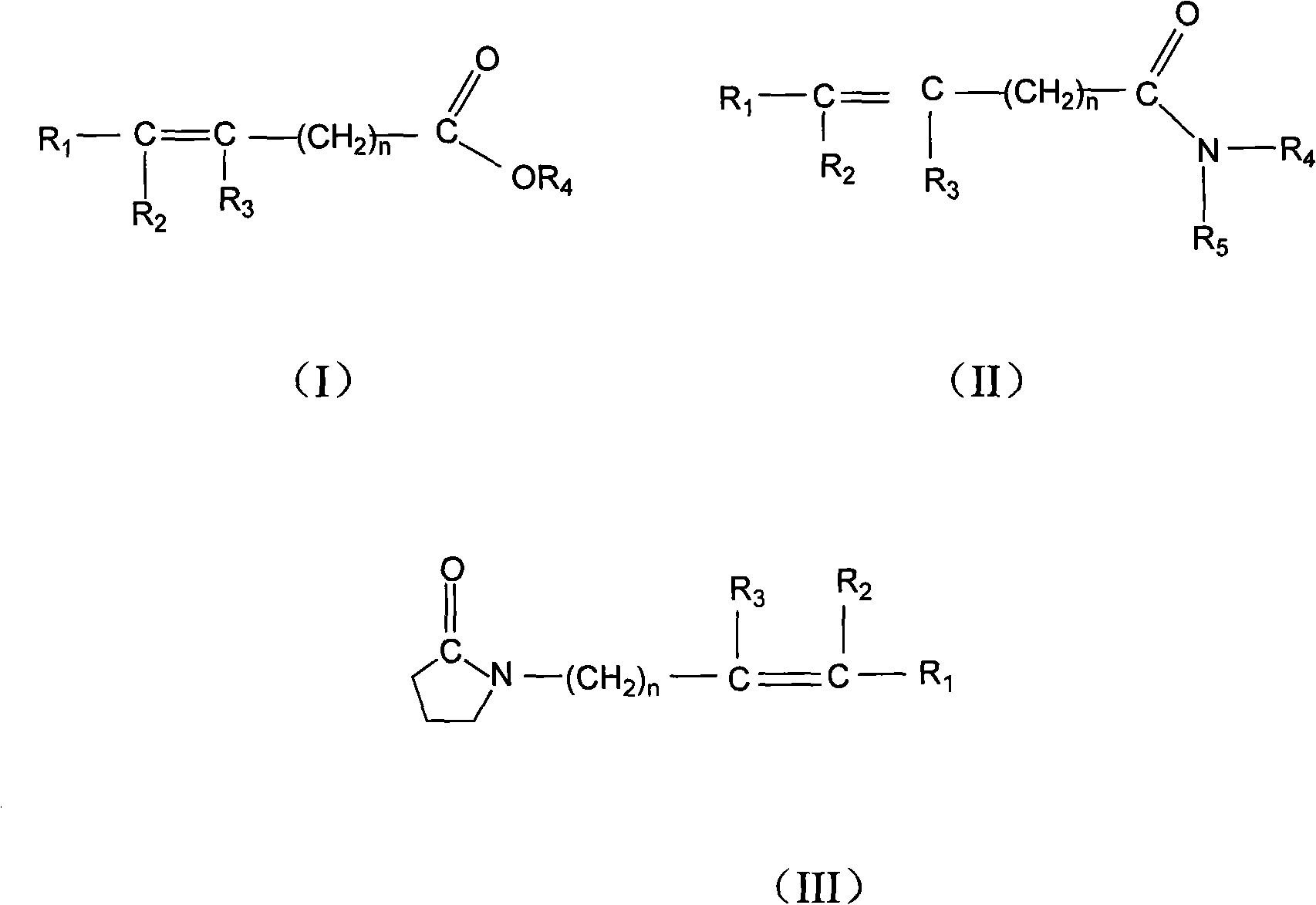

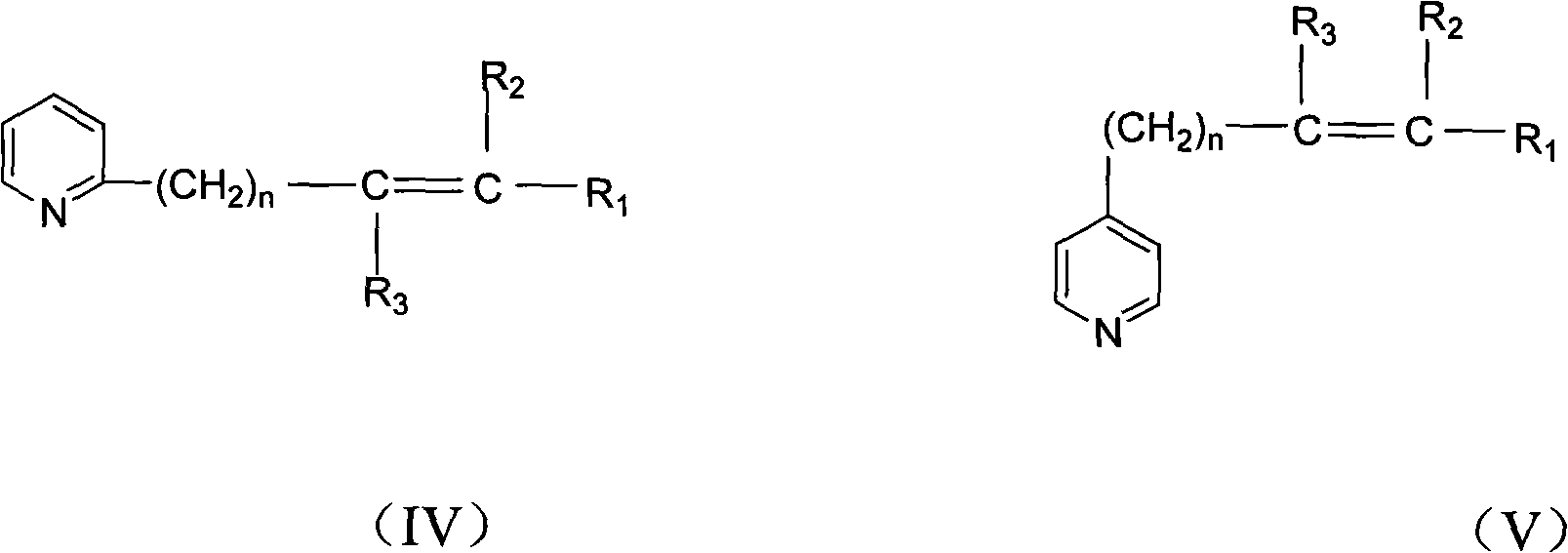

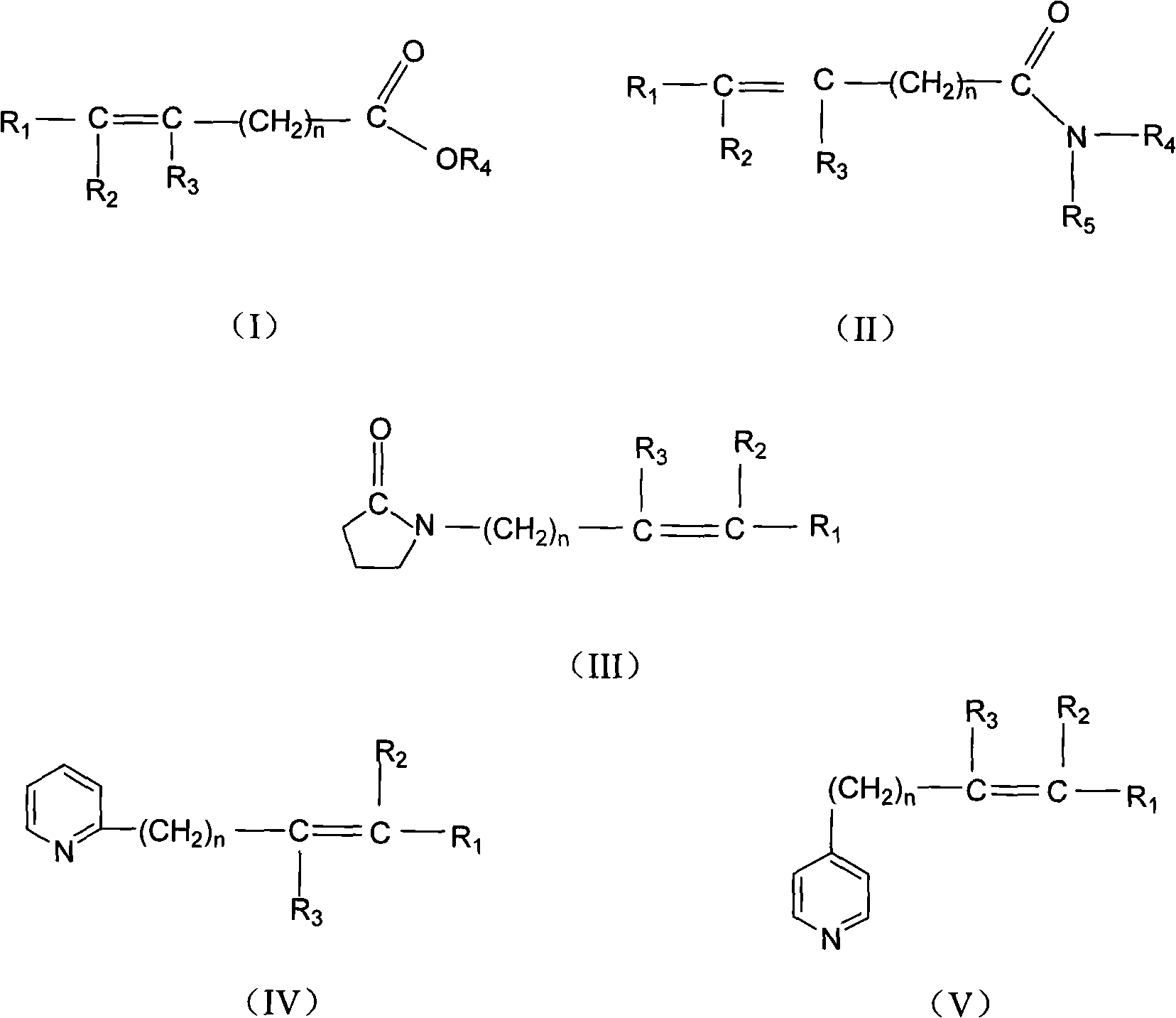

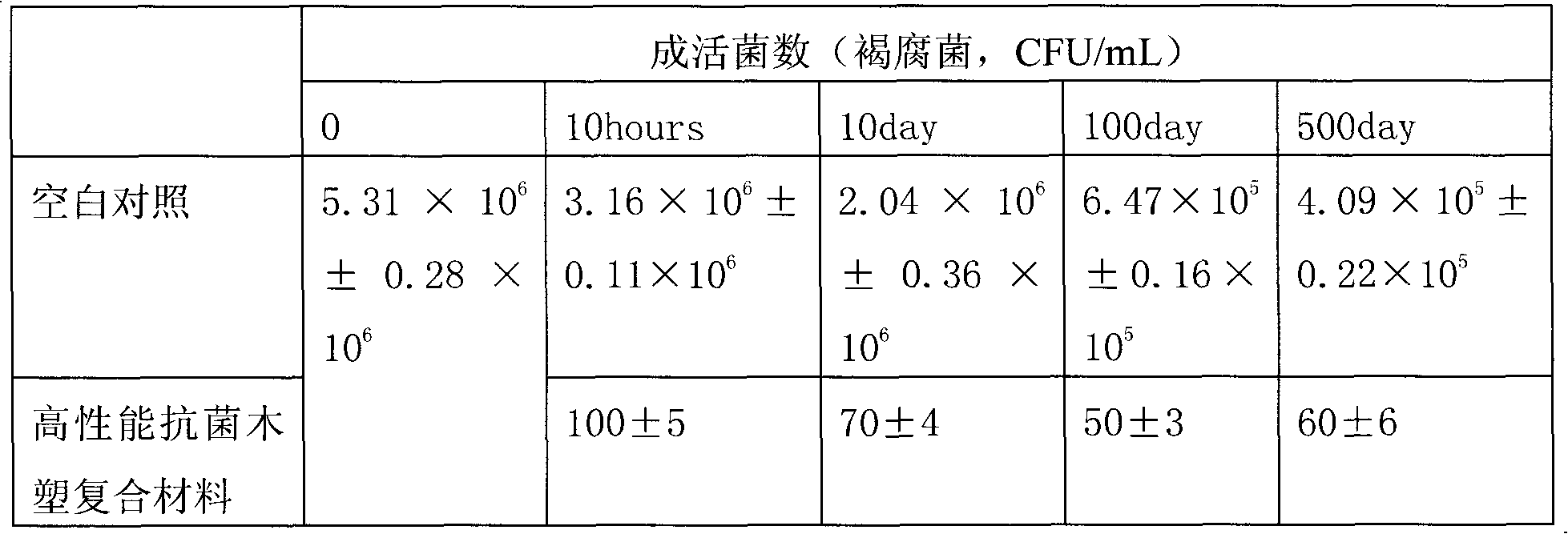

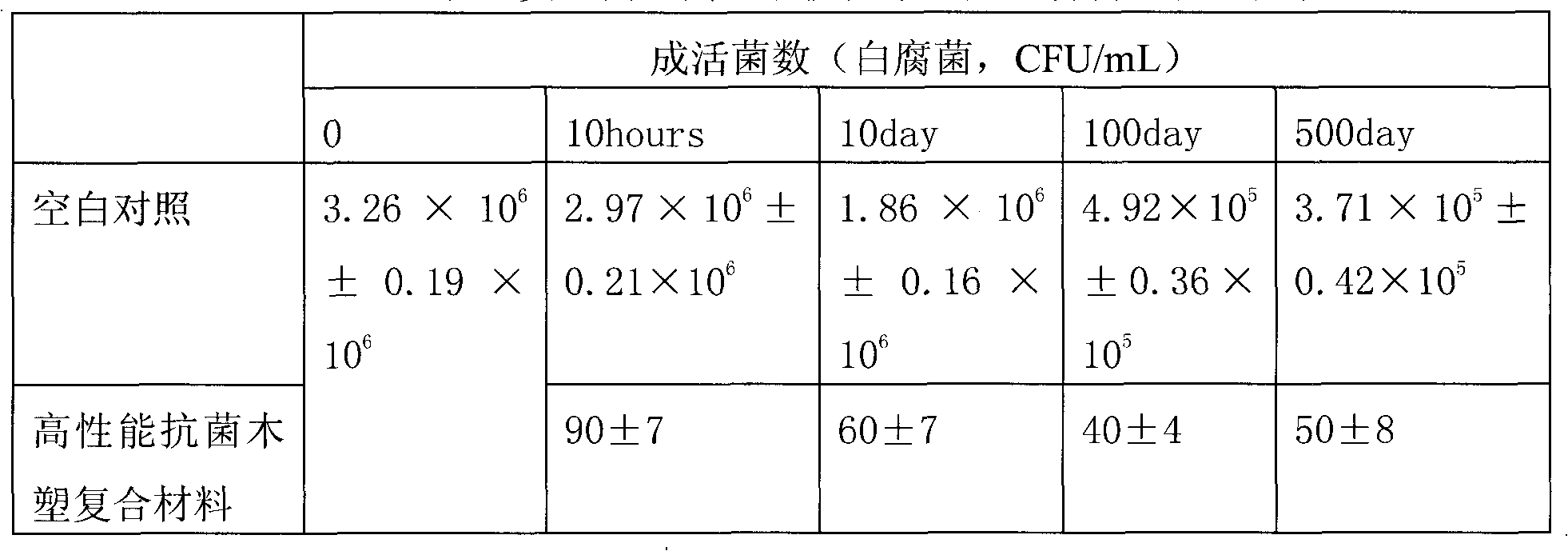

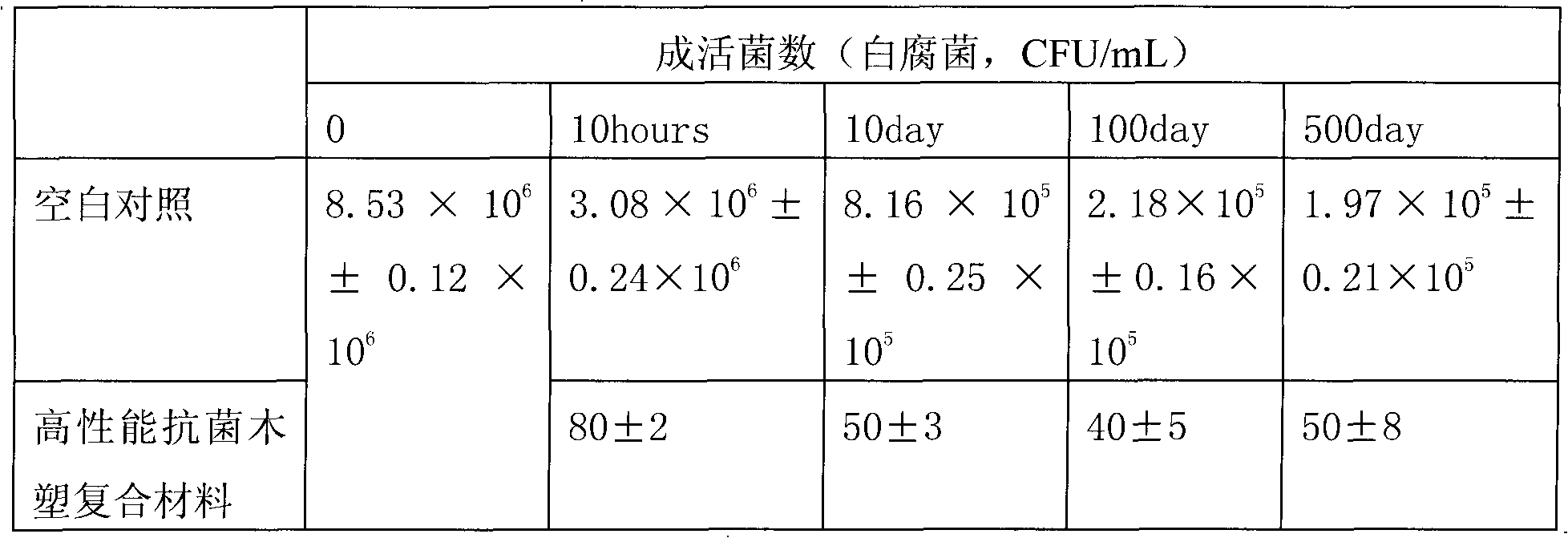

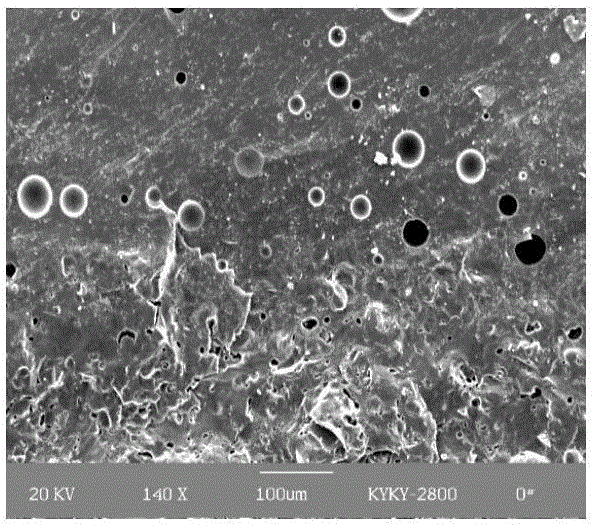

High-performance antibiosis wood plastic composite material and preparation method thereof

InactiveCN101787167AGood long-lasting antibacterial propertiesImprove mechanical propertiesVegetable fibersAntimicrobial

The invention provides a high-performance antibiosis wood plastic composite material and a preparation method thereof, and relates to a composite material obtained by blending surface grafting modification vegetable fiber powder and molding powder. The high-performance antibiosis wood plastic composite material comprises components of modification vegetable fiber powder of which the surface is grafted with various germifuga, recycled molding powder and the like. The various activity antibiosis monomers are grafted on the surface of the vegetable fiber powder by high-energy radiation, so that the antibacterial long residual action and mechanical property of the wood plastic composite material are improved obviously. The high-performance antibiosis wood plastic composite material in the invention is prepared from the components by a general method of fusing and blending in plastic processing. The wood plastic composite material has excellent antibacterial long residual action, and obviously improves the interface of wood and plastic in the wood plastic composite material because of the chemistry grafting modification of the surface of the vegetable fiber, and ensures that the material mechanical property and the water absorbency resistance are improved greatly, and can be applied in the fields of indoor or outdoor decoration, furniture, packaging and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

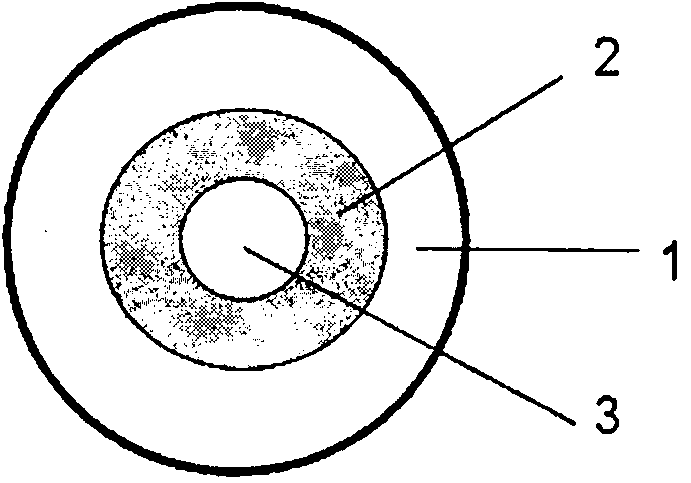

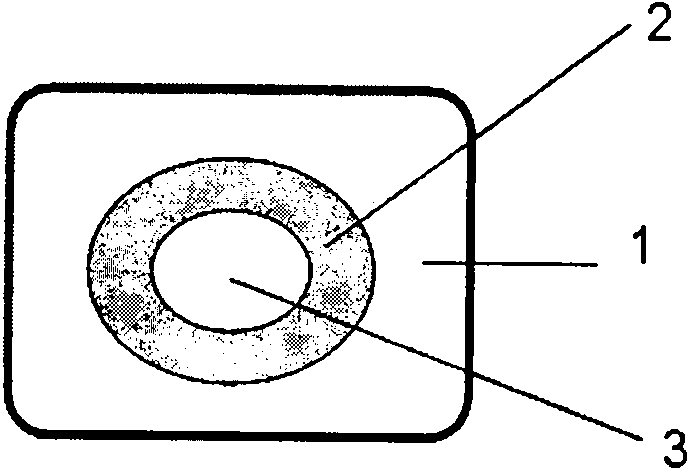

Preparation method of antibacterial fiber

InactiveCN102041562AImprove antibacterial propertiesGuaranteed antimicrobial propertiesHollow filament manufactureFilament/thread formingCore componentSilver phosphate

The invention relates to a preparation method of antibacterial fiber. A melting spinning process is adopted in the preparation method, two screw machines are respectively used for supplying materials to a core-skin spinneret plate assembly, and the core components of the core-skin spinneret plate assembly comprise a melt processed hydrophilic polymer of an inorganic antibacterial agent with the weight percentage of 0.1-10 and grain size of 100nm to 10mum; the inorganic antibacterial agent comprises one of silver zeolite, silver silica gel, silver phosphate, silver silicate and titanium oxide; and the hydrophilic polymer comprises one of polyoxyethylene, polyoxypropylene and kollidon. The preparation method of the antibacterial fiber is characterized in that controllable air flow is injected into the core components by using a gas flowmeter while the core components are supplied, so that a core layer is made into a structure with one or more hollow holes and core components are mainly distributed on the walls of the hollow holes in the core layer; the core layer of the hollow holes accounts for 5-60 percent of the total volume of the fiber; and the weight ratio of the core components to a skin component is (1-20):(99-80).

Owner:YINGBAO FIBER TECH RENHUA

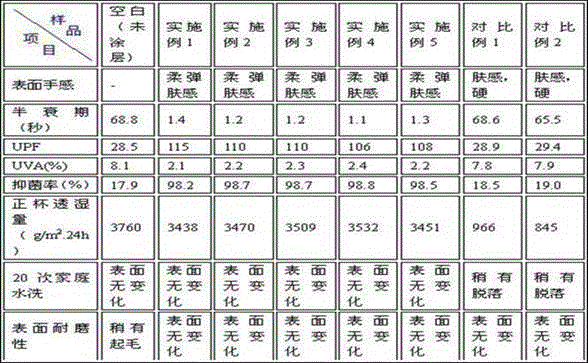

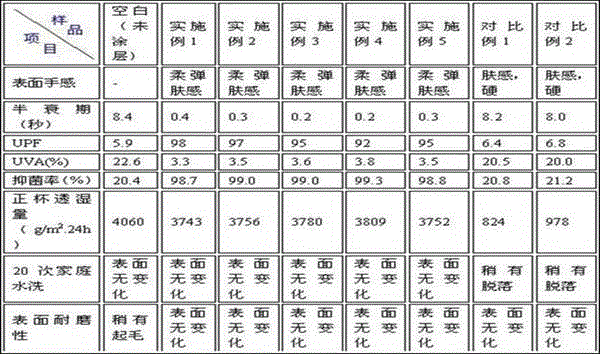

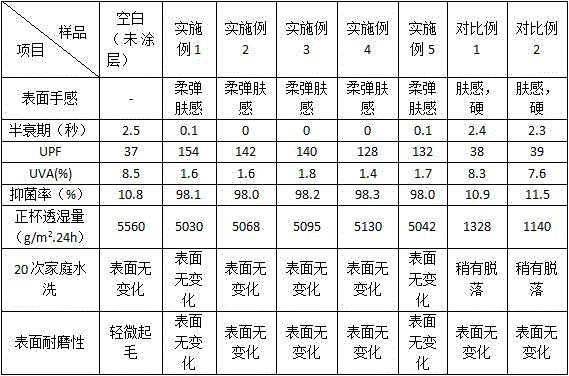

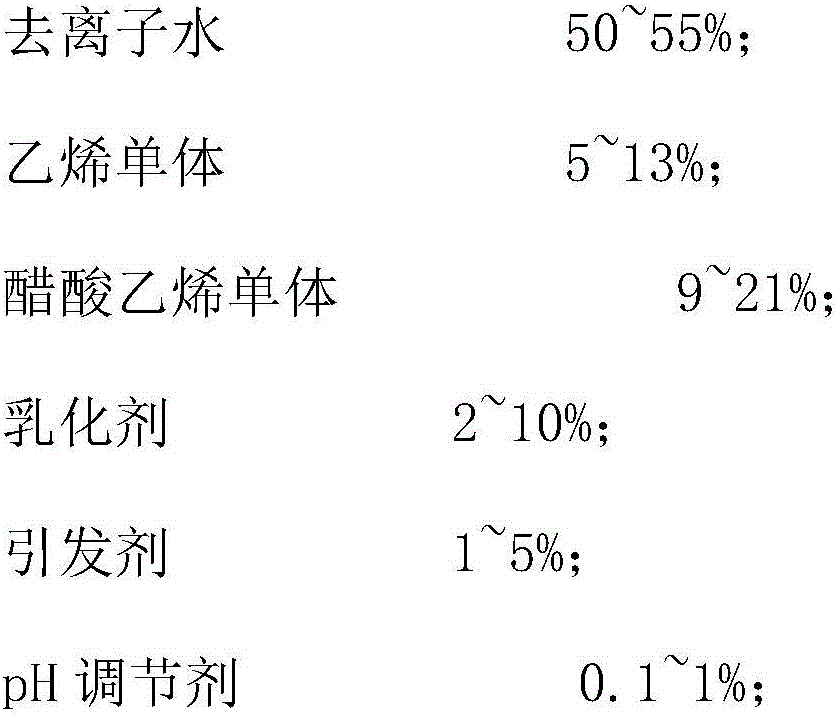

Antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive for textile and preparation method thereof

ActiveCN106436324AGuaranteed antistatic effectGuaranteed UV resistanceBiochemical fibre treatmentLight resistant fibresPolyesterPolymer science

The invention provides an antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive and a preparation method thereof. The coating adhesive is prepared from, by weight, 20-30 parts of deionized water, 0.5-3.0 parts of diisopropyl octadecanalkoxyl acetyl aluminum chelate, 5.0-15 parts of modified hemp lignocellulose powder, 3.0-5.0 parts of polyurethane elastic powder, 50-70 parts of polyurethane adhesive, 0.1-0.3 part of defoaming agent, 1.0-5.0 parts of associative polyurethane thickener, 2.0-5.0 parts of anti-static agent, 5.0-10 parts of organic silicon smooth handfeel agent, 2.0-5.0 parts of organic silicon anti-sticking agent and 1.0-3.0 parts of ultraviolet absorbent in a compounding mode. The coating adhesive is suitable for pure cotton, polyester, chinlon and various blended fabrics and good in wear resistance and washability.

Owner:LIAONING FIXED STAR FINE CHEM

Antibacterial deodorant and anti-wrinkle finishing process

ActiveCN105648771ATidy up steps simplifiedSave time organizingBiochemical fibre treatmentSingeingCooking & bakingHazardous substance

The invention provides an antibacterial deodorant and anti-wrinkle finishing process of cotton / silk blended fabric. The finishing process includes steps: (a), singeing; (b), performing one-bath desizing, scouring and bleaching; (c), performing antibacterial deodorant and anti-wrinkle finishing; (d), pre-baking; (e), baking; (f), washing with water; (9), drying. An antibacterial deodorant anti-wrinkle finishing agent is formed by reasonably proportioning components like citric acid, polyethylene glycol, waterborne polyurethane and beta-cyclodextrin, and is environment-friendly, free of releasing toxic and harmful substances like formaldehyde, safe and secure. By adding a softener into the finishing agent, the cotton / silk blended fabric of cotton fabric can be further ensured to be maintained soft without deforming, and practicability is improved.

Owner:深圳市歌中歌服饰有限公司

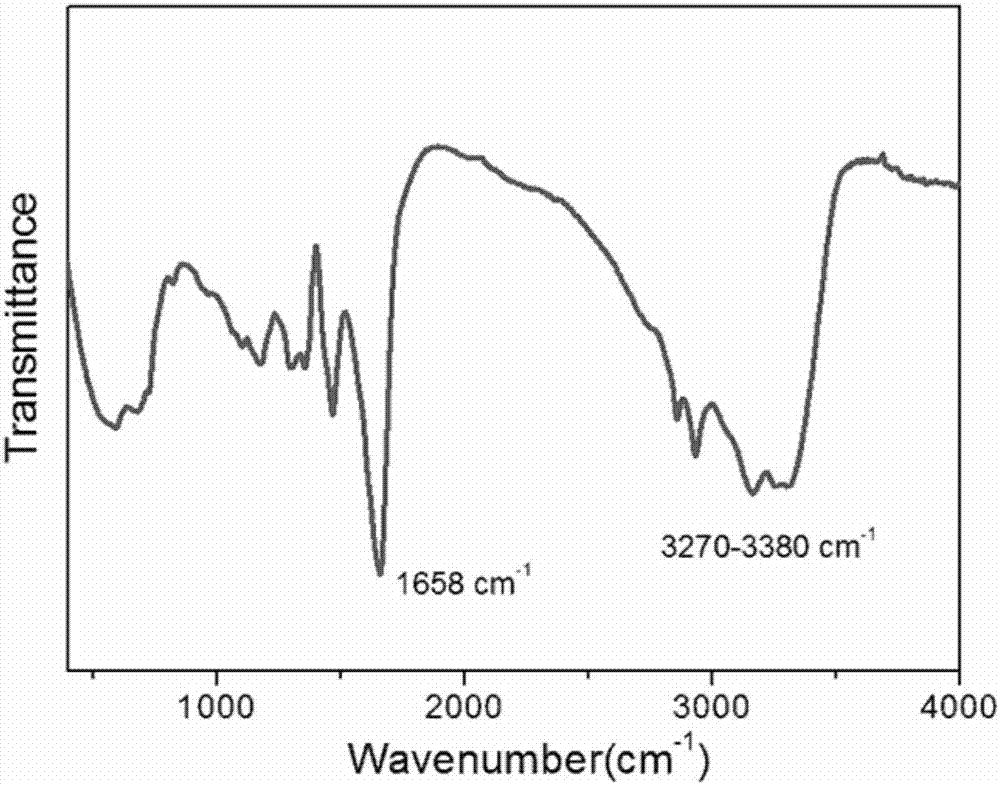

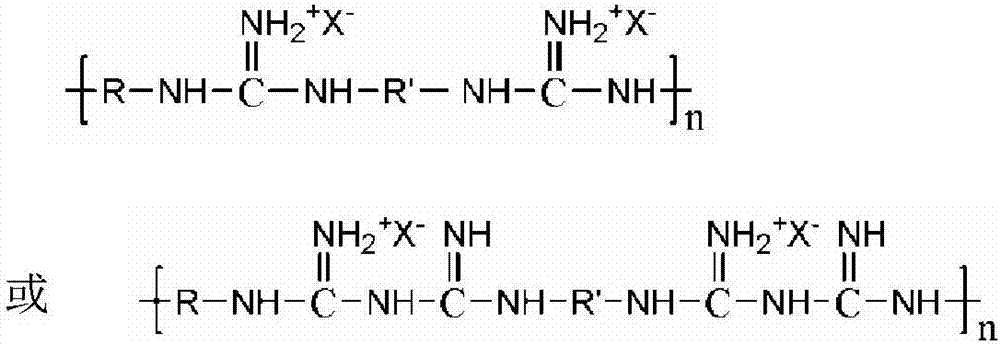

Preparation method of guanidine polymer fungicides

The invention discloses a preparation method of guanidine polymer fungicides. The preparation method includes that mass polymerization is adopted, and polymerization reaction is divided into two stages: prepolymerization and condensation; guanidine salt and endamine-based polymers are placed in a reaction kettle to be evenly mixed; the mass ratio of the guanidine salt to the endamine-based polymers is 1:10-1:1; under nitrogen protection, temperature is raised to 70-100DEG C for refluxing reaction in stirring, and guanidyl containing low polymers are obtained; polyamine small molecules are added to the reaction kettle to be evenly mixed; the mass ratio of the polyamine small molecules to the guanidine salt is 1:4-2:1; under nitrogen protection, temperature is raised to 120-200DEG C for refluxing reaction in stirring, and the guanidine polymers are obtained. The preparation method is simple in process and easy to implement and high in yield; the guanidine polymers contain a great deal of reactive amine on the basis of retaining fungicidal-group guanidyl, grafting to the surface of the product in the subsequent steps is facilitated, and the fungicides are good in practicability and application prospect.

Owner:TIANJIN UNIV

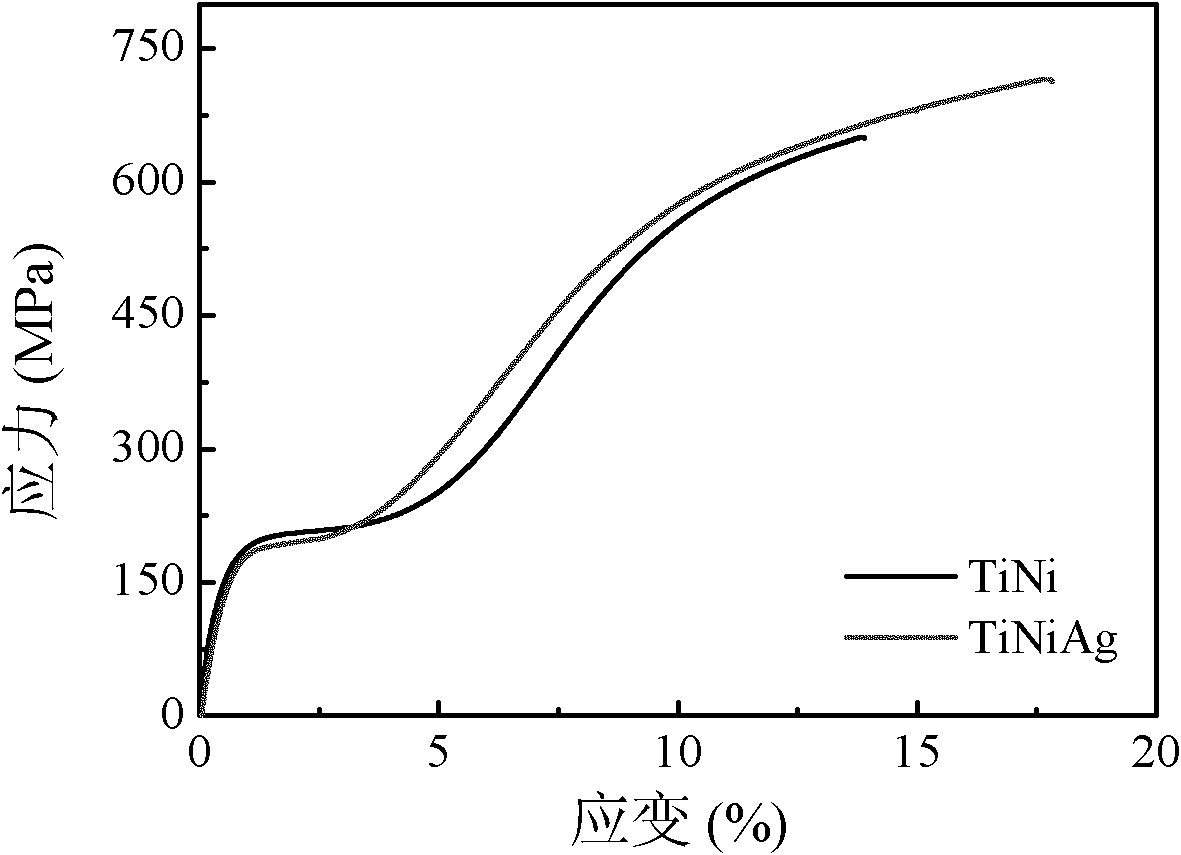

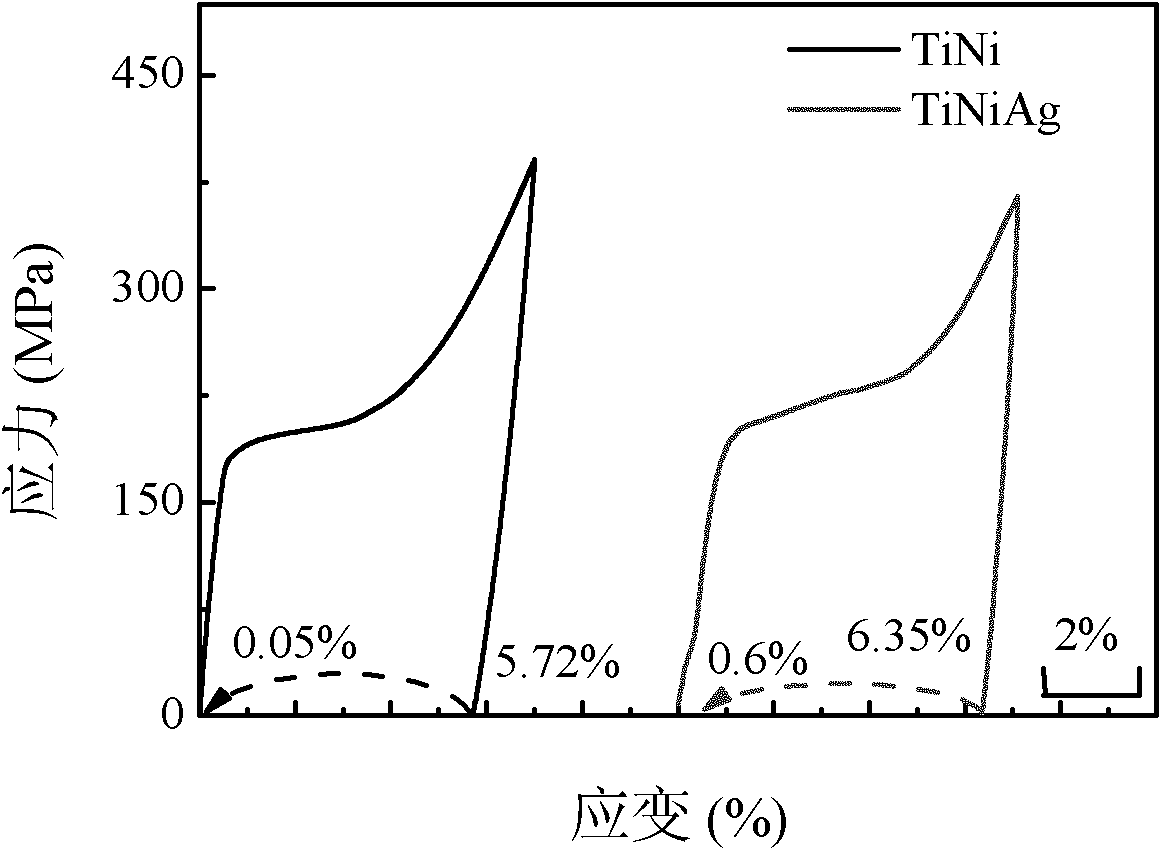

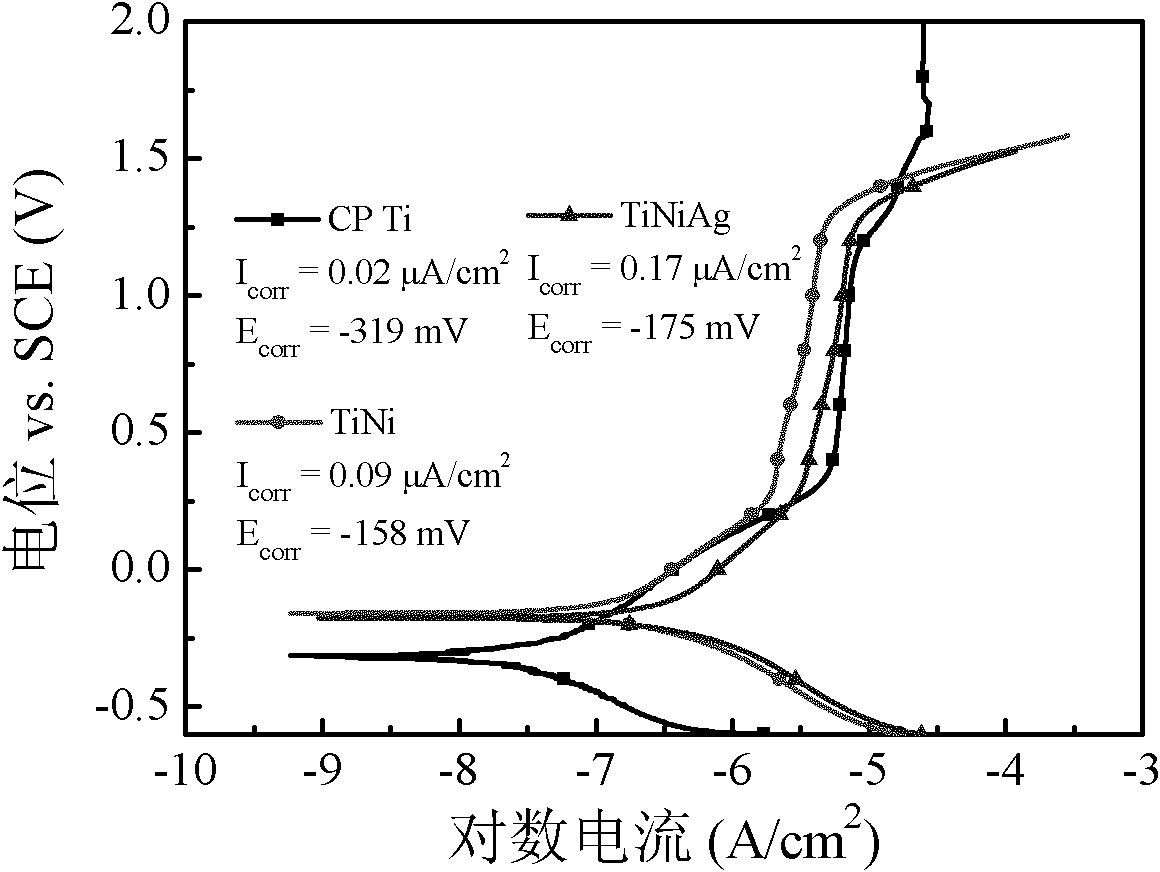

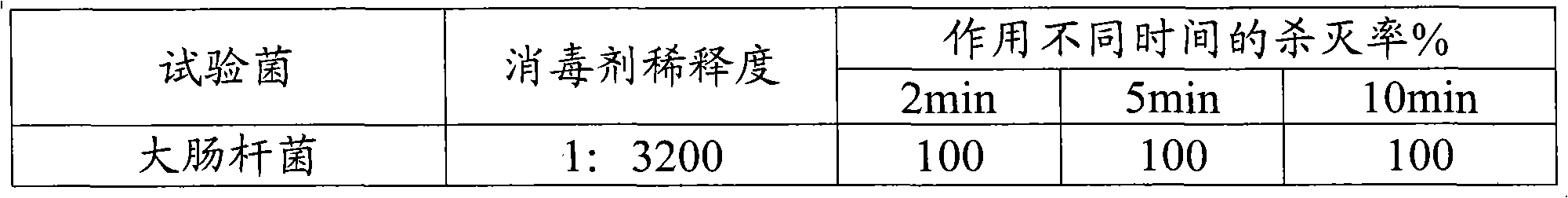

TiNiAg memory alloy with antibacterial function and preparation method thereof

InactiveCN101988166AGood shape memory effectIncrease elasticityEscherichia coliBiocompatibility Testing

The invention provides a TiNiAg memory alloy with the antibacterial function and a preparation method thereof. The TiNiAg memory alloy contains 20%-80% of nickel, 0.1%-10% of silver and the balance of titanium by atomic percent. The alloy not only has good shape memory effect and superelasticity, but also has good matching of mechanical properties. Simultaneously, the alloy material has good corrosion resistance and biocompatibility in simulated body fluid, and cytotoxicity is in the same level of a TiNi alloy. In addition, the alloy material has a broad antimicrobial spectrum and can well inhibit Staphylococcus aureus, Escherichia coli, Staphylococcus epidermidis and other gram-negative and positive bacteria.

Owner:HARBIN ENG UNIV

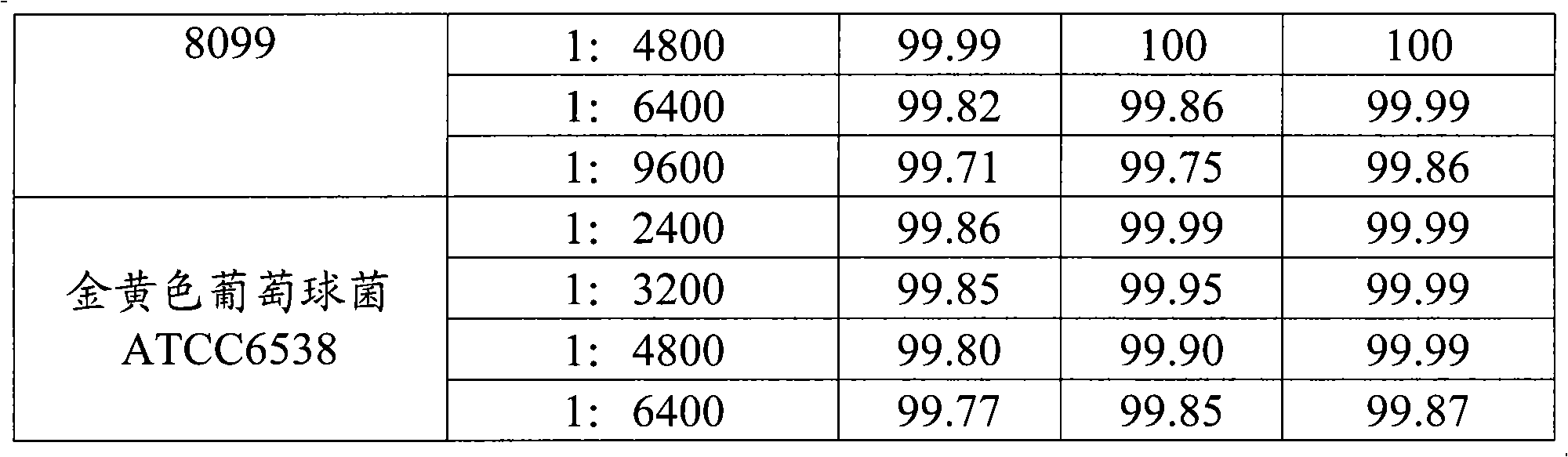

Composition of disinfectant and preparation method thereof

The invention relates to a composition of a disinfectant and a preparation method thereof, and belongs to the field of medicines for veterinary use. The liquid disinfectant comprises 2 to 15 percent (W / V) of aldehydes, 0.6 to 1 percent (W / V) of biguanides, 0 to 15 percent (W / V) of quaternary ammonium salt and the balance of carrier, and the total percentage of the materials is 100 percent. The preparation method comprises the following steps of: 1) adding 2 to 15 percent (W / V) of aldehydes into purified water in an amount which is 40 to 70 percent of the total volume, and stirring uniformly; 2) adding 0 to 15 percent W / V of quaternary ammonium salt and 0 to 3 percent (W / V) of fatty alcohol-polyoxyethylene ether into the mixture in the step 1), and stirring uniformly; 3) adding 1 to 3 percent (W / V) of turpentine, 1 to 3 percent (W / V) of terpineol and 0.6 to 1 percent (W / V) of biguanides into the mixture in the step 2), stirring uniformly, and regulating the pH value to between 3.0 and 7.0 by using glacial acetic acid; 4) adding 0.01 to 0.1 percent (W / V) of chelant and 0.05 to 1 percent (W / V) of corrosion inhibitor into the mixture in the step 3), adding the purified water to the total amount, stirring uniformly, filtering and filling to obtain the composition. The disinfectant has the advantages of high efficiency, no irritation, small corrosivity and the like, is used for disinfection of livestock and poultry environment, equipment and the like, and has a wide market prospect and a high market value.

Owner:LUOYANG HUIZHONG ANIMAL MEDICINE

100% regenerated fiber spunlace non-woven fabric

ActiveCN106048889AImprove cohesionImprove bindingFibre treatmentNon-woven fabricsCardingHair falling

The invention discloses a 100% regenerated fiber spunlace non-woven fabric which uses recycled spunlace non-woven fabric leftover material as a raw material. The production method of the 100% regenerated fiber spunlace non-woven fabric includes raw material pretreatment, raw material retreatment, opening, mixing and impurity removing, carding and netting, spunlace and primary drying, and drying and product finishing. Opening adopts a non-holding manner; a carding machine is additionally provided with a fiber cohesion roller and uses air flow to assist stripping; spunlace water is recycled water which is circularly supplied by a multilevel water circulation processing system, and filtering manners including an air flotation filtering manner, a sand filtering manner, a metal filtering manner and a bag refined filtering manner are used to filter out impurities in water; a novel safe emulsion is used to treat a spunlace fiber net by adoption of an impregnation method or a foam method; the cohesion and the combination among the regenerated fiber can be effectively improved, and the physical performance of the spunlace non-woven fabric finished product is improved; hair falling and bit falling can be avoid during use of the spunlace non-woven fabric, the service life of the spunlace non-woven fabric is prolonged, or the use times of the spunlace non-woven fabric are increased; and the spunlace non-woven fabric has excellent water absorbing performance, is durable and laundering-resistant, and can be used with most of cationic type antibacterial agents.

Owner:JIANGSU AIKOP NEW MATERIALS CO LTD

Preparation method of stable sepiolite antibacterial powder

InactiveCN106665651AHigh specific surface areaLarge adsorption capacityBiocideDead animal preservationChemical adsorptionSilica coating

The invention discloses a preparation method of stable sepiolite antibacterial powder. The preparation method comprises the following steps: activating of sepiolite, antibacterial treatment of the sepiolite, silica coating and the like. According to the preparation method disclosed by the invention, acid and a surfactant are respectively adopted for modifying the sepiolite, so that the specific surface area of an antibacterial material can be increased, and the adsorption quantity of a carrier on silver ions, chitosan and the like is further increased; simple physical adsorption is changed into chemical adsorption, so that release of silver is slowed down, and the long-time antibacterial effect is kept; after the modified sepiolite is utilized for adsorbing nano silver and the chitosan, drying treatment and milling are carried out, antibacterial powder is dispersed into a water solution or an organic solvent, silicon compounds and catalysts are added for carrying out coating reaction, the stability of the obtained antibacterial powder is remarkably increased, and not only can antibacterial broad spectrum be still ensured under severe environment of acid, base, organism, strong ultraviolet radiation and the like, but also the release of antibacterial active components can be slowed down by coating one layer of SiO2, so that the service life of the stable sepiolite antibacterial powder is prolonged.

Owner:XIANGTAN UNIV +1

Preparation method of traditional Chinese medicine anti-microbial underwear fabric

InactiveCN109247627AGuaranteed antimicrobial propertiesGood skin affinityMonocomponent cellulose artificial filamentHandkerchiefsChemical industryFiber

The invention belongs to a separation and extraction technology for effective components of natural products of light industry and chemical industry biological technologies in biology and new medicine, and relates to the field of extraction and application of natural active components, in particular to a preparation method of a traditional Chinese medicine anti-microbial underwear fabric. The preparation method comprises the steps: the anti-microbial active components are extracted from traditional Chinese medicine through an ultrasound-assisted ethyl alcohol extraction technology firstly; then a mesoporous silica and chitosan composite is adopted to pack the natural anti-microbial components, and chitosan / mesoporous silica nano particles loaded with the medicine are prepared; and finally,after bamboo fibers, the chitosan / mesoporous silica nano particles loaded with the medicine, a natural antioxidant, water and a spinning assistant are mixed, then traditional Chinese medicine anti-microbial fibers are obtained through electrostatic spinning, then the traditional Chinese medicine anti-microbial fibers and hydrophobic modified cotton fibers are blended, and then the traditional Chinese medicine anti-microbial underwear fabric is obtained. The traditional Chinese medicine anti-microbial underwear fabric prepared by the preparation method has the anti-microbial and health-care effects, and has the wearing experience feeling of good skin-friendly property and high moisture-absorption and ventilating properties.

Owner:唐卫兵

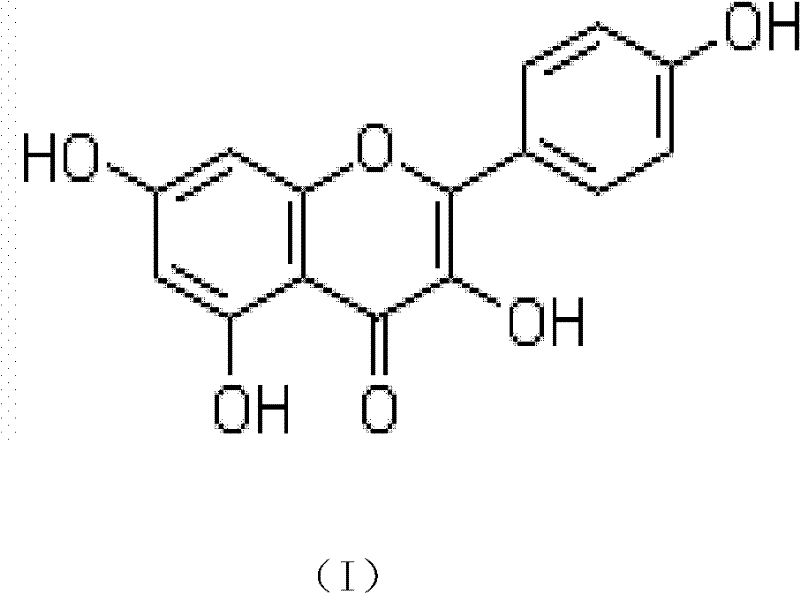

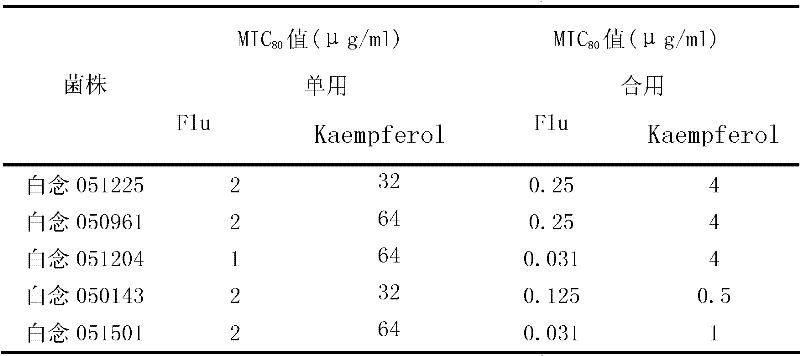

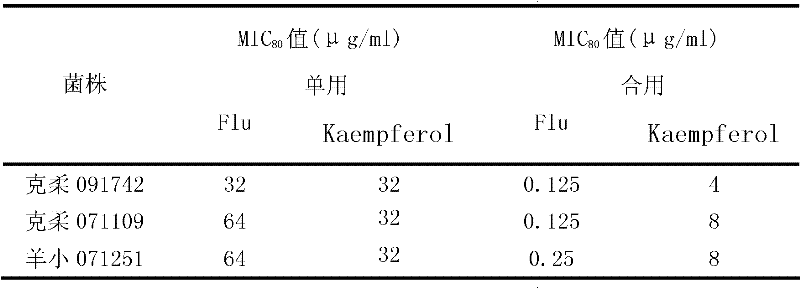

Application of kaempferol as synergist of anti-fungal medicaments

InactiveCN102218052AEliminate side effectsReduce doseOrganic active ingredientsAntimycoticsSide effectAntifungal drug

The invention relates to the technical field of medicaments, in particular to novel application of kaempferol as a synergist of anti-fungal medicaments. The anti-fungal medicaments are azole-type or polyene-type anti-fungal medicaments and based on the effective concentration of the anti-fungal medicaments, the adding ratio of the kaempferol is 0.5 to 16 mu g / ml. Tests show that when the kaempferol and the anti-fungal medicaments such as fluconazole, ketoconazole, miconazole and amphotericin B are used together, not only the anti-fungal effect is guaranteed on the premise of lowering the consumption of the anti-fungal medicaments, but also the anti-fungal medicaments can restore the function of killing the drug-resistant fungi, so that the kaempferol can be used as a synergist of the anti-fungal medicaments. The kaempferol used as the synergist of the anti-fungal medicaments can lower the consumption of the azole-type or polyene-type anti-fungal medicaments so as to reduce the toxic and side effects of the medicaments; and the kaempferol can make the anti-fungal medicaments restore the function of killing the drug-resistant fungi, so that the kaempferol can effectively treat mycotic infection, particularly drug-resistant t mycotic infection, and has quite important clinical application values.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Wear-resisting anti-microbial sweat-absorbing fabric and preparation method thereof

ActiveCN109501400AHigh strengthIncrease elasticityLamination ancillary operationsWeft knittingPolyesterUltimate tensile strength

The invention discloses a wear-resisting anti-microbial sweat-absorbing fabric and a preparation method thereof. The wear-resisting anti-microbial sweat-absorbing fabric comprises a wearing layer andan anti-microbial layer; the wearing layer is weaved by blending the following fibers in parts by weight: 30-60 parts of nylon fiber, 20-40 parts of polyester fiber and 5-15 parts of bamboo fiber; theanti-microbial layer is weaved by blending the following fibers in parts by weight: 40-60 parts of cotton fiber and 15-45 parts of linen fiber. The wear-resisting anti-microbial sweat-absorbing fabric prepared according to the invention has high strength, high abrasive resistance, excellent antibacterial property and capability of keeping anti-microbial effect after repeated washing; the preparation method is simple; the production process is easy for operation; the wear-resisting anti-microbial sweat-absorbing fabric is suitable for large-scale promotion.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Crease-resistant deformation-preventing finishing process for cotton fabric

InactiveCN105839387AGood anti-wrinkle and anti-deformation effectImprove anti-wrinkle and anti-deformation effectDry-cleaning apparatus for textilesBleaching apparatusPolyethylene glycolPulp and paper industry

The invention provides a crease-resistant deformation-preventing finishing process for a cotton fabric. The finishing process comprises the following steps: desizing; scouring and bleaching; whitening; crease-resistant finishing; predrying; baking; washing; and drying. According to the invention, modified tea saponin is added in the procedure of scouring and bleaching and process temperature is strictly controlled, so the whiteness of the cotton fabric is improved; as the procedure of whitening is carried out after the procedure of scouring and bleaching and low-temperature whitening is employed in the procedure of whitening, little damage is posed to the cotton fabric, the whiteness of the cotton fabric is further improved, and whiteness maintenance of the cotton fabric after finishing is facilitated; and and a crease-resistant finishing agent prepared from citric acid and polyethylene glycol in proportion is safe and nontoxic, improves the crease-resistant and deformation-preventing effect, and enables the rebounce angle of the cotton fabric to reach 245 DEG or above.

Owner:TAICANG JINDA PRINTING & DYEING CO LTD

Antimicrobial self-cleaning PPR pipe

ActiveCN109253321AHas antibacterial propertiesObvious shrinkagePipe elementsRigid pipesWrinkle skinThermal expansion

The invention provides an antimicrobial self-cleaning PPR pipe, and belongs to the technical field of pipelines. A main material PPR for preparing a pipe body is modified and prepared, POE and nano-silver SiO2 are blended in the PPR material on the inner layer, the PPR blending material has antimicrobial performance and obvious shrinkage and expansion performance, the thermal expansion coefficientof the material is increased, when thermal expansion and cold shrinkage happen, and the shrinkage and expansion performance is also easily shown on the surface of the inner wall. In addition, a curing layer can be additionally arranged, the shrinkage and expansion phenomenon of the surface of the inner wall of the inner layer is more obvious, meanwhile, the inner wall of the inner layer can be designed into a wrinkle shape, especially an arc turn folded shape, when thermal expansion and cold shrinkage happen, the shrinkage and expansion phenomenon of the convex portion of the inner surface ofthe pipe body is more prominent, the change of the convex portion and the change of the concave portion are not synchronous, then dirt attached to the inner surface is gradually separated, self-cleaning is achieved, and the antimicrobial effect is kept for a long time.

Owner:CHONGQING GONGQI TECH CO LTD

Ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method thereof

ActiveCN1827824AExcellent long-lasting antibacterial effectLow content of alloying elementsTemperature control deviceHeat treatment process controlPre treatmentChromium

Disclosed is a ferrite antibacterial stainless steel for low-chrome copper-containing dishware and manufacturing method, wherein the stainless steel matrix comprises (by wt%) Cr 12.0-14.0%, Cu 0.70-2.20%, C <=0.08-0.15, the preparing process comprises pre-processing melted iron, passing through composite revolving furnace, vacuum oxygen decarbonization furnace, refined-smelting ladle furnace, continuous plate blank casting, casting blank annealing, tandem rolling, and annealing in a bell-type furnace.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Antibacterial master batch and preparation method of antibacterial master batch, antibacterial artificial grass and preparation method of antibacterial artificial grass

ActiveCN104558776AGuaranteed antimicrobial propertiesHigh tensile strengthMonocomponent polyolefin artificial filamentArtifical filament manufactureMasterbatchLow-density polyethylene

The invention discloses an antibacterial master batch, a preparation method of the master batch, antibacterial artificial grass and a preparation method of the artificial grass. The antibacterial master batch is prepared by the step of performing double screw co-extrusion on the following components in percentage by weight: 20-30 percent of low-density polyethylene, 30-40 percent of an antibacterial material, 10-20 percent of a plasticizer, 10-20 percent of acetone and 10-20 percent of polyphthalamide (PPA). The method for preparing the antibacterial artificial grass comprises the following steps: adding the antibacterial master batch disclosed by the invention into a matrix resin, mixing, extruding, stretching, setting, dropping and twisting. The antibacterial material, the low-density polyethylene and PPA are co-extruded to process the antibacterial master batch, so that the tensile strength, deflection and other performances of the artificial grass can be improved; and moreover, the antibacterial artificial grass disclosed by the invention is subjected to hot extrusion in a spinning screw, so that the antibacterial master batch and the matrix resin are fused and therefore the antibacterial artificial grass has resistance and good processability.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

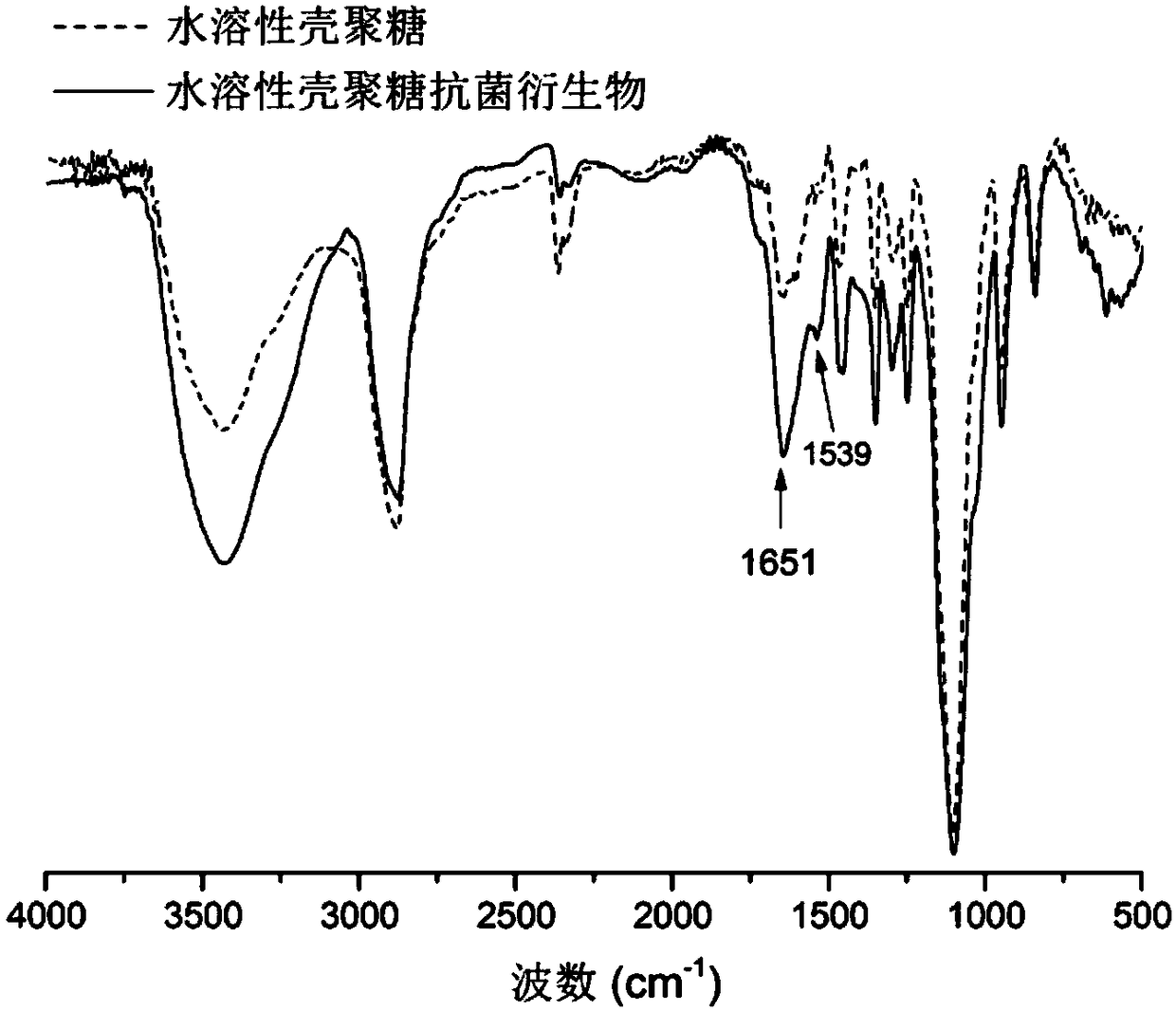

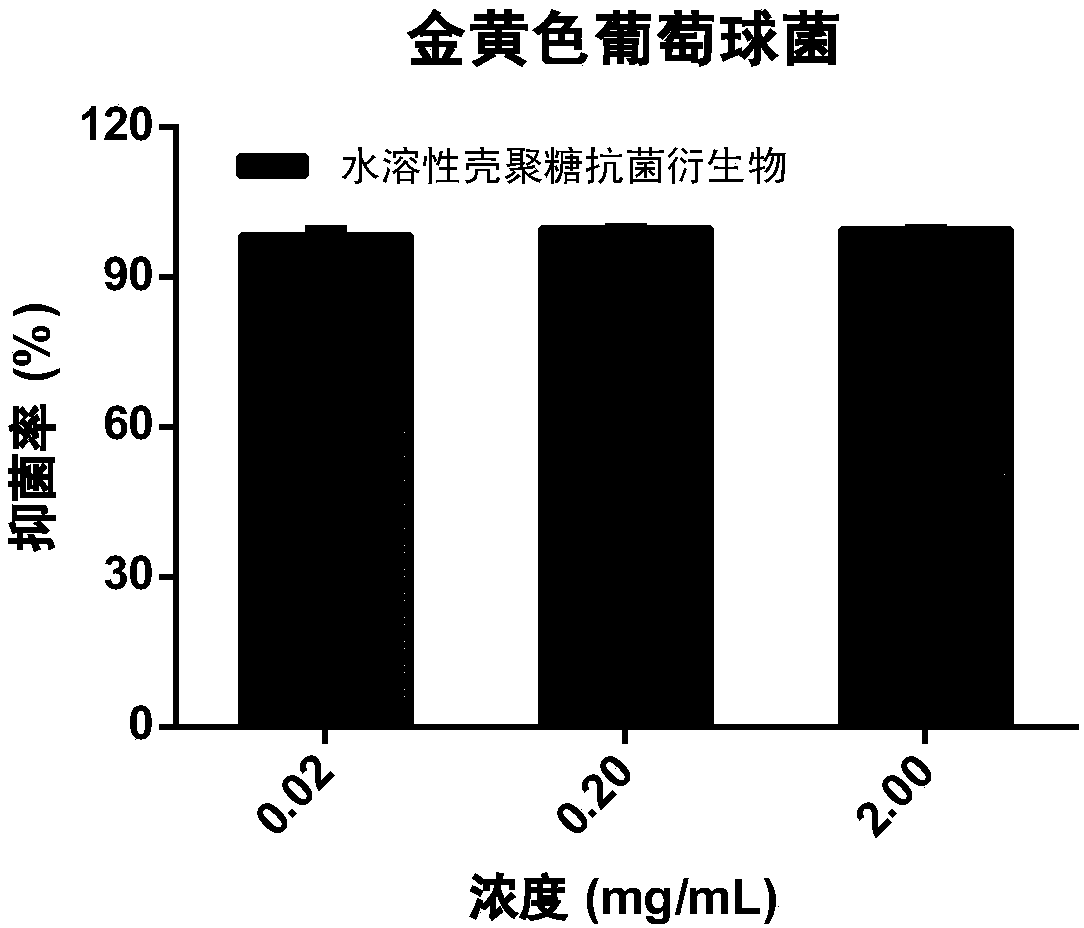

Water-soluble chitosan antibacterial derivative and preparation method thereof

ActiveCN109485747ABalanced antimicrobial propertiesBalance securityBiocideFungicidesSolubilityThiourea

The invention discloses a water-soluble chitosan antibacterial derivative and a preparation method thereof. The water-soluble chitosan antibacterial derivative comprises a chitosan framework and a bifunctional group for modifying amino on the chitosan framework, wherein the bifunctional group comprises guanidino and carbonyl methoxy polyethylene glycol. The side chain of chitosan is modified withguanidino and short-chain polyethylene glycol, and the chitosan achieves good antibacterial property and higher biological safety. According to the preparation method, firstly, the chitosan reacts with the carbonyl methoxy polyethylene glycol, water solubility of the chitosan is sufficiently improved, and biological safety is greatly improved; secondly, the chitosan reacts with thiourea trioxide,participation of the amino in subsequent reaction is effectively avoided if the guanidino is grafted in the first step, rich positive charge of the guanidino is effectively retained, and the positivecharge density of the water-soluble chitosan antibacterial derivative is ensured, so that the antibacterial effect of the water-soluble chitosan antibacterial derivative is better.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Preparation method of antibacterial austenitic stainless steel band

InactiveCN103667978AImprove performanceGuaranteed antimicrobial propertiesAustenitic stainless steelAir cooling

The invention discloses a preparation method of an antibacterial austenitic stainless steel band. The stainless steel consists of the following components in percentage by weight: 0.05-0.08% of C, 4.4-4.8% of Mn, 14.5-15.5% of Cr, 5.5-6.5% of Ni, 1.0-1.2% of Cu, 0.4-0.6% of Ag, 1.2-1.4% of Si, less than or equal to 0.025% of S, less than or equal to 0.060% of P, 0.5-0.7% of Ce, 0.2-0.4% of Ti and the balance of Fe and unavoidable impurity elements. The preparation method comprises the following steps: (1) smelting; (2) cogging; (3) hot rolling; (4) cold rolling and annealing; (5) solid solution and aging treatment: firstly preserving heat at 1,200-1,220 DEG C for 1-2 hours, and performing air cooling to room temperature; then performing aging treatment: preserving heat at 620-630 DEG C for 6-8 hours, and performing air cooling to room temperature.

Owner:WUXI XINDAZHONG STEEL SHEET

Invisible plant-source fiber antibacterial mask and production method thereof

ActiveCN105146812AGuaranteed antimicrobial propertiesGuaranteed bonding effectNon-woven fabricsProtective garmentPolyesterSurface layer

The invention discloses an invisible plant-source fiber antibacterial mask. The mask comprises a mask body composed of a mask surface layer and a mask inner layer. Mask tying belts facilitating wearing are sewn on the mask body. A middle layer used for filtering out fine dust is arranged between the mask surface layer and the mask inner layer. Both the mask surface layer and the mask inner layer are made of antibacterial fiber layers composed of plant antibacterial fibers and synthetic fibers reinforced with the plant antibacterial fibers. The plant antibacterial fibers are made of plant antibacterial agents and viscose spinning solutions; the synthetic fibers are hot-melt fibers or viscose fibers reinforced with the plant antibacterial fibers in a heat bonding mode, or one or more of cotton fibers, viscose fibers and polyester fibers reinforced with the plant antibacterial fibers in a spunlacing mode. The mask is simple in structure, low in cost and remarkable in antibacterial effect, the antibacterial effect of the mask can be controlled at will, and discriminability between the mask and the face can be reduced to achieve an invisible effect without affecting the antibacterial performance of the mask.

Owner:上海淳梧新材料科技有限公司

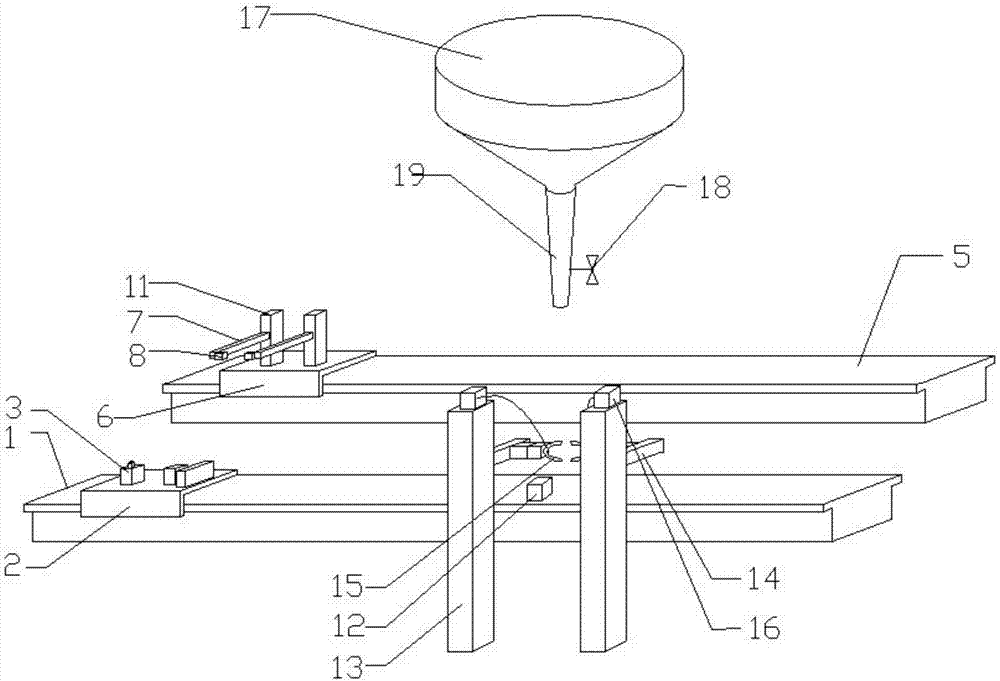

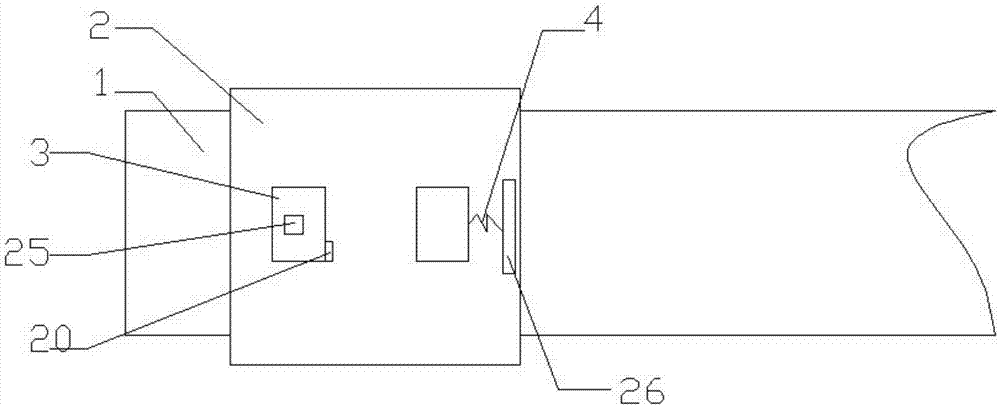

Nutritious powder solid drink suitable for pregnant women and preparation method thereof

InactiveCN107410814AEnhance immunity of pregnant womenPromote growth and developmentPackaging automatic controlSolid materialPolydextrosePumpkin seed

The present invention discloses a nutritious powder solid drink suitable for pregnant women and a preparation method thereof, and relates to the technical field of nutritious powder preparing. The nutritious powder comprises the following raw materials: brown rice flour, powdered crystal sugar, peanut flour, lotus root flour, polydextrose, resistant dextrin, grape powder, black sesame powder, pumpkin seed powder, apple powder, cherry powder, walnut powder, pectin, broad bean flour, fagopyrum esculentum flour, DHA algal flour, prune powder and folic acid. The preparation method comprises the following steps: (1) washing; (2) dehydrating; (3) baking at low temperature; (4) crushing; (5) total mixing and sterilizing; (6) filling; and (7) finished product inspecting. During the filling process, a new type filling device is used. The filling device comprises a friction member, a clamping member, a separating member and a filling member. The nutritious powder solid drink can promote fetal cardiovascular and immune system developments, promote fetal brain and eye developments, and supplement pregnant women with high-quality proteins and rich vitamins.

Owner:湖南中佰农业发展有限公司

Antibacterial surface decorative material and its preparation method

InactiveCN1730582AGood antibacterial propertiesSafe to useEpoxy resin coatingsPolyester coatingsOxideZinc

Disclosed is an antibacterial surface decorative material and its preparation method, wherein the material comprises (by weight percentage) adhesive 100 parts, acicular zinc oxide crystal whisker antibacterial agent 0.1-10 parts, pre-dispersing agent 0.1-10 parts, auxiliary agent 0.1-5 parts. The preparing process consists of charging into a reaction kettle, stirring at 30-60 deg. C, and mixing the pre-dispersion system with other components.

Owner:SOUTHWEST JIAOTONG UNIV +1

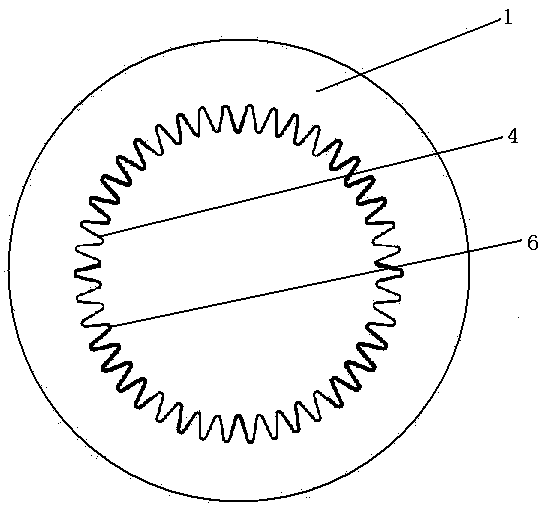

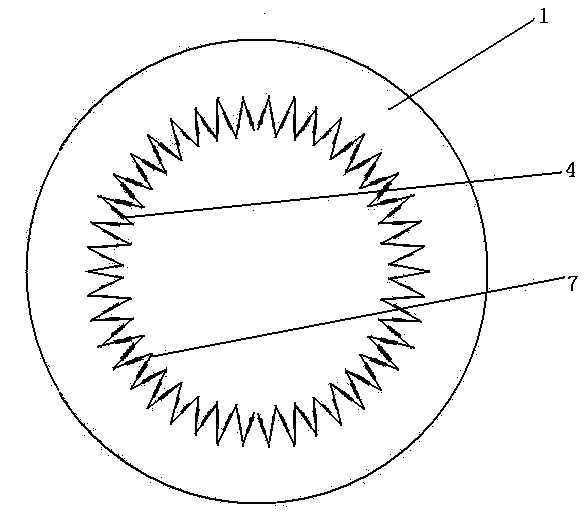

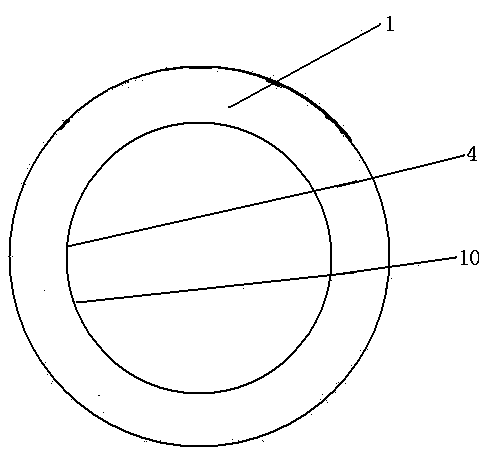

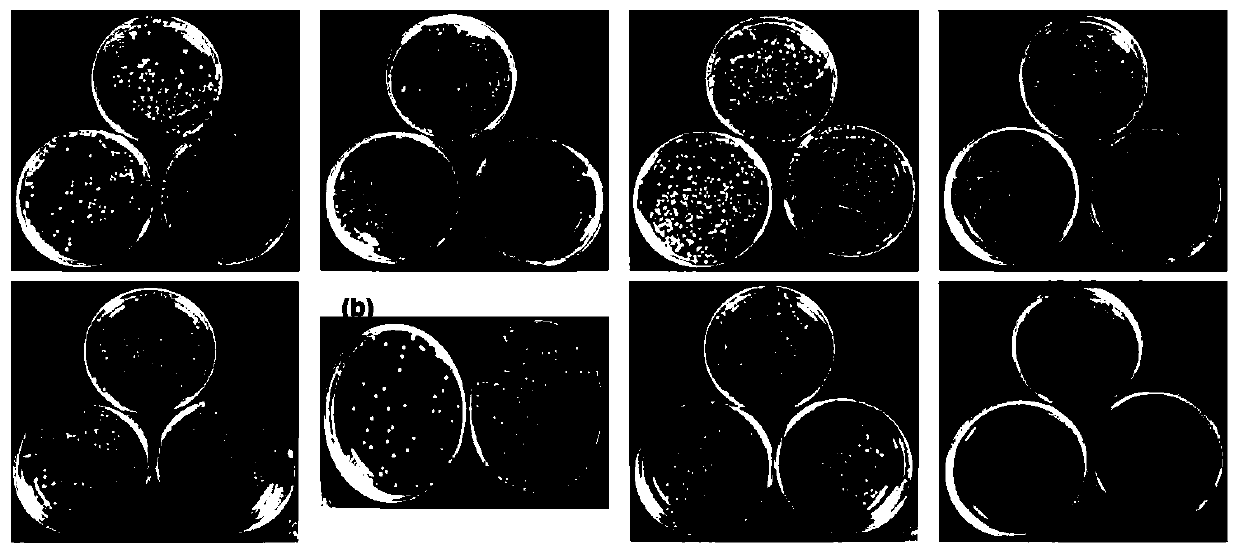

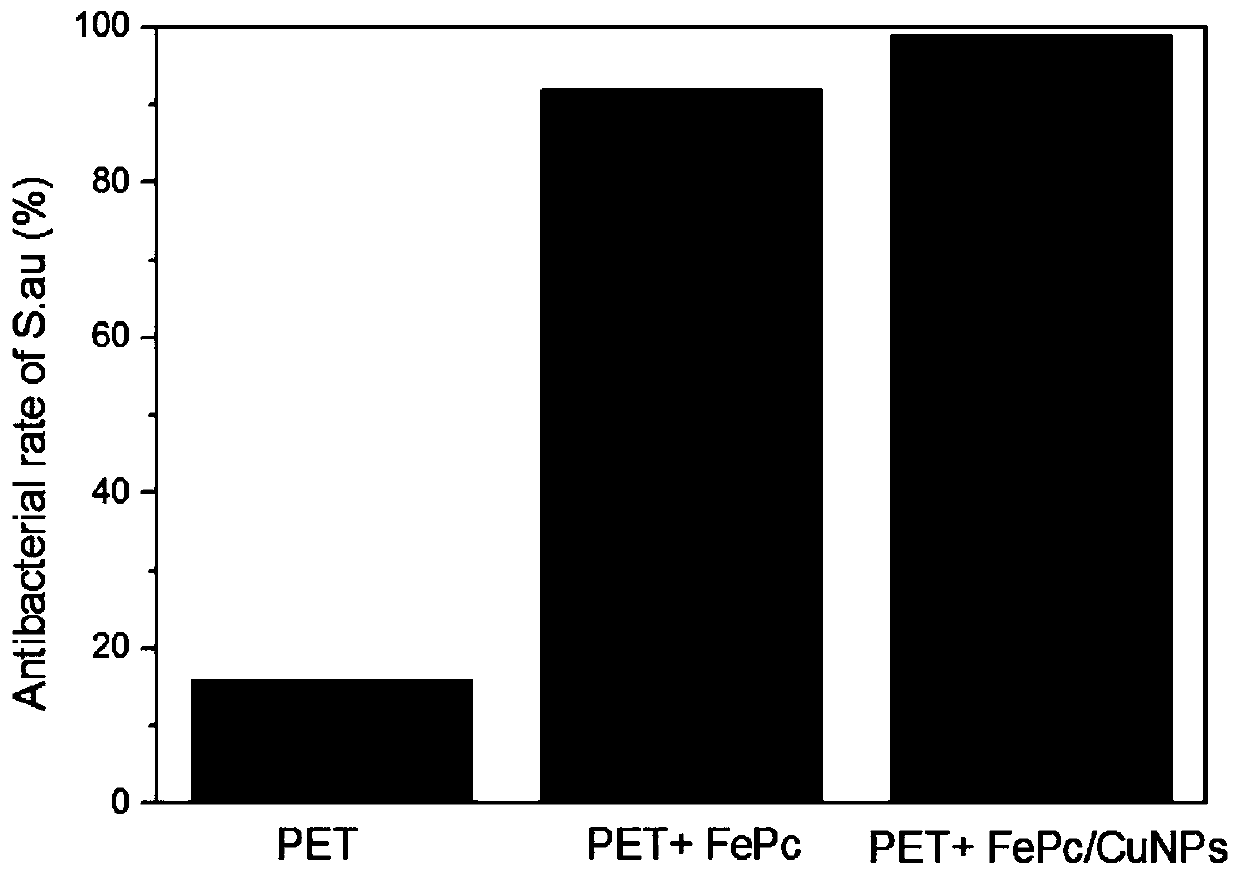

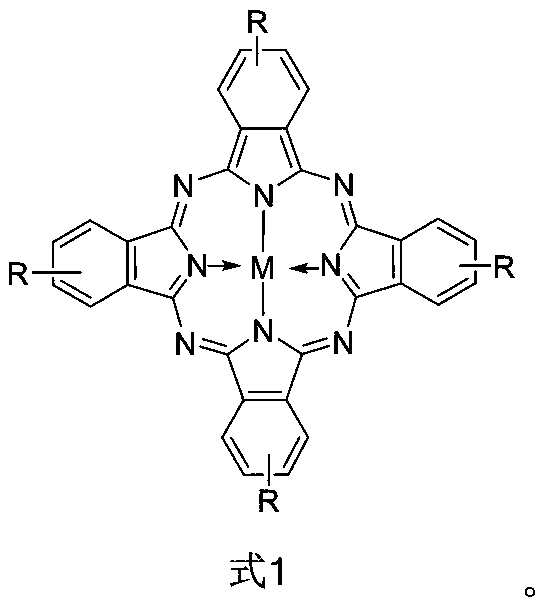

Catalytic composite anti-bacterial fiber and preparation method and application thereof

ActiveCN109797450AImprove liquidityImprove surface activityFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention provides a preparation method for a catalytic composite anti-bacterial fiber, and belongs to the field of fiber materials. The catalytic composite anti-bacterial fiber is prepared by performing profiled spinning treatment on a functional master batch and a polymer matrix. The functional master batch comprises a composite anti-bacterial catalyst, an additive and a high polymer. The composite anti-bacterial catalyst comprises nano metal particles and a photocatalyst. The high polymer and the polymer matrix independently comprise polyester or polyamide. The catalytic composite anti-bacterial fiber is capable of selecting the nano metal particles and the photocatalyst as the composite anti-bacterial catalyst, so the catalytic composite anti-bacterial fiber has the better anti-bacterial effect compared with the anti-bacterial fiber with a single anti-bacterial catalyst, and through using the additive, flowability and surface activity of the anti-bacterial catalyst are increased, so the anti-bacterial catalyst is uniformly distributed in the polymer matrix, and the composite anti-bacterial catalyst is prevented from being aggregated while mixed.

Owner:ZHEJIANG SCI-TECH UNIV

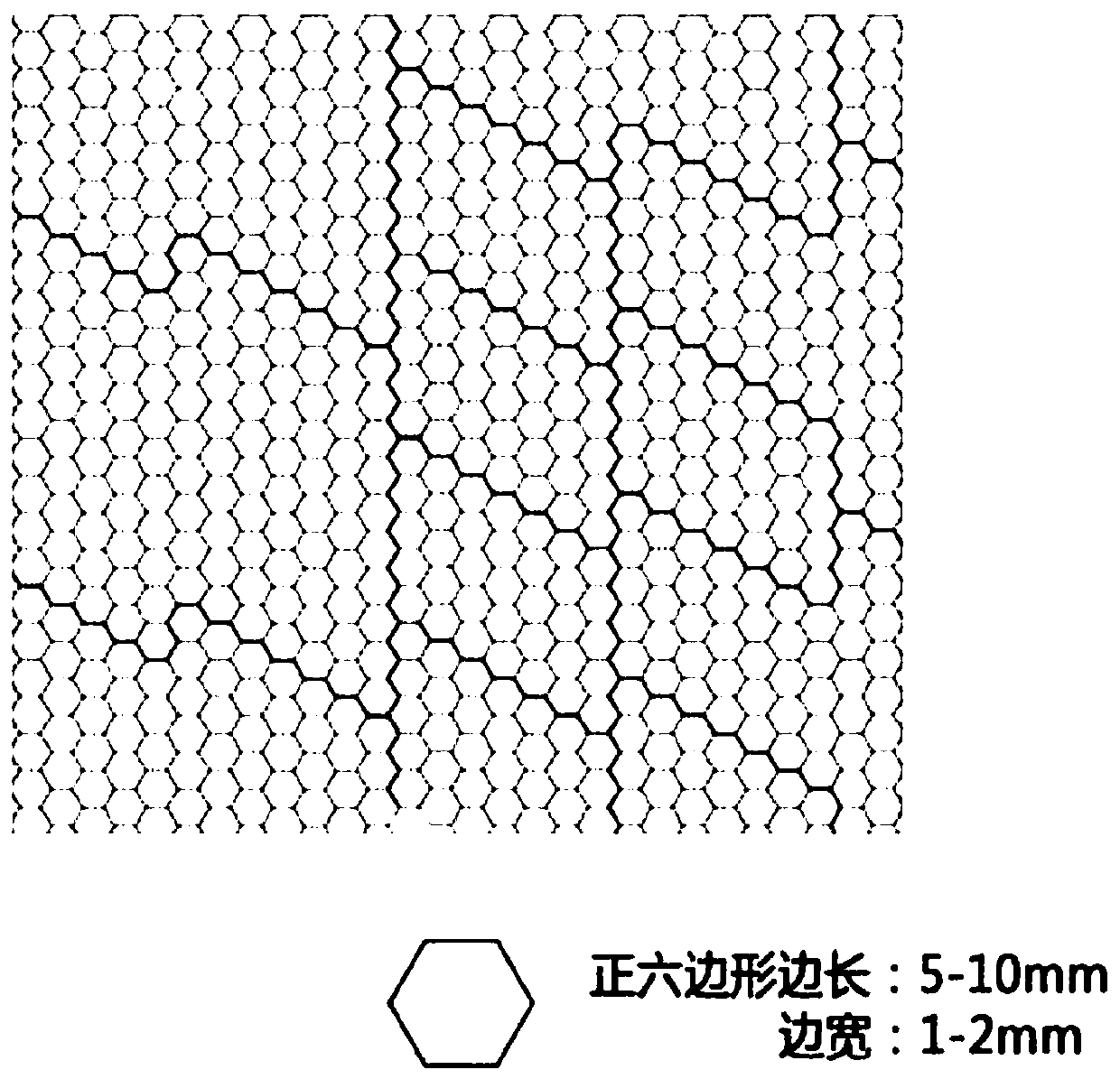

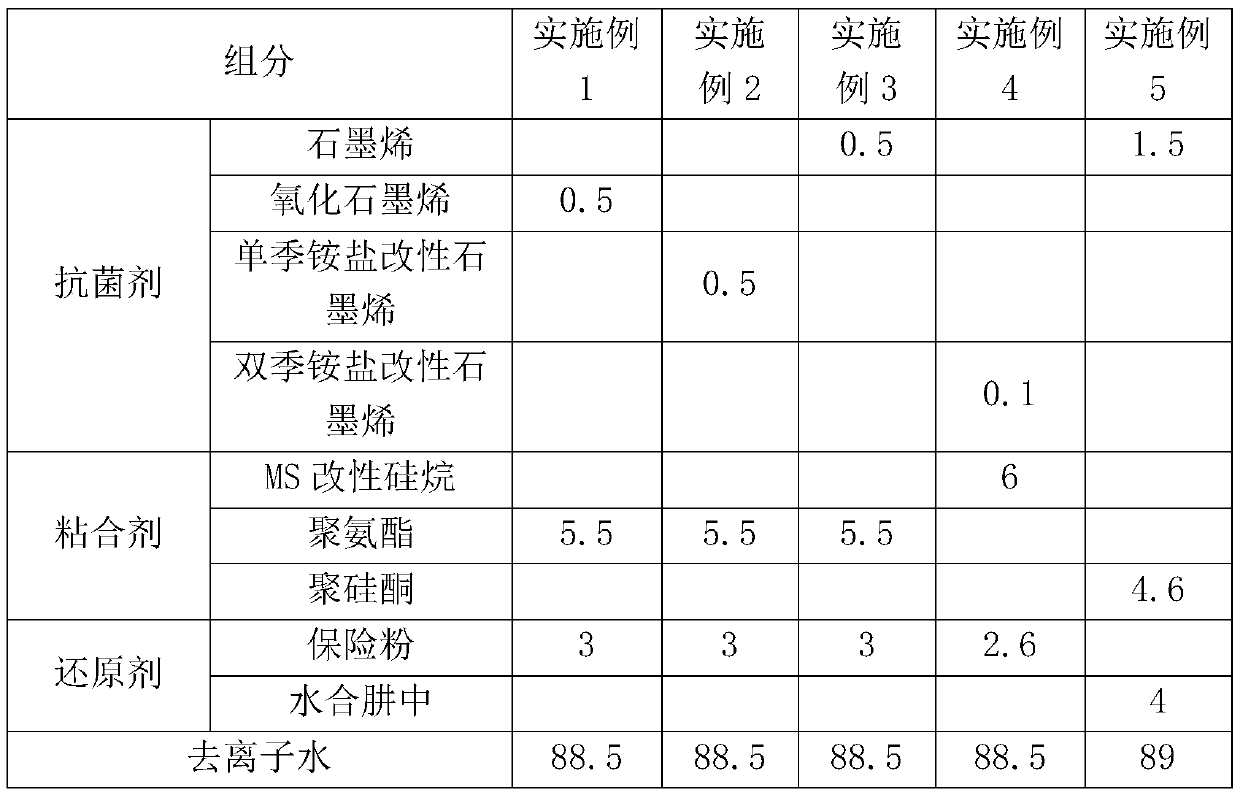

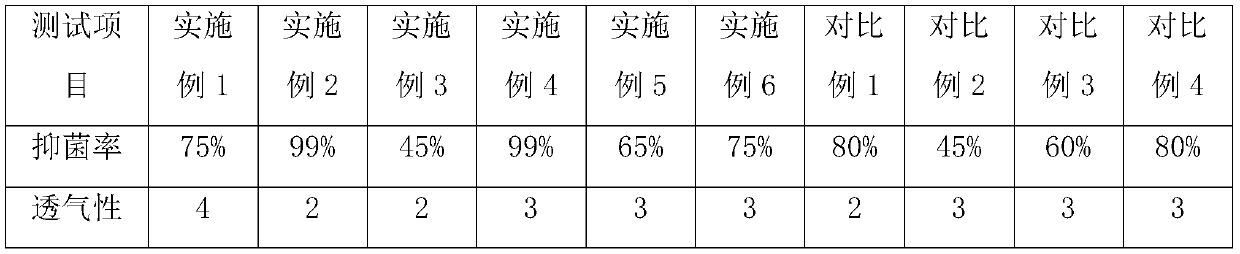

Graphene antibacterial fabric and preparation method thereof

InactiveCN110453494AImprove bonding fastnessGuaranteed breathabilityBiochemical fibre treatmentIonOxide

The invention provides a preparation method of a graphene antibacterial fabric. The method comprises the following steps that S1, an antibacterial agent and a binder are uniformly mixed and then applied to the surface of a fabric, and then drying is conducted; S2, the dried fabric is put into a mixed solution of a reducing agent and deionized water, and then the fabric is taken out and dried, wherein the antibacterial agent is one or multiple of graphene, graphene oxide and amino-modified graphene. Accordingly, a novel graphene antibacterial raw material is combined with bonding and chemical bonding modes to achieve the antibacterial function on a single layer fabric, not only are the antibacterial property and the washing fastness of the fabric ensured, but also the antibacterial water washing resistance of the fabric is improved.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

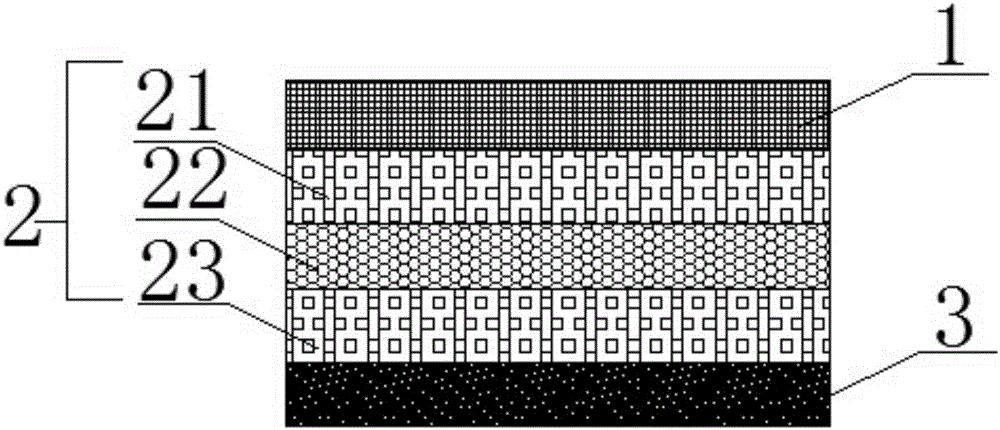

High-strength ultraviolet-proof antibacterial type textile fabric

InactiveCN106739215AImprove fitImprove breathabilitySynthetic resin layered productsCellulosic plastic layered productsSurface layerCarbon fibers

The invention discloses a high-strength ultraviolet-proof antibacterial type textile fabric and a preparation process thereof, and relates to the field of textile fabrics. The high-strength ultraviolet-proof antibacterial type textile fabric comprises a surface layer, a middle layer and an inner layer, wherein the surface layer is made of ultraviolet-proof fabrics; the middle layer comprises a first fabric layer, a second fabric layer and a third fabric layer; each of the first fabric layer and the second fabric layer is formed by 40 to 60 weight percent of bamboo carbon fiber, 10 to 30 weight percent of Shengma fiber and 10 to 30 weight percent of gossamer through blended spinning and weaving; the second fabric layer is formed by weaving 100 weight percent of bamboo carbon fiber; the inner layer is formed by 30 to 40 weight percent of bamboo charcoal fiber, 20 to 30 weight percent of heating fiber and 40 to 50 weight percent of cotton through blended spinning and weaving. The high-strength ultraviolet-proof antibacterial type textile fabric provided by the invention has the efficacies that the strength is high; the wear resistant performance is good; the ultraviolet-proof effect is achieved; bacteria resistance and bacteriostasis are realized; the hand feeling is comfortable; ventilation and heat insulation are realized, and the like. The preparation process is simple and reasonable; the production efficiency is high.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

Antistatic antibiotic sock

ActiveCN101716019ANot easy to fall offSolve the problem of easy falling offPanty-hoseHosieryFiberAntibiotic Y

The invention discloses an antistatic antibiotic sock, which is formed by interweaving 10-70 parts of antibiotic chemical fiber filament, 0.5-5 parts of electrically-conducting filament and 10-70 parts of special section chemical fiber filament by weight. The invention provides an antistatic antibiotic sock having the characteristics of little falling possibility of fiber, excellent antibiotic and electrically-conducting performances and great durability.

Owner:SHENZHEN KINGKYLIN ENVIRONMENT TECH CO LTD

Anti-bacterial polypropylene plastic and preparation method thereof

InactiveCN107501726AImprove water resistanceStrong water resistanceAntioxidantPolyhexamethylene guanidine

The invention relates to the field of plastic anti-bacteria and particularly provides anti-bacterial polypropylene plastic and a preparation method thereof. The method comprises steps as follows: (1), in the presence of an aqueous solvent, poly guanidine salts and sodium 2-mercaptopyridine N-oxide are mixed and contacted, solid substances are obtained, dried and smashed, and an anti-bacterial agent is obtained, wherein the poly guanidine salts comprise polyhexamethylene guanidine salt and polyhexamethylene biguanidine salt; (2), polypropylene, the anti-bacterial agent, an optional antioxidant, an optional dispersing agent and an optional compatilizer are subjected to melt blending, extrusion pelletizing, drying and injection molding. The preparation method is simple and easy, and the anti-bacterial plastic has good anti-bacterial and anti-mold effects, is high in water resistance and has bright application prospect.

Owner:WUHU BLUE SKY ENG PLASTIC CO LTD

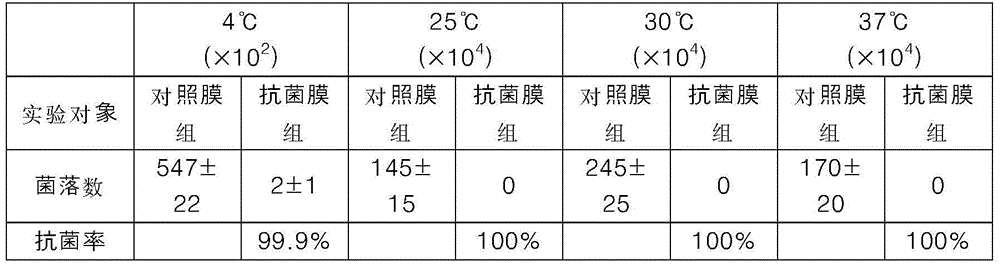

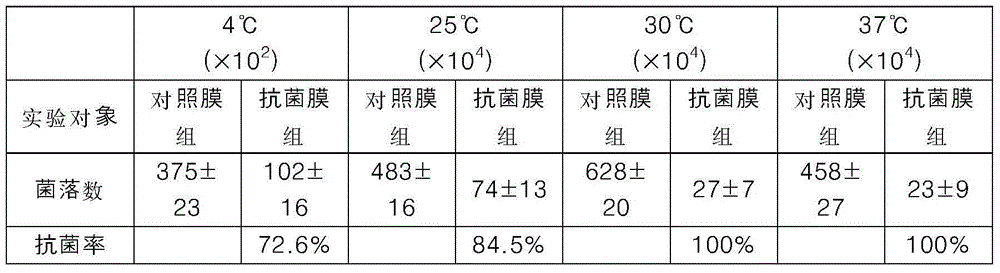

Preparation method of efficient and antibacterial composite film with water-meeting sensitivity

ActiveCN104441899AFacilitated releaseHigh tensile strengthSynthetic resin layered productsLaminationChlorine dioxideComposite film

The invention provides a preparation method of an efficient and antibacterial composite film with water-meeting sensitivity. Natural essential oil is used as an antibacterial agent, and the safety and free toxin of the antibacterial composite film are effectively kept; an atmosphere type antibacterial effect is introduced so that the antibacterial efficiency is effectively improved; and slow release type solid chlorine dioxide is used as the antibacterial agent in order to further improve the antibacterial efficiency, so that the antibacterial efficiency and the antibacterial period are effectively improved. The antibacterial film is prepared by adopting a multilayered co-extrusion method so that various function properties of the antibacterial film are sufficiently realized; antibacterial atmosphere is prevented from escaping to the outside and the antibacterial period is prolonged; meanwhile, a water-soluble slow release type material is adopted so that the responsiveness to water by the antibacterial efficiency of chlorine dioxide is realized; the concentration of the antibacterial agent is effectively regulated and controlled; and the antibacterial effect in a high-humidity temperature is guaranteed. The antibacterial efficiencies of the antibacterial film are kept as follows according to different types of the antibacterial agents: the antibacterial efficiency to colon bacillus is 73%-100% and the antibacterial efficiency to staphylococcus aureus is 86%-100%.

Owner:HUAQIAO UNIVERSITY

Production technology of antibacterial blended cotton yarns

InactiveCN109610058AHas sweat-absorbing propertiesFeelMonocomponent cellulose artificial filamentWet spinning methodsYarnCotton fibre

The invention discloses a production technology of antibacterial blended cotton yarns. The production technology comprises the following steps: firstly, respectively preparing 10 to 16 parts of cottonfibers and 3 to 5 parts antibacterial fibers according to weight parts; secondly, respectively preparing the cotton fibers and the antibacterial fibers in the first step into a first lap and second lap in an opening and cleaning procedure; thirdly, respectively preparing the first lap and the second lap obtained in the second step into a first card sliver and a second card sliver in a cotton carding procedure; preparing the first card sliver and the second card sliver into a drawn sliver through a drawing procedure; fourthly, enabling the drawn sliver obtained in the third step to undergo a roving procedure and the spinning procedure to obtain the antibacterial blended cotton yarns. The antibacterial blended cotton yarns with an antibacterial effect, disclosed by the invention, are obtained by blending ordinary fibers with antibacterial fibers, and have sweat absorbing performance and hand feel of cotton and a certain antibacterial effect.

Owner:湖北德永盛纺织有限公司

Antibacterial sanitary ceramic glaze and preparation method

The invention belongs to the technical field of ceramics, and relates to an antibacterial sanitary ceramic glaze and a preparation method. The antibacterial sanitary ceramic glaze is prepared from the following raw materials: potash feldspar, sandstone, dolomite, limestone, zircon powder, frit, aluminum oxide, zinc oxide, Suzhou clay, zirconium iron pink, praseodymium yellow, cellulose and compound antibacterial powder; the composite antibacterial powder is prepared from the following raw materials in percentage by mass: 15 to 20 percent of silver molybdate, 60 to 65 percent of zinc molybdate and 20 to 25 percent of titanium dioxide. The preparation method of the antibacterial sanitary ceramic glaze comprises the following steps of A, preparation of the composite antibacterial powder; B, preparation of glaze slip; C, preparation of the antibacterial sanitary ceramic glaze. The preparation method provided by the invention is simple and is easy to operate; the antibacterial sanitary ceramic glaze is resistant to a high temperature, does not discolor, and is excellent in antibacterial property.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com