Graphene antibacterial fabric and preparation method thereof

An antibacterial fabric, graphene technology, applied in textiles and papermaking, fiber processing, biochemical fiber processing and other directions, can solve the problems of poor washing fastness and poor fastness, and achieve improved washing resistance and high bonding fastness. , to ensure antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

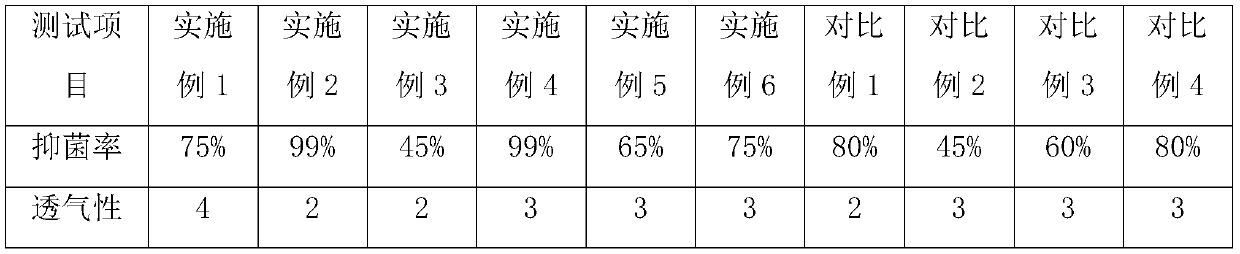

Examples

Embodiment 1-5

[0029] Embodiment 1-5 relates to a kind of preparation method of graphene antibacterial fabric respectively, and concrete operation steps are as follows:

[0030] S1. Mix the antibacterial agent and the adhesive according to the mass fraction in Table 1. After mixing evenly, apply the coating to the surface of the fabric evenly, and then take it out after drying at 60° for 30 minutes;

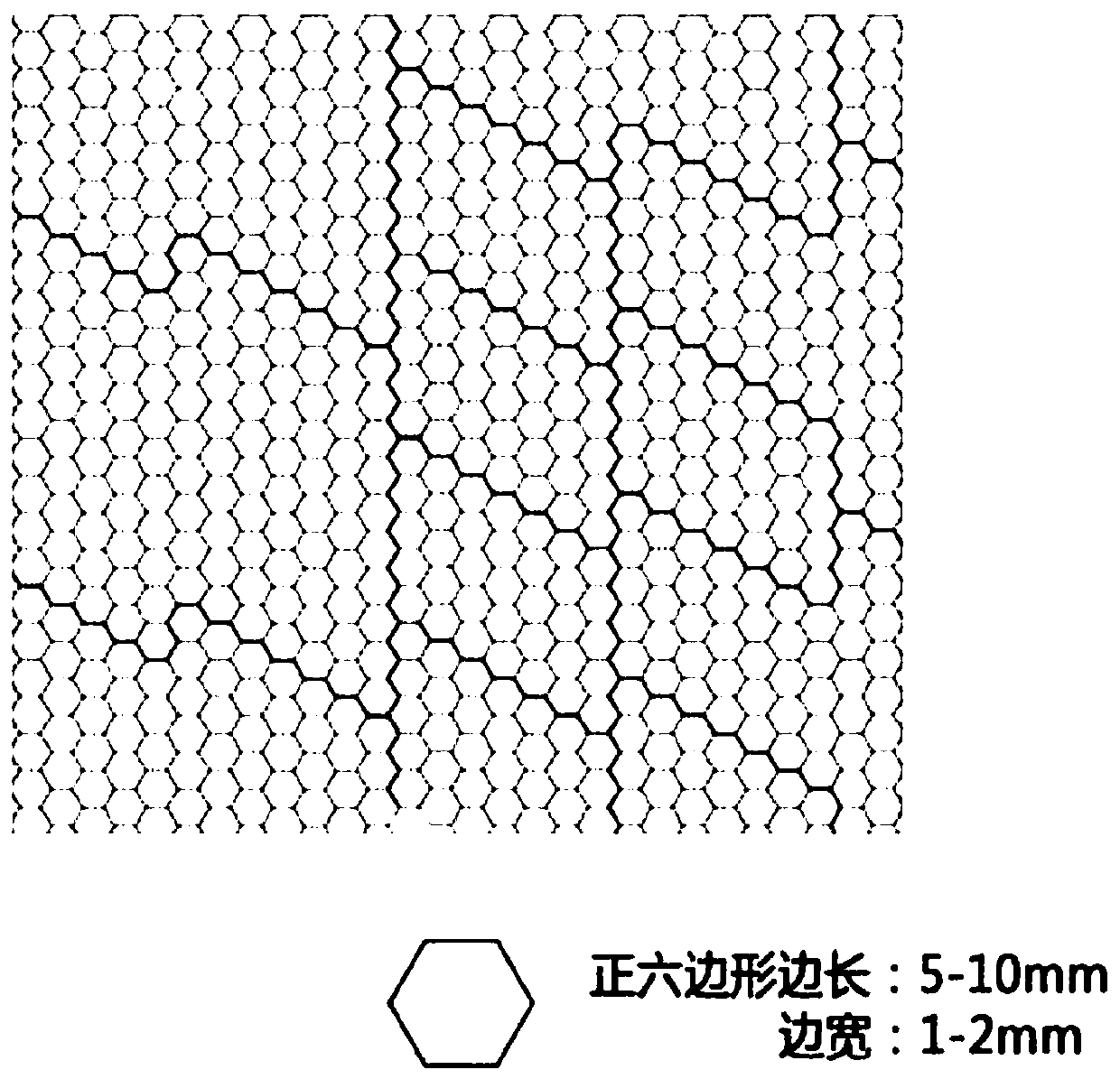

[0031] S2. Prepare the reducing agent solution according to the type and mass fraction in Table 1, put the dried cloth into the reducing agent at 80° for water bath reduction for 60 minutes, and dry. The structural representation of the printing pattern of gained graphene antibacterial fabric is as figure 1 shown.

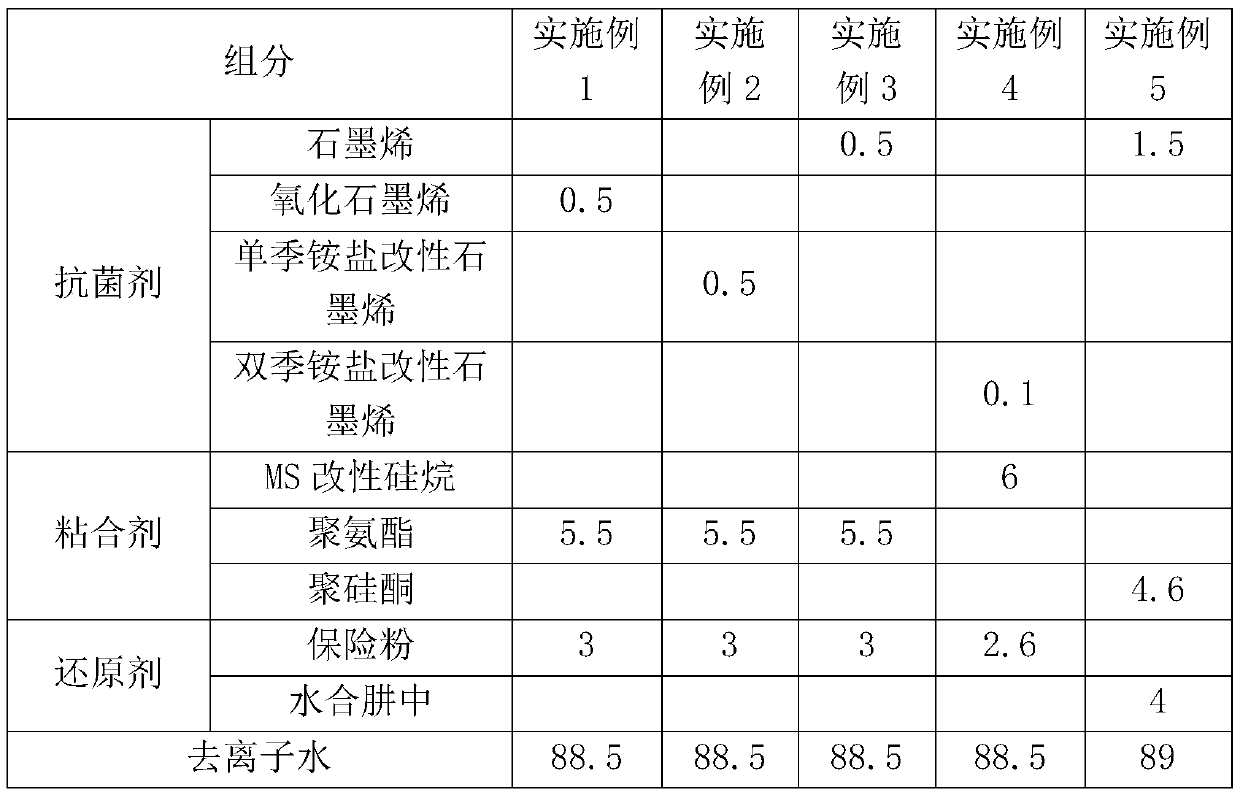

[0032] The types and contents of raw materials involved in Examples 1-5 are shown in Table 1 below:

[0033] Table 1

[0034]

[0035] In the above table 1, the preparation steps of single quaternary ammonium salt modified graphene and double quaternary ammonium salt modified ...

Embodiment 6

[0037] This embodiment provides a preparation method of graphene antibacterial fabric, the specific operation steps are basically the same as in Example 2, the only difference is: in this comparative example, polyquaternium-11 is selected to modify graphene oxide to Amino-modified graphene was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com