Preparation method of guanidine polymer fungicides

A guanidine polymer and bactericide technology is applied in the field of preparation of guanidine polymer bactericides, which can solve the problems of difficulty in stabilizing the surface of a product matrix product, loss of antibacterial properties, and easy dissolution in water, etc., and achieves a good broad-spectrum Antibacterial properties, broad practicability and application prospects, the effect of maintaining bactericidal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

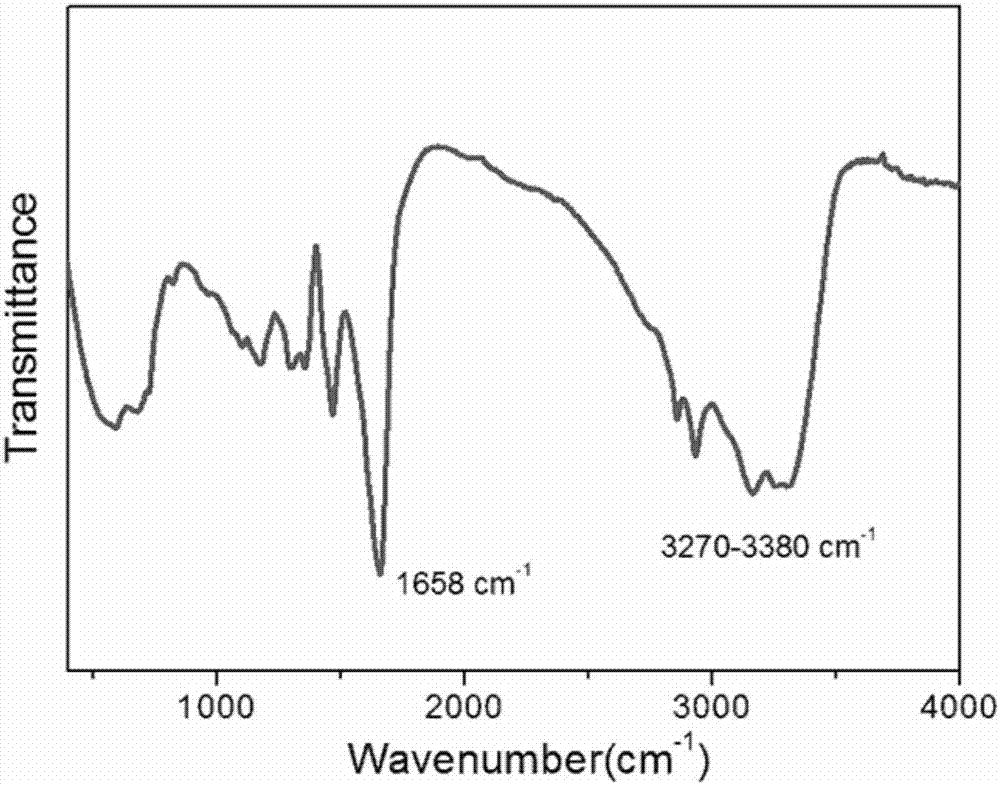

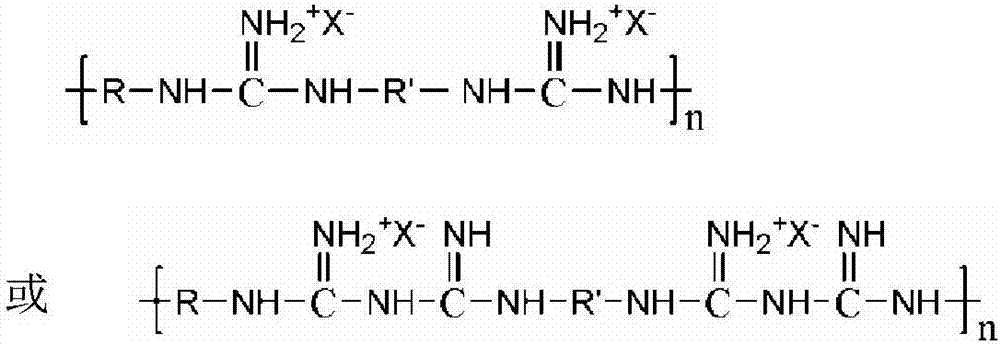

Image

Examples

Embodiment 1

[0025] Take 5g of guanidinium hydrochloride and 50g of polyethyleneimine (molecular weight: about 600), put them into a three-necked flask, mix well, under the protection of nitrogen, raise the temperature to 70°C, reflux under stirring for 2 hours, then add 1,6-hexanedi amine 2.5g, continue to heat up to 120 ℃ under the protection of nitrogen, stop after reflux reaction under stirring for 5 hours, obtain guanidine polymer, its molecular weight is about 1.2×10 4 , the minimum bactericidal concentration detected by the agar dilution method is 12ppm.

Embodiment 2

[0027] Take 5 g of guanidinium nitrate salt and 10 g of polyethyleneimine (molecular weight is about 1800), put them into a three-necked flask, mix well, under the protection of nitrogen, raise the temperature to 90 ° C, stir and reflux for 1 hour, then add 10 g of triethylenetetramine, Continue to heat up to 160°C under the protection of nitrogen, and stop the reflux reaction after stirring for 6 hours to obtain a guanidine polymer with a molecular weight of about 1.0×10 4 , using the agar dilution method to detect the minimum inhibitory concentration of 25ppm.

Embodiment 3

[0029] Take 5g of aminoguanidine hydrochloride and 25g of polyoxyethylene diamine (molecular weight about 1000), put them into a three-necked flask, mix well, under the protection of nitrogen, heat up to 100°C, reflux under stirring for 2 hours, then add trimethyl Hexamethylenediamine 5g, continue to heat up to 150 ℃ under the protection of nitrogen, stop after reflux reaction under stirring for 8 hours, obtain the polymer containing guanidine group, its molecular weight is about 2.2 * 10 4 , using the agar dilution method to detect the minimum inhibitory concentration of 45ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com