Preparation method of antibacterial fiber

An antibacterial fiber and product technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of antibacterial agent surface and durability, weakened antibacterial ability of textiles, and inability to exert antibacterial function, etc., to maintain antibacterial Sexuality, low cost, and the effect of increasing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

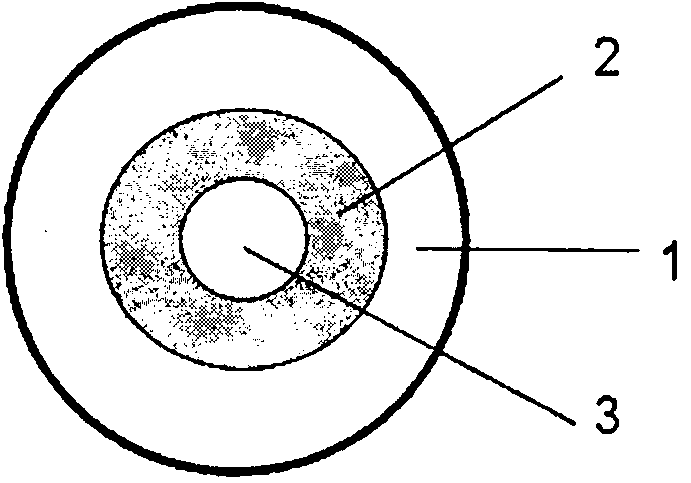

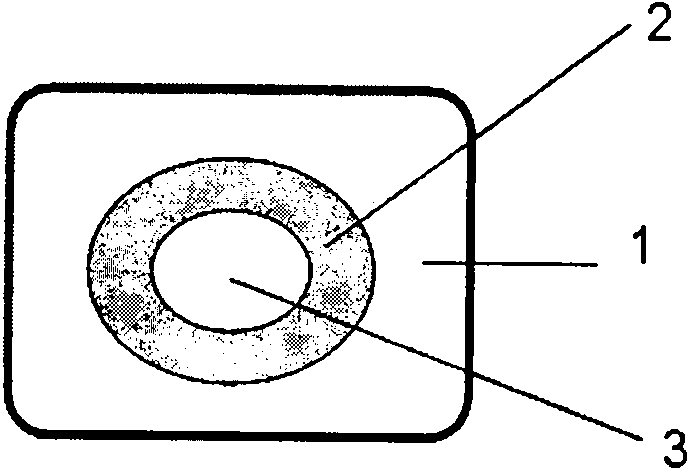

[0020] The mixture of the silver zeolite antibacterial agent with an average particle diameter of 100 nanometers and the polyvinylpyrrolidone with a weight average molecular weight of 58000 is the core component of the fiber (the weight ratio of the silver zeolite antibacterial agent and polyvinylpyrrolidone is 1: 9), and the melt index is The 28g / 10min polypropylene slices are the sheath components of the fiber, which are extruded through two screw extruders respectively, and enter the composite spinneret, and at the same time insert a controllable air duct in the core layer, and the sheath and core components are passed through the metering pump and Extruded through spinneret holes with a circular cross-section, the sheath and core composition weight percentage is 2:1, after air cooling, the antibacterial fiber primary fiber is formed, and then the finished fiber is formed by two-stage heat stretching.

[0021] During the fiber preparation process, the temperature of the shea...

Embodiment 2

[0033] The core component is a mixture of silver silicate powder with an average particle size of 3 microns and polyoxyethylene with a weight average molecular weight of 320,000 (the weight ratio of silver silicate to polyoxyethylene is 1:99), and polycaprolactam (intrinsic viscosity 0.65) is the skin component of the fiber, which is injected into two screw extruders and extruded, and enters the composite spinneret. out, air-cooled to form antibacterial fiber primary fibers, and then through conventional processes such as bundling, primary drafting, secondary drafting, crimping, drying, shaping, and cutting, it is made into short fibers with a length of 36mm.

[0034] The temperature of the screw extruder is 260°C, the air flow rate is 25ml / min, the winding speed is 1200m / min, the number of spinneret holes with a triangular cross-section is 72 holes, the weight ratio of the sheath and the core is 8:1, and the fiber is drawn and fed Speed 15m / min, water bath temperature 75°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com