Anti-bacterial polypropylene plastic and preparation method thereof

An antibacterial polypropylene and plastic technology, applied in the field of antibacterial polypropylene plastic and its preparation, can solve problems such as poor water resistance of antibacterial plastics, and achieve the effects of good antibacterial and antifungal effect, simple and easy preparation method, and strong water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

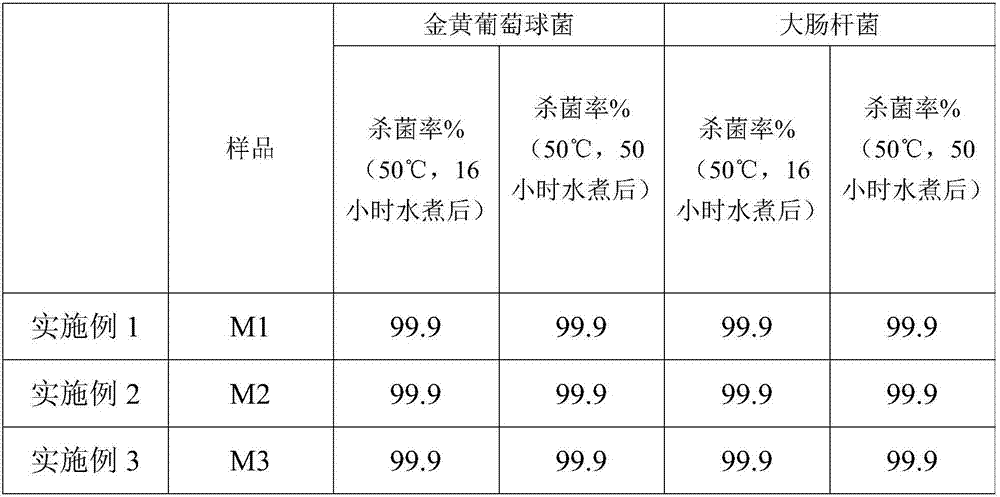

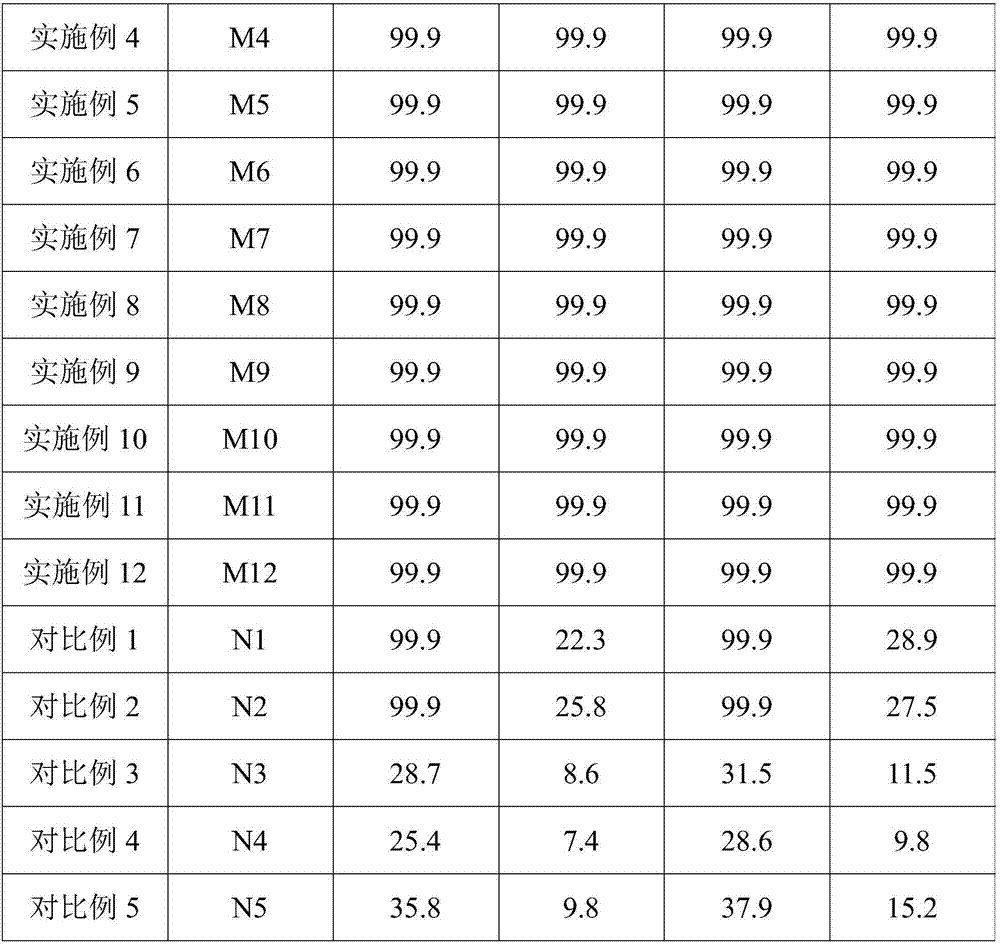

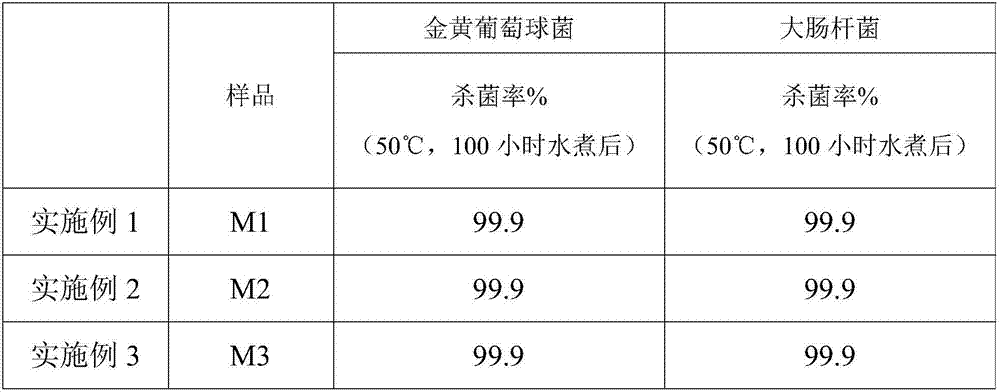

Examples

preparation Embodiment 1

[0044] Sodium pyrithione (Hangzhou Wanjing, NPT) 77.6g (0.52mol) was joined in 530g acetone aqueous solution (acetone 20% by weight, water 80% by weight), then added polyhexamethylene guanidine propionate (Shanghai Gao Poly, F3000) 21.0g (0.098mol), polyhexamethylene biguanide hydrochloride (Shanghai Shan's Industrial Co., Ltd., PHMB) 32g (0.146mol) carry out the first mixed contact, and the temperature of contact is 30 ℃, and the time is 10 minutes; then carry out the second mixing contact, the contact temperature is 5°C, and the contact time is 30 minutes; then the solid obtained after the contact is dried and pulverized to obtain the antibacterial agent A1.

preparation Embodiment 2

[0046] Sodium pyrithione (Hangzhou Wanjing, NPT) 64.2g (0.43mol) is joined in 540g acetone aqueous solution (acetone 25% by weight, water 75% by weight), then adds polyhexamethylene guanidine propionate (Shanghai Gao Poly, F3000) 11.1g (0.052mol), polyhexamethylene biguanide hydrochloride (Shanghai Mountain's Industrial Co., Ltd., PHMB) 32g (0.146mol) carry out the first mixed contact, the temperature of contact is 20 ℃, the time is 15 minutes; then carry out the second mixing contact, the contact temperature is 10°C, and the contact time is 40 minutes; then the solid obtained after the contact is dried and pulverized to obtain the antibacterial agent A2.

preparation Embodiment 3

[0048] Sodium pyrithione (Hangzhou Wanjing, NPT) 64.2g (0.43mol) was joined in 670g acetone aqueous solution (acetone 30% by weight, water 70% by weight), then added polyhexamethylene guanidine propionate (Shanghai Gao Poly, F3000) 15.6g (0.073mol), polyhexamethylene biguanide hydrochloride (Shanghai Shan's Industrial Co., Ltd., PHMB) 32g (0.146mol) carry out the first mixed contact, and the temperature of contact is 40 ℃, and the time is 5 minutes; then carry out the second mixing contact, the contact temperature is 0° C., and the contact time is 60 minutes; then the solid obtained after the contact is dried and pulverized to obtain the antibacterial agent A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com