High-strength ultraviolet-proof antibacterial type textile fabric

A technology for anti-ultraviolet and textile fabrics, applied in the field of textile fabrics, can solve the problems of reducing the comfort of wearing clothes, unsatisfactory fabric effects, and no improvement, and achieves the effects of convenient preparation, good air permeability and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

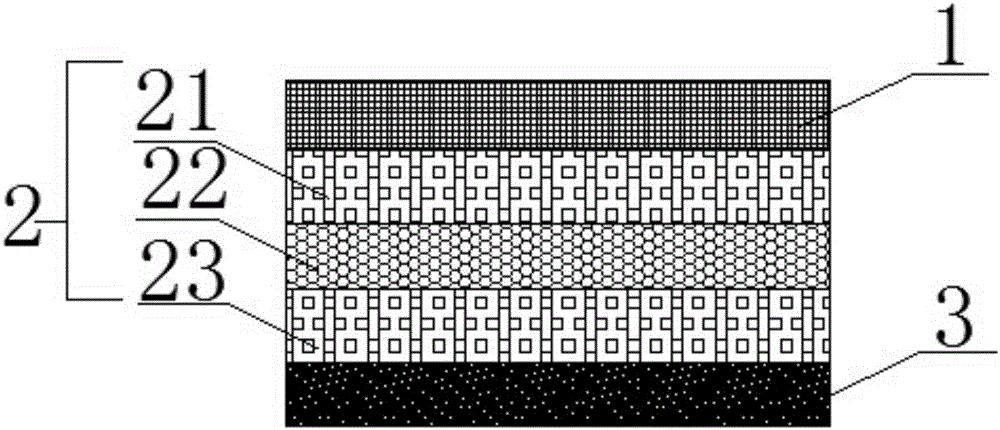

[0033] A high-strength anti-ultraviolet and antibacterial textile fabric, including a surface layer, a middle layer and an inner layer, the surface layer is made of an anti-ultraviolet fabric, and the middle layer includes a first fabric layer, a second fabric layer and a third fabric layer, Both the first fabric layer and the third fabric layer are made of 60wt% bamboo carbon fiber, 20wt% Shengma fiber and 20wt% tencel blended fabric, and the second fabric layer is woven from 100wt% bamboo carbon fiber. The inner layer is made of 30wt% bamboo charcoal fiber, 20wt% heating fiber and 50wt% cotton blended fabric.

[0034] In this embodiment, the heating fiber is composed of Lunes fiber and acrylic fiber, and the weight ratio of Lunes fiber and acrylic fiber is 2:3.

[0035] A preparation process for high-strength anti-ultraviolet and antibacterial textile fabrics, comprising the following steps:

[0036] (1) Surface manufacturing

[0037] The surface layer is made of anti-ultr...

Embodiment 2

[0048] A high-strength anti-ultraviolet and antibacterial textile fabric, including a surface layer, a middle layer and an inner layer, the surface layer is made of an anti-ultraviolet fabric, and the middle layer includes a first fabric layer, a second fabric layer and a third fabric layer, Both the first fabric layer and the third fabric layer are made of 50wt% bamboo carbon fiber, 25wt% Shengma fiber and 25wt% tencel blended fabric, and the second fabric layer is woven from 100wt% bamboo carbon fiber. The inner layer is made of 35wt% bamboo charcoal fiber, 25wt% heating fiber and 40wt% cotton blended fabric.

[0049] In this embodiment, the heating fiber is composed of Lunes fiber and acrylic fiber, and the weight ratio of Lunes fiber and acrylic fiber is 2:3.

[0050] A preparation process for high-strength anti-ultraviolet and antibacterial textile fabrics, comprising the following steps:

[0051] (1) Surface manufacturing

[0052] The surface layer is made of anti-ultr...

Embodiment 3

[0063] A high-strength anti-ultraviolet and antibacterial textile fabric, including a surface layer, a middle layer and an inner layer, the surface layer is made of an anti-ultraviolet fabric, and the middle layer includes a first fabric layer, a second fabric layer and a third fabric layer, Both the first fabric layer and the third fabric layer are made of 40wt% bamboo carbon fiber, 30wt% Shengma fiber and 30wt% tencel blended fabric, and the second fabric layer is woven from 100wt% bamboo carbon fiber. The inner layer is made of 30wt% bamboo charcoal fiber, 25wt% heating fiber and 45wt% cotton blended fabric.

[0064] In this embodiment, the heating fiber is composed of Lunes fiber and acrylic fiber, and the weight ratio of Lunes fiber and acrylic fiber is 2:3.

[0065] A preparation process for high-strength anti-ultraviolet and antibacterial textile fabrics, comprising the following steps:

[0066] (1) Surface manufacturing

[0067] The surface layer is made of anti-ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com