Patents

Literature

1099results about How to "Good skin affinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing colored fabric containing polylactic acid fiber and silk components

InactiveCN102102268AAvoiding paradoxes of decompositionLow costWeft knittingPolymer sciencePolylactic acid

The invention discloses a method for preparing a colored fabric containing polylactic acid fiber and silk components, which comprises the following steps of: dyeing polylactic acid fibers and silk fibers respectively, and weaving into the colored fabric. By the method, the respective advantages of the polylactic acid fibers and silk are fully exerted, high skin affinity is achieved, the cost of areal silk fabric can be reduced, and the prepared fabric has a wide market prospect.

Owner:HENAN LONGDU BIOLOGY TECH

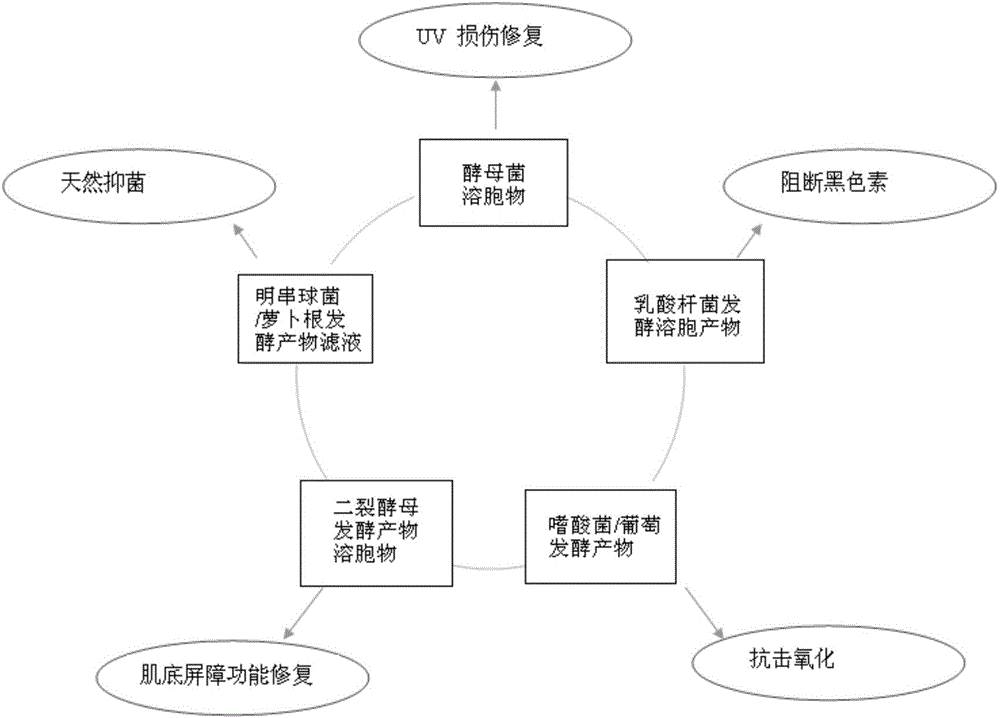

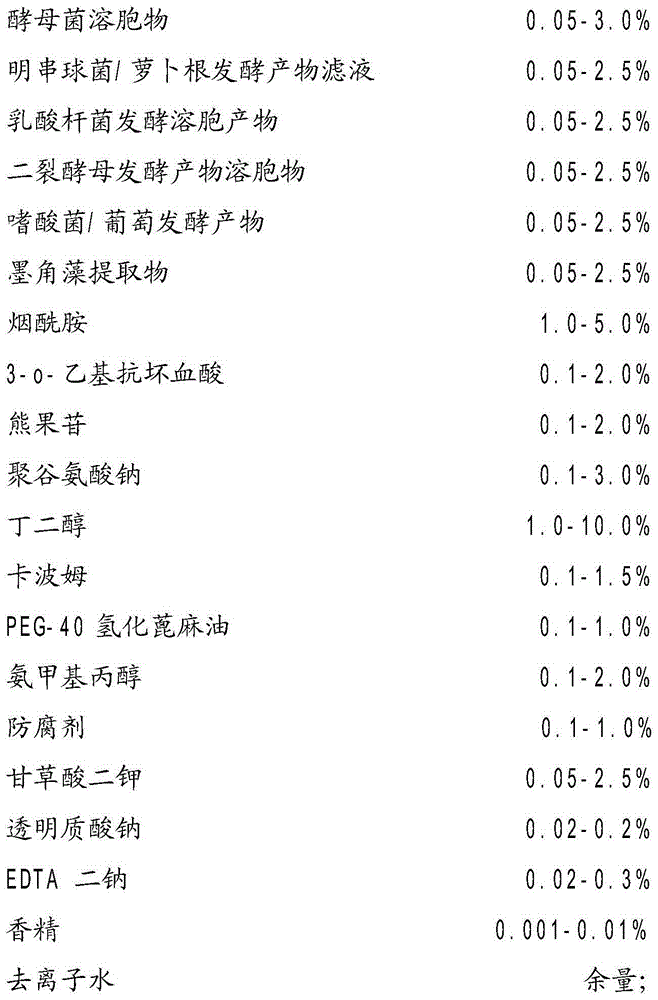

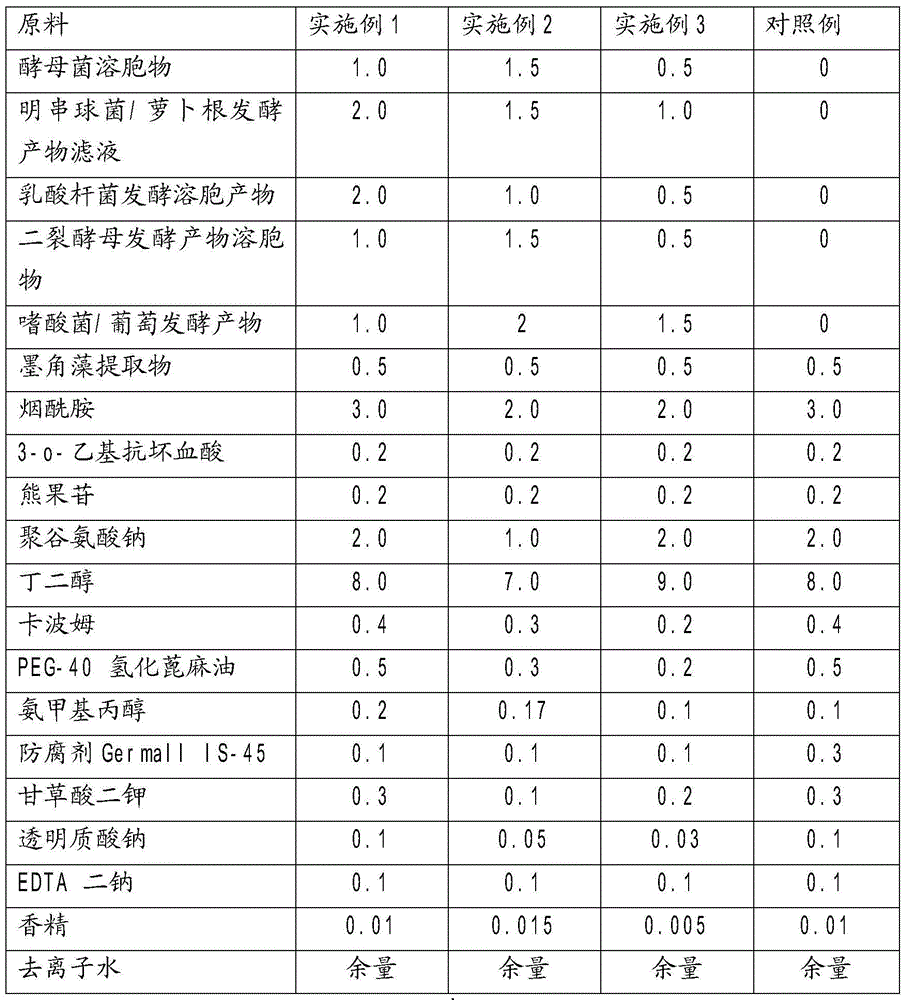

Probiotic whitening recovery mask essence and preparation method thereof

InactiveCN104586737AGood skin affinityFine and smooth textureCosmetic preparationsToilet preparationsAdditive ingredientBULK ACTIVE INGREDIENT

The invention discloses probiotic whitening recovery mask essence which comprises five natural probiotic active ingredients, namely saccharomyces lysate, leuconostoc / radish root fermented product filtrate, lactobacillus fermentation lysate, bifida ferment product lysate and acidophil / grape fermentation product respectively. The essence is high in skin-friendly property and fast in permeation, and the skin is safely and effectively whitened for a long time. The invention also discloses a method for preparing the probiotic whitening recovery mask essence.

Owner:上海圣婕化妆品有限公司

Method for producing modified cation polyester filament and product thereof

ActiveCN102094256ABionic features are obviousLow boiling water shrinkageMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterPolymer science

The invention belongs to the field of manufacture of chemical fibers, in particular to a method for producing a modified cation polyester filament imitating a cellulose fiber. The method comprises the following steps of: preparing modified cation polyester; carrying out melting spinning by aiming at the characteristics of the modified cation polyester to obtain an orientated filament; and carrying out false twisting on the orientated filament under the condition of a special elasticizing process. The invention also provides a modified cation polyester filament prepared with the production method. The cation polyester filament disclosed by the invention has favorable fuzzing and pilling resistance, can be dyed at normal pressure without high-temperature and high-pressure conditions, saves the dyeing cost and has bright color after being dyed and high skin intimacy, and the hygroscopicity is better than that of common cation terylene filament.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Heating fiber underwear face fabric and processing technique thereof

InactiveCN101235573AGood flexibilityGood skin affinityWeft knittingDry-cleaning apparatus for textilesYarnCellulose fiber

The invention relates to a heating fiber underwear fabric, which is characterized in that the heating fiber underwear fabric is composed of raw materials with following weight percent: heating fiber 3-25%, anti-pilling acrylic fiber 30-52%, lenzing cellulose fiber 35-40%, polyamide fiber 4-6% and lycra elastic fiber 0.5-0.15%. A processing technique of the heating fiber underwear fabric comprises: firstly, spinning the heating fiber, the anti-pilling acrylic fiber and the lenzing cellulose fiber into sirospun union yarn, then, coating the lycra elastic fiber with the polyamide fiber, weaving and forming knitted underwear fabric, dying, soaping with nonionic soft finishing agent, vertically drying, shaping, and forming finished products of the heating fiber underwear fabric. The heating fiber underwear fabric of the invention has the advantages that the heating fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also has good warmth retention effect.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV +1

Preparation process for fine denier and superfine denier polypropylene fibers

InactiveCN101736416AReduce consumptionSave dyeing energyMonocomponent polypropylene artificial filamentMelt spinning methodsPolymer scienceAbnormal shaped

The invention mainly discloses a preparation process for fine denier and superfine denier polypropylene fibers, which comprises the following steps of: adopting a spinning special material of which the melting point is between 165 and 175 DEG C; in a spinning device, extruding and melting the spinning special material by a single screw extruder, wherein a melt flows evenly; performing spinning through a round or abnormal spinneret orifice of a spinneret plate of a spinning box, wherein the spinning speed is 2,200 miters per minute; cooling and oiling tows; and then performing hot drawing and winding to finally obtain the fine denier and superfine denier polypropylene fibers of 0.5 to 2 deniers, wherein the hot drawing temperature is between 45 and 105 DEG C, the drawing multiple is 1.5 to 4 times, and the winding speed is 80 meters per minute for overfeeding. The preparation process is a nuisanceless, environment-friendly, energy-saving and innovative process, and the finally obtained product has the advantages of light in texture, high strength, good abrasion resistance and elastic resilience, small static electricity, small coefficient of heat conductivity and good electrical insulating property.

Owner:绍兴前瞻化纤有限公司

Multi-moisturizing double-layer makeup remover and preparation method thereof

InactiveCN106333898AStrong makeup removerIncrease elasticityCosmetic preparationsMake-upAnti-Allergic AgentsAlcohol

The invention provides a multi-moisturizing double-layer makeup remover. The multi-moisturizing double-layer makeup remover is characterized by being prepared from, by weight, 20%-35% of grease, 1%-15% of alcohol moisturizer, 0.25%-2.5% of sugar moisturizer, 0.01%-0.25% of macromolecular moisturizer, 5%-20% of surfactant, 0.25%-2.5% of natural moisturizing factors (NMF), 0.1%-0.6% of preservative, 0.1%-0.4% of anti-allergic agent and the balance deionized water. The double-layer makeup remover greatly integrates cleansing oil and cleansing water and adopts an oil-water separation structure, the bottom layer is water, and the upper layer is oil. Before the makeup remover is used, the makeup remover is needed to be shaken to be uniform, the water-oil proportion is adjusted to reach the state that the makeup remover is non-irritant to the skin, the advantage of string makeup removing capability of the cleansing oil is played, and a mild and non-irritant effect is also achieved. In addition, the composite moisturizing system formed by four different types of moisturizing components serves as a whole, the defect that single moisturizing components are not comprehensive and not remarkable in effect is greatly overcome. Furthermore, the invention further provides a preparation method of the multi-moisturizing double-layer makeup remover.

Owner:CANTON DAMEKISS DAILY CHEM FACTORY LIMITED

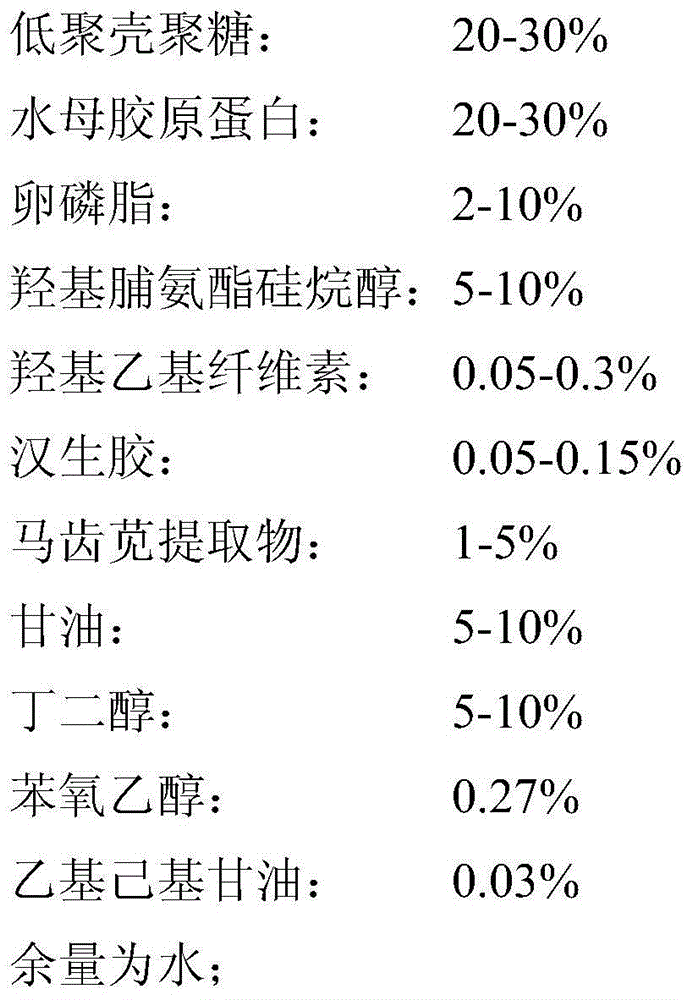

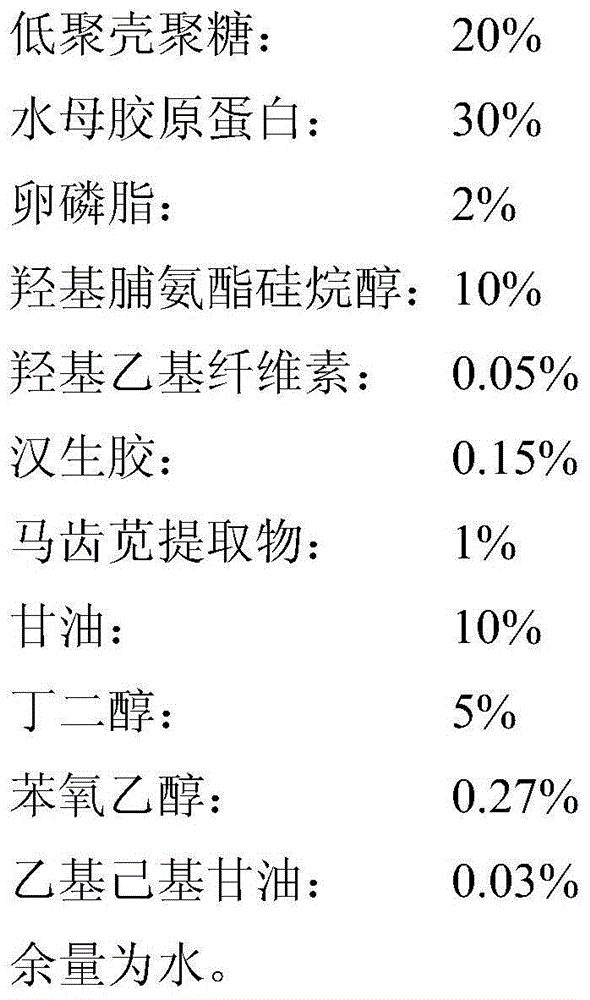

Essence containing chitosan oligosaccharide and jellyfish collagen and facial mask manufactured from essence

ActiveCN104546532ALow densityHigh affinityCosmetic preparationsToilet preparationsCelluloseHydroxyethyl ethylcellulose

The invention discloses essence containing chitosan oligosaccharide and jellyfish collagen and a facial mask manufactured from the essence. The essence is prepared by mixing the following components: chitosan oligosaccharide, jellyfish collagen, lecithin, hydroxyl prolinol ester silanol, hydroxyethyl ethylcellulose, xanthan gum, a portulaca oleracea extract, glycerol, butanediol, phenoxyethanol, ethylhexylglycerin and water. The facial mask can be manufactured by soaking a carrier facial mask, that is, a biological cellulose facial mask containing chitin, into the essence till being completed wetted. The essence of the facial mask contains chitosan oligosaccharide and jellyfish collagen, and has a good synergistic effect with the carrier facial mask (the biological cellulose facial mask containing chitin). Compared with an ordinary cellulose facial mask (such as cellulose obtained from wood pulp and cellulose obtained from coconuts), the biological cellulose facial mask containing chitin is relatively low in density, relatively large in pore surface, high in aperture, relatively strong in absorption property and capable of conducting more active matters.

Owner:广州丽丰化妆品制造有限公司

Bamboo carbon fiber underwear fabric and manufacture method thereof

InactiveCN101532204AFully reflect the decomposition of odorFully reflect the functionWeft knittingYarnFiberTextile technology

The invention relates to a bamboo carbon fiber underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The bamboo carbon fiber underwear fabric consists of a lining layer and an external layer, and is characterized in that the lining layer consists of bamboo carbon fibers and cotton fibers according to the weight ratio of 15-30:70-85; the external layer consists of cotton fibers, Newdal fibers and polyurethane elastic fibers according to the weight ratio of 43-54:40-54:3-6. The manufacture method comprises that: the bamboo carbon fibers and the cotton fibers, the cotton fibers and the Newdal fibers are respectively spun into Sirospun blended yarns; the Sirospun blended yarns are interwoven with polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric forms a final finished product, namely the bamboo carbon fiber underwear fabric through dyeing, drying, sanding and shaping treatment. The fabric and the manufacture method have the advantages that the bamboo carbon fiber underwear fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, and has functions of good odor decomposition, smell elimination and the like.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

Fabric used for making warm underclothes

InactiveCN101002633AExcellent Texture and HygroscopicitySoft-touch texture and hygroscopicityHeating/cooling textile fabricsCircular knitting machinesPolyesterYarn

A fabric for heat-insulating underwear is composed of the surface structure made of polyester fibers and substrate made of polyurethane cored cotton yarn. Its productive method includes such steps as weaving by dual-surface loom, pre-treating, and dyeing, finishing, post-treating, scotching, pre-fixating shape, napping, combining, shearing, ironing, swinging, and fixating shape.

Owner:常熟市东方染整有限公司

Coffee cashmere fabric and manufacturing method thereof

The invention discloses a coffee cashmere fabric and a manufacturing method of the coffee cashmere fabric, and aims to provide the warming, comfortable, light and thin coffee cashmere fabric and the manufacturing method thereof. The technical key points of the fabric are that: the fabric consists of the following raw materials in percentage by weight: 13.3 percent of carbon fiber, 29.1 percent of terylene, 19.8 percent of lenzing viscose fiber, 3 percent of spandex and 34.8 percent of normal viscose fiber; and the manufacturing method comprises the following steps of: feeding pure viscose yarn in a first path, terylene in a second path and coffee carbon fiber and lenzing viscose fiber blended yarn in a third path; sequentially and circularly arranging weft yarns; forming two loops by using different thread lengths to form approximate loops on one side of a texture; forming an air retaining layer; and finally dyeing and tidying. The fabric and the method belong to the technical field of textile.

Owner:上海缀菱纺织品有限公司

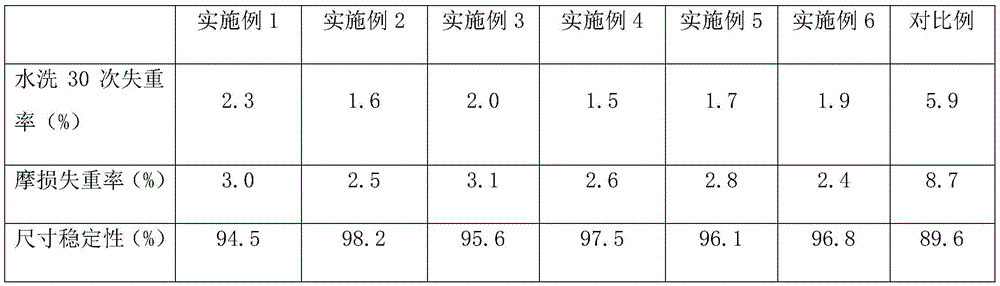

Fabric post-finishing agent based on modified silk fibroin solution and preparation method of fabric post-finishing agent

ActiveCN105544210ASkin-friendlyHigh affinityBiochemical fibre treatmentGrip property fibresDissolutionSolvent

The invention provides a fabric post-finishing agent based on a modified silk fibroin solution and a preparation method of the fabric post-finishing agent. The preparation method comprises the following specific operational steps: (1) removing impurities from waste silk, putting the impurity-free waste silk in a sodium bicarbonate solution for boiling and degumming, taking out and wringing out the degummed waste silk, washing with clean water till the greasy feel is eliminated, putting the primarily treated waste silk in the sodium bicarbonate solution again for boiling and degumming, taking out and wringing out the degummed waste silk again, washing again with clean water till the greasy feel is eliminated, putting the secondarily treated waste silk in an oven for drying, so as to obtain degummed silk; (2) putting the degummed silk in a lithium bromide solution for standing and dissolution, taking out the treated silk, and performing cooling, dialysis and concentration to obtain a silk fibroin solution; and (3) adding glycerin and gelatin into the silk fibroin solution, uniformly stirring to form a membrane solution, adjusting the pH value of the membrane solution and then adding glutaraldehyde and chitosan, uniformly stirring, and finally mixing the treated membrane solution with a solvent containing additives, so as to obtain the fabric post-finishing agent. The fabric post-finishing agent obtained according to the preparation method covers the fabric surface in the form of a composite membrane; and the preparation method is beneficial to improvements in the membrane forming property, the ductility and the like of a silk fibroin finishing agent.

Owner:SUZHOU INSILK CO LTD

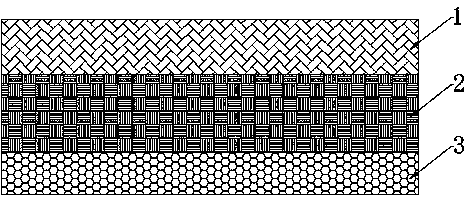

Multifunctional fiber fabric

InactiveCN104260513AGood skin affinityGood sweat absorptionSynthetic resin layered productsWoven fabricsSurface layerEngineering

The invention discloses a multifunctional fiber fabric which comprises a surface layer, an intermediate layer and an inner layer, wherein the surface layer is a sunscreen scratch-resistant layer and is formed by weaving warp yarns and weft yarns; the warp yarns are polyacrylonitrile fibers; the weft yarns are polyamide fibers; the intermediate layer is a moisture-absorbing breathable layer and is formed by weaving blended yarns of ramie fibers and polyester fibers; and the inner layer is a skin-touch bacteriostatic layer and is formed by weaving blended yarns of wild silk yarn, bamboo fibers and colored cotton fibers. The multifunctional fiber fabric disclosed by the invention is designed by adopting the structures of the inner layer, the intermediate layer and the outer layer according to the actual clothing needs and fiber characteristics and has the performances such as wear resistance, skin touch, sweat absorption, sterilization and bacteria inhibition, a human body can be kept dry, comfortable, clean and healthy, the absorbed sweat is discharged through the ramie fibers in the intermediate layer, and the fabric is kept in a dry and comfortable state under the actions of the polyester fibers. The multifunctional fiber fabric disclosed by the invention integrates multiple functions such as high practicality, high serviceability and health care into a whole and is high in practical value.

Owner:CHANGSHU LEDEWE WEAVING

Preparation method of ecological non-iron cotton high-grade fabric

InactiveCN101982601AGood skin affinityIn line with the concept of consumptionVegetal fibresCitric acidFibroin

The invention discloses a preparation method of an ecological non-iron cotton high-grade fabric. The method comprises the steps of preparation of fibroin / chitosan / citric acid anti-crease shrink-proof finishing agent, finishing and the like. In the invention, since waste silk, chitosan and citric acid, which are natural green healthy products, are utilized as raw materials, the ecological non-iron cotton high-grade fabric prepared by using the finishing agent conforms to the direction that the function classification of the textiles in the 21th century is required to be finished and processed on the premise of comfort, cleanness and safety. Since the fibroin finishing agent contains substantive fibroin proteins, the ecological non-iron cotton high-grade fabric has favorable skin affinity, and caters for the consumption concepts of environmental friendliness, health and fashion of people.

Owner:南通曙光染织有限公司

Production method for antistatic Raschel blanket

The invention relates to the field of blanket preparation, and discloses a production method for an antistatic Raschel blanket. The production method comprises the following steps: 1) weaving: carrying out warping, weaving and fine hair cutting on plush yarns and ground yarns sequentially, thereby preparing an antistatic Raschel blanket semi-finished product; 2) carrying out pre-finishing: setting, brushing, lustring and rolling fabric; 3) dyeing and finishing: dyeing the fabric, reducing and cleaning the fabric, neutralizing the fabric with an acetic acid solution, washing the fabric and discharging the fabric out of a cylinder, drying the fabric, ageing the fabric for fixation, carrying out soft and smooth treatment, and re-drying the fabric; 4) carrying out after treatment: drying and setting the fabric, lustring, brushing, ironing and shearing the front surface of the fabric, napping, brushing, lustring, shearing and re-setting the back surface of the fabric, ironing and shearing the front surface of the fabric, ironing and shearing the back surface of the fabric, slitting and stitching the fabric; 5) carrying out finished product inspection, packaging and warehousing. The antistatic Raschel blanket disclosed by the invention has the characteristics of being flexible and straight in naps, good in elasticity, excellent in fabric skin-friendliness, moisture absorption and desorption and gas permeability, and anti-static.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

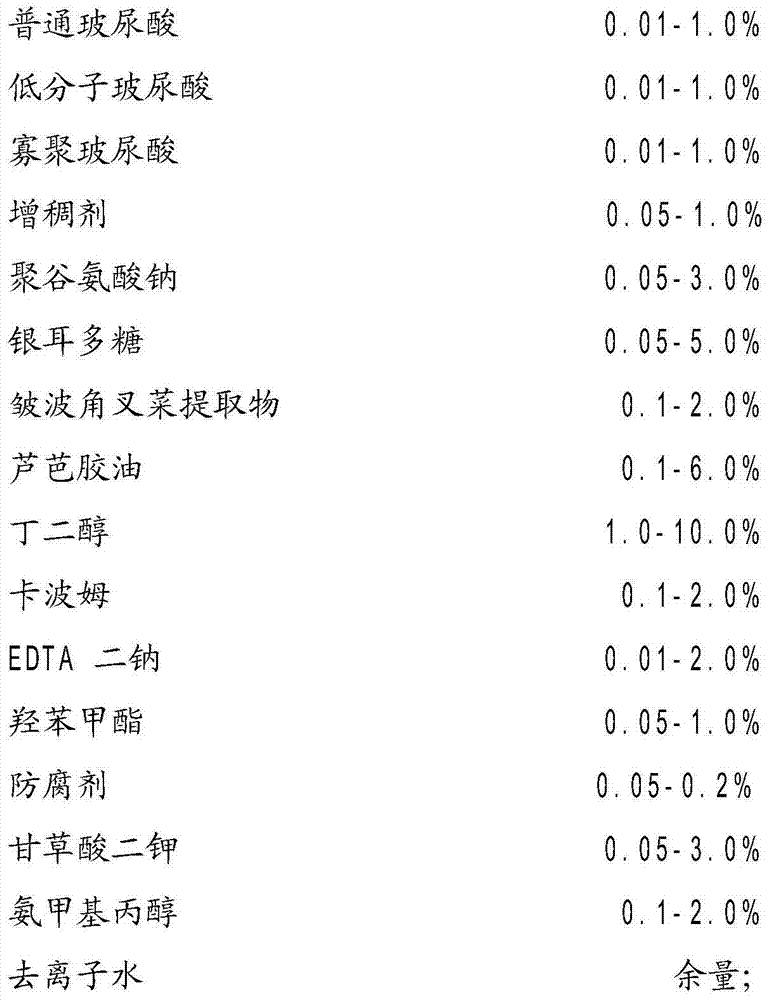

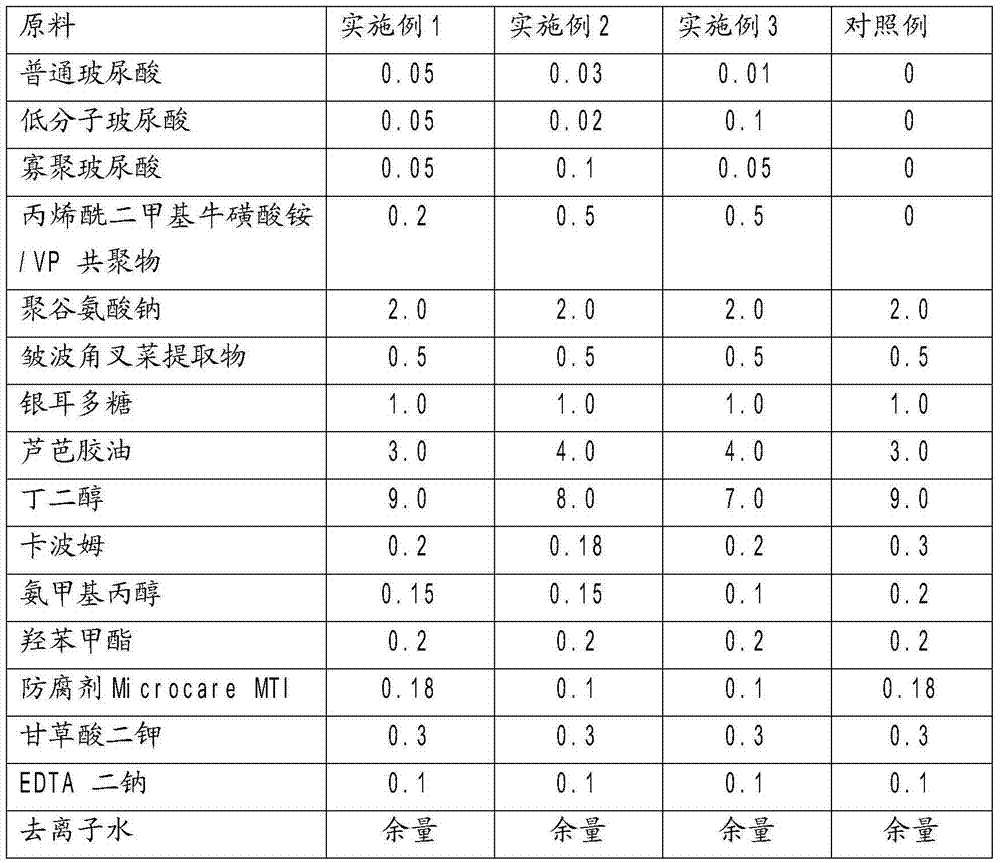

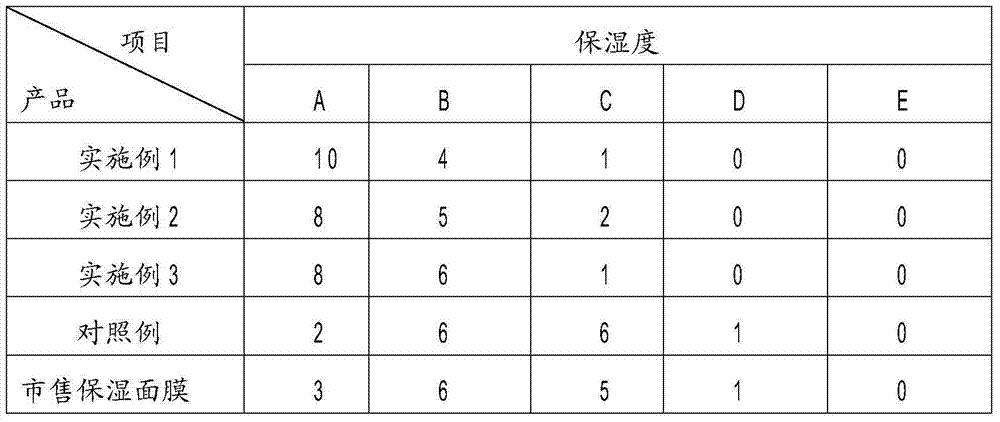

Hyaluronic acid hydrating mask essence and preparation method thereof

InactiveCN104490717APrevent intrusionIntrusion fromCosmetic preparationsToilet preparationsHyaluronic acidChemistry

The invention discloses a hyaluronic acid hydrating mask essence. Hyaluronic acid of three molecular weights is added, namely ordinary hyaluronic acid with a molecular weight being greater than or equal to 1000kDa, low-molecular-weight hyaluronic acid with a molecular weight being between 10kDa-1000kDa and oligomerization hyaluronic acid with a molecular weight being smaller than 10kDa. The hyaluronic acid of three molecular weights is respectively used for moisturizing dry skin instantly, quickly permeating the skin, deeply nourishing the skin, locking water for a long time and stereoscopically moisturizing. The invention also discloses a preparation method of the hyaluronic acid hydrating mask essence.

Owner:上海圣婕化妆品有限公司

Production process for flame retardant polyester staple fibre

InactiveCN102517684ALow costPromote environmental protectionFlame-proof filament manufactureFilament forming substance formingPolyethylene terephthalate glycolDrum drying

The invention discloses a production process for a flame retardant polyester staple fibre. In the production process, regenerative PET (Polyethylene Terephthalate) material is used as the raw material, and the finished product is acquired by pre-treating, rotary drum drying, melt spinning, cooling and forming, winding, drafting, curling, oil applying, thermosetting and cutting-off in sequence, wherein the rotary drum drying comprises the steps of firstly drying the regenerative PET material for 7.5h-8.5h and then adding flame retardant chips with the final mass fraction of 6%-8%; the flame retardant chips are halogen-free flame retardant copolyester chips, and the total drying time is 9.5h-10.5h; both the screw rod and the spinning beam of a screw extruder in the melting spinning step areat the temperature from 268 DEG C to 278 DEG C; spinneret plates are provided with 3500 bores having the diameter of 0.2mm and are arranged in 14 circles; cooling forming is realized through circularair blow; the total draft multiple is 2.7-2.9 times; and the thermosetting temperature is 168 DEG C to 172 DEG C, and the thermosetting time is 13 minutes to 17 minutes. The production process can save the cost and is helpful for environmental protection; the produced product has a smaller linear density, a higher limited oxygen index and good flame retardant effects.

Owner:HANGZHOU BEST CHEM FIBER

Composition of yeast fermentation extract and application of composition in cosmetics

InactiveCN108096081AHigh activityIncrease elasticityCosmetic preparationsToilet preparationsSaccharomycesWrinkle

The invention discloses a composition of yeast fermentation extract. The composition is prepared from 75-95% of bifid yeast fermentation product lysate and the balance of multi-yeast complex, whereinthe multi-yeast complex is prepared from lactobacillus fermentation product filtrate and saccharomycete fermentation product filtrate. The invention also discloses application of the composition of the yeast fermentation extract in cosmetics. By combining the effects of anti-ultraviolet damage, purification, regeneration, oxidation resistance and wrinkle prevention of the bifid yeast fermentationproduct lysate and the multi-yeast complex as well as the synergistic effect of the multiple yeast for caring skin, the composition disclosed by the invention realizes multiple care effects on skin and realizes safe and durable effective care.

Owner:上海晶妆生物科技有限公司

Method of staining copper ammonia fiber and tencel interwoven cloth

ActiveCN101016683AFeel goodIncrease elasticityLiquid/gas/vapor open-width material treatmentDyeing processCuprammonium rayonCellulose

The invention relates to a dying method of copper ammonia fiber and silk interwoven cloth, comprising that (1) washing with water, (2) refining, (3) washing with cellulose, (4) dying. And the fur burning process is purpose to remove silk fiber exposed outside the interwoven cloth and the short flannel, eyebrow and foreign material adhered on the face of cloth. The water washing process is purposed to clean the dirt on the face of interwoven cloth. The refining process is purposed to remove the slurry, grease of wrap and the dirt on the face of cloth. The cellulose washing process is purposed to remove the hair generated by fibrosis, to avoid balling. The inventive product has the appearance of silk brocade cloth and improves bacteria resistance function.

Owner:WUJIANG DEYI FASHIONS CLOTHS

Polyester/cotton blended flame-retardant core spun yarn and production method thereof

InactiveCN104674408AStrong and goodGood moisture absorption and releasePhysical treatmentYarnPolyesterYarn

The invention relates to a polyester / cotton blended flame-retardant core spun yarn and a production method thereof. The yarn is produced by blending 40 to 60 weight percent of polyester and 40 to 60 weight percent of cotton fibers. A process comprises the following steps: performing opening picking and carding on polyester to obtain polyester card slivers, performing blowing-carding, pre-drawing and combing on cotton to obtain cotton drawn slivers, performing drawing, roving and spinning on the polyester card slivers and the cotton drawn slivers to obtain polyester / cotton core yarns, and performing plasma pretreatment and yarn flame-retardant finishing to obtain flame-retardant polyester / cotton core yarns; blending polyester fibers and cotton fibers by a blowing-carding procedure, and performing pre-drawing, combing, drawing and roving to obtain polyester / cotton covering thick yarns; performing spinning on the obtained flame-retardant polyester / cotton core yarns and the obtained polyester / cotton covering thick yarns to obtain polyester / cotton blended core spun yarns in a core spinning manner, and performing plasma pretreatment and yarn flame-retardant finishing to obtain polyester / cotton blended flame-retardant core spun yarns. According to the polyester / cotton blended flame-retardant core spun yarn and the production method thereof, polyester and cotton are blended in the core spinning manner, and the core yarns and spun yarns are subjected to flame-retardant treatment, so that the spun yarns have high flame retardance.

Owner:JINFA LABI MATERNITY & BABY ARTICLES

Method for preparing cashmere fabric

The invention discloses a method for preparing a cashmere fabric, comprising the following steps of: with basolan undercoat, cashmere, coffee carbon fiber and soft loose fiber as raw materials, blending, and carrying out semi-worsted spinning to obtain high count semi-worsted yarns which are taken as wraps, wherein wefts are mercerized cotton yarns; spinning the wraps and the wefts under the conditions that 2 / 2 texture is adopted and total tightness is 95-100, so as to obtain a grey fabric; and carrying out the following processes on the grey fabric: sizing, single boiling, double boiling, scouring, milling, double boiling, drying, middle inspection, finishing, brushing, softening and smoothening, napping, shearing, decating and natural lustre finishing, thus obtaining the finished product. According to the technical scheme provided by the invention, after finishing combines the advantages of fine spinning and roving processes, the obtained product has mild nature, soft feel and silkylustre and also has antibacterial, deodorizing and heat insulating effects, and the cashmere fabric reaches the requirement on relaxation size of 1*7A and can be washed by a machine.

Owner:ZHANGJIAGANG HUALU WOOL SPINING

Compound essential oil for improving skin properties

InactiveCN102397182AStrong natural rose fragranceStrong fragranceCosmetic preparationsToilet preparationsTraditional medicineSecretion

The invention discloses compound essential oil for improving skin properties and aims to better satisfy people's appeal to natural skin care in the aspect of skin care. The compound essential oil provided in the invention comprises, by weight percentage, 32 to 45% of rose essential oil, 5 to 10% of lavender essential oil, 3 to 8% of Yilan essential oil, 20 to 30% of teaplant essential oil, 10 to 20% of fish pelargonium essential oil, 2 to 6% of mastic essential oil and 3 to 8% of aloe essential oil. The compound essential oil can effectively solve the skin problems of a tarnished color, poor absorption capability, dryness, poor elasticity, proneness to wrinkling, too much secretion of grease, etc., and has a good effect on improving skin properties.

Owner:HANGZHOU AILISI ROSE TECH

Corn polylactic acid short-fiber spunlaced face mask material

InactiveCN101491486ASoft touchImprove breathabilityCosmetic preparationsToilet preparationsFiberMildew

The invention discloses a hydroentanglement facial mask material made of corn polylactic acid short fiber. The hydroentanglement facial mask material combines the advantages of polylactic acid fiber products and hydroentanglement nonwoven cloth, and has the advantages of soft and even hand, good air permeability, hygroscopic property, skin affinity property, favorable anti-bacterial, bacteria inhibiting and mildew proofing properties, and complete biological degradability.

Owner:JIANGNAN UNIV

Bamboo leaf flavonoid mint core-sheath compound fiber

ActiveCN104357952AHigh concentration of air ionsUnique polygonal structureConjugated cellulose/protein artificial filamentsFilament/thread formingPolyesterCalcium hydroxide

The invention relates to a fiber, and in particular relates to a bamboo leaf flavonoid mint core-sheath compound fiber. The bamboo leaf flavonoid mint core-sheath compound fiber is prepared by the following steps: treating tourmaline; treating a core layer material to form a non-woven needle-punched hemp palm fiber aerogel core layer material; treating a sheath layer material, namely, preparing first slurry from 0.1-0.3 part by weight of treated tourmaline, 0.6-0.8 part by weight ethylene glycol, 0.01-0.04 part by weight of bamboo leaf flavonoid and 0.02-0.05 part by weight of beta-cyclodextrin mint oil micro-powder, wherein the preparation method of the beta-cyclodextrin mint oil micro-powder comprises the step of mixing beta-cyclodextrin and mint oil according to the mass ratio of (8-15) to (40-65) at the temperature of 20-30 DEG C to form the beta-cyclodextrin mint oil micro-powder with morphology of a clathrate compound; carrying out an esterification reaction on phthalic acid and glycerol; after the reaction, feeding the first slurry, magnesium oxide and calcium hydroxide, and carrying out a polycondensation reaction; casting a belt and carrying out grain-sized dicing to obtain a polyester chip sheath layer material; carrying out composite melt spinning to prepare the bamboo leaf flavonoid mint core-sheath compound fiber. The bamboo leaf flavonoid mint core-sheath compound fiber has the functions of antibiosis and health protection, and is comfortable and environment-friendly.

Owner:HEYE HEALTH TECH CO LTD

Jutecell underwear fabric and manufacture method thereof

The invention discloses a Jutecell underwear fabric and a manufacture method thereof, belonging to the technical field of textiles. The Jutecell underwear fabric is characterized by comprising the following components based on part by weight: 50 to 70 parts of Jutecell, 10 to 20 parts of Modal, 10 to 20 parts of Newdal, and 5 to 10 parts of polyurethane elastic fibers. The manufacture method comprises the following steps that: the Jutecell, the Modal and the Newdal are spun into compact spinning blended yarns; the compact spinning blended yarns are interwoven with the polyurethane elastic fibers to form a knitted underwear fabric; and the knitted underwear fabric is subjected to preshaping, dyeing, drying and shaping treatment. The fabric not only has good skin-friendly property, low pilling tendency and comfortable elasticity, but also sufficiently reflects itching feel, bactericidal and antifungal activity, moisture absorption and fast dryness; and Modal has soft hand feeling, bright color, the Newdal is smooth and has good drapability, and the polyurethane elastic fiber has excellent performance of stretching and extending. The fabric adopts a unique textile structure to lead the appearance of the fabric to be more unique.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

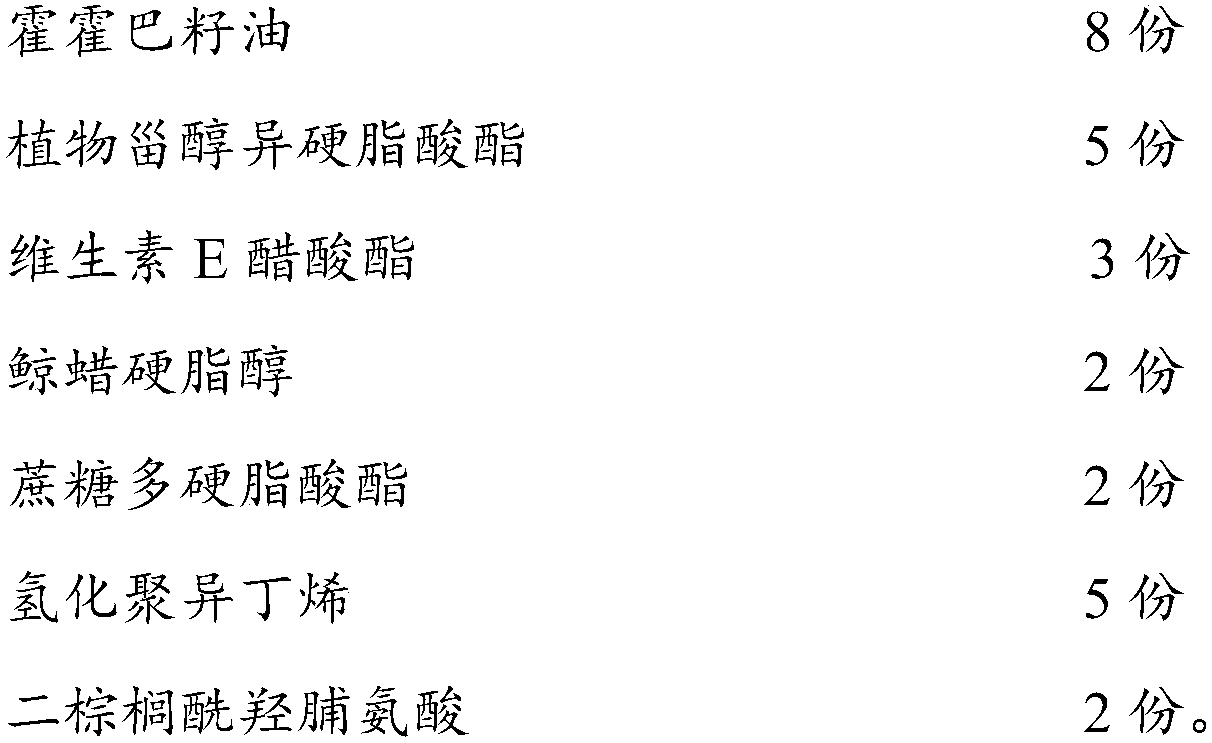

Acne removal restoring mask applying camellia oleifera seed meal and preparation method thereof

InactiveCN105902436AGood stabilityExcellent spreading performanceCosmetic preparationsToilet preparationsAdemetionineCuticle

The invention relates to an acne removal restoring mask applying camellia oleifera seed meal and a preparation method thereof. The acne removal restoring mask comprises the following components by weight percentage: a phase A: 1-5% of camellia oleifera seed oil, 0.5-4% of beta-cyclodextrin, and 2-8% of Tween 20, 0.5-1.5% of D-panthenol, and 43.5-87.58% of deionized water; a phase B: 5-20% of a camellia oleifera seed meal extracted solution, 0.02-0.2% of hyaluronic acid, 0.2-1% of allantoin, 0.5-3% of vitamin E, and 1-5% of collagen; and a phase C: 1-8% of xanthan gum, and 0.2-0.8% of essence. The mask prepared by the invention is conducive to discharge of skin epidermal toxin and elimination of free radicals, at the same time has the efficacy of enhancing skin immunity, improving skin metabolism, inhibiting acne recurrence, and strengthening skin restoration function.

Owner:CHANGSHA HAORUI BIOLOGICAL SCI & TECH

Method for preparing natural yarn-dyed fabric and application of natural yarn-dyed fabric

The invention aims to provide a natural yarn-dyed fabric and application thereof in home textile products. The pure natural yarn-dyed fabric is prepared according to a method comprising the following steps: (1) making color silk fiber and natural color cotton fiber into yarn respectively; and spinning sequentially according to the procedures of cotton grabbing, cotton blending, cotton opening, cotton feeding, coiling, cotton carding, cotton drawing, roving, spinning, and spooling; and (2) interweaving the color silk yarn and the natural color cotton yarn to obtain the natural yarn-dyed fabric, wherein the color silk yarn is 30 to 60 percent by weight, and the natural color cotton yarn is 40 to 70 percent by weight; and weaving sequentially according to the procedures of beaming, slashing, reeding, jacquard weaving, perching, plaiting, packing and warehousing. Compared with the prior art, the obtained product not only has the characteristics of softness, pendency, special tactility, elegant and dynamic feeling, air and moisture penetrability, simple but elegant luster, and the like, but also feels soft, and has the special health functions of adjusting blood circulation and metabolization of a human body, keeping skin clean, enhancing cell viability of the skin, and preventing the skin from aging and white blood cell from declining in quantity, so that the purpose of the invention is achieved.

Owner:SHANGHAI SHUIXING HOME TEXTILE

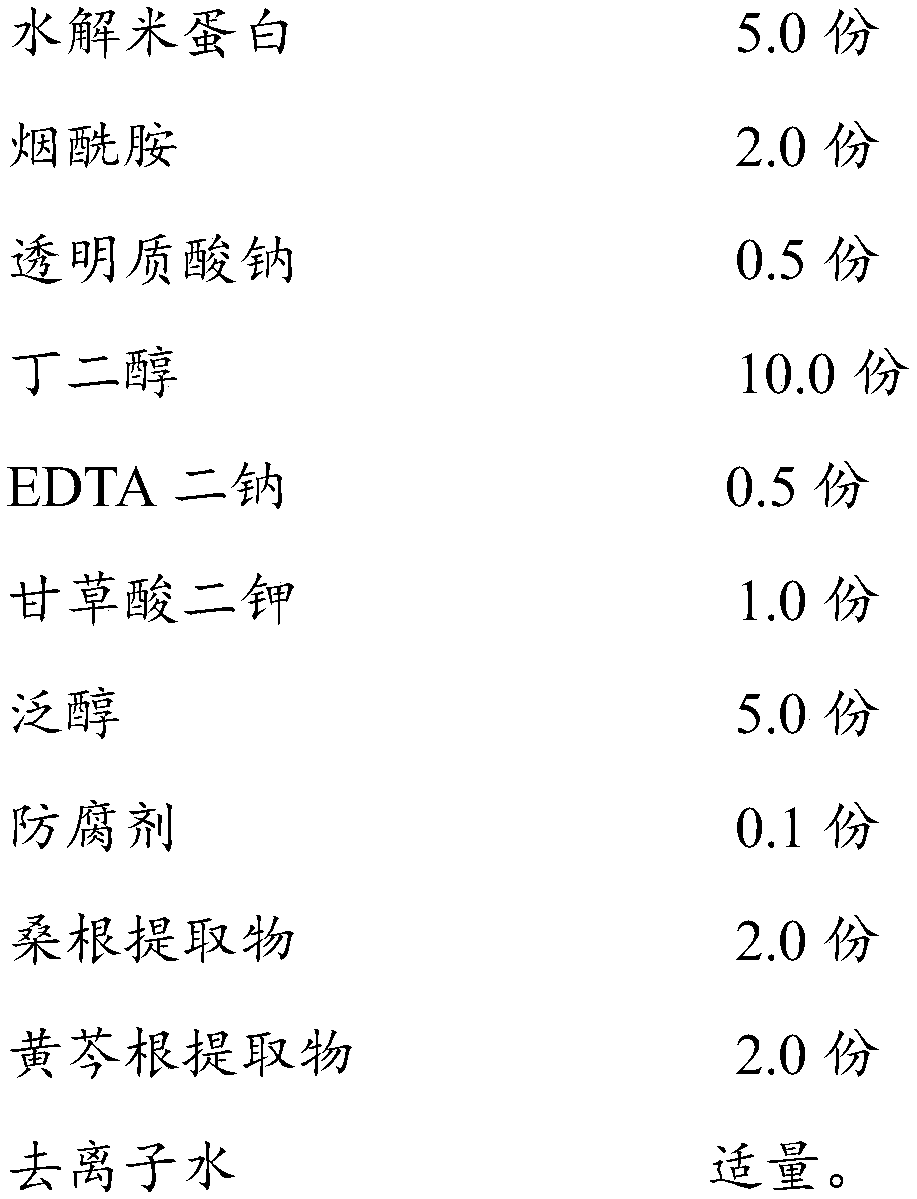

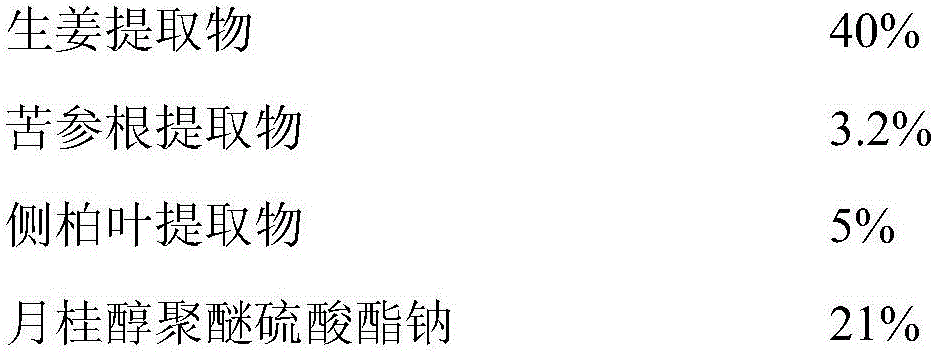

Shampoo capable of preventing hair loss

InactiveCN106214583AEffective in preventing itchingGood skin-friendly abilityCosmetic preparationsHair cosmeticsCitrate sodiumSodium hyaluronate

The invention discloses a shampoo capable of preventing hair loss. The shampoo is prepared from the following materials according to weight percentage through normal mixing: 40% of a fresh ginger extract, 3.2% of a kuh-seng root extract, 5% of a cacumen biotae extract, 21% of sodium laureth sulfate, 2% of cocamidopropyl, 0.8% of glycol distearate, 0.6% of spermaceti stearyl alcohol, 4.5% of cocamidopropyl betaine, 0.5% of guar hydroxypropyltrimnonium chlide, 0.2% of polyquaternium 10, 0.05% 0f sodium hyaluronate, 0.1% of citric acid, 0.25% of sodium citrate, 0.35% of bispyrithione, 1.2% of dimethiconol, 1.5% of vitamin B6, 0.2% of carbopol, 0.5% of panthenol, 0.1% of methylisothiazolinone, 0.5% of essence, and the balance of water. Compared with the prior art, the shampoo has the beneficial effects that the proper materials are selected to form a formula, the effects of preventing hair loss and relieving itching are good, the skin-friendly performance is excellent, the seepage force is also relatively strong, the shampoo is a mild cleaning product and can better clean hair and scalp.

Owner:广州市发雅丝精细化工有限公司

Dyeing and finishing process of cotton/wool blended fabric

InactiveCN105803790AHigh whitenessTidy up steps simplifiedDry-cleaning apparatus for textilesBleaching apparatusEngineeringThermal stability

The invention provides and discloses a dyeing and finishing process of cotton / wool blended fabric.The process includes the steps of 1, singeing; 2, one-bath desizing-scouring-bleaching; 3, shrink-resistant finishing; 4, pre-setting; 5, mercerizing; 6, dyeing; 7, fixation; 8, padding; 9, drying; 10, baking; 11, setting; 12, rolling.The one bath process is adopted for dyeing, and dyeing steps are simplified.The cotton / wool blended fabric is dyed at the same time through double-active-radical type active dye, dyeing steps are effectively simplified, and working efficiency is improved by 15-20%.In the dyeing procedure, the temperature and the temperature rise speed are strictly controlled, so that it is guaranteed that the strength and whiteness of the fabric are slightly affected; a high-temperature leveling agent is added to the dye, so that the situation that heat-resisting stability of fuel is reduced due to rise of the temperature, then dye is gathered, and leveling and deep dyeing effects are affected is avoided, dyeing problems such as color dots and color patches are avoided, and the dyeing effect is good.

Owner:TAICANG JINDA PRINTING & DYEING CO LTD

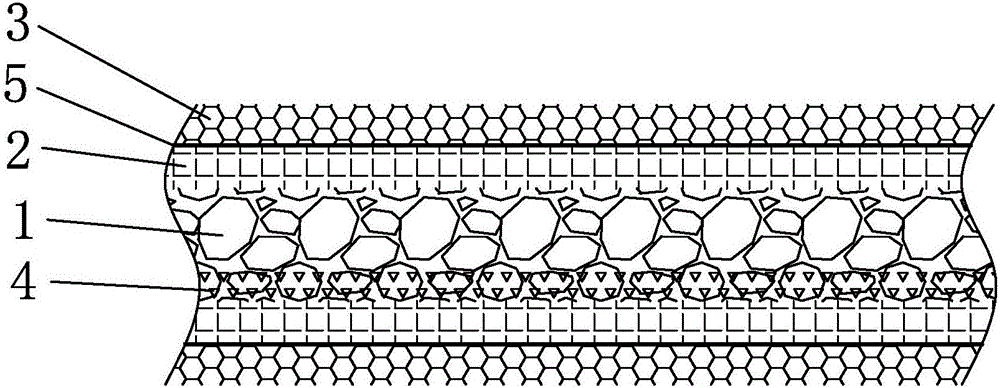

Novel composite core material for paper diapers and preparation method of novel composite core material

ActiveCN106420173AFast absorptionSmall amount of reverse osmosisSanitary towelsBaby linensNonwoven fabricPolymer

The invention discloses a novel composite core material for paper diapers and a preparation method of the novel composite core material. The novel composite core material is prepared from a fluffy non-woven fabric, a polymer absorbent material and dust-free paper, wherein wood pulp fiber is embedded into the bottom layer of the fluffy non-woven fabric. The novel composite core material has the advantages that the phenomenon that agglomerating and lumping are generated in the using process is effectively avoided; meanwhile, the fault phenomenon generated after longitudinal and transverse stretching is reduced, and the skin friendliness and the comfort degree are improved; after urine seeps downwards to arrive at the embedded wood pulp fiber, the urine diffuses around, therefore, the absorption speed of the urine is increased, the liquid absorption time of the polymer absorbent material is prolonged, and the reverse seepage amount of the urine is decreased.

Owner:贵州卡布婴童用品有限责任公司

Super cotton-like cashmere double-side fabric and production process thereof

InactiveCN103276500AMaintain propertiesConvenient careFibre treatmentMulti-ply fabricsYarnPolymer science

The invention relates to super cotton-like cashmere double-side fabric. The super cotton-like cashmere double-side fabric is characterized by being made of supercool / cotton blended yarn, cotton / cashmerino blended yarn, and mercerized gassed woolen yarn. The super cotton-like cashmere double-side fabric is in double-side weave; warps are made of 7.3tex Supercool / cotton blended yarn; and accordingly the whole cover of the fabric reveals no warp but weft, the weft front side of the fabric is made of 18.2tex mercerized gassed woolen yarn, and the weft reverse side is made of 18.2tex cotton / cashmerino blended yarn. Super cotton-like fiber is high in strength, wear-resistant, highly breathable, antistatic, wrinkle-resistant, and as warm as cashmerino. With perfect combination of wefts and warps by the special double-side weave, the fabric looks and feels different on two sides.

Owner:江苏保丹服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com