Polyester/cotton blended flame-retardant core spun yarn and production method thereof

A production method and technology of core-spun yarn, which is applied in liquid/gas/steam textile material processing, yarn, textile and papermaking, etc. It can solve the problems of cotton fiber such as poor wrinkle resistance and stretchability, strong acid resistance, easy pilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

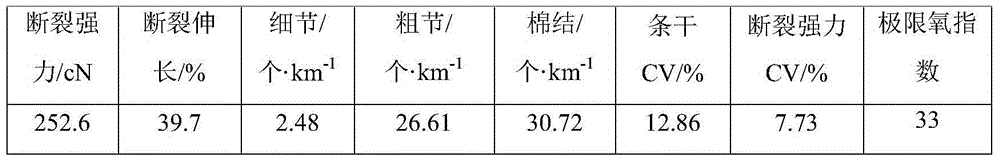

[0029] Taking the production of 40S polyester-cotton blended flame-retardant core-spun yarn as an example, 120S polyester / cotton flame-retardant blended yarn is used as the core yarn, and 60S polyester / cotton blended yarn is used as the outer covering yarn, which contains 50% polyester and cotton by weight. 50% cotton fiber, the yarn has good wearing performance, good moisture absorption and moisture permeability, high strength, good elasticity and excellent flame retardancy.

[0030] In order to realize the production of the above-mentioned flame-retardant yarn, the following methods are adopted:

[0031] Preparation of Polyester / Cotton Blended Flame Retardant Core Yarn

[0032] 1. Preparation of polyester raw sliver

[0033] (1) Cotton opening and cleaning process: the quantitative setting of the polyester roll is 380g / m, the speed of the catching beater is set to 720r / min, the speed of the beater of the mixed cotton opener is 550r / min, and the speed of the cotton equalizin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com