Novel composite core material for paper diapers and preparation method of novel composite core material

A composite core and body material technology, applied in the core material field of hygiene products, can solve the problems of reducing the comfort of diapers, affecting the use of diapers, clumping and other problems, to solve the fault phenomenon, speed up the absorption speed, and reduce reverse osmosis volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

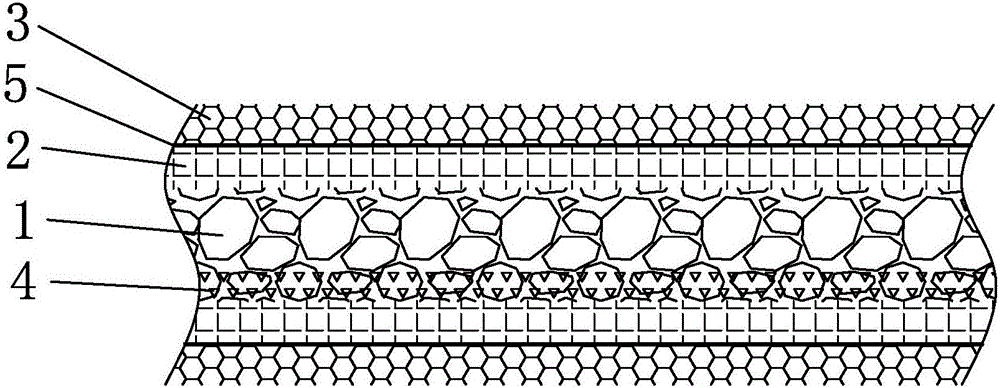

[0023] refer to figure 1 , a new composite core material for diapers, comprising a fluffy non-woven fabric 1, a polymer absorbent material 2, and a dust-free paper 3, and wood pulp fibers 4 are embedded in the bottom layer of the fluffy non-woven fabric 1. Wherein, the upper and lower surfaces of the fluffy non-woven fabric 1 are respectively provided with evenly arranged polymer water-absorbing materials 2 and dust-free paper 3 . Wherein, the polymer water-absorbing material 2 and the dust-free paper 3 are bonded by a hot-melt adhesive layer 5 .

[0024] Further: the thickness of the fluffy non-woven fabric 1 is 2-5 mm. Wherein, the density of the polymer water-absorbing material 2 is 50-150 grams per square meter. Wherein, the thickness of the dust-free paper 3 is 0.2-0.5 mm. Wherein, the length of the wood pulp fiber 4 is 0.8-1.2 mm, and the density of the wood pulp fiber 4 is 5-15 grams per square meter. Wherein, the thickness of the hot melt adhesive layer 5 is 0.08-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com