Patents

Literature

171results about How to "Skin-friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

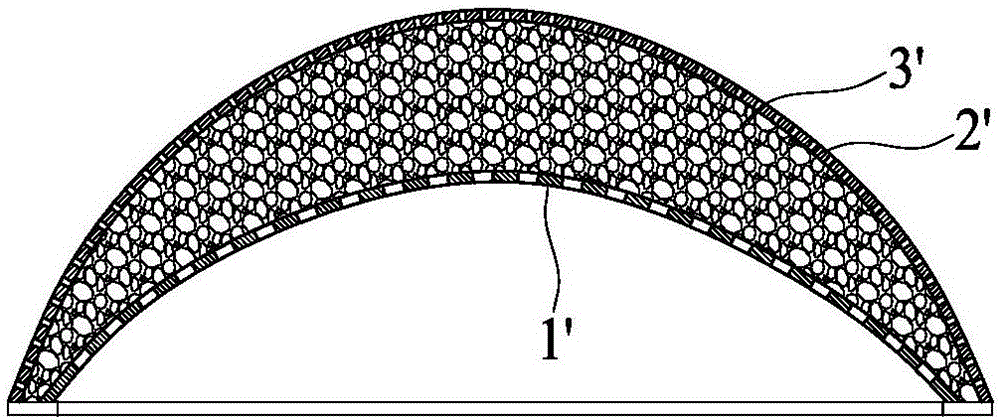

Perforated non-woven fabric

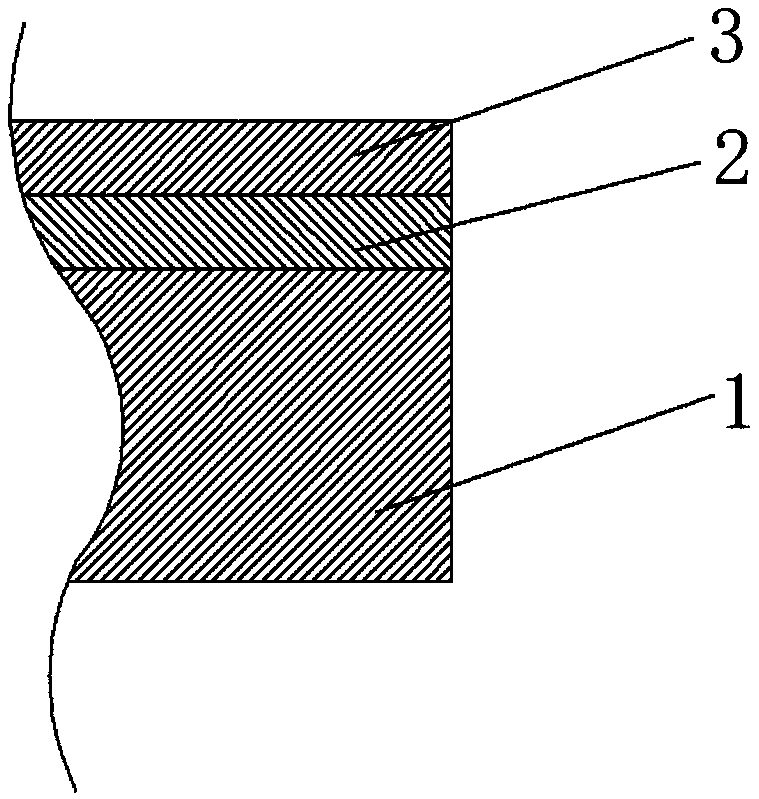

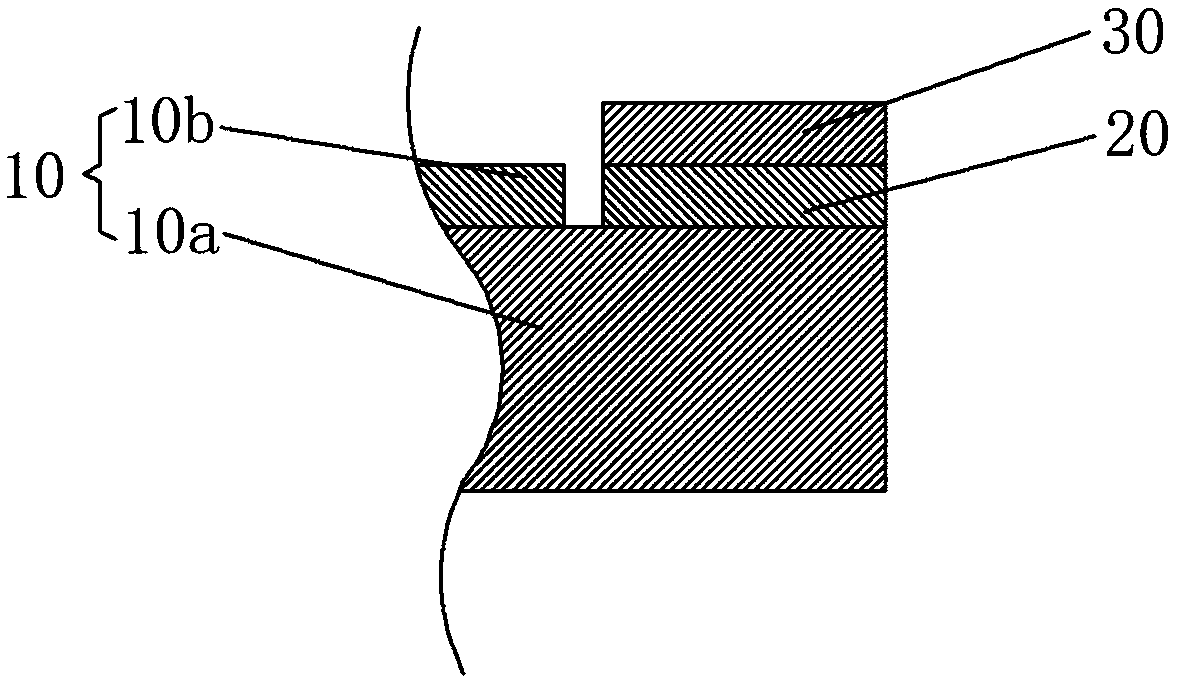

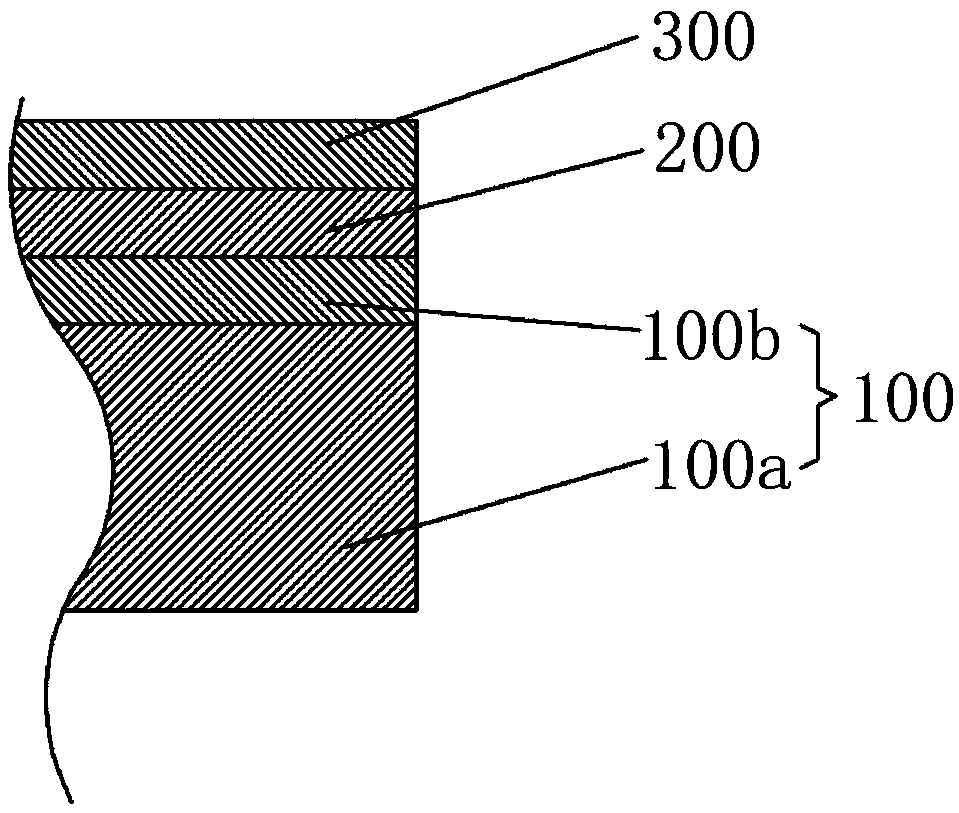

InactiveCN102673030AIncrease solid thicknessImprove moisture barrier effectLayered productsBandagesSurface layerGram

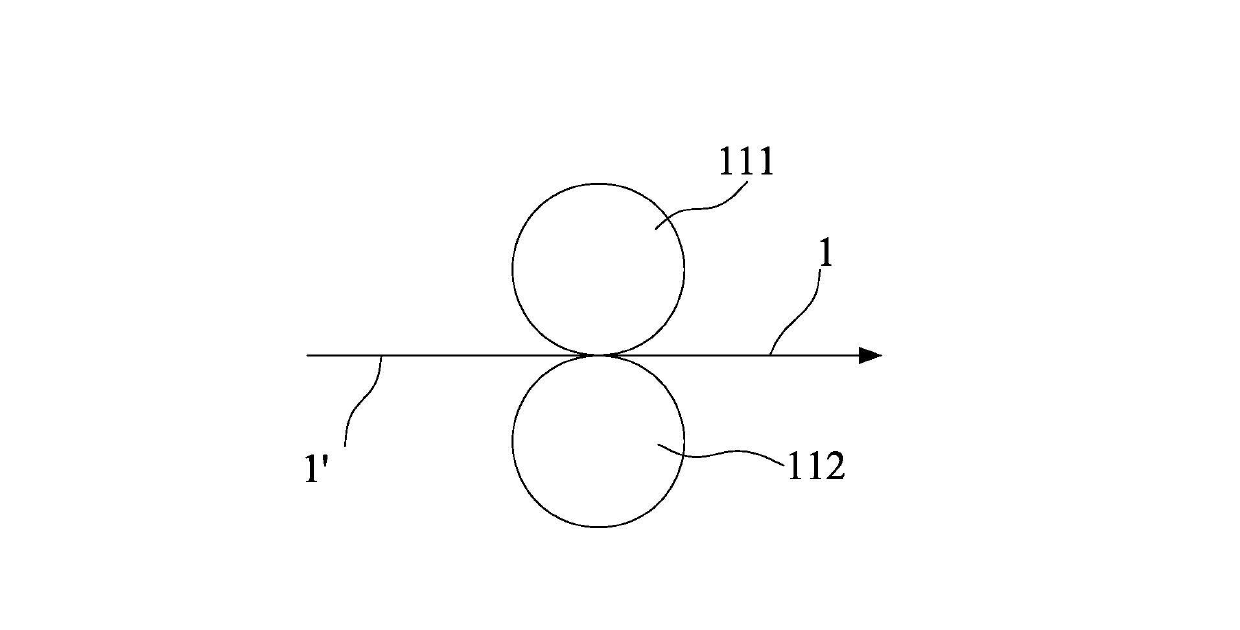

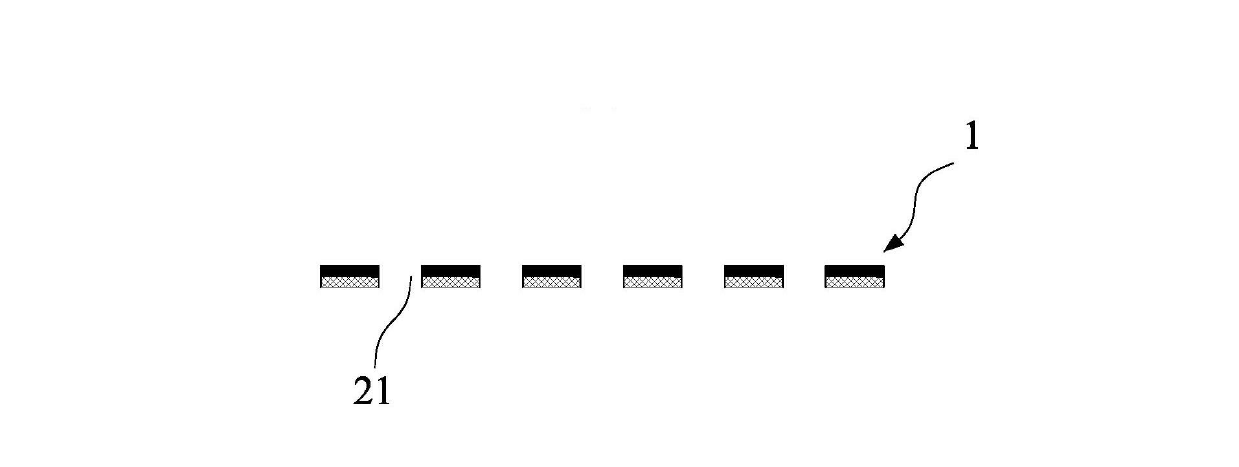

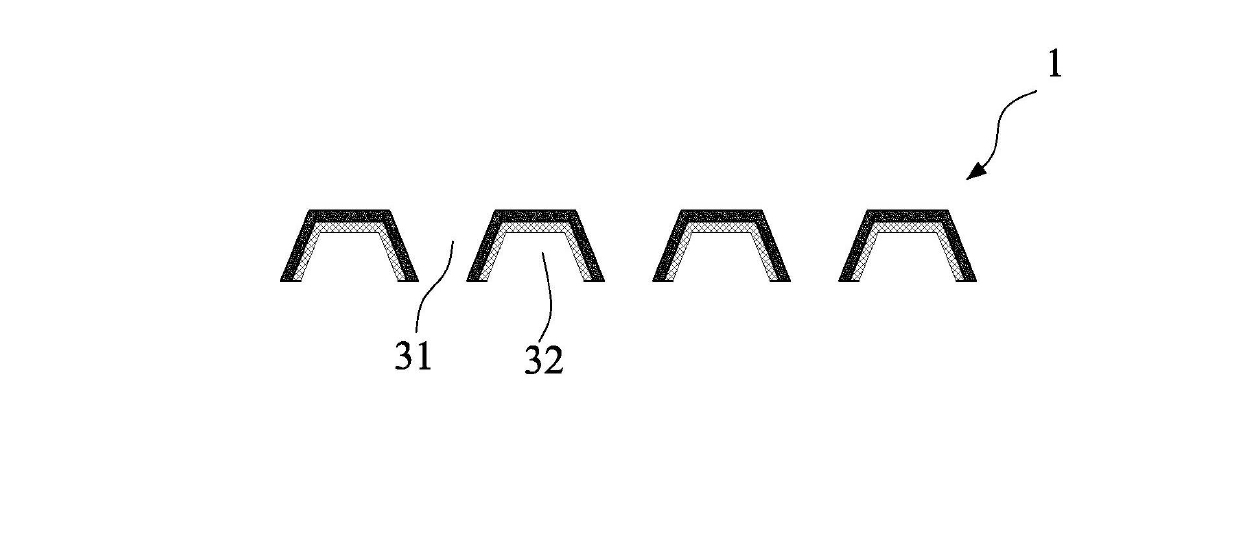

The invention provides perforated non-woven fabric, consisting of at least two fibrous layers, wherein a surface layer is such a fibrous layer, with a more than 70 degree contact angle with water and having the gram weight of 3 to 30 grams per square meters; and a bottom layer is such a fibrous layer, with a less than 90 degree contact angle with water and having the gram weight of 3 to 30 grams per square meters. The non-woven fabric has through apertures from the surface layer to the bottom layer, with the aperture ratio of 5 to 50% and the stereo thickness of 0.1 to 1.5mm. On a contact face between the two fibrous layers of the perforated non-woven fabric, the fibrous layers with mutually intersected fiber are usefully wetted by body fluid in use, so that the body fluid rapidly reaches the fibrous layer with the less than 90 degree contact angle with the water under the action of capillary tubes and energy level differences; the fibrous layer with the more than 70 degree contact angle with the water is a face contacting a user; and therefore, after being absorbed, the body fluid is difficultly adsorbed around the fiber due to the more than 70 degree contact angle between the fiber and the water, as well as is prevented from returning to the surface of the perforated non-woven fabric under the action of the capillary tubes, thereby achieving a dry and comfortable effect.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

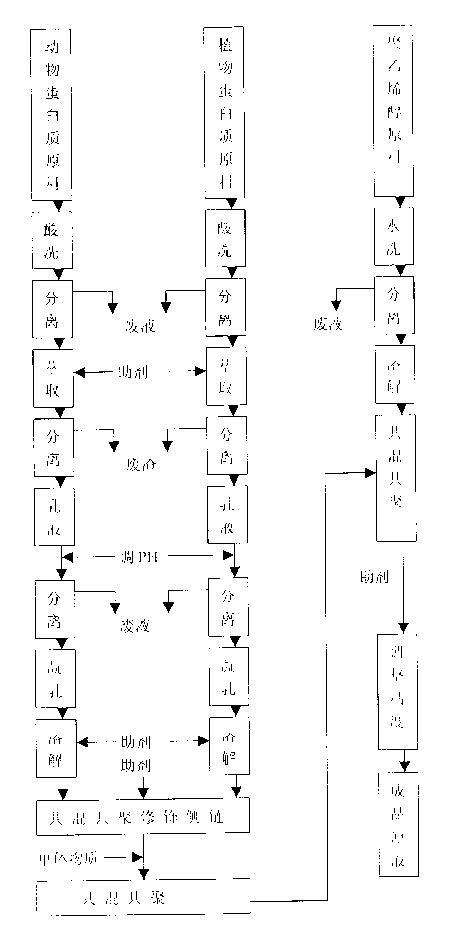

Protein synthetic fibre spinning solution and its producing method

InactiveCN1364948ASkin-friendlyBreathableConjugated cellulose/protein artificial filamentsPolymer scienceAmino acid side chain

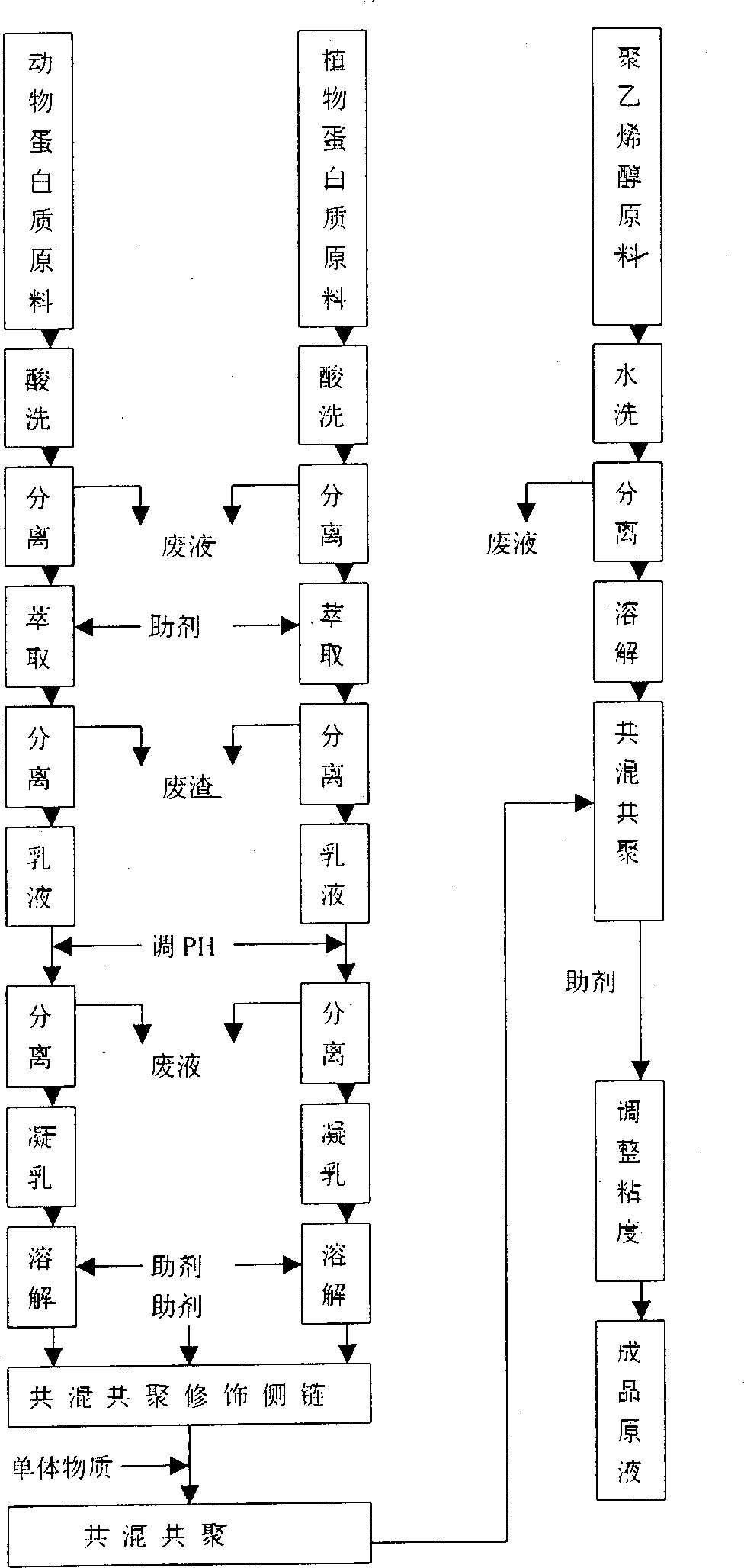

The protein fiber spinning solution is produced by using animal and plant material and through the processes of acid pickling, extraction, pH regulation to obtain protein curd, dissolving with cosolvent to form water solution, mixing, modifying side chain of amino acid with modifying agent, copolymerization with coloring monomer, mixing with PVA water solution and addition crosslinking agent to regualte viscosity. It may be used in spinning fiber with the same strengt has chemical fiber, the skin friendship, air penetrability and hygroscopicity the same as natural protein fiber, and improved hot water resistance, shrinkage and color.

Owner:卓宝松 +1

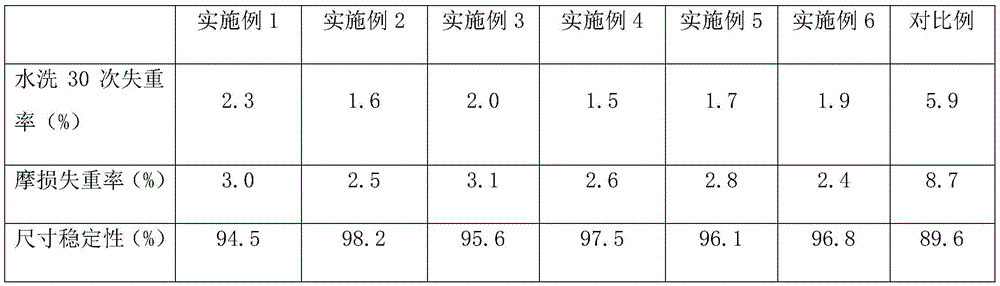

Fabric post-finishing agent based on modified silk fibroin solution and preparation method of fabric post-finishing agent

ActiveCN105544210ASkin-friendlyHigh affinityBiochemical fibre treatmentGrip property fibresDissolutionSolvent

The invention provides a fabric post-finishing agent based on a modified silk fibroin solution and a preparation method of the fabric post-finishing agent. The preparation method comprises the following specific operational steps: (1) removing impurities from waste silk, putting the impurity-free waste silk in a sodium bicarbonate solution for boiling and degumming, taking out and wringing out the degummed waste silk, washing with clean water till the greasy feel is eliminated, putting the primarily treated waste silk in the sodium bicarbonate solution again for boiling and degumming, taking out and wringing out the degummed waste silk again, washing again with clean water till the greasy feel is eliminated, putting the secondarily treated waste silk in an oven for drying, so as to obtain degummed silk; (2) putting the degummed silk in a lithium bromide solution for standing and dissolution, taking out the treated silk, and performing cooling, dialysis and concentration to obtain a silk fibroin solution; and (3) adding glycerin and gelatin into the silk fibroin solution, uniformly stirring to form a membrane solution, adjusting the pH value of the membrane solution and then adding glutaraldehyde and chitosan, uniformly stirring, and finally mixing the treated membrane solution with a solvent containing additives, so as to obtain the fabric post-finishing agent. The fabric post-finishing agent obtained according to the preparation method covers the fabric surface in the form of a composite membrane; and the preparation method is beneficial to improvements in the membrane forming property, the ductility and the like of a silk fibroin finishing agent.

Owner:SUZHOU INSILK CO LTD

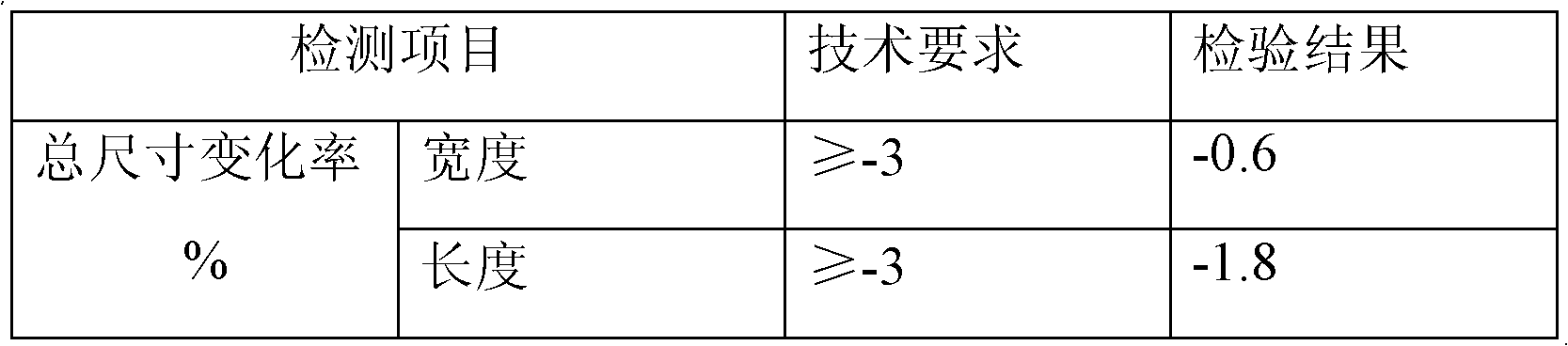

Method for preparing cashmere fabric

The invention discloses a method for preparing a cashmere fabric, comprising the following steps of: with basolan undercoat, cashmere, coffee carbon fiber and soft loose fiber as raw materials, blending, and carrying out semi-worsted spinning to obtain high count semi-worsted yarns which are taken as wraps, wherein wefts are mercerized cotton yarns; spinning the wraps and the wefts under the conditions that 2 / 2 texture is adopted and total tightness is 95-100, so as to obtain a grey fabric; and carrying out the following processes on the grey fabric: sizing, single boiling, double boiling, scouring, milling, double boiling, drying, middle inspection, finishing, brushing, softening and smoothening, napping, shearing, decating and natural lustre finishing, thus obtaining the finished product. According to the technical scheme provided by the invention, after finishing combines the advantages of fine spinning and roving processes, the obtained product has mild nature, soft feel and silkylustre and also has antibacterial, deodorizing and heat insulating effects, and the cashmere fabric reaches the requirement on relaxation size of 1*7A and can be washed by a machine.

Owner:ZHANGJIAGANG HUALU WOOL SPINING

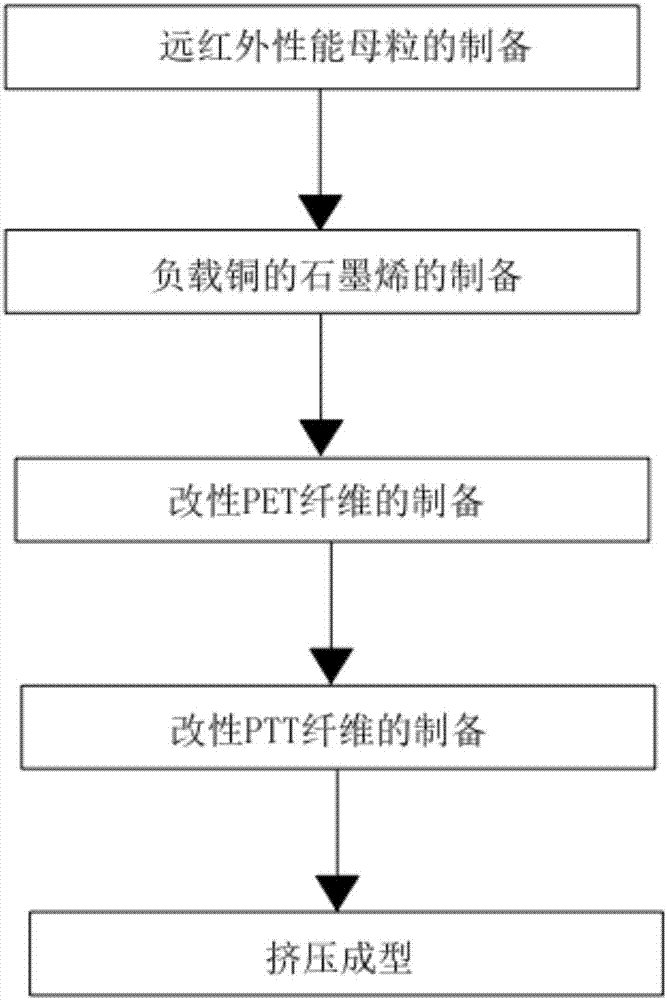

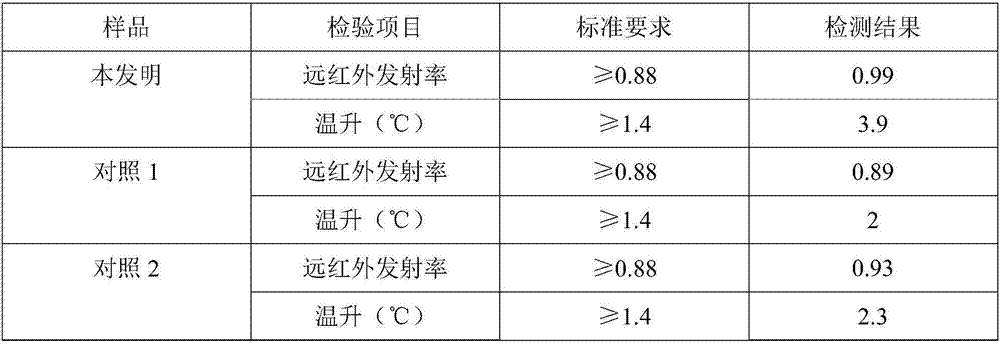

Far-infrared polyester fiber

ActiveCN107059156AGood hygroscopicityImprove dyeing effectElectroconductive/antistatic filament manufactureBiochemical fibre treatmentPolyethylene terephthalate glycolMicroparticle

The invention discloses far-infrared polyester fiber. The far-infrared polyester fiber is prepared by blending PET (polyethylene terephthalate) fiber, PTT (polytrimethylene terephthalate) fiber, far-infrared property master batch and copper-loaded graphene powder, wherein the PET fiber is prepared from dimethyl terephthalic acid and ethylene glycol polyester according to a molar ratio of 1.2:2.3; the PTT fiber is prepared from dimethyl terephthalic acid and propylene glycol polyester according to a molar ratio of 1.5:2.5; the far-infrared polyester fiber is prepared from the following raw materials in percentage by weight: 0.05% to 0.1% of far-infrared property master batch, 0.05 to 25% of copper-loaded graphene powder, and the balance of PET fiber slice and PTT fiber slice, and the raw materials of the far-infrared property master batch are mainly vermiculite and medical stone microparticles. The invention also discloses a preparation method of the polyester fiber. The polyester fiber prepared by the preparation method has excellent far-infrared property, bacteria-resisting and inhibiting properties, and skin-friendly and skid-care properties.

Owner:黄蕊烨

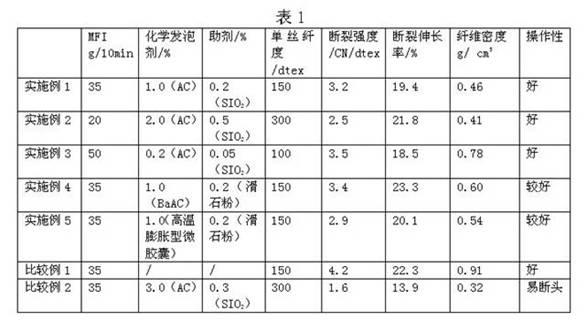

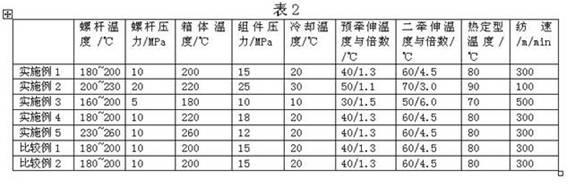

Microporous foaming polypropylene fiber and preparation method thereof

ActiveCN102174717ALightweightResilientFilament/thread formingMonocomponent polyolefin artificial filamentSocial benefitsPolymer science

The invention discloses a microporous foaming polypropylene fiber and a preparation method thereof. In the method, a polypropylene resin of which the melt index is 20-50g / 10min is used as a raw material, and a chemical foaming agent, assistants and master batches are added, wherein the chemical foaming agent, the assistants and the master batches respectively account for 0.2-2wt%, 0.05-0.5wt% and1-5wt% of the raw material, and the decomposition temperature of the chemical foaming agent is 180-250 DEG C. In the invention, spinning and drawing processes are completed in one step, the operatingperformance of the production process is fine, the production cost is low, and better economic and social benefits are achieved. Besides, the fiber has light weight, rebound elasticity, breathabilityand skin adaptability, and still maintains favorable mechanical properties.

Owner:ZHEJIANG SCI-TECH UNIV

Preparation method of home textile fabric

InactiveCN104404679ASimple processSimple and efficient operationWoven fabricsYarnAgricultural engineeringAfter treatment

The invention discloses a preparation method of a home textile fabric. The method comprises the following steps: (1) preparing raw materials; (2) spinning; (3) spooling; (4) performing beam warping; (5) slashing; (6) weaving; (7) performing after-treatment. The preparation method of the home textile fabric disclosed by the invention is simple in process, and is easy and convenient to operate; through reasonable process adjustment and blending of cotton fibers, the defects caused by spinning and weaving through separate use of tencel fibers are overcome effectively; the woven tencel / surface blended home textile fabric has the advantages of tencel fibers and cotton fibers, has the advantages of soft handfeel, skin friendliness, smoothness, hygroscopic property, air permeability, high intensity, durability and the like, and is a high-grade home textile fabric.

Owner:CHANGSHU TIANCHEN KNITTING

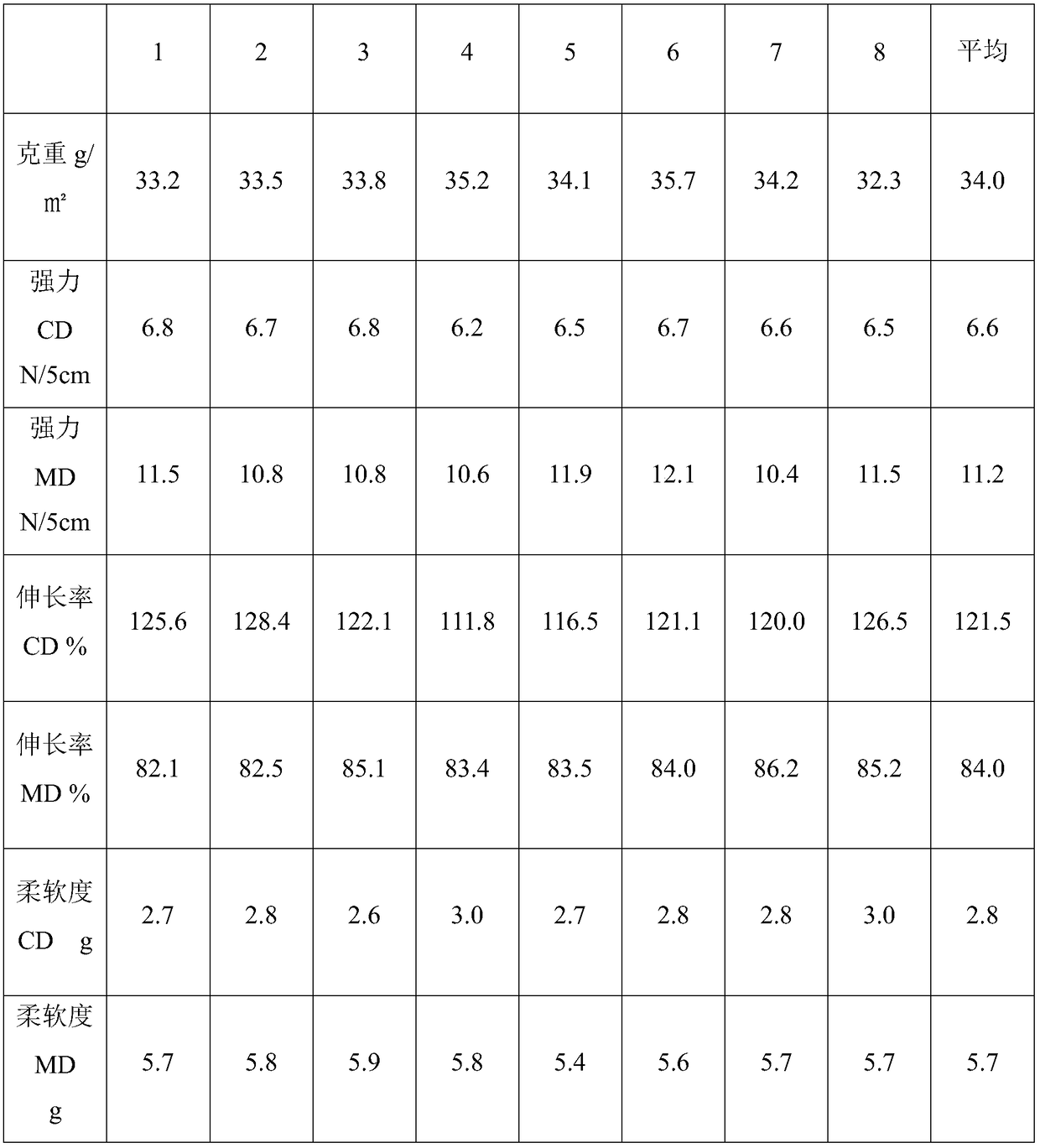

Super-soft spunbond nonwoven cloth double reinforcing and forming technology

ActiveCN108708071AWith fluffy feelingSoftTextile treatment machine arrangementsConjugated synthetic polymer artificial filamentsElastomerMasterbatch

The invention provides super-soft spunbond nonwoven cloth double reinforcing and forming technology. The technology includes following steps: fully mixing and feeding 81-86.5 parts of polypropylene PP, 12.5-16 parts of allyl elastomer, 0.5-1.5 parts of soft masterbatch and 0.5-1.5 parts of titanium dioxide into a hopper; fusing, filtering, and entering a spinning system; cooling filament obtainedby spinning through lateral cooling air to obtain primary filament; performing airflow drafting on the primary filament to obtain a fiber net; feeding the fiber net into a hot mill through continuousconveying of a finished net conveying belt for reinforcing, and performing spunlace reinforcing after hot milling to obtain nonwoven cloth; spraying antibacterial finishing liquid to the nonwoven cloth through an antibacterial treatment system, and conveying the nonwoven cloth into an oven for drying. A spunbond-spunlace double reinforcing process is adopted to produce the nonwoven cloth to replace conventional hot air cloth production, so that the nonwoven cloth has the characteristics of being fluffy, soft and skin-friendly. A novel nonwoven cloth processing technique is adopted, so that a direction is provided for development of the nonwoven cloth in the future.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

Blended non-woven fabric and preparation technology thereof

InactiveCN105908371ABeneficial elasticityBeneficial water absorptionSolvent-treatmentSucessive textile treatmentsRespiratorVegetable fibers

The invention discloses blended non-woven fabric and a preparation technology thereof. The blended non-woven fabric comprises the preparation raw materials of degummed silk protein fiber and degummed natural vegetable fiber, wherein the mass ratio of the degummed silk protein fiber to the degummed natural vegetable fiber is (20:80) to (80:20). The blended non-woven fabric not only has the advantages of softness, skin protection and skin favorableness of silk, but also has the elasticity and water absorption of fiber. The blended non-woven fabric is simple in preparation technology, and can be widely applied to industrials of facial masks, sanitary towels, sanitary pads, paper diapers, cosmetics, respirators, hygienic products and medical supplies.

Owner:SUZHOU YAZHOU COMMODITY TECH CO LTD

Medical composition for health-care pillow and silk traditional Chinese medicine cervical vertebra health-care pillow

ActiveCN103006947AEliminate fatigueRelax the bodyPillowsHeavy metal active ingredientsWhole bodyAtractylodes chinensis

The invention relates to a medical composition for a health-care pillow and a silk traditional Chinese medicine cervical vertebra health-care pillow. Silk, silkworm excrement, wild chrysanthemum flower, notopterygium root, calcined magnet, borneol, albizia flower, tuber fleeceflower stem, rhizoma acori graminei, flos caryophylli, sandalwood, keel, oyster, tetrapanax papyriferus, radix angelicae, safflower, radix crotonis crassifolii, ligusticum wallichii, cassia twig, magnolia obavata, rhizoma atractylodis and kudzu root powder are added into a health-care pillow; and when the health-care pillow is used, due to head temperature and pressure of a head, effective components of medicines in the pillow are slowly released to be sucked into a lung and enter blood circulation, so as to be conveyed to a whole body. Medical research and analysis show that mulberry silks have skin-friendly property, heat retention property and air permeability; the content of organic matters in the silkworm excrement is 83.77-90.44% and the silkworm excrement mainly contains leaf essence, pohytol, sitosterol, free amino acid and the like; and therefore, the health-care pillow has the effects of improving eyesight, nourishing eyes, nourishing brain, calming the nerves and the like, and has the effect of removing heat to cool blood when people with strong lung fire use the health-care pillow. Meanwhile, silkworm fibroins are warm in winter and cool in summer, are also comfortable and have the effects of enabling heart and blood vessels to have no load, accelerating sleep, preventing skin diseases and the like.

Owner:曼居家居科技有限公司

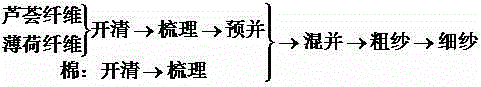

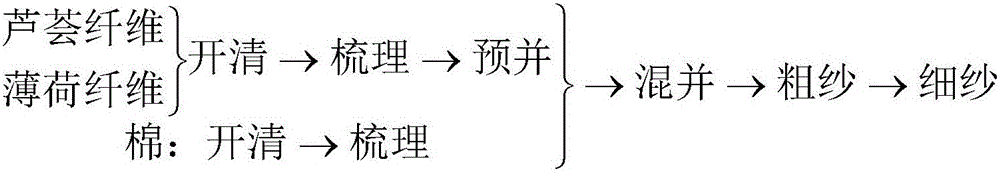

Aloe fiber, mint fiber and cotton blended yarns and production process thereof

InactiveCN104420041AImprove performanceImproved performance of individual spinningYarnBreathingSpecific gravity

The invention discloses aloe fiber, mint fiber and cotton blended yarns and a production process thereof. The yarns consist of the following components in percentage by weight: 10 to 50 percent of aloe fibers, 10 to 50 percent of mint fibers and 40 to 70 percent of cotton fibers, wherein the aloe fibers have high moisture absorption performance and moisture release performance, good hand feeling and high fluffiness; the mint fibers have the characteristics of fragrance, odor removal, antisepsis and anti-inflammation, and high moisture absorption performance and breathability; meanwhile, the cotton fibers also have high moisture absorption performance and breathability; the three types of fibers are blended to take advantages of all fibers; the obtained yarns have the efficacies of moisture absorption, breathing, skin friendliness, skin care and long-time bacteria inhibition.

Owner:NANTONG GRACE SWEATER

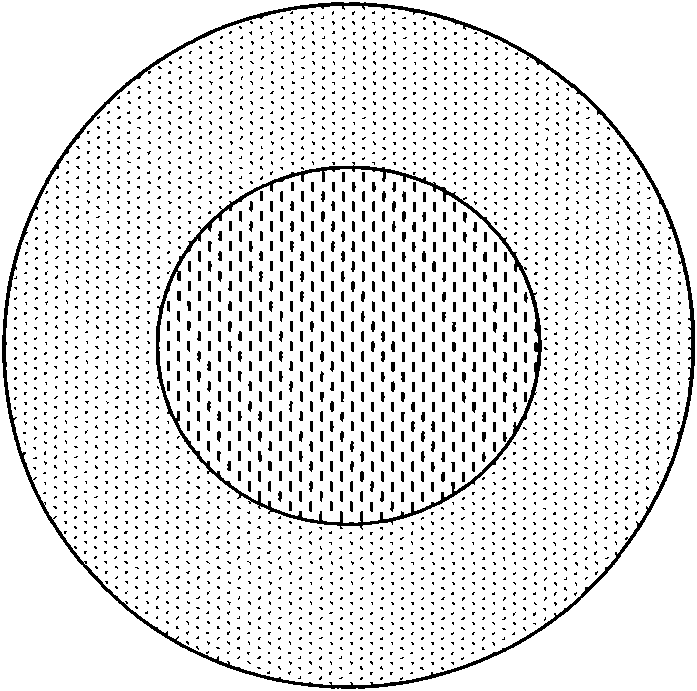

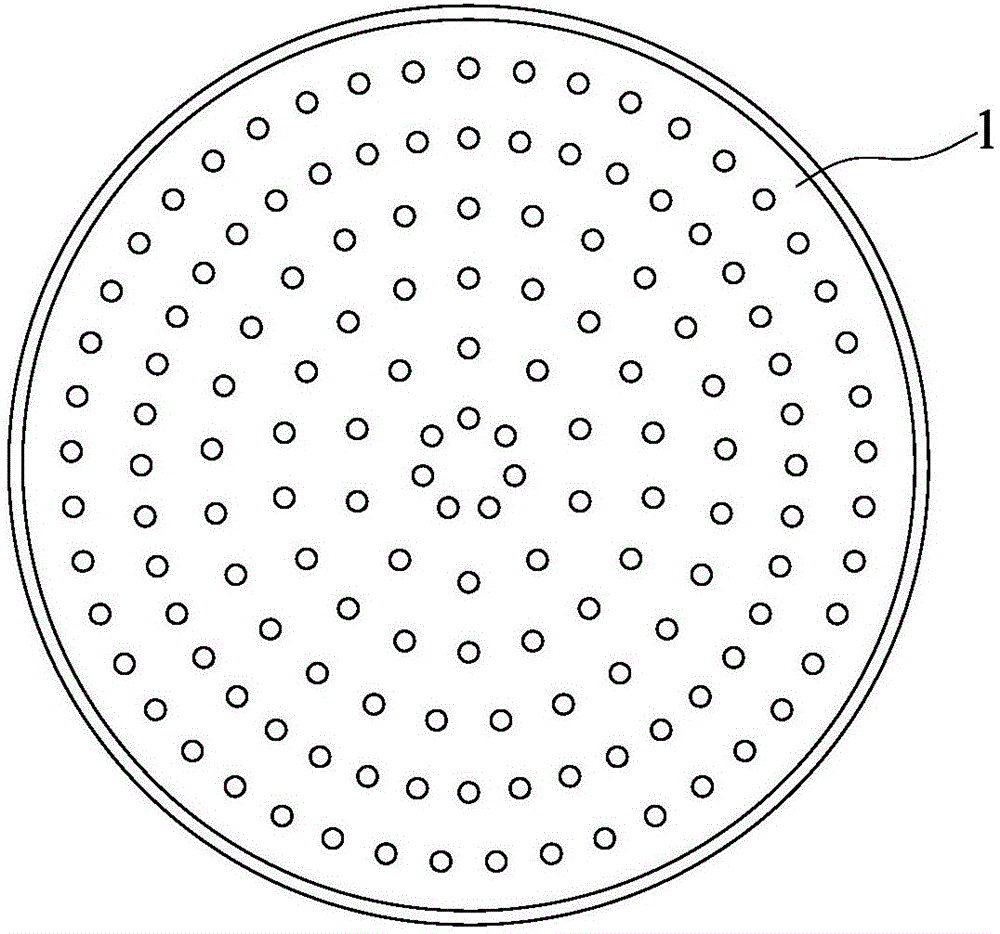

Polyolefin composite fiber

InactiveCN101974795ASkin-friendlySexual functionFilament/thread formingConjugated synthetic polymer artificial filamentsPolyolefinSurface layer

The invention relates to a polyolefin composite fiber. The fiber number is between 1.0 and 7.0dtex; the cross section has a round and sheath core structure; polyolefin containing nanometer pearl powder is taken as a surface layer, polyolefin containing attapulgite is taken as a core layer, and a mass ratio of the surface layer to the core layer is 25:75 to 80:20; and the attapulgite in the core layer accounts for 1 to 10 percent of the mass of the core layer, and the nanometer pearl powder in the surface layer accounts for 3 to 20 percent of the mass of the surface layer. The polyolefin composite fiber is prepared by a surface-core type composite melt spinning process. The fiber has skin affinity, antistatic behavior, health-care function, pearly luster and smooth handfeel and has the effects of improving strength and heat resistance of the fiber and removing peculiar smell. In addition, the core layer does not contain the nanometer pearl powder, so that the total using amount of the nanometer pearl powder is low, the production cost is reduced, and the additional value is improved. The polyolefin composite fiber can be used for clothing, medical and hygienic products, bedding products and the like.

Owner:CHUZHOU YOULIN TECH DEV

Composite functional regenerated cellulose fiber with pearl and chitosan and its prparing process

InactiveCN1986917ASoft touchGood hygroscopicityConjugated cellulose/protein artificial filamentsWet spinning methodsCellulose fiberAntiseptic

The present invention is composite functional regenerated cellulose fiber with pearl and chitosan and its preparation process. The composite functional fiber consists of cellulose 92 wt%, pearl grain 3 wt% and chitosan grain 5 wt%. Its preparation process includes the steps of adding superfine pearl powder of size below 200 nm and chitosan grain into pulp, preparing regenerated cellulose spinning liquor and wet spinning. The composite functional regenerated cellulose fiber may be used to produce fabric with soft hand feeling, high hydroscopicity and antiseptic and deodorizing health function.

Owner:DONGHUA UNIV

Head-wearing earphone with breathing ear cushion

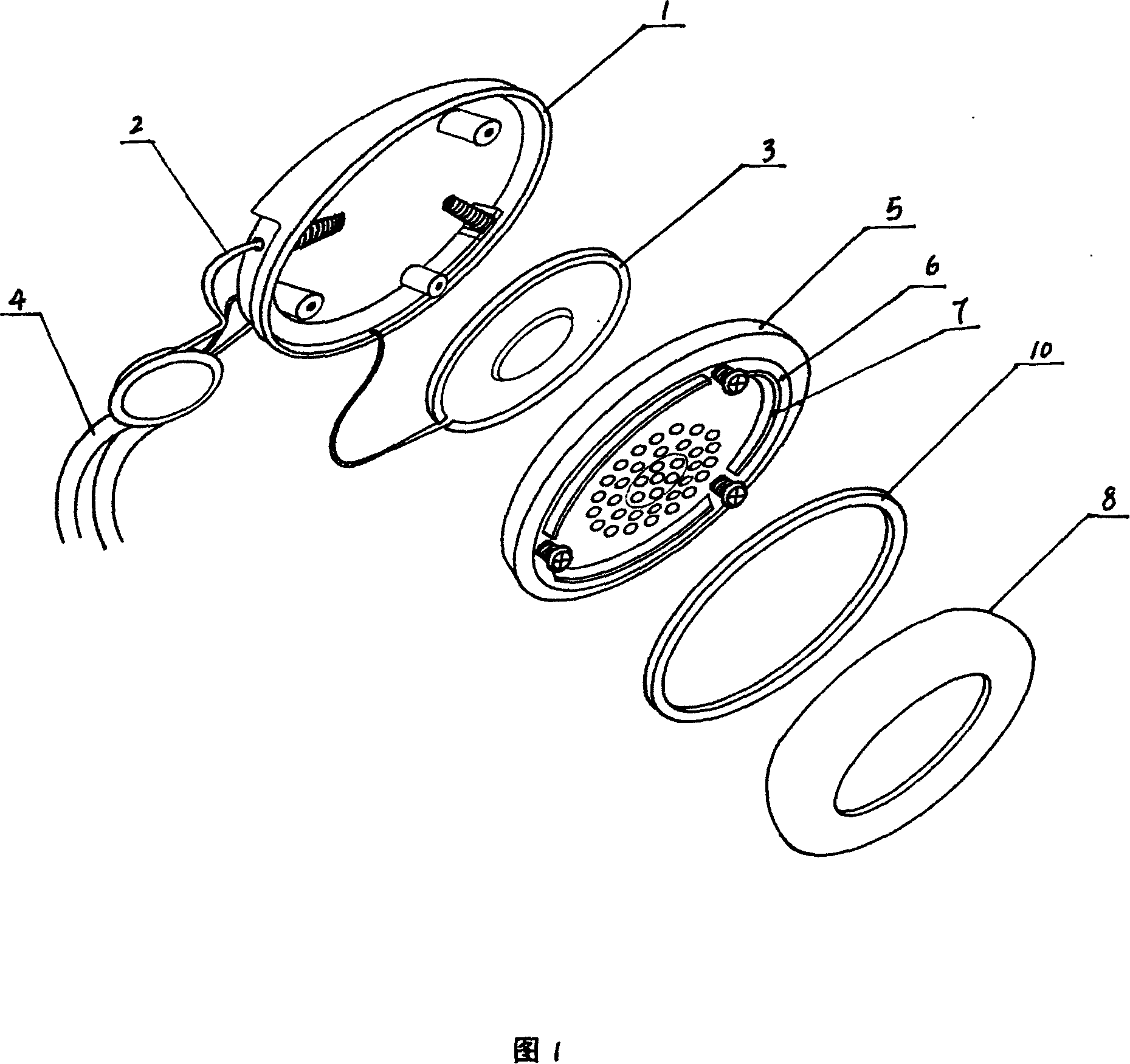

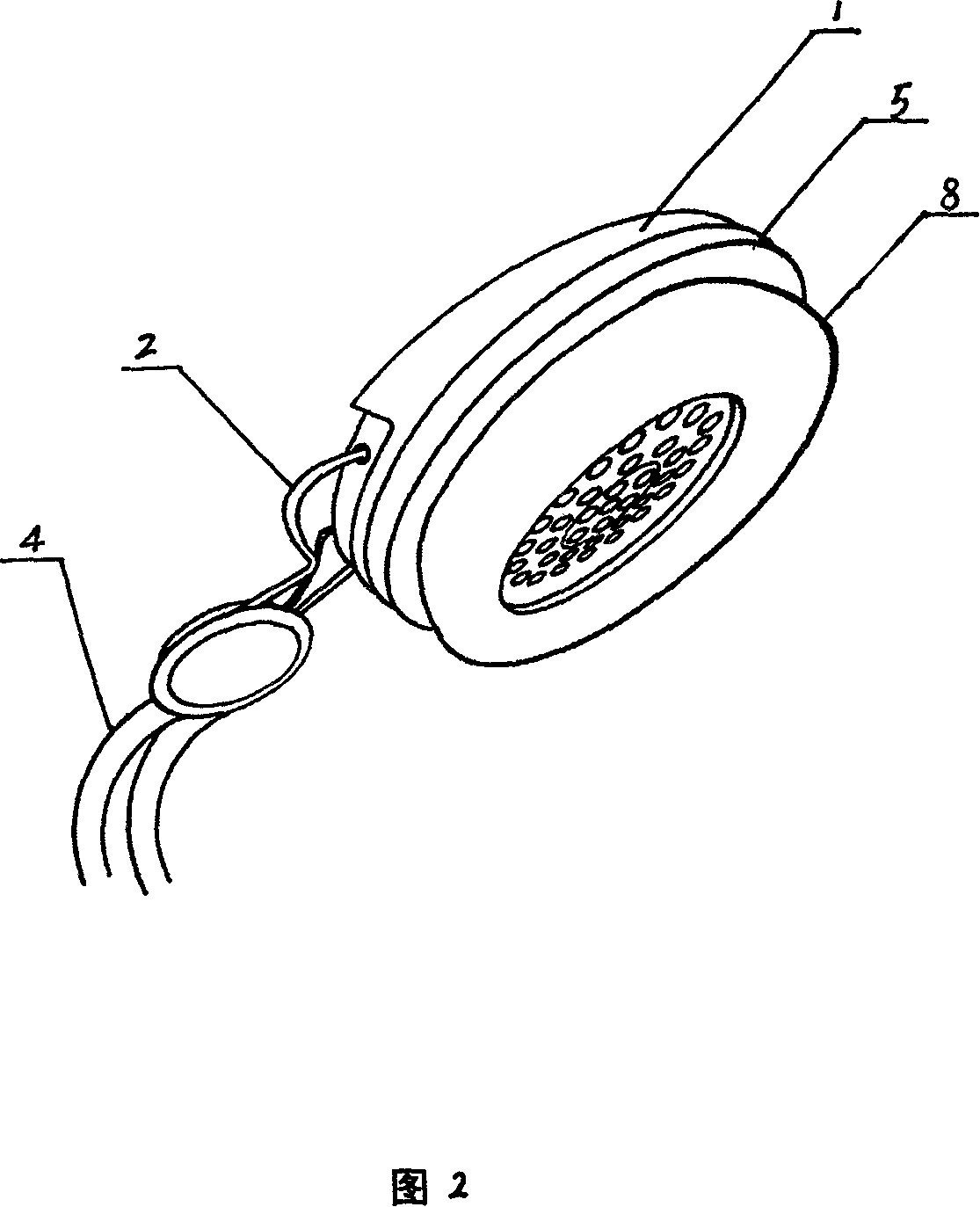

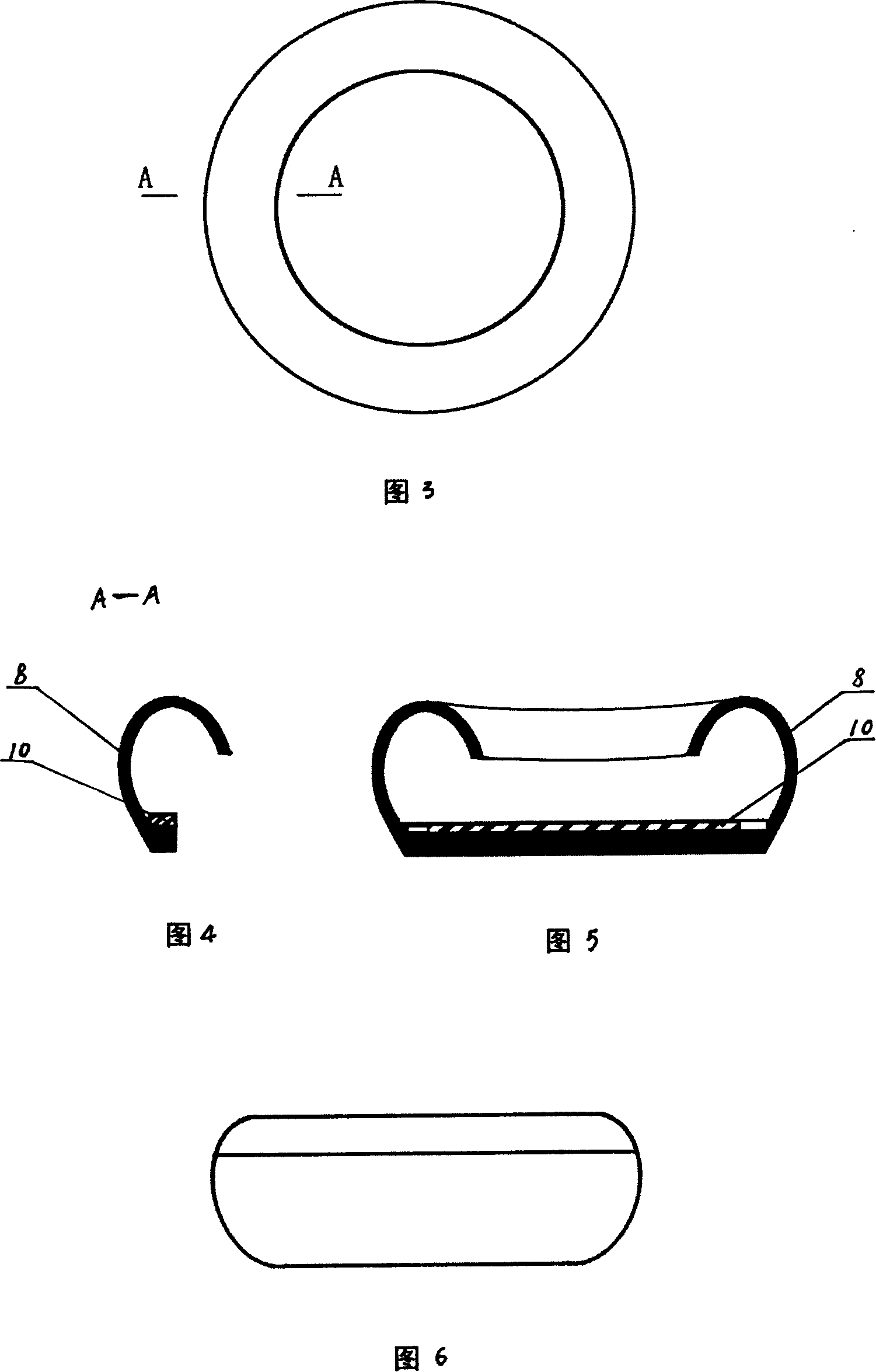

InactiveCN1937851AGood stabilityProtect earsHeadphones for stereophonic communicationEarpiece/earphone attachmentsCushionEngineering

This invention relates to a kind of headset with aeration ear pad, including shell, speakers, speaker board, headband, linking handle, the speaker is fixed on the speaker board, the speaker board is fixed in the shell, its characteristic is that setting ring ear pad in the speaker board, installing lock seized location in the board, locking the ring ear pad in the seized location by pressure circle. The ear pad in this invention is made of nontoxic, good stability soft silicone and thermoplastic material, the structure is new, it also has the characteristic such as aeration, cool, sanitation, durable. Wearing long will not make the user feel pain pressure and stivy, it is a kind of headset that wearing comfortable, protecting the ears, listening with good effect, convenient, durable.

Owner:林伟生

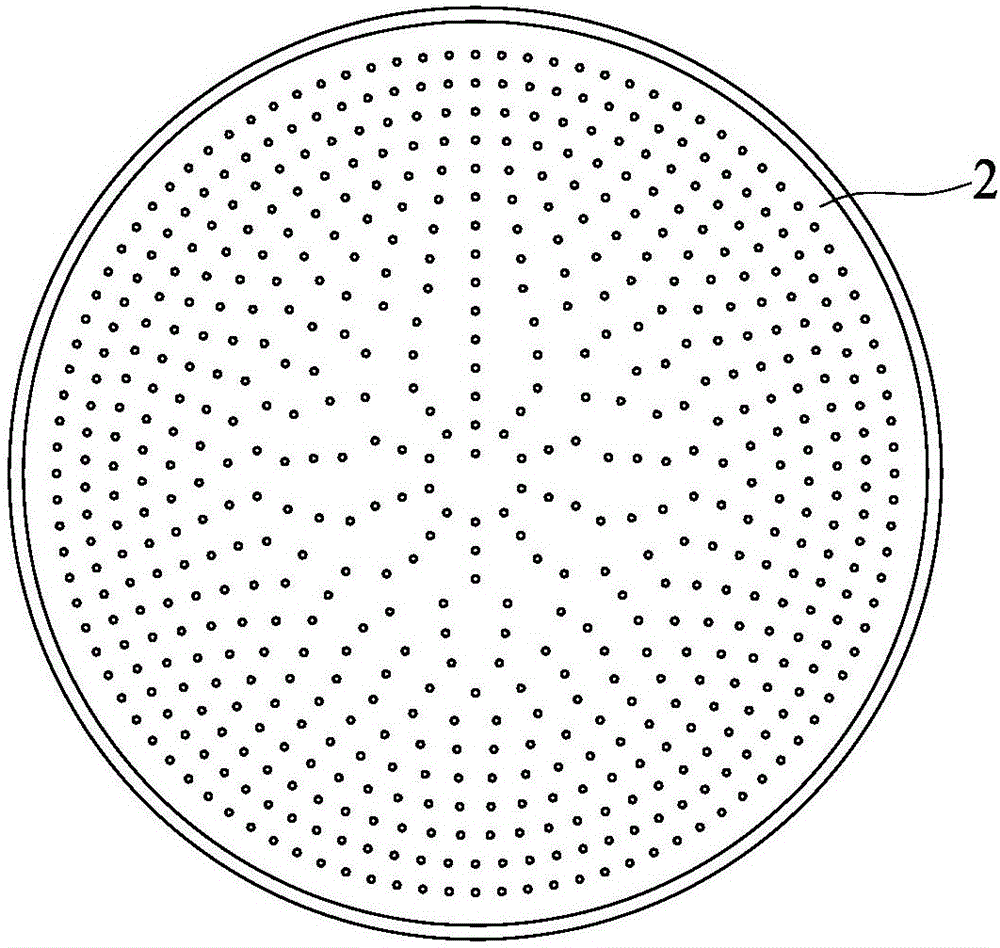

Cup structure of bra and manufacturing method of cup structure

InactiveCN106072813AGood stability and flexibilitySkin friendlyBrassieresCorsetsYarnBiomedical engineering

The invention discloses a cup structure of a bar and a manufacturing method of the cup structure. The cup structure comprises an inner layer, an outer layer and a support body arranged between the inner layer and the outer layer, wherein the inner layer and the outer layer are made of breathable materials and are mesh-yarn-shaped silica gel layers or latex layers; the support body is a fence-shaped silica gel or latex framework. By the arrangement, the cup structure is similar to a hollowed deformed cage structure, has a pressing or elevating effect on the breast, and is good in elasticity and stability, lightweight, breathable, water-permeable and friendly to the skin.

Owner:XIAMEN BONAI MOLD DESIGN CO LTD

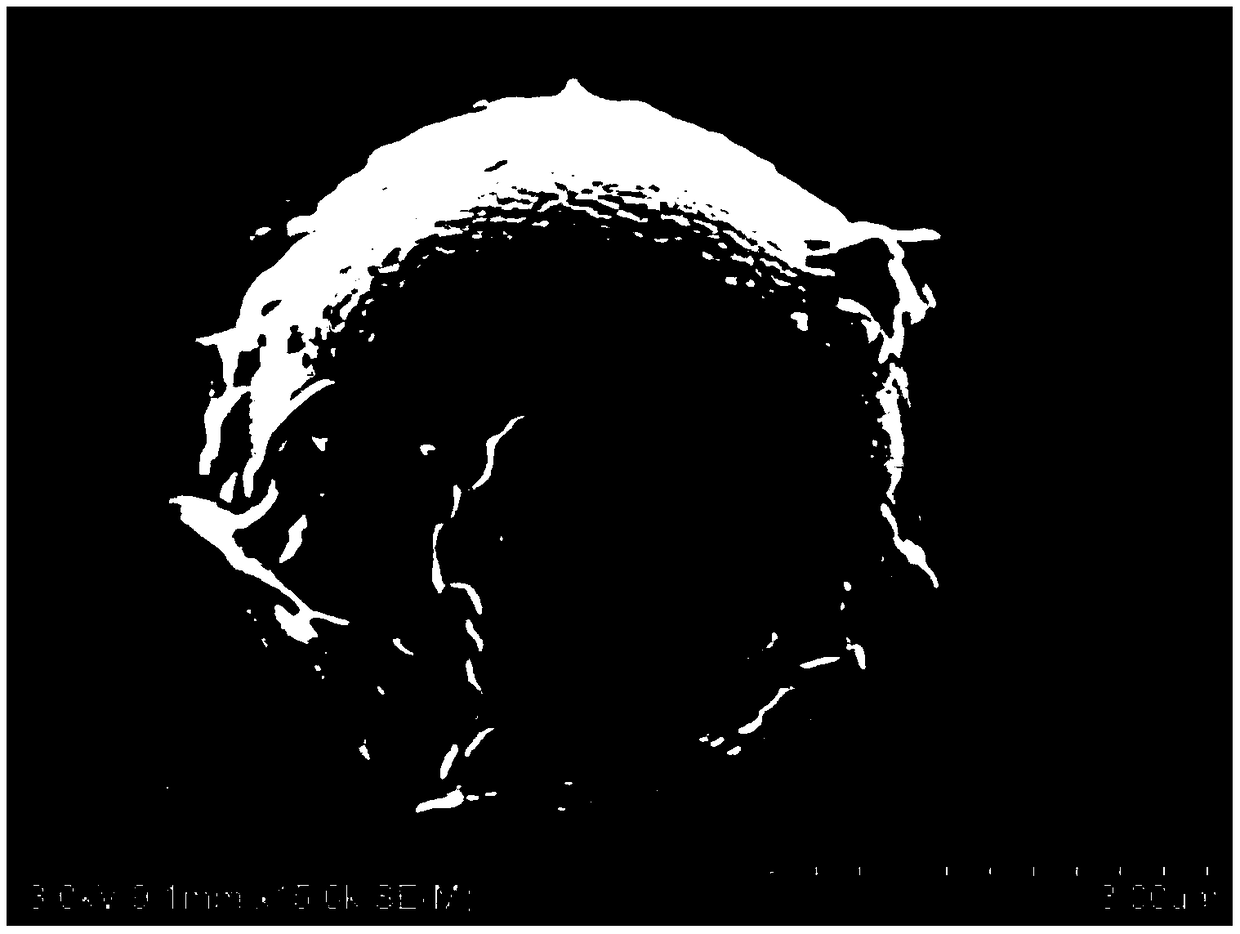

Method capable of photocatalytically degrading dyes to prepare copper-loaded nano titanium dioxide chitosan composite microspheres in microfluidic mode

ActiveCN108855233AIncrease profitLarge catalytic surface areaWater/sewage treatment by irradiationWater treatment compoundsIonChemistry

The invention discloses a method capable of photocatalytically degrading dyes to prepare copper-loaded nano titanium dioxide chitosan composite microspheres in a microfluidic mode. The method comprises the steps: adding a tetrabutyl titanate solution into an acid solution, mixing to form nano titanium dioxide gel, utilizing an organic solvent to mixing the nano titanium dioxide gel with amine terminated hyperbranched polymer to obtain mixed liquor, then adding a copper ion solution into the mixed liquor, drying to obtain copper-loaded nano titanium dioxide powder, adding the copper-loaded nanotitanium dioxide powder and chitosan into the acid solution to be mixed to obtain a dispersion phase, mixing sorbitan fatty acid ester with a hydrocarbon mixture to obtain a continuous phase, mixingthe dispersion phase with the continuous phase in a microfluidic mode and drying to obtain the copper-loaded nano titanium dioxide chitosan composite microspheres. According to the method disclosed bythe invention, the composite microspheres are prepared in the microfluidic mode, so that a material utilization rate is high; the microspheres have large self catalyzing surface areas and high catalytic activity, can effectively reduce dye concentration, reduce toxic components in dye wastewater and protect environment and water resources.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

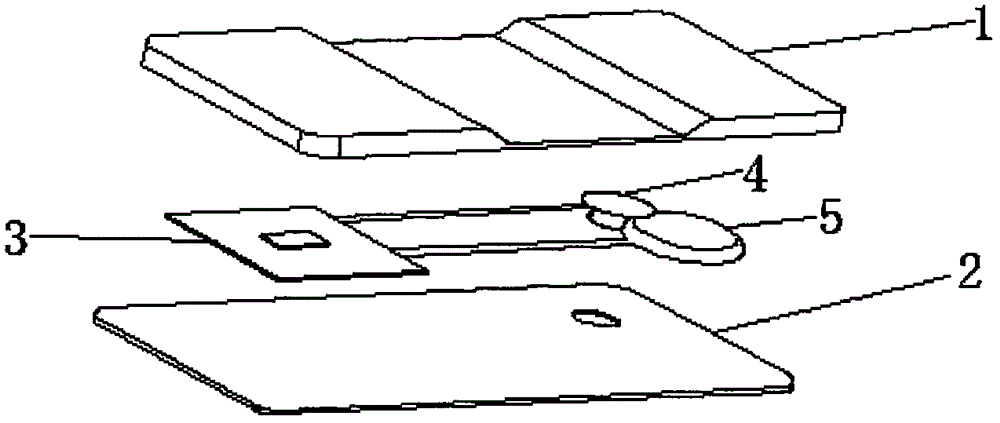

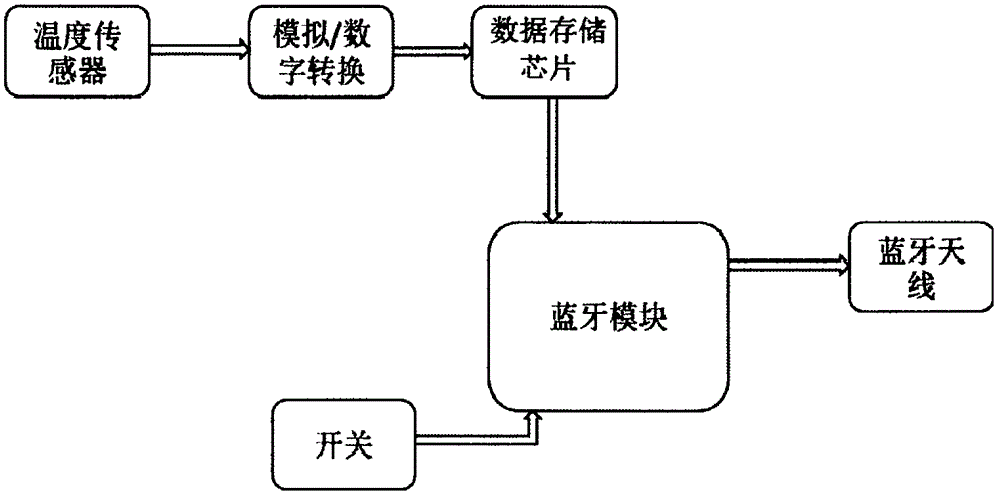

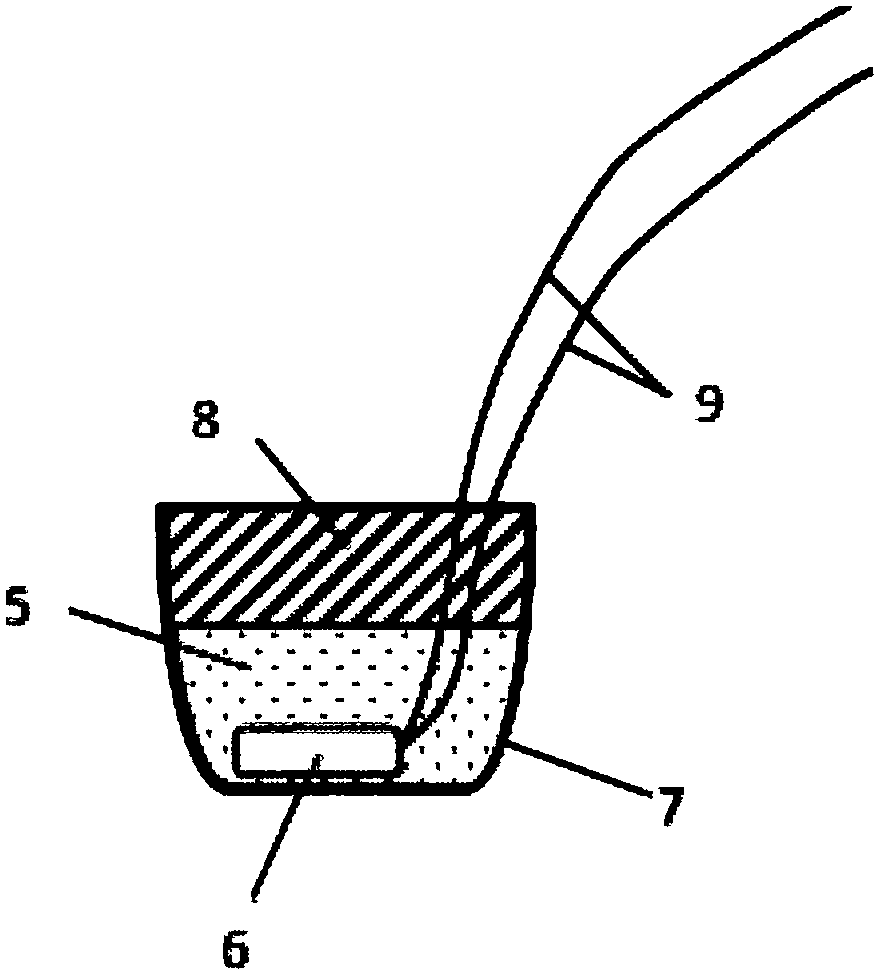

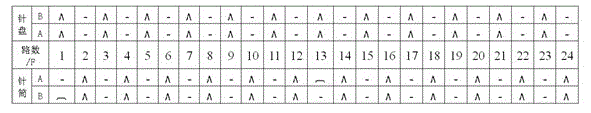

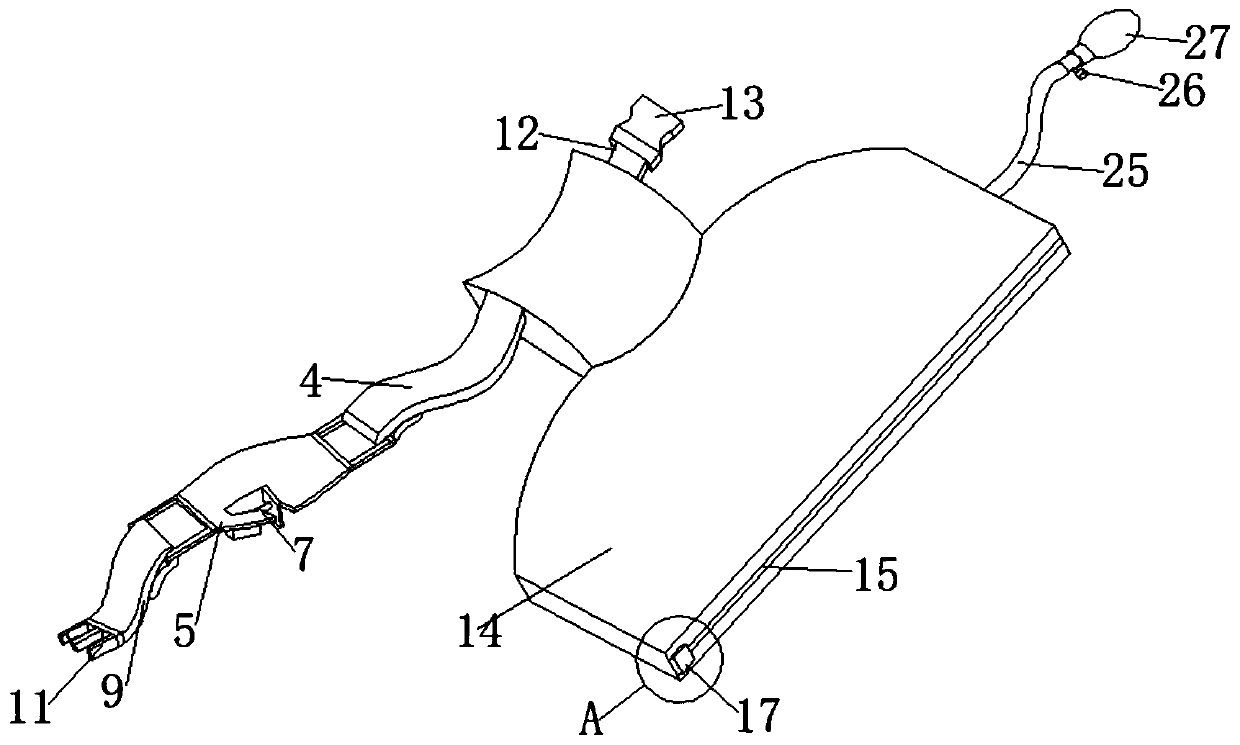

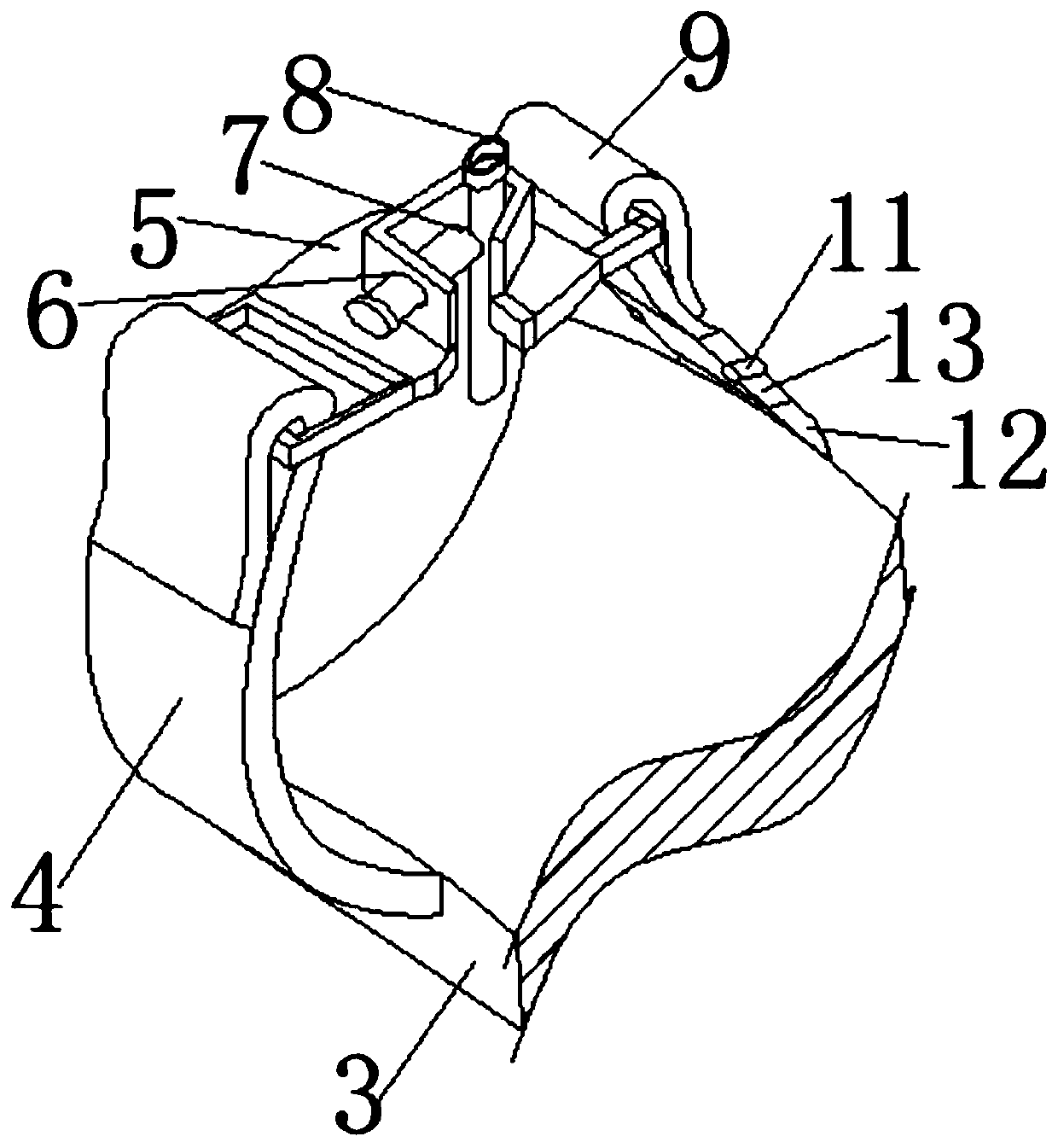

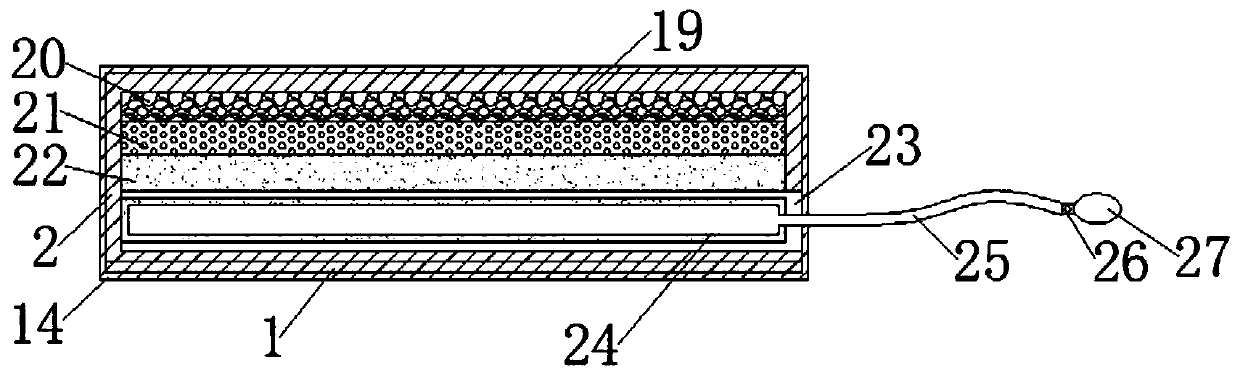

Rechargeable flexible ultrathin intelligent human body temperature paste and production method thereof

InactiveCN106618512AIntegrity guaranteedGuaranteed accuracyPersonal careFilm/foil adhesivesBody temperature measurementTreatment fever

The invention provides a rechargeable flexible ultrathin intelligent body temperature paste and a production method thereof, belongs to the technical field of body temperature measurement and relates to a body temperature paste and a production method thereof. The invention aims at solving the problems that an existing thermometer is basically made from a hard material, is serious in foreign body sensation when being worn and can not effectively measure body temperature when a baby and the like cooperates improperly during body temperature measurement and an existing body temperature paste has no temperature memory function and is poor in real-time temperature monitoring effect. The rechargeable flexible ultrathin intelligent body temperature paste comprises a flexible packaging material, a center layer coats the inside of the flexible packaging material, a circuit board is arranged at the center layer, the circuit board comprises a data storage chip, and a flexible pasting film is arranged outside the flexible packaging material. The rechargeable flexible ultrathin intelligent body temperature paste is especially applicable to infants to teenagers when have a fever and fall ill, the trouble that parents measure the body temperature of the infants repeatedly can be effectively avoided, and the infants also can be avoided from being disturbed when having a rest, so that the infants can rehabilitates beneficially and rapidly; and the rechargeable flexible ultrathin intelligent body temperature paste has a rechargeable function and be repeatedly charged, so that service life period of the body temperature paste can be effectively prolonged.

Owner:FACON CO LTD

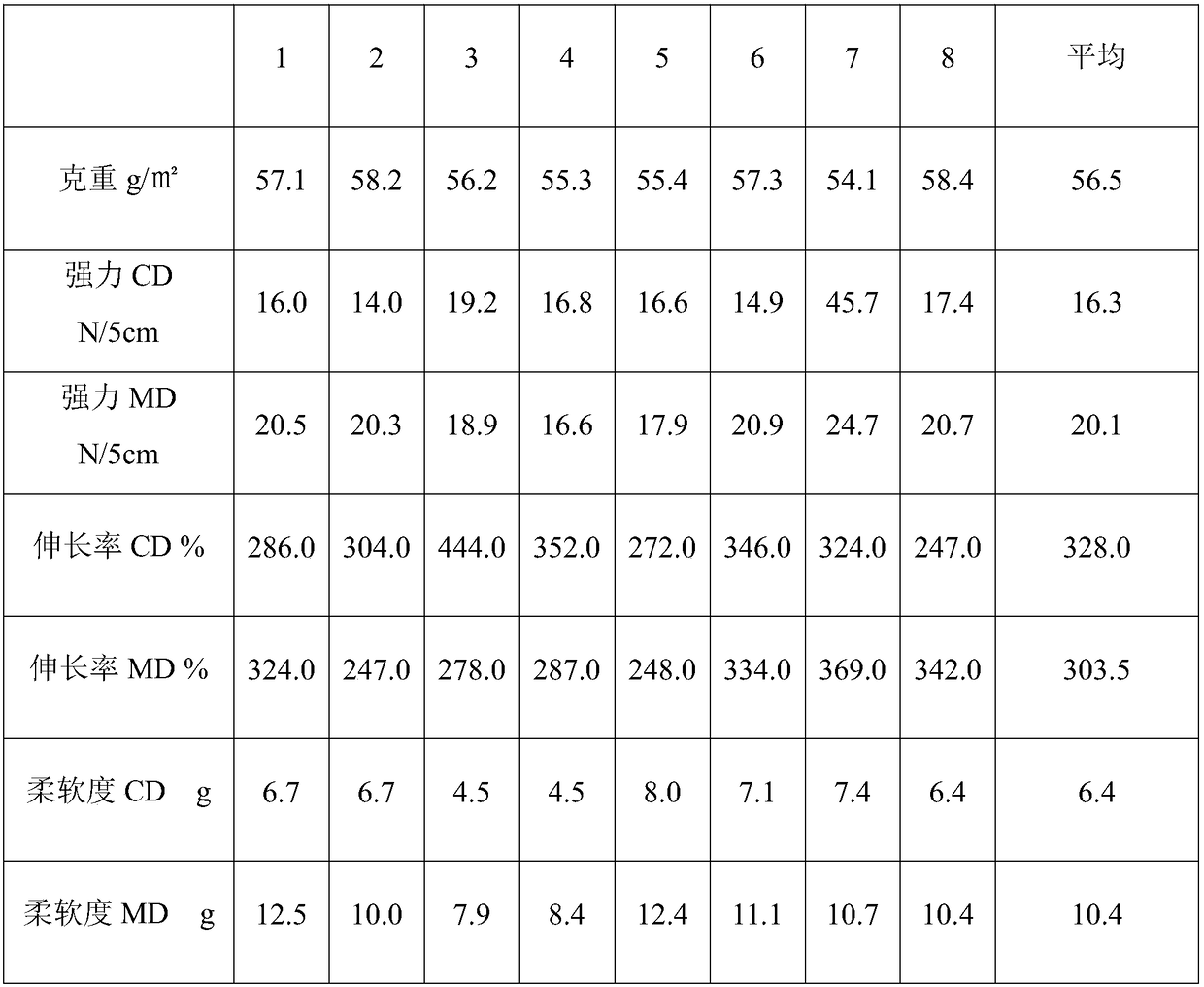

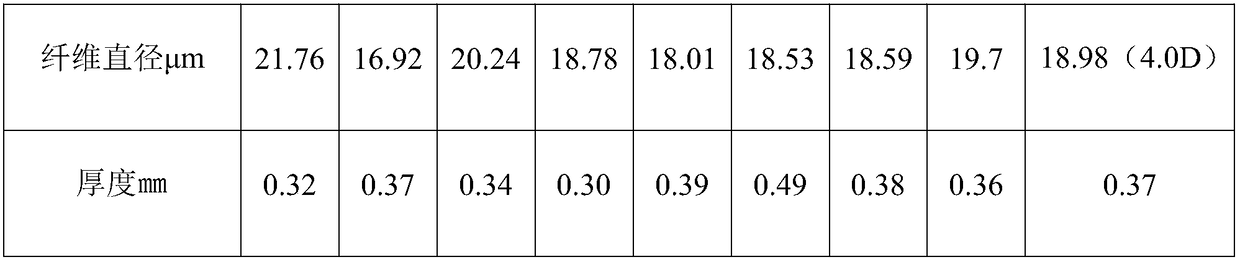

PE spun-bonded non-woven fabric and manufacturing method thereof

The invention relates to a PE spun-bonded non-woven fabric which is composed of PE raw material and elastomer mixed at a ratio of 98%: 2%. The elastomer is VISTAMAXX 6020FL, and the PE raw material isLL6101XR. A manufacturing method of the PE spun-bonded non-woven fabric is further disclosed. A bottom film product for composite air permeable films is produced by using the PE raw material insteadof the conventional PP raw material. The composite bottom film of the conventional PP spun-bonded non-woven fabric needs to be bonded by adhesive. The novel PE spun-bonded non-woven fabric has good adhesion, and can be directly composited with an air permeable film after heating without adding adhesive materials. On the other hand, the PE spun-bonded non-woven fabric can be used in wallpaper without gluing.

Owner:山东恒鹏卫生用品有限公司

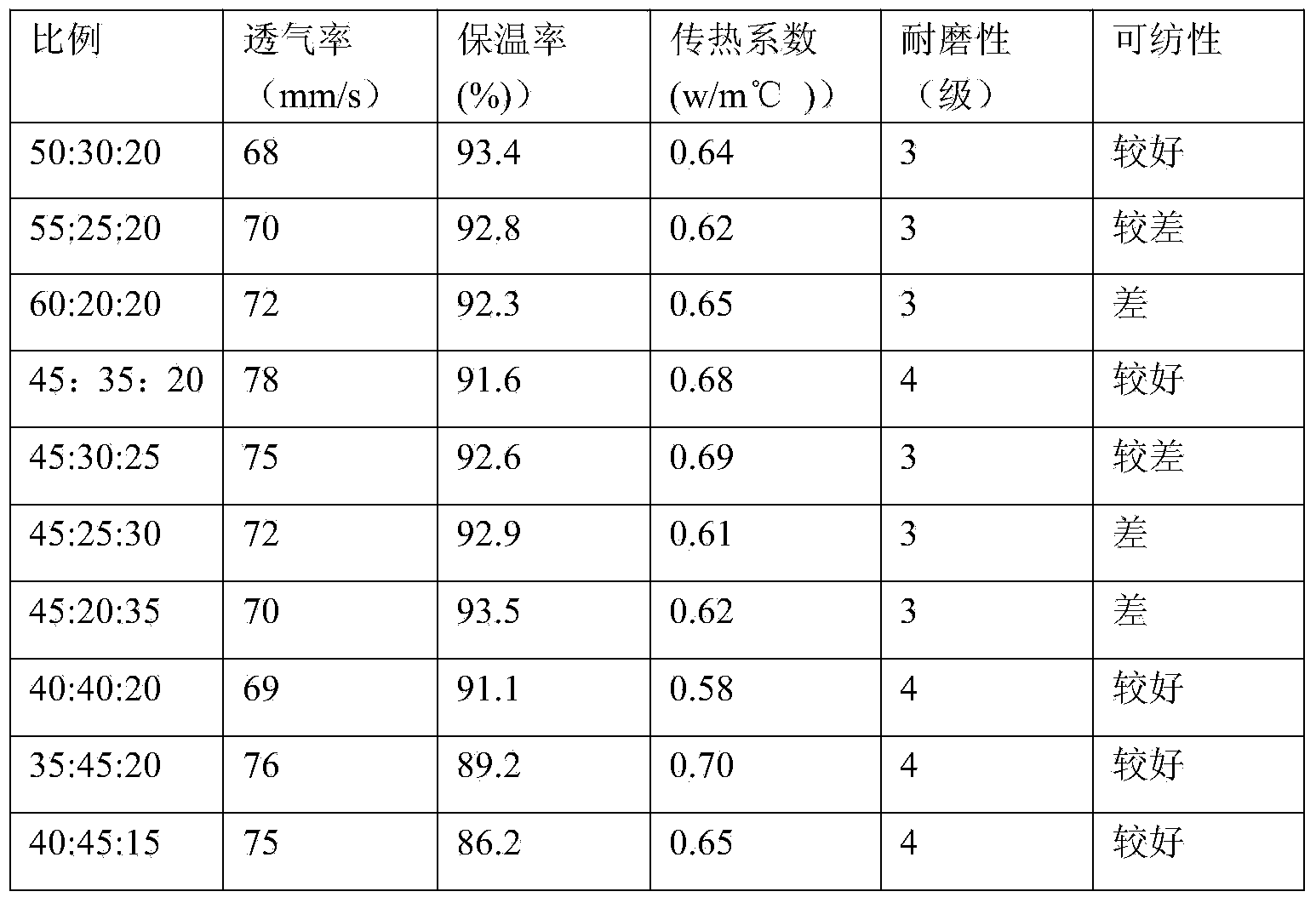

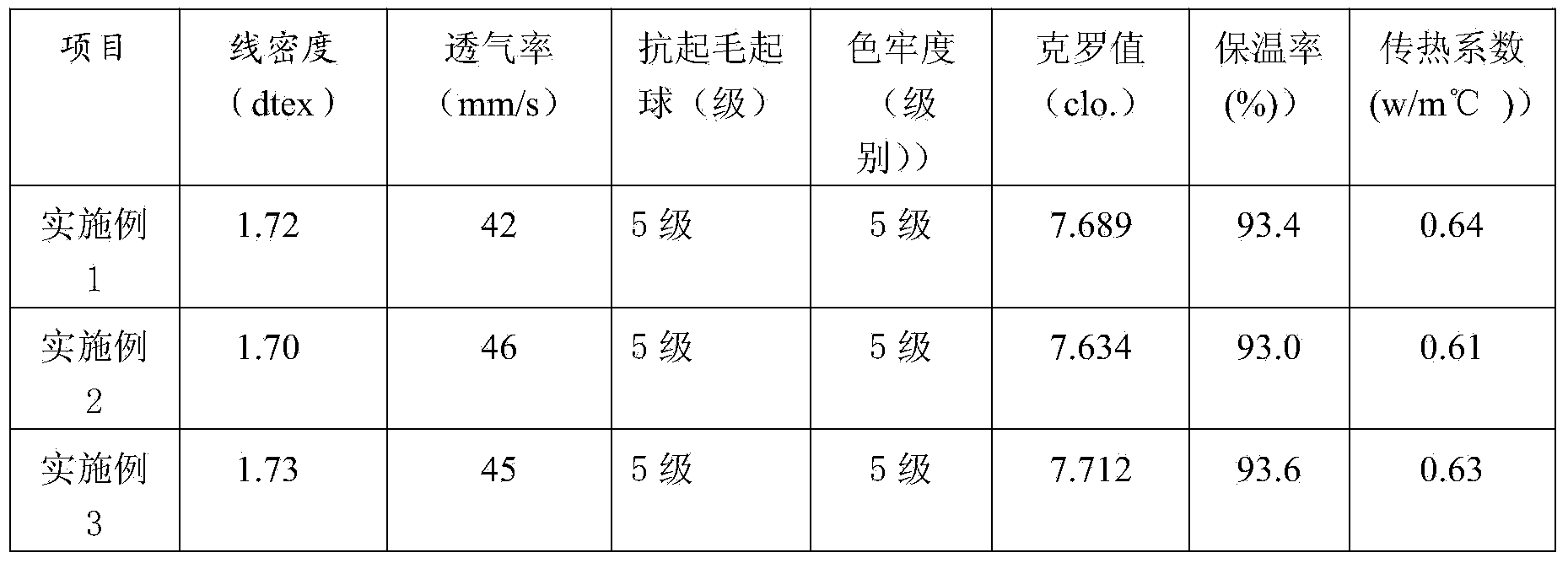

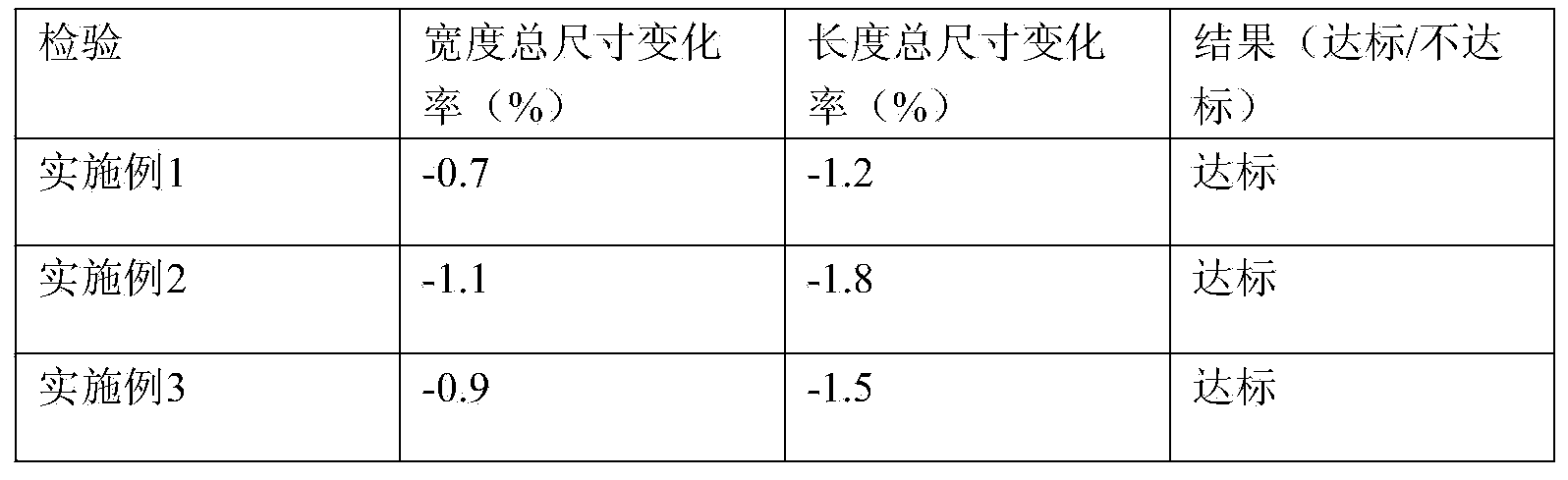

Method for weaving composite fiber heat-insulating fabric

The invention discloses a method for weaving composite fiber heat-insulating fabric. The method includes the following steps: (1), raw material selection; (2), fiber pretreatment; (3), yarn spinning; (4), weaving; (5), aftertreatment. The method has the advantages that the method is novel in concept, simple, convenient, easy in operation and high in enforceability; non-heat-insulating raw material are adopted to weave an air layer structure, so that the composite fiber heat-insulating fabric has good heat-insulating performance, and cost of the fabric is lowered; four raw materials different in function are blended and woven to form the fabric, so that the fabric integrates various excellent performances of heat insulation, fashion, healthcare and skin friendliness; the fabric woven by the method has various comprehensive performances and is high in practicability, capable of meeting pursuit on clothing fabric of modern consumers and wide in market prospect on the basis that heat-insulating performance is guaranteed.

Owner:CHANGSHU TIANCHEN KNITTING

Phototherapy carpet with skin-friendly performance

ActiveCN108505346AImprove mechanical propertiesGood antibacterial effectFibre treatmentLight therapyYarnEngineering

The invention discloses a phototherapy carpet with skin-friendly performance. The phototherapy carpet comprises a phototherapy carpet body, an optical fiber woven fabric which is arranged on the phototherapy carpet body and is woven by weaving yarns and optical fiber yarns, and a light source box which is connected with one ends of the optical fiber yarns through light transmission optical fibers;the surfaces of the weaving yarns are covered with a skin-friendly layer; the skin-friendly layer is formed by spraying skin-friendly coating on the surfaces of the weaving yarns and then drying. According to the phototherapy carpet with the skin-friendly performance, disclosed by the invention, the optical fiber woven fabric for emitting light is formed by weaving the weaving yarns and the optical fiber yarns; the optical fiber yarns are inserted and woven in the weaving yarns, so that the mechanical property of the optical fiber woven fabric can be enhanced and the cost also can be saved; the skin-friendly layer is formed by spraying the skin-friendly coating on the surfaces of the weaving yarns so that the optical fiber woven fabric has very strong bacterium-inhibition performance andhealth of patients is ensured; the surfaces of the weaving yarns also can be smooth and cool and have a good touch feeling and an aromatic flavor, so that the comfort of the patients in a phototherapyprocess is improved.

Owner:苏州国科盈睿医疗科技有限公司

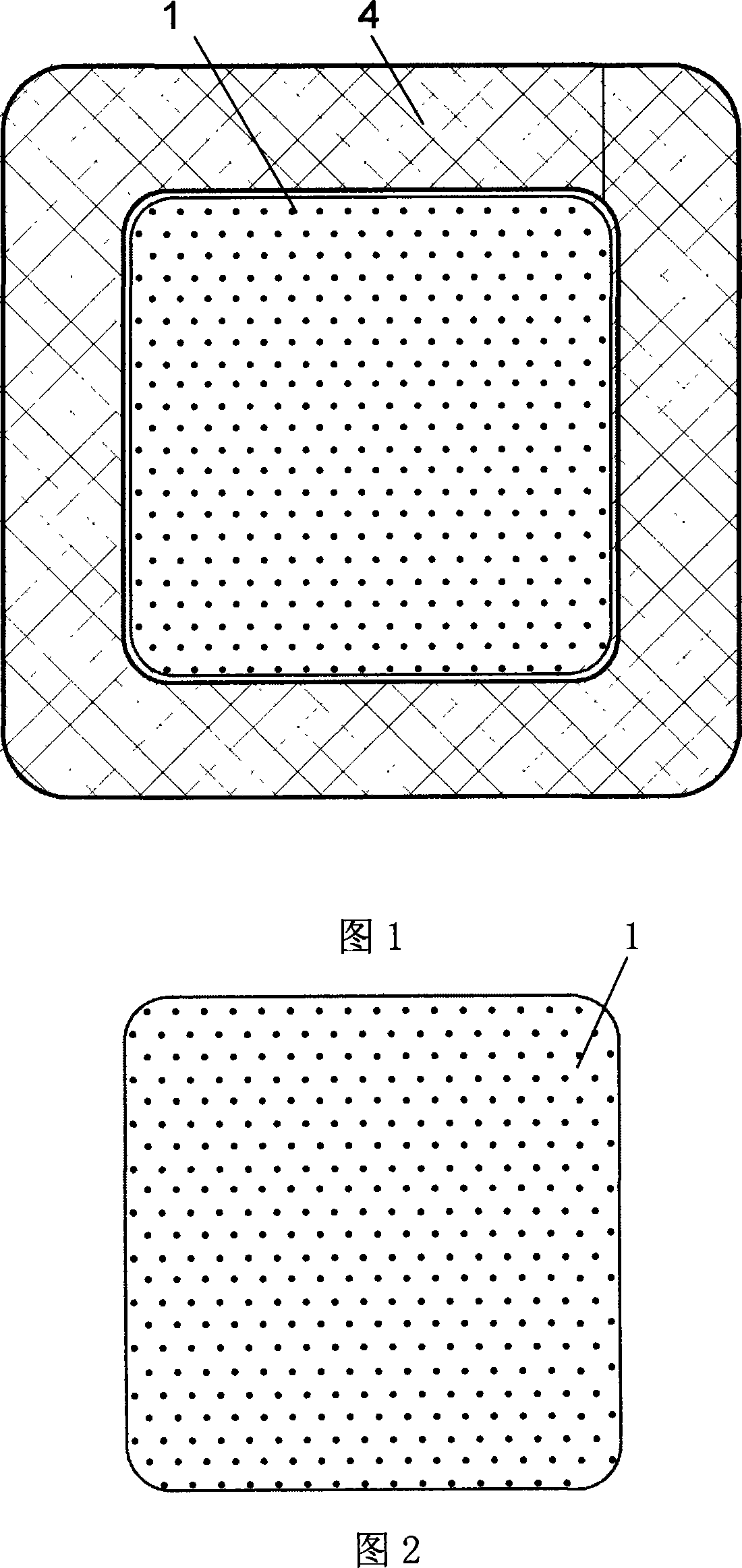

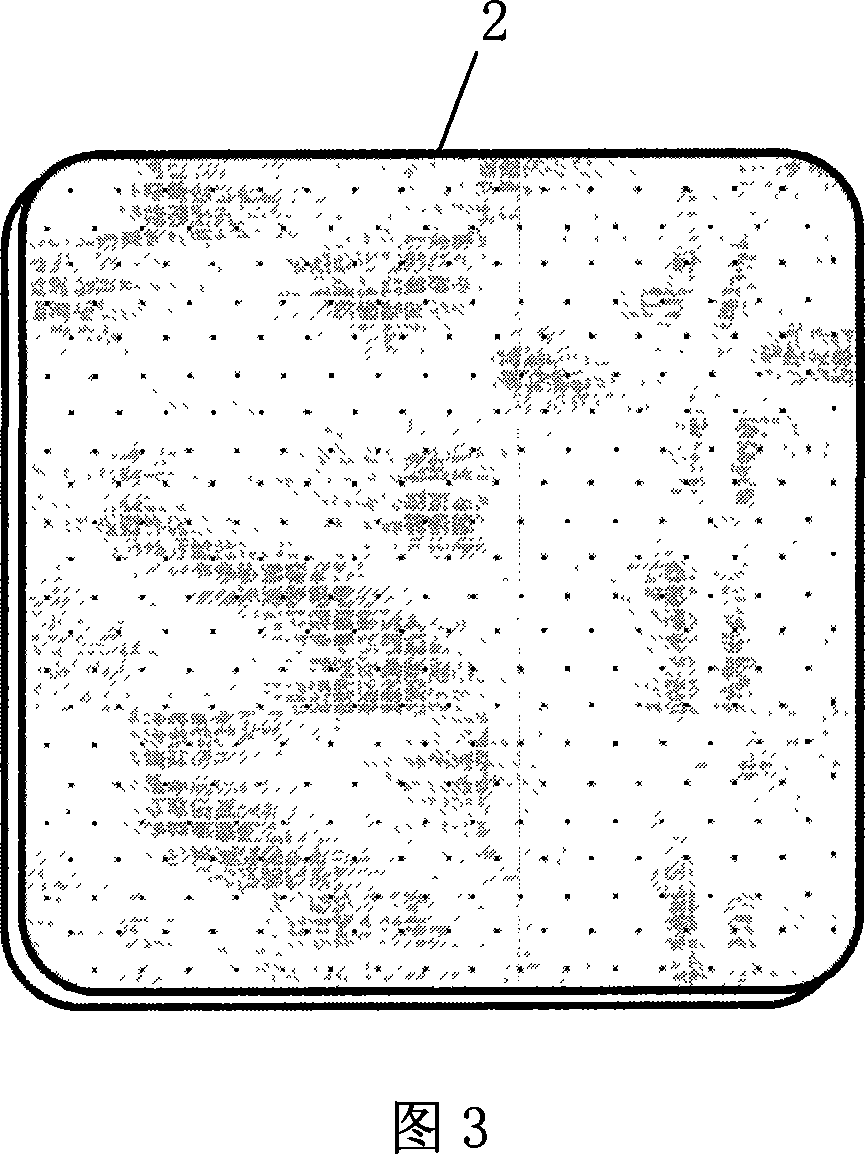

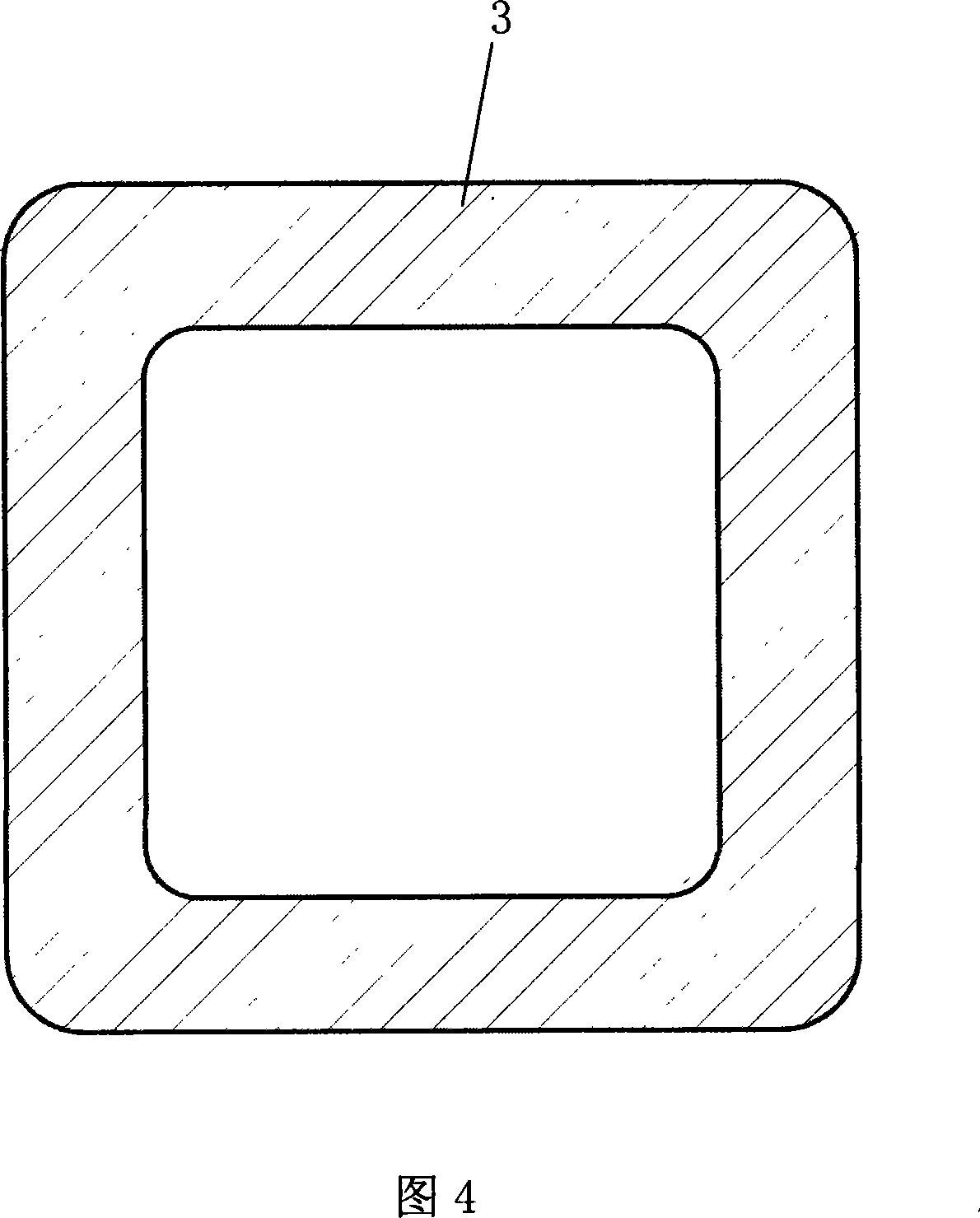

External fixed medical use paster for material with memory and bonding dressing, and method of application

InactiveCN101049519AStrong togetherSkin-friendlySurgeryPlastersUltimate tensile strengthBiomedical engineering

A medical paster for externally fixing the memory material and adhesive dressing in order to improve the respiratory function of lung and prevent complications is composed of an adhesive film paster, a dressing bag stuck on the central position of said film, a high-molecular memory material in said dressing bag, and a parting paper in the hollow square shape for surrounding said dressing bag. Its usage method is also disclosed.

Owner:张骥

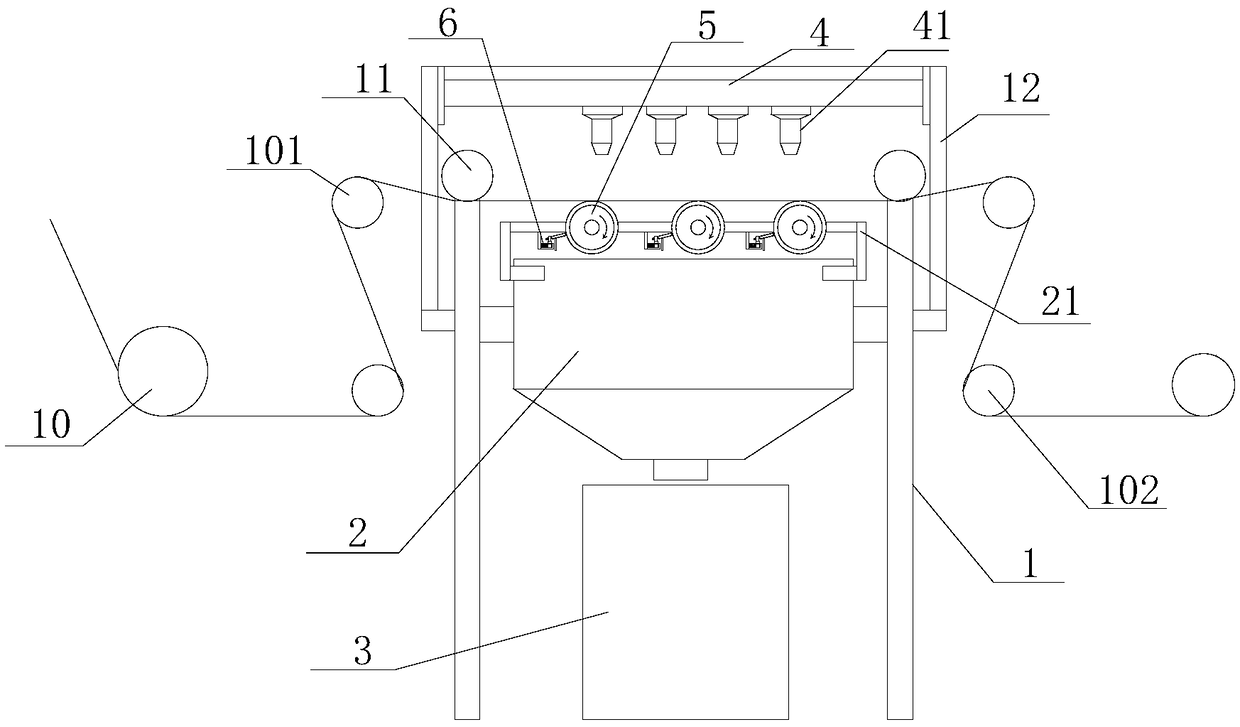

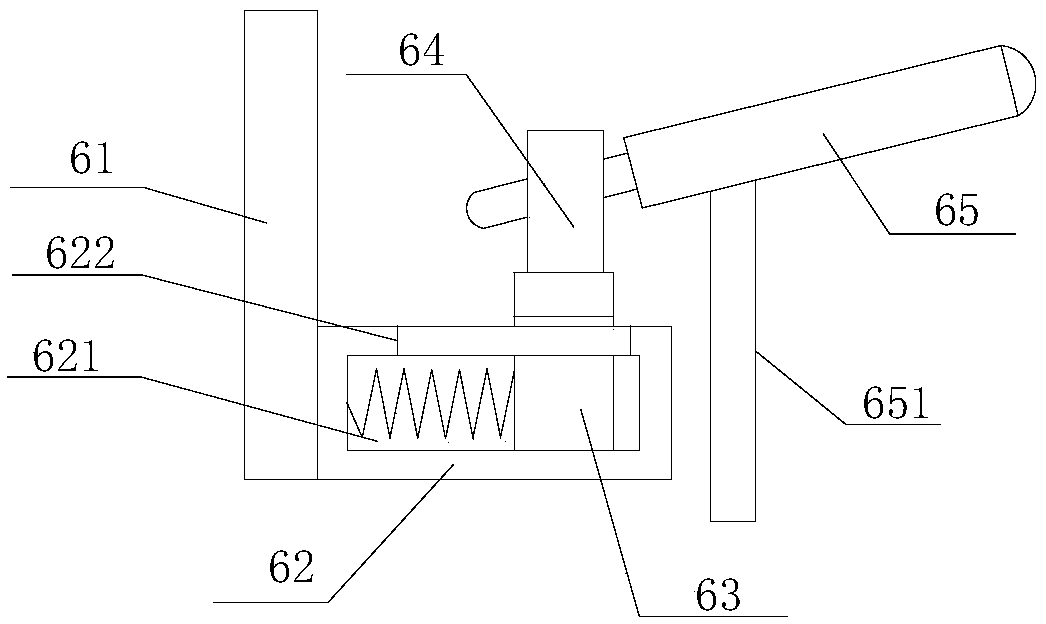

Novel flexible textile fabric, round-net continuous printing production technology and equipment

PendingCN108755167AExcellent elasticity and viscositySkin-friendlyScreen printersCoatingsEngineeringTextile

The invention discloses a novel flexible textile fabric, a round-net continuous printing production technology and equipment. The production technology comprises S1, obtaining a basic fabric layer; S2, printing liquid silica gel on the surface of the upper end of the basic fabric layer to form a fabric with the basic fabric layer and a liquid silica gel layer; S3, embedding fluff on the surface ofthe upper end of the liquid silica gel layer to form a fabric with the basic fabric layer, the liquid silica gel layer and a fluff layer; S4, drying the fabric with the basic fabric layer, the liquidsilica gel layer and the fluff layer to form a fabric with the basic fabric layer, a silica gel fabric layer and a fluff embedded fabric layer. By means of the novel flexible textile fabric, the round-net continuous printing production technology and the equipment disclosed by the invention, the production efficiency is improved, meanwhile skin friendliness and comfortableness of the fabric can meet requirements of people, and quality of printed finished products is ensured.

Owner:广东榕树谷智能系统有限公司

Artificial wig fibers containing peacock feather and having heat accumulation effect

InactiveCN105887236ADoes not damage the structureDoes not destroy colorConjugated cellulose/protein artificial filamentsGrip property fibresBiocompatibility TestingCarbon nanotube

The invention discloses artificial wig fibers containing peacock feather and having a heat accumulation effect. The wig fibers have the following steps of: (1) mixing polyacrylonitrile and collagen as a spinning raw solution, wherein composite fibers prepared from the spinning solution have good biocompatibility and excellent skin-friendly experience; (2) the peacock feather is treated into nanometer-magnitude fillers, so that natural biological structure and color of the peacock feather are not damaged and the natural feeling of the fibers is improved; nano bamboo charcoal powder and carbon nanotubes are added so that the fibers have the effects of accumulating heat, preserving heat, adjusting humidity and the like; and (3) the wig fibers prepared by the invention have the advantages of smooth hand feeling and skin friendliness, softness and dropping, heat accumulation and heat preservation and humidity elimination and foreign odor removal, and the quality and grade of synthetic fiber type wigs are remarkably improved.

Owner:ANHUI PEACOCK PRINCESS ARTS & CRAFTS CO LTD

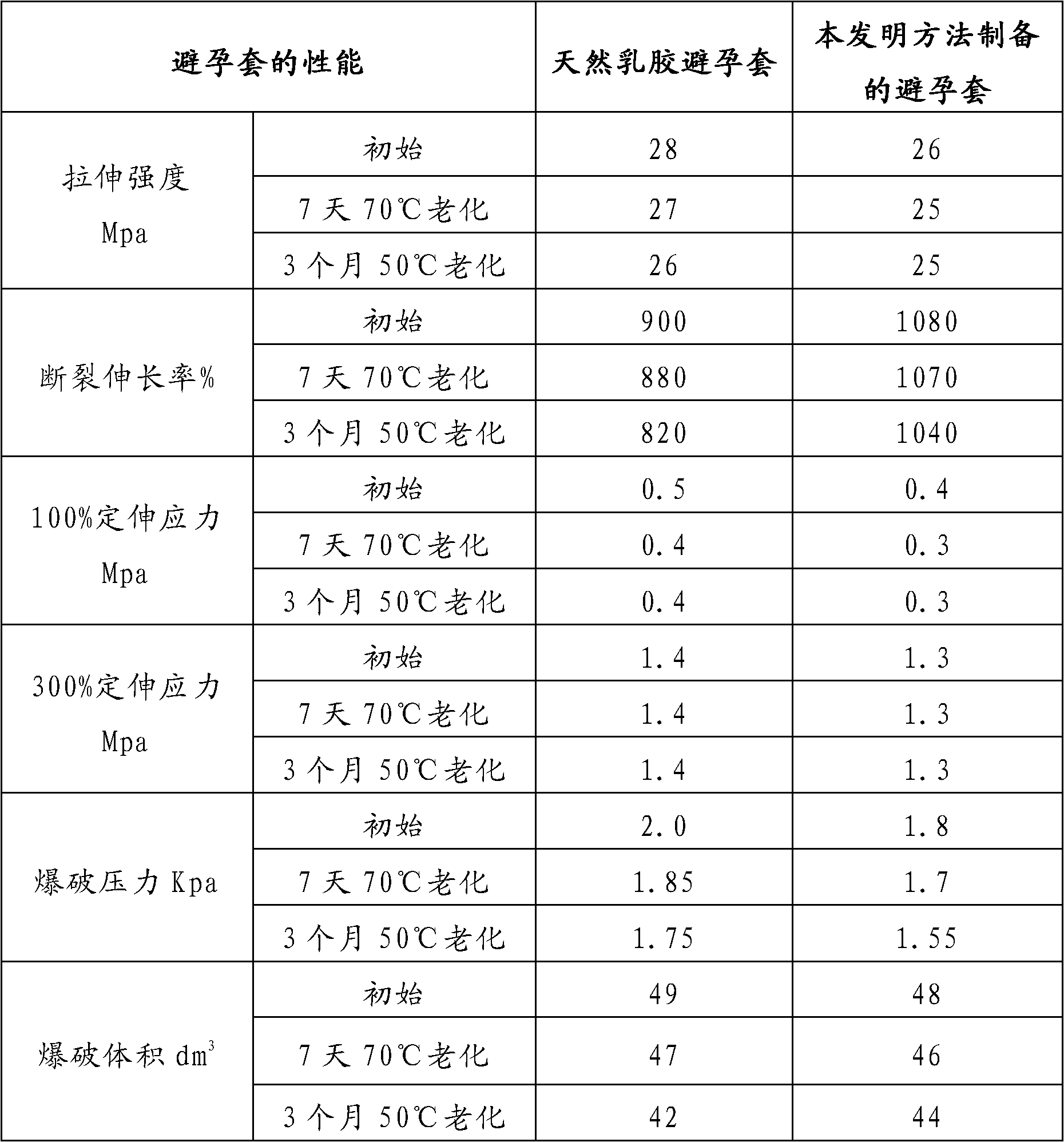

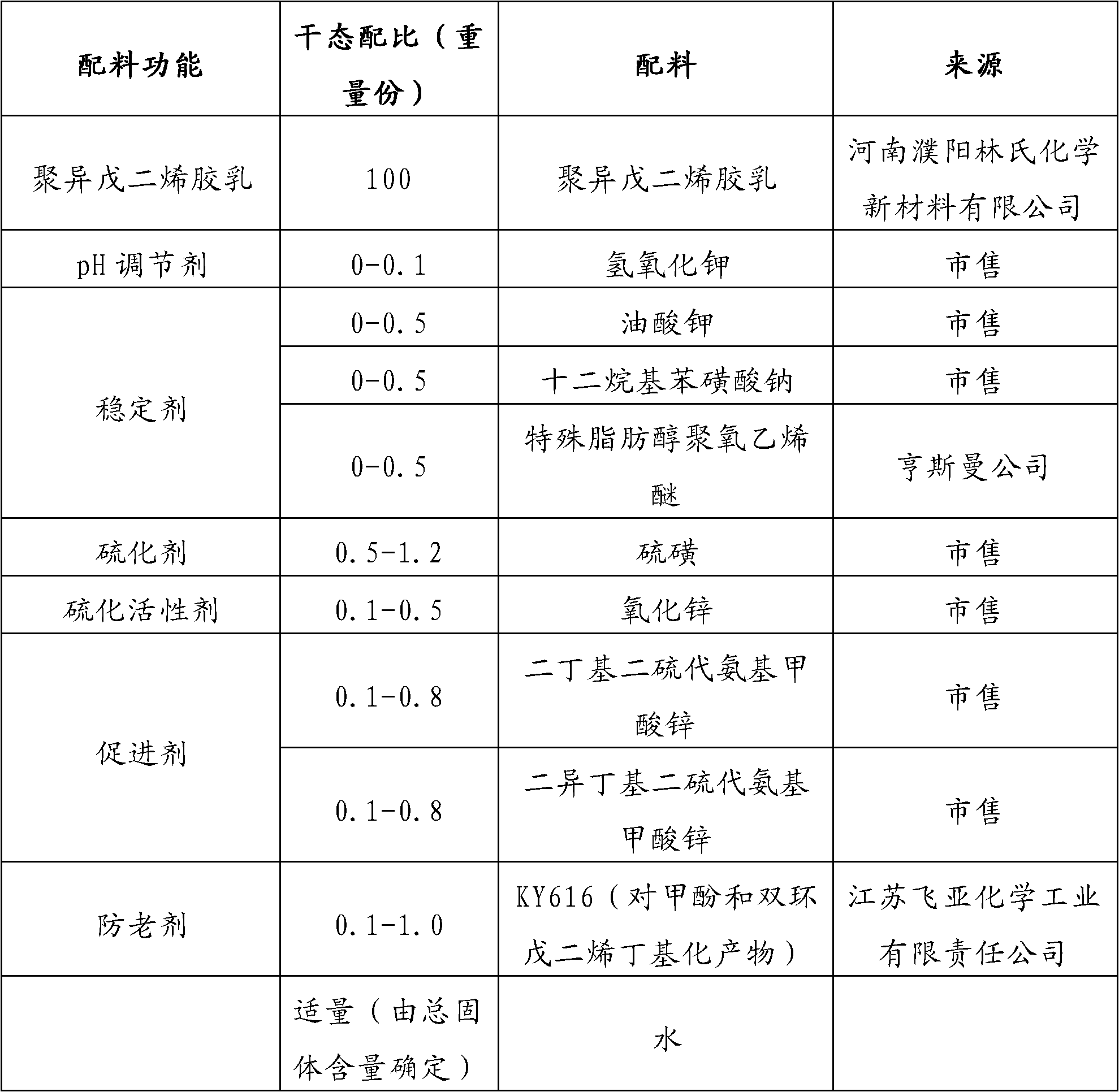

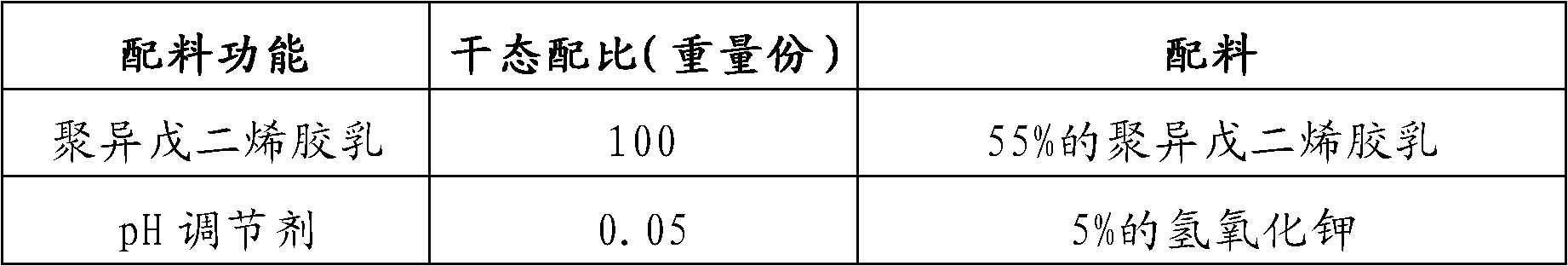

Method for preparing condom by using polyisoprene rubber latex

The invention discloses a method for preparing condom by using a polyisoprene rubber latex. The method comprises the steps of mixing the polyisoprene rubber latex and a proper amount of mixed component at the temperature of 20-26 DEG C to obtain a mixed latex, controlling a total solid content within 48-52% and a pH value of 10.3-10.8 during the mixing process, and standing the latex for ripening; immersing a condom mould with a proper shape in the mixed latex ripened in the step S1, and taking out the immersed condom mould and drying at the temperature of 80-90 DEG C, so as to form an adhesive film on the immersed condom mould; performing treatment of regular rolled hem, drying, swelling, removing the mould, foaming and powdering and dehydrating on the adhesive film formed on the immersed condom mould, and drying and vulcanizing the adhesive film at the temperature of 105-115 DEG C to form the condom. The obtained condom can reach required tensile strength and elongation with no need of mixing the polyisoprene rubber latex at a low temperature and immersing the condom mould.

Owner:SHANGHAI MINGBANG RUBBER PROD

Top-grade shirt fabric formed by interweaving long stapled cotton and mulberry silk

ActiveCN104082888AConvenient careOvercome the shortcomings of poor washing and easy shrinkageSucessive textile treatmentsBiochemical fibre treatmentBreaking strengthYarn

The invention discloses a top-grade shirt fabric formed by interweaving long stapled cotton and mulberry silk. The top-grade shirt fabric is formed by blending 42-65wt% of Egyptian long stapled cotton and 35-58wt% of the mulberry silk, the Egyptian long stapled cotton is warp, the mulberry silk is weft, the density of the warp is 80-120 pieces per centimeter, the density of the weft is 58-65 pieces per centimeter, and the specification of yarn made of the long stapled cotton is 180 N / 3. The top-grade shirt fabric has the advantages that the Egyptian long stapled cotton is added to the mulberry silk, characteristics of cotton are integrated with real silk, the smooth and skin-care characteristics of a common real silk fabric are achieved, real silk raw materials are saved, and accordingly production cost is reduced, and the product can be popular with more consumers; meanwhile, due to the adoption of cotton yarn, the fabric is easy to clean, the defects that the real silk is not suitable for being washed in water and is prone to wrinkling are overcome, water shrinkage is reduced, and elastic resilience, wear resistance, breaking strength and moisture absorption are improved; when the fabric is worn next to the skin, and the fabric does good to the human body, enables the skin to be smooth and has good moisture absorption performance and breathability.

Owner:苏州新超针纺织有限公司

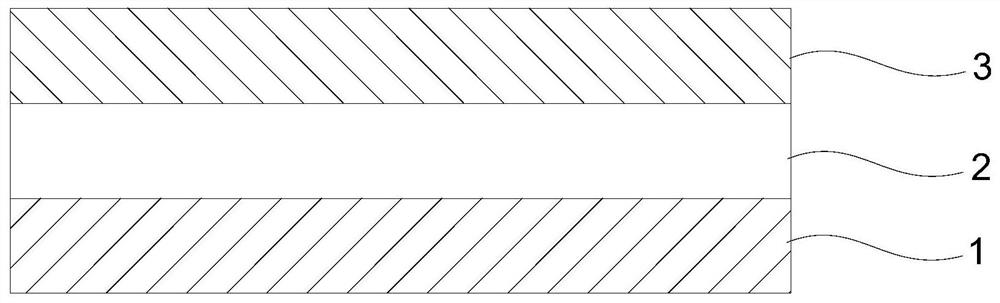

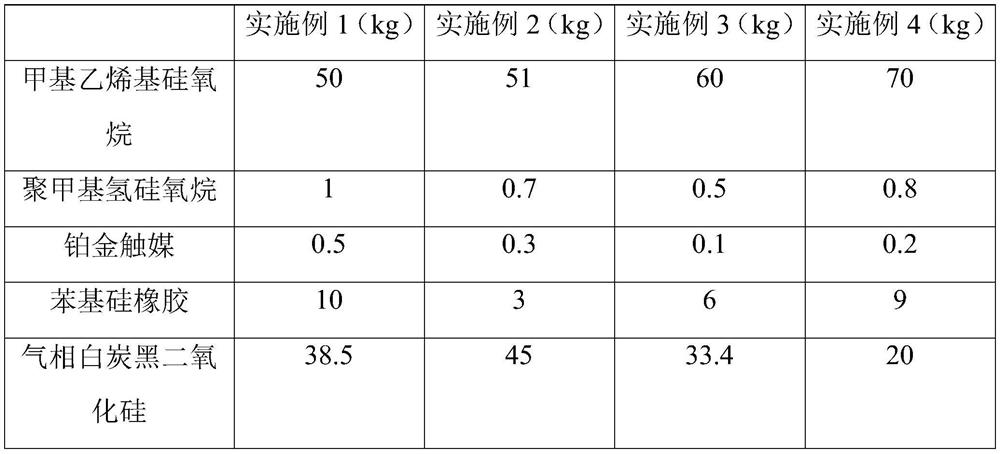

Soft wear-resistant silica gel leather and preparation method thereof

The invention belongs to the technical field of artificial leather, and particularly relates to soft wear-resistant silica gel leather and a preparation method thereof. The soft wear-resistant silica gel leather comprises a base material, a middle silica gel layer and a silica gel surface layer. The middle silica gel layer is arranged on the surface of the base material and comprises the following raw materials in percentage by mass of 50%-70% of methyl vinyl siloxane, 0.5%-1% of polymethylhydrosiloxane, 0.1%-0.5% of a platinum catalyst, 3%-10% of phenyl silicone rubber and 20%-45% of fumed silica. The silica gel surface layer is arranged on the surface of the middle silica gel layer and comprises the following raw materials in percentage by mass of 20-30% of methyl vinyl silicone resin, 30-50% of polymethylvinyl siloxane, 20-30% of fumed silica, 0.5-1% of polymethylhydrosiloxane, 0.1-0.5% of a platinum catalyst, 5-15% of matte reinforcing micro powder and 0.1-0.8% of fluorine-containing particles. According to the soft wear-resistant silica gel leather, the phenyl silicone rubber is added into the middle silica gel layer, and the phenyl and the fumed silica are introduced for reinforcement, so that the wear resistance is enhanced.

Owner:DONGGUAN TIANAN SILICONES TECH

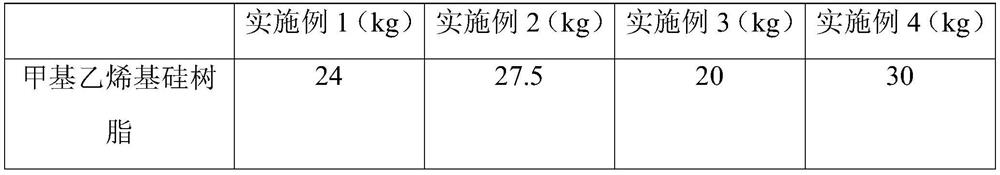

Aloe fiber, mint fiber and cotton blended yarn and production process thereof

InactiveCN105937073AImproved performance of individual spinningMoisture-absorbing and breathableYarnFiberYarn

The invention discloses aloe fiber, mint fiber and cotton blended yarn and a production process thereof. The yarn is composed of, by weight, 10%-50% of aloe fibers, 10%-50% of mint fibers and 40%-70% of cotton fibers; the aloe fibers have a good hygroscopic property and moisture releasability, good handfeel and fluffiness; the mint fibers have the advantages that the mint fibers are fragrant and deodorant, antisepsis and anti-inflammation are achieved, and a good hygroscopic property and air permeability are achieved; meanwhile, the cotton fibers have good absorption and air permeability; the three fibers are subjected to blending and make good for deficiency, and the obtained yarn has the effects of moisture absorption, air permeability, skin friendly and skin nourishing performance and lasting bacteriostasis.

Owner:南通中兴多元复合钢管有限公司

Shoulder pad dedicated for trachea cannulas

InactiveCN109692101ATo achieve the protective effectSweat hasTracheal tubesOperating tablesFlax fiberTrach tube

The invention discloses a shoulder pad dedicated for trachea cannulas. The shoulder pad comprises a pad body. The upper surface of the pad body is fixedly connected to a shoulder cushion and a neck cushion. The surface of one end of the shoulder cushion is fixedly connected to the surface of one end of the neck cushion. The surface of the pad body is in a convex shape. The surface of one side of the neck cushion is fixedly connected to a first connection belt. One end of the first connection belt is fixedly provided with a cannula fixer. The surface of one side of the upper end of the cannulafixer is provided with a threaded hole. The inner wall of the threaded hole is connected to a fixed bolt through threads. The other end of the cannula fixer is fixedly provided with a second connection belt. One free end of the second connection belt is fixedly connected to an insertion tongue. The provided shoulder pad can protect the neck of a patient; when the shoulder pad is used, the neck ofa patient contacts with the neck cushion, through the air holes, flax fibers in the neck cushion can exert a health care effect, and the neck of the patient is protected and relieved.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Warmth knitted fabric and preparation method thereof

InactiveCN104385752ANatural drape feels goodGood breathability and water absorptionLayered productsClothingsYarnAdditive ingredient

Owner:HUZHOU NEW ZHONGHU KNITTED CLOTHING MAKING

Bacteriostatic non-woven fabric for paper diaper

InactiveCN111826943ASmall molecular weightGood water solubilityPhysical treatmentBiochemical fibre treatmentPolypropyleneWoven fabric

The invention discloses a bacteriostatic non-woven fabric for a paper diaper, and relates to the technical field of novel functional materials. Spun-bonded polypropylene non-woven fabric is preprocessed by vacuum plasma to be subjected to activation, and therefore dip-coated chitosan oligosaccharide can be combined with the surface of the non-woven fabric, and the manufactured bacteriostatic non-woven fabric is used for a surface layer, making contact with the human skin, of a paper diaper body. The paper diaper surface layer non-woven fabric manufactured according to a method does not requirea chemical cross-linking agent, has the good air permeability and the good moisture permeability and also can effectively inhibit microorganisms from breeding. Compared with the prior art, the bacteriostatic non-woven paper diaper made of the bacteriostatic non-woven fabric has the advantages of being bacteriostatic, skin-friendly and environmentally friendly and being free of pollution. Meanwhile, the antistatic performance and the moisture absorption performance of the non-woven fabric are improved to a certain extent compared with the performance of a common product, and the comfort of theproduct is improved.

Owner:VINDA PAPER ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com