Warmth knitted fabric and preparation method thereof

A knitted fabric, warm-keeping technology, which is applied in the field of clothing fabrics to achieve the effect of increasing the count, increasing the textile density, and good hygroscopicity of silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

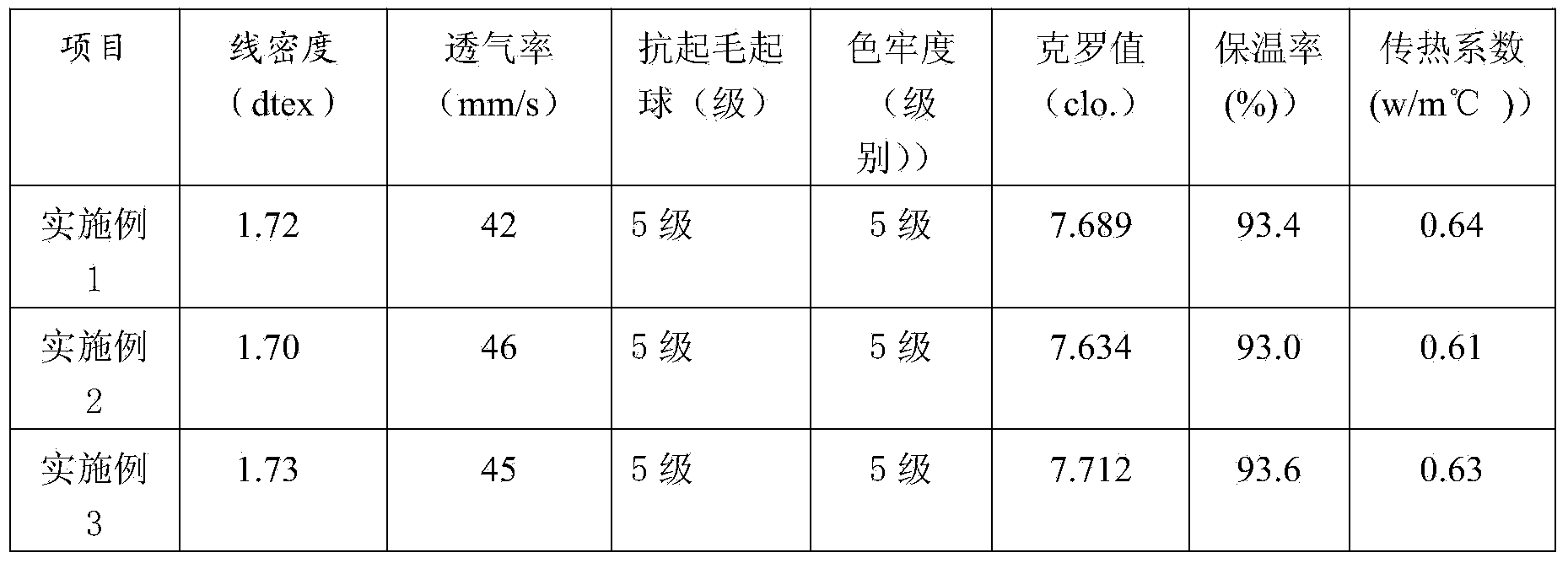

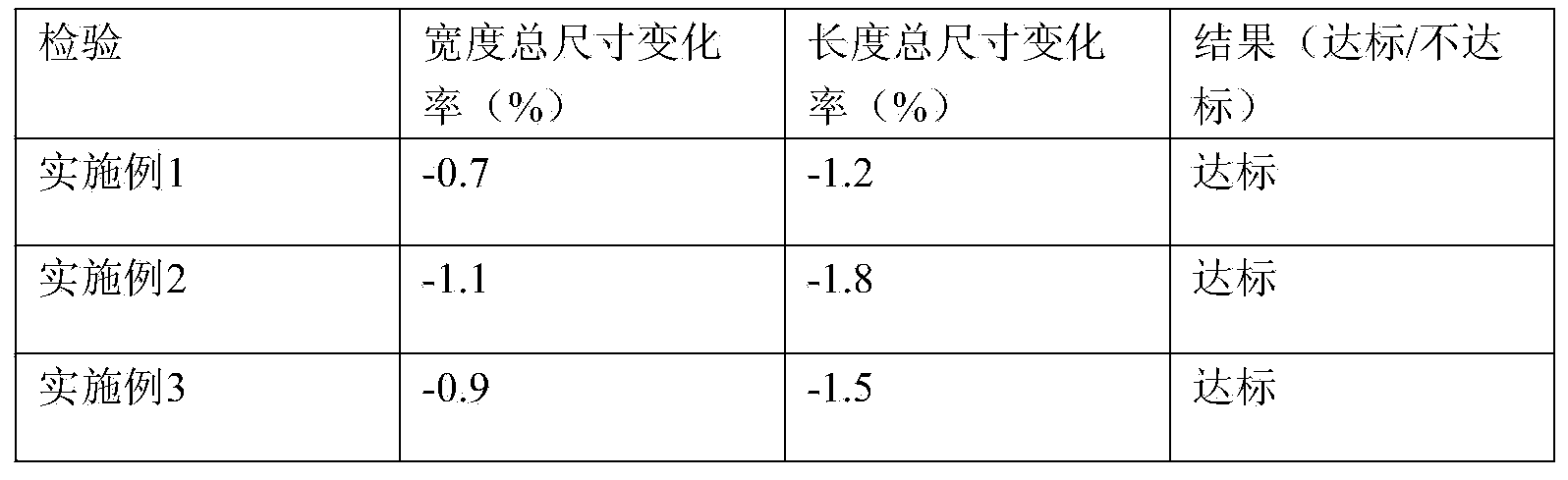

Embodiment 1

[0034] A preparation method of warm-keeping knitted fabric is as follows:

[0035] 1. Preparation of inner layer:

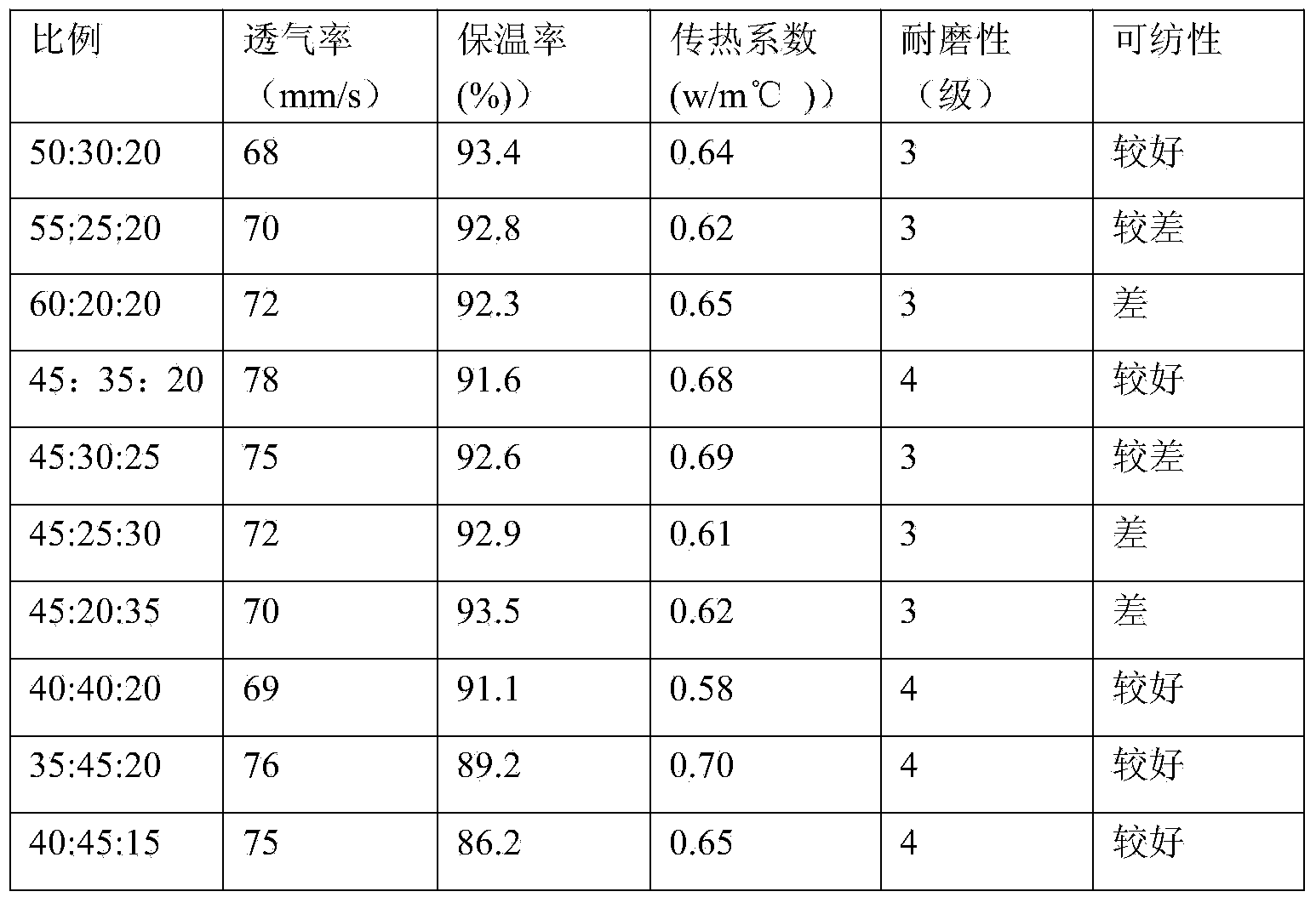

[0036] First, mercerize the wool, soak the wool in 20% NaOH solution for 40 seconds at 20°C, mix wool, silk, and cashmere in a ratio of 45:35:20 to prepare functional yarns . First, the inner layer is blended and woven, and then dyed, fixed, washed, sizing, weaving, desizing, washed, pre-dried, shaped and baked, and finally the inner layer fabric is made.

[0037] Among them, dyeing is the use of cheese dyeing technology. Yarn moisture regain control equipment is used to control the moisture regain of the package yarn, and the yarn loading robot is used to load the package yarn after the controlled moisture regain on the sarong, and the automatic crane is used to move the sarong to the pre-dyeing buffer area, and then from the pre-dyeing buffer area Move to the vertical dyeing machine, and use the vertical dyeing machine to dye the package yarn after the moist...

Embodiment 2

[0044] A preparation method of warm-keeping knitted fabric is as follows:

[0045] 1. Preparation of inner fabric

[0046] First, mercerize the wool, soak the wool in 22% NaOH solution for 30 seconds at 25°C, mix wool, silk, and cashmere in a ratio of 45:35:20 to prepare functional yarns . First, the inner layer is blended and woven, and then dyed, fixed, washed, sizing, weaving, desizing, washed, pre-dried, shaped and baked, and finally the inner layer fabric is made.

[0047] Among them, dyeing is the use of cheese dyeing technology. Yarn moisture regain control equipment is used to control the moisture regain of the package yarn, and the yarn loading robot is used to load the package yarn after the controlled moisture regain on the sarong, and the automatic crane is used to move the sarong to the pre-dyeing buffer area, and then from the pre-dyeing buffer area Move to the vertical dyeing machine, and use the vertical dyeing machine to dye the package yarn after the moist...

Embodiment 3

[0054] A preparation method of warm-keeping knitted fabric is as follows:

[0055] 1. Preparation of inner fabric

[0056] First, mercerize the wool, soak the wool in 24% NaOH solution at 25°C for 20 seconds, then mix wool, silk, and cashmere in proportions of 45%, 35%, and 20% to prepare functional fabrics. Yarn lines. First, the inner layer is blended and woven, and then dyed, fixed, washed, sizing, weaving, desizing, washed, pre-dried, shaped and baked, and finally the inner layer fabric is made.

[0057] The aforementioned dyeing is to utilize the cheese dyeing technique. Yarn moisture regain control equipment is used to control the moisture regain of the package yarn, and the yarn loading robot is used to load the package yarn after the controlled moisture regain on the sarong, and the automatic crane is used to move the sarong to the pre-dyeing buffer area, and then from the pre-dyeing buffer area Move to the vertical dyeing machine, and use the vertical dyeing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com