Baby diaper

A technology for diapers and babies, applied in the field of daily necessities, can solve problems such as poor leak-proof performance, poor air permeability of waterproof materials, etc., and achieve the effects of increasing bearing capacity, good electrostatic adsorption, and preventing side leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

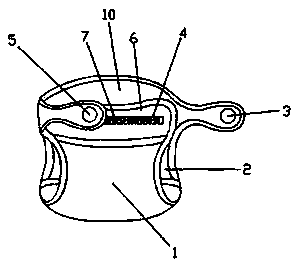

[0043] Such as Figure 1 to Figure 5 As shown, a baby diaper comprises a front part 6, a middle part 1 and a rear part 2, the front part 6 is connected to the middle part 1, the middle part 1 is connected to the rear part 2, and the front part 6 is provided with Velcro 4 and some Velcro holes 7 on the surface of Velcro 4, the middle part 1 includes a urine pad; the rear part 2 includes a rear waist 10, a first Velcro 3 and a second Velcro 5, the rear The waist 10 is provided with two extension sections, the first magic button 3 and the second magic button 5 are located at the ends of the two extension sections of the back waist 10 respectively, the first magic button 3 and the second magic button 5 Fastened with the hook and loop hole 7, the urine pad has a layered structure, which includes an adsorption layer, an absorption layer, a first expansion layer, a second expansion layer, and a leak-proof layer from top to bottom. The adsorption layer is woven by modified nano-polyv...

Embodiment 2

[0045] Such as image 3As shown, the modified nano-polyvinyl alcohol electrostatic wire is prepared by the following steps,

[0046] Step 1: Weigh 1 part of cellulose, take an appropriate amount of deionized water and stir to dissolve, add tetramethylpiperidine oxide to the solution according to the molar ratio of cellulose: tetramethylpiperidine oxide 1:0.05, according to the cellulose: Add sodium hypochlorite to the solution at a molar ratio of sodium hypochlorite of 1:1 to adjust the pH of the system to 10.3, and stir at room temperature for 24 hours;

[0047] Step 2: disperse the system into a gel form through a homogenizer, undergo ultrasonic treatment for 10 minutes, filter and then freeze-dry to obtain nanocellulose;

[0048] Step 3: Weigh 1 part of polyvinyl alcohol, take an appropriate amount of deionized water, heat to 80°C and maintain a constant temperature, stir for 2 hours until completely dissolved;

[0049] Step 4: Cool naturally to room temperature, dilute t...

Embodiment 3

[0052] Such as Figure 4 to Figure 5 As shown, the flexible absorbent fiber was prepared by the following steps,

[0053] Step 1: Weigh 1 part of xanthan gum, add an appropriate amount of deionized water, stir and dissolve, add acrylic acid with a neutralization degree of 85% to the xanthan gum solution according to the volume ratio of xanthan gum solution:acrylic acid solution=1:2.5 Solution, after stirring, add acrylamide solution to the mixed solution according to the volume ratio of acrylic acid solution: acrylamide solution = 1:1;

[0054] Step 2: Heat the mixed solution to 70°C, mix the solution according to the volume ratio: crosslinking agent = 1:0.05, add the crosslinking agent N,N-methylenebisacrylamide, and keep stirring at a constant temperature of 70°C for 1 hour;

[0055] Step 3: Heating to 85°C, adding the initiator potassium persulfate solution into the solution according to the volume ratio of crosslinking agent:initiator = 1:1, and continuing to stir at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com