Leather electric arc penetrating system

An arc and leather technology, applied in the field of leather arc penetration system, can solve the problems of chemical substances, health hazards, environmental pollution, poor water absorption, etc., achieve high practical value, reduce production processes, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

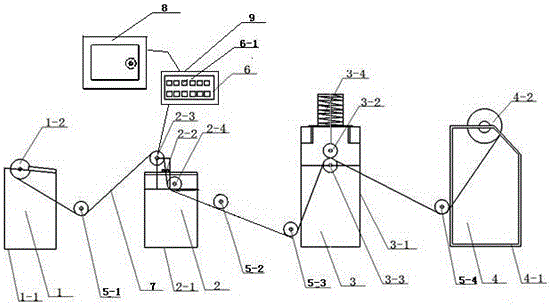

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] A leather arc penetration system, comprising an unwinder 1, a rolling car 3, a winder 4, an intermediate drive roller 5, and an arc penetration device 2, which includes a penetration bracket 2-1, a penetration Penetrating transmission roller, penetrating electrode 2-2, insulation board, high-voltage line, high-voltage package 6, high-voltage package integrated circuit board 6, high-voltage package electrical cabinet 9, adjustable voltage control cabinet 8, penetrating transmission roller includes the first penetrating transmission Roller 2-3, second penetrating drive roller 2-4, unwinder 1 includes unwinding support 1-1, unwinding roller 1-2, rolling car 3 includes rolling car support 3-1, cylinder 3-4, The first rolling car drive roller 3-2, the second rolling car driving roller 3-3, the rolling car motor, the cylinder 3-4 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com