Cup structure of bra and manufacturing method of cup structure

A technology for cups and bras, which is applied to the cup structure of bras and its production, which can solve the problems that bras cannot achieve light weight, breathability, and safety in use, and achieve good elasticity, stability, and skin-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

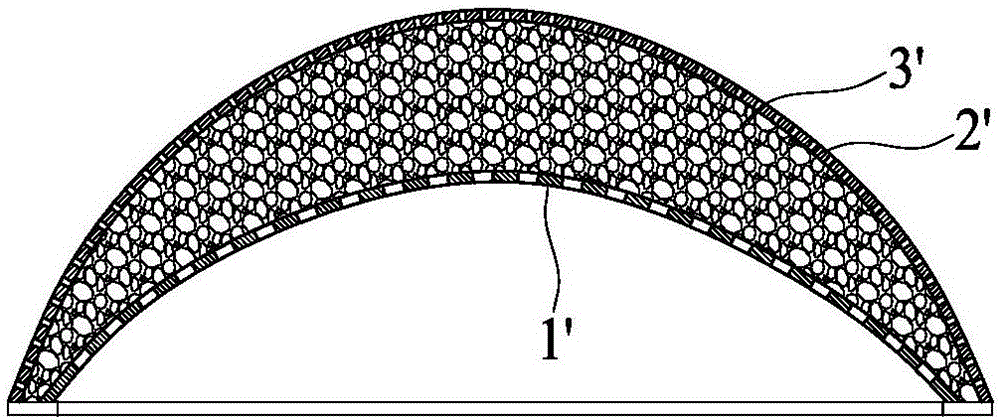

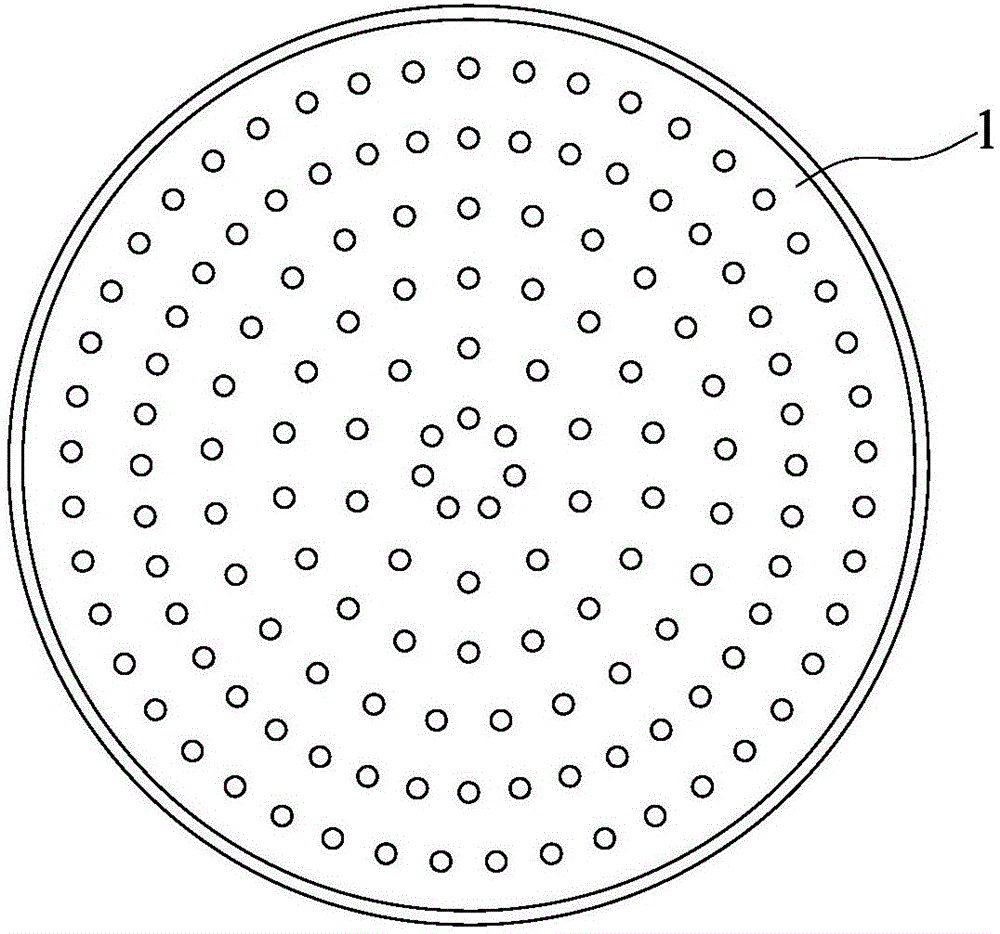

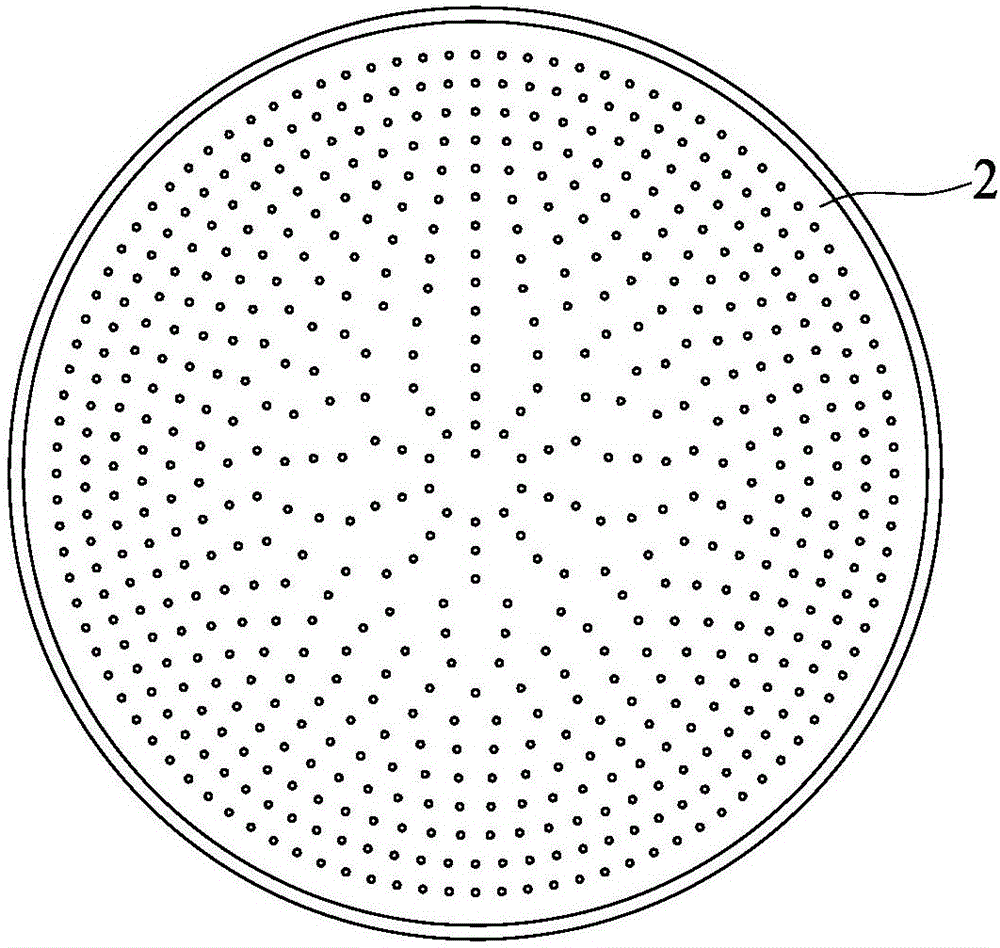

[0031] Such as Figure 2 to Figure 9 As shown, the present invention discloses a cup structure of a bra, which includes an inner layer 1, an outer layer 2 and a support body arranged between the inner layer 1 and the outer layer 2, and the materials of the inner layer 1 and the outer layer 2 are both Air-permeable material; the key point of the present invention is: the support body is a fence-like skeleton 3 .

[0032] The inner layer 1 and the outer layer 2 can be a mesh-like silicone layer or a latex layer, and the fence-like framework 3 can be a three-dimensional fence-like silicone framework or a latex framework.

[0033] The fence-like skeleton in this embodiment is described by taking the silica gel skeleton 3 as an example. The silica gel skeleton 3 forms a concave disk shape matching with a female breast, and is composed of several s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner layer thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com