Hydrophobic polyurea sealant and preparation method thereof

A technology of beautifying agent and polyurea, applied in the field of beautifying agent, can solve the problems of large taste, easy shrinkage and poor environmental protection of the beautifying agent, and achieve the effect of improving viscosity, storage stability, good stability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

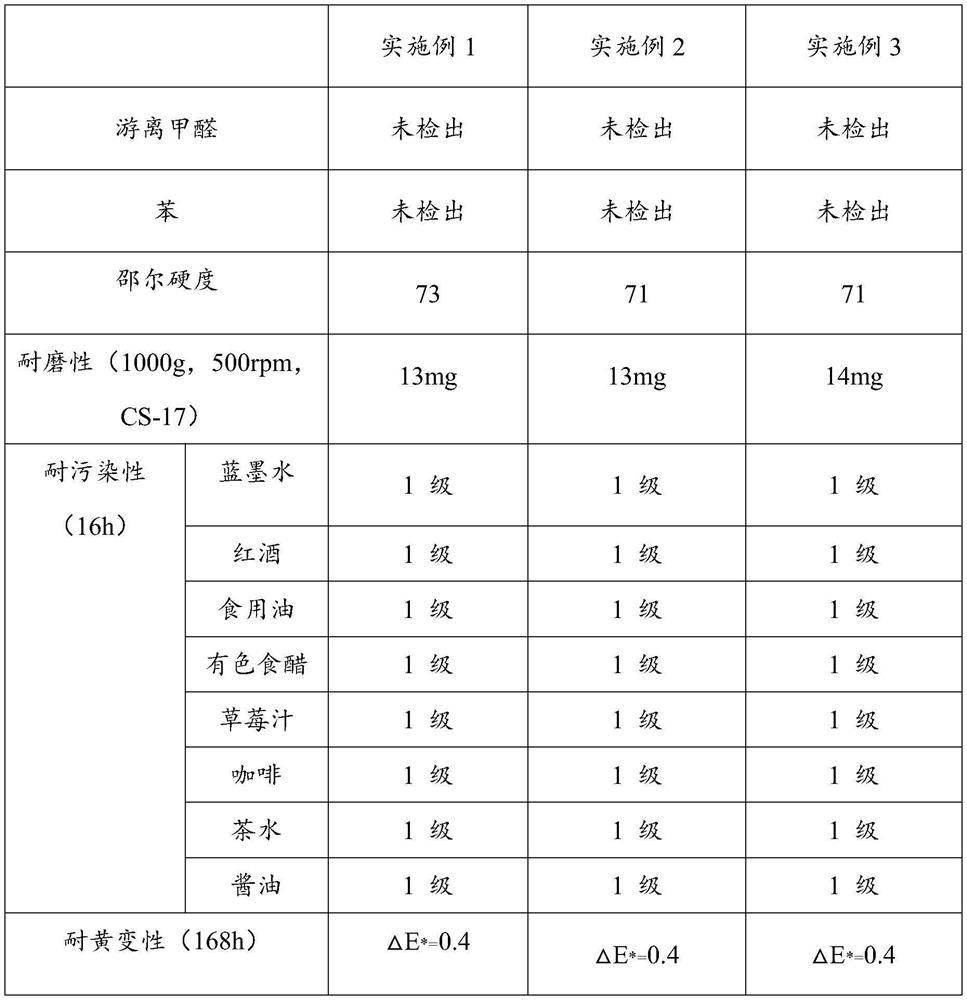

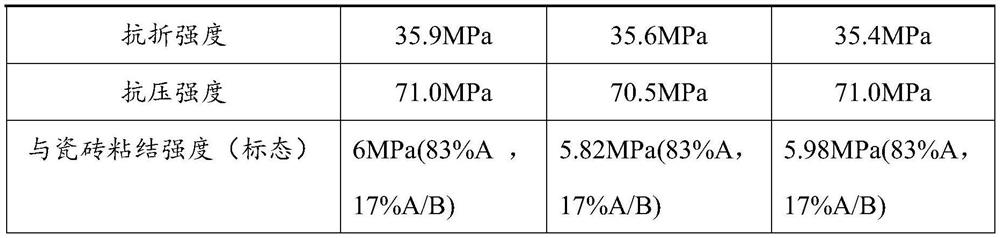

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of a hydrophobic polyurea seam beauty agent, comprising the following steps:

[0030] Preparation method of component A: firstly disperse polyurea resin 5240A, defoamer, dispersant and hydrophobic fumed silica at 1200-2000rpm for 40-80min, preferably at 1400-1700rpm for 50-70min, and further Preferably, disperse at 1500rpm for 60min; then add dispersant and pigment at a speed of 800-1200rpm, stir for 20-40min, preferably at a speed of 900-1100rpm, stir for 25-35min, more preferably at a speed of 1000rpm Stir for 30min at lower speed; Finally, under the speed of 400-600rpm, vacuum stirring for 40-80min obtains component A, preferably stirring 50-70min at the speed of 450-550rpm, more preferably stirring 60min at the speed of 500rpm;

[0031] The preparation method of component B: the polyurea curing agent 5240B, defoamer, dispersant and hydrophobic fumed silica are stirred for 40-80min under a protective atmosphere...

Embodiment 1

[0036] The preparation method of component A: First, 84.6 parts of polyurea resin 5240A, 0.2 parts of German BYK-A530 high-efficiency defoamer, 0.1 part of German BYK-2152 dispersant and 9 parts of hydrophobic fumed silica (Degussa R202) disperse at 1500rpm for 60min, then add 0.1 part of German BYK-2152 dispersant and 6 parts of titanium dioxide, stir at 1000rpm for 30min to adjust to the desired color, and vacuum at 500rpm for 60min to obtain component A;

[0037] Preparation method of component B: 89.8 parts of curing agent 5240B, 0.2 parts of BYK-A530 high-efficiency defoamer, 6 parts of hydrophobic fumed silica (Degussa R202), 4 parts of silane coupling agent at 1500rpm And under the protection of dry nitrogen, it was dispersed for 60 minutes, and the component B was obtained by vacuum stirring for 60 minutes at a speed of 500 rpm.

[0038] When in use, the two components A and B are mixed in a mass ratio of 1:1 to obtain a hydrophobic polyurea seam beauty agent.

Embodiment 2

[0040] The preparation method of component A: firstly, 85 parts of polyurea resin 5240A, 0.4 parts of BYK-014 high-efficiency defoamer from Germany, 0.2 parts of BYK-AT204 dispersant from Germany and 10 parts of hydrophobic fumed silica (Degussa R202) disperse at 2000rpm for 40min, then add 0.2 parts of German BYK-AT204 dispersant and 8 parts of iron oxide pigments, stir at 1200rpm for 20min and adjust to the desired color, and vacuum at 400rpm for 80min to obtain component A;

[0041] Preparation method of component B: 90 parts of curing agent 5240B, 0.4 parts of BYK-A530 high-efficiency defoamer, 8 parts of hydrophobic fumed silica (Degussa R202), 5 parts of silane coupling agent at 2000rpm And under the protection of dry nitrogen, the mixture was dispersed for 40 minutes, and the component B was obtained by vacuum stirring for 80 minutes at a speed of 400 rpm.

[0042] When in use, the two components A and B are mixed in a mass ratio of 1:1 to obtain a hydrophobic polyurea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com