Method for preparing condom by using polyisoprene rubber latex

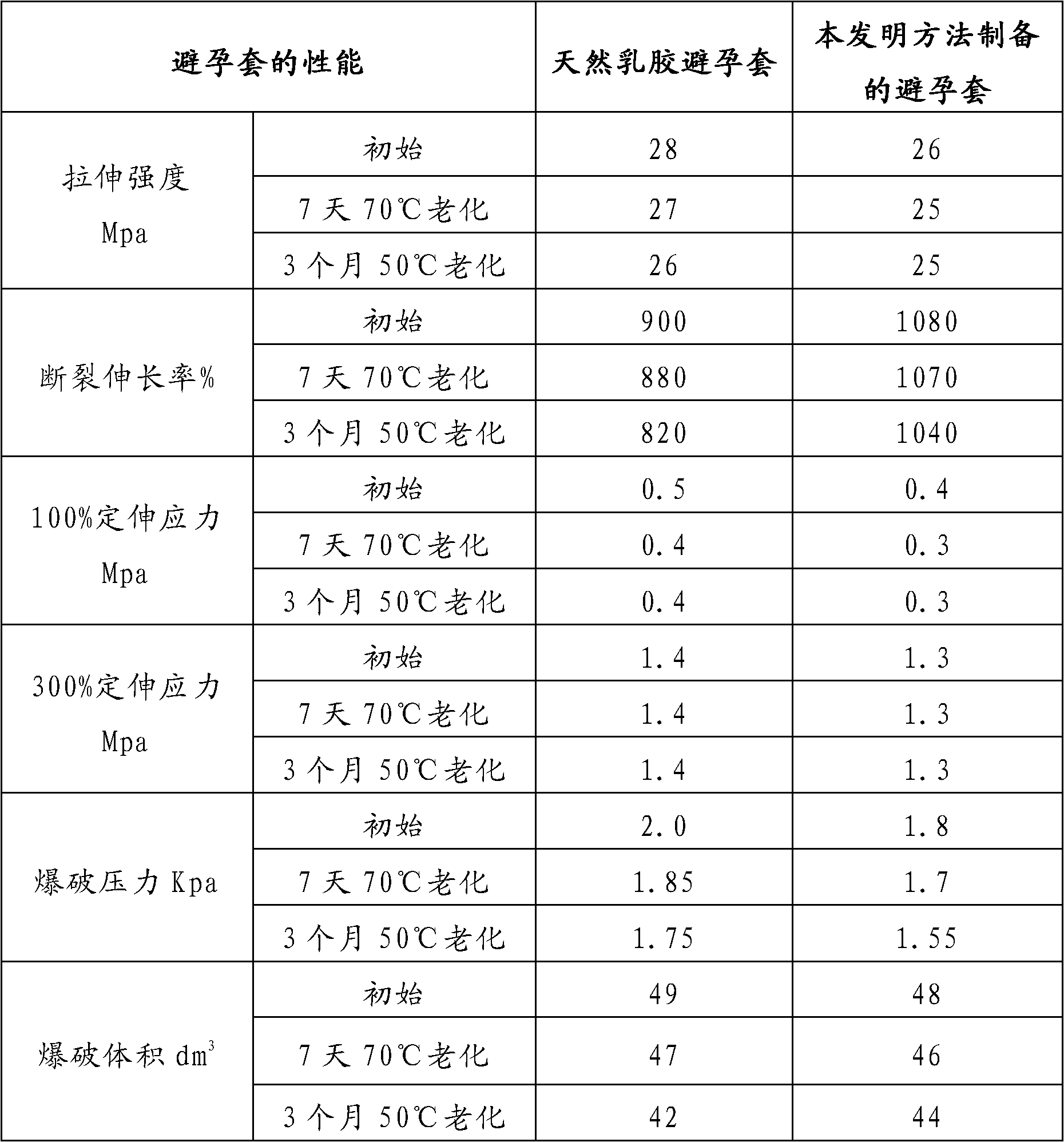

A polyisoprene and condom technology, applied in the coating and other directions, can solve the problems that the tensile strength of the condom does not meet the requirements and the production cost is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

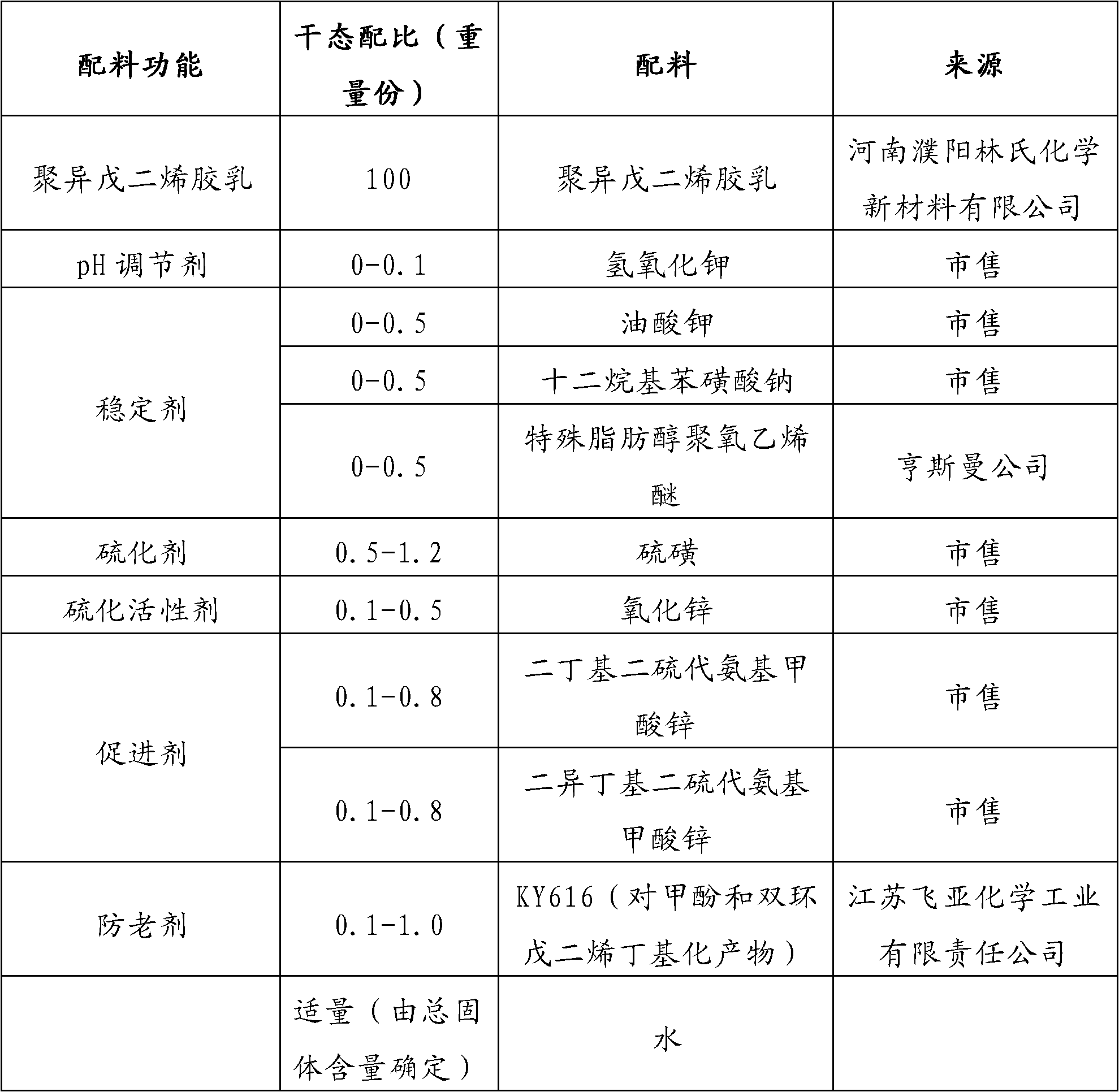

Method used

Image

Examples

Embodiment 2

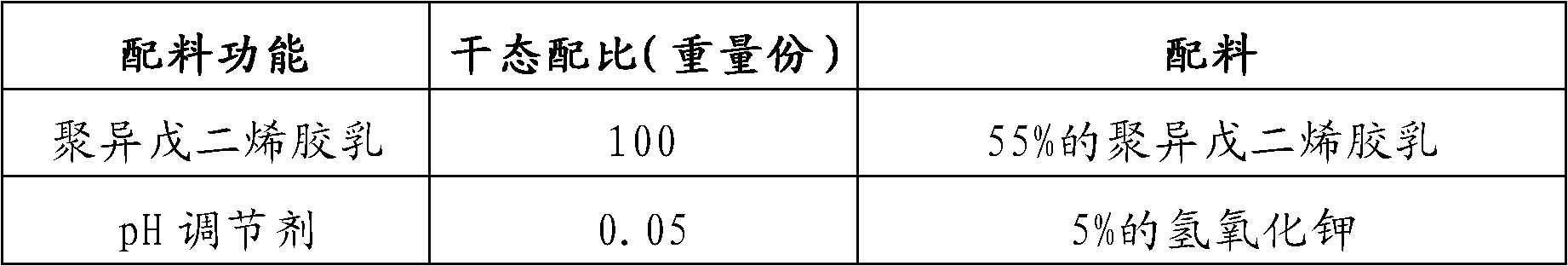

[0033] A specific example of the formulation according to Example 1 is as follows:

[0034]

[0035]

[0036] In the above table, the percentages in the "ingredients" column are the concentration of the aqueous solution of the ingredients, that is, the mass percentage of the solute contained in the solution per unit mass.

Embodiment 3

[0038] A kind of method that adopts polyisoprene latex to prepare condom, comprises the following steps:

[0039] S1: Mix the polyisoprene latex with the ingredients in Example 1, stir at a low speed (30-60 rpm) at 20-26°C for 24 hours, and control the total solid content at 49% during the mixing process, When the pH value is 10.5, the mixed latex is obtained, and the mixed latex is parked and matured for 5 days;

[0040] S2: Under the condition of 20-26°C, dip the condom mold with a suitable shape in the mixed latex after parked and matured for the first time, take out the condom mold and dry it at 80-95°C for 5 -10 minutes, until the film on the condom mold is transparent, then do the second impregnation at 20-26°C, and then dry at 80-95°C for 5-10 minutes until the condom mold is on The film is transparent;

[0041] S3: After conventional crimping, drying, swelling, mold removal, soaking, powdering, and dehydration, the film on the condom mold is dried and vulcanized at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com