Method for weaving composite fiber heat-insulating fabric

A composite fiber and fabric technology, applied in the direction of weft knitting, knitting, textiles and papermaking, etc., can solve the problems of inability to meet the comprehensive performance requirements of thermal insulation performance, high clothing price, single function, etc., to achieve simple weaving method, reduce The effect of fabric cost and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

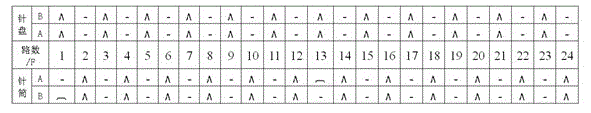

Method used

Image

Examples

Embodiment 1

[0028] A method for weaving a composite fiber thermal fabric, the specific steps are as follows:

[0029] (1) Raw material selection: select soybean protein fiber, polyester fiber, jade silkworm fiber and medical stone viscose fiber as raw materials for blended knitted sweaters; the fineness of the soybean protein fiber is 3.13-3.42dtex, and the average length is 80mm The fineness of the polyester fiber is 4.13~4.42dtex, and the average length is 60mm; the fineness of the silkworm fiber is 2.38~2.88dtex, and the average length is 40mm; the fineness of the medical stone viscose fiber is 1.71~1.93dtex, the average length is 40mm;

[0030] (2) Fiber pretreatment: Spray the pretreatment liquid containing antistatic agent and anti-slip agent on the surface of the raw material in step (1), and then spray a layer of textile lubricating oil, cover it with a plastic film and let it sit for 24 hours, and then use an open wool machine opening; the pretreatment solution is an aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com