Hot spicy poached almonds and processing method thereof

A processing method and almond technology, which are applied to the field of spicy boiled almonds and the processing thereof, can solve the problems of unsatisfactory, mushy taste, inconvenience in eating and the like, and achieve the effects of convenient eating, crisp taste and novel style.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

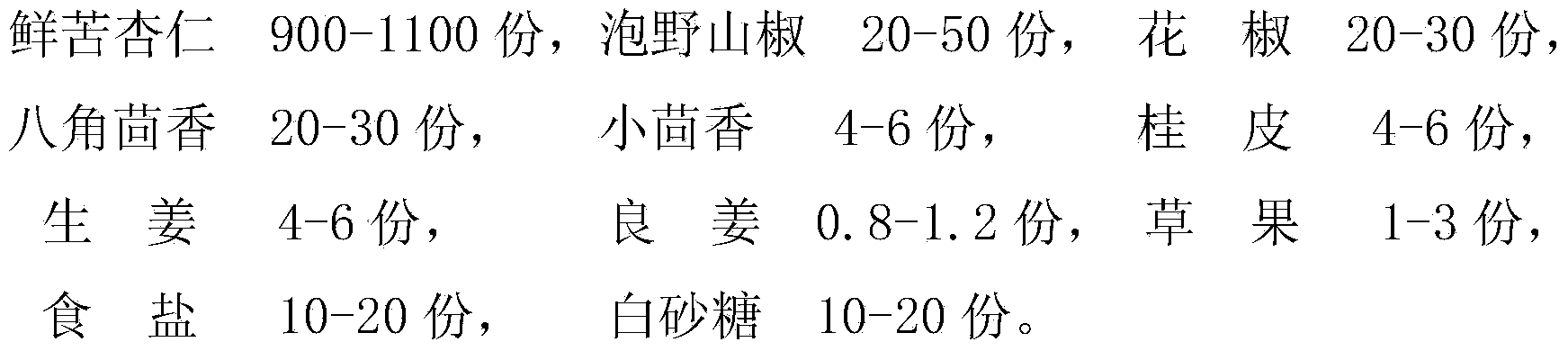

Embodiment 1

[0033] Weigh raw materials: 950kg of fresh bitter almonds, 40kg of soaked wild sansho, 22kg of Chinese prickly ash, 28kg of star anise, 4.5kg of cumin, 5.5kg of cinnamon, 4.5kg of ginger, 1.1kg of galangal, 1.5kg of grass fruit, 18kg of salt, and 12kg of white sugar .

[0034] processing methods:

[0035] a) Place fresh bitter almonds, soaked wild sansho, table salt, and white sugar separately; crush pepper, star anise, fennel, cinnamon, ginger, galangal, and tsaoko into fine powders, mix them evenly, and set aside;

[0036] b) Soak the fresh bitter almonds in a hot water pool at 98°C for 1.5 minutes, drain the water in the pool, and let it stand for 6 minutes. get blanched almonds;

[0037] c) Soak the peeled almonds in a warm water pool at 35°C for 3 days at a constant temperature, and perform debittering treatment. During the soaking period, change the water every 3 hours. After soaking, remove the almonds and drain the surface water for later use;

[0038] d) Put crushe...

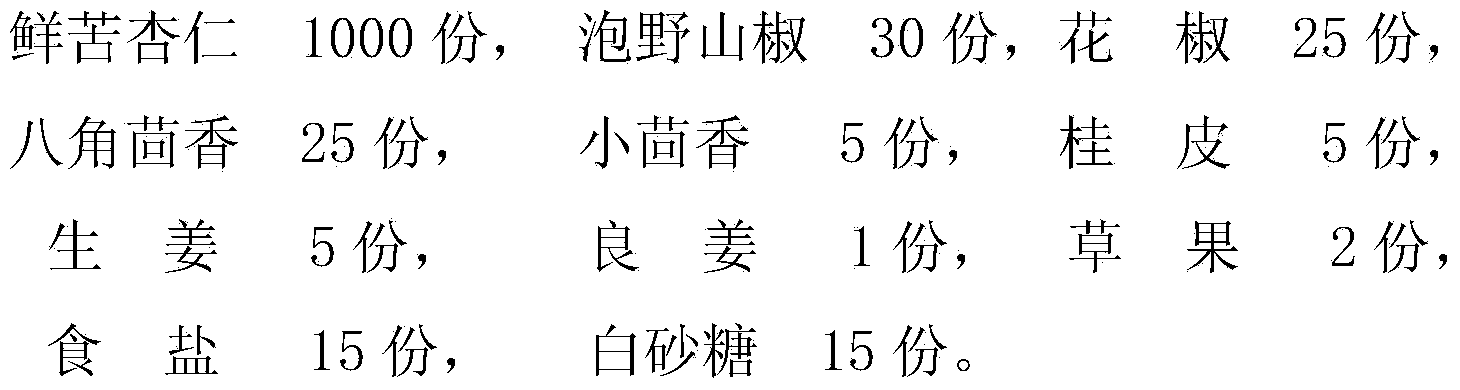

Embodiment 3

[0049]Weigh raw materials: 1000kg of fresh bitter almonds, 30kg of soaked wild sansho, 25kg of Chinese prickly ash, 25kg of star anise, 5kg of cumin, 5kg of cinnamon, 5kg of ginger, 1kg of galangal, 2kg of grass fruit, 15kg of table salt, and 15kg of white sugar.

[0050] processing methods:

[0051] a) Place fresh bitter almonds, soaked wild sansho, table salt, and white sugar separately; crush pepper, star anise, fennel, cinnamon, ginger, galangal, and tsaoko into fine powders, mix them evenly, and set aside;

[0052] b) Soak the fresh bitter almonds in a hot water pool at 95°C for 2 minutes, drain the water in the pool, and let it stand for 5 minutes. get blanched almonds;

[0053] c) Soak the peeled almonds in a warm water pool at 40°C for 2 days at a constant temperature, and perform debittering treatment. During the soaking period, change the water every 4 hours. After soaking, remove the almonds and drain the epidermis in clear water for later use;

[0054] d) Put cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com