Polyaniline nanometer flower-modified carbon cloth electrode and preparation method and application thereof

A carbon cloth electrode, polyaniline technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of carbon cloth electrodes and MFCs applications that have not been reported, and achieve low electrode cost, novel electrode morphology, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of polyaniline nanoflower-modified carbon cloth electrodes:

[0028] The purchased commercial carbon cloth was cut into a size of 1cm×2cm, and then assembled with a 12cm titanium wire to form an electrode, immersed in deionized water and ultrasonicated for 30min to drive away the air bubbles on the surface. Add tartaric acid aqueous solution (0.8mmol / 9mL water) and aniline monomer (5mL, 0.8M, 4mmol) successively to a 20cm glass bottle, and ammonium persulfate (APS) aqueous solution (2mL, 0.8M, 1.6mmol) is directly Add the above solution. Then, the ultrasonically treated carbon cloth connected with titanium wires was quickly immersed in the above-mentioned glass bottle, and finally the glass bottle was left standing for 12 hours at 0°C. The modified carbon cloth was taken out, washed three times with deionized water, and air-dried to obtain the polyaniline nanoflower-modified carbon cloth electrode.

Embodiment 2

[0030] The purchased commercial carbon cloth was cut into a size of 1cm×2cm, and then assembled with a 12cm titanium wire to form an electrode, immersed in deionized water and ultrasonicated for 30min to drive away the air bubbles on the surface. Add tartaric acid aqueous solution (0.8mmol / 8mL water) and aniline monomer (5mL, 0.8M, 4mmol) into a 20cm glass bottle successively, and ammonium persulfate (APS) aqueous solution (3mL, 0.8M, 2.4mmol) is directly Add the above solution. Then, the ultrasonically treated carbon cloth connected with titanium wires was quickly immersed in the above-mentioned glass bottle, and finally the glass bottle was left standing at 5° C. for 14 h. The modified carbon cloth was taken out, washed three times with deionized water, and air-dried to obtain the polyaniline nanoflower-modified carbon cloth electrode.

Embodiment 3

[0032] The purchased commercial carbon cloth was cut into a size of 1cm×2cm, and then assembled with a 12cm titanium wire to form an electrode, immersed in deionized water and ultrasonicated for 30min to drive away the air bubbles on the surface. Add tartaric acid aqueous solution (0.8mmol / 7mL water) and aniline monomer (5mL, 0.8M, 4mmol) to a 20cm glass bottle successively, and ammonium persulfate (APS) aqueous solution (4mL, 0.8M, 3.2mmol) is directly Add the above solution. Then, the ultrasonically treated carbon cloth connected with titanium wires was quickly immersed in the above-mentioned glass bottle, and finally the glass bottle was left standing for 16 hours at 0°C. The modified carbon cloth was taken out, washed three times with deionized water, and air-dried to obtain the polyaniline nanoflower-modified carbon cloth electrode.

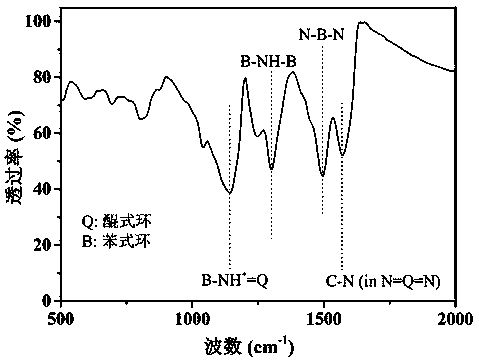

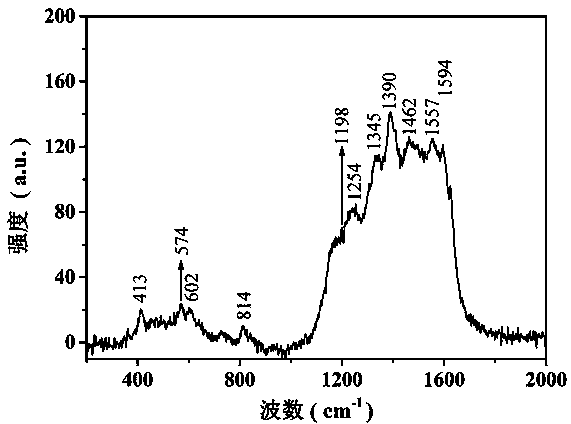

[0033] Infrared (such as figure 1 ) characterization, the results show that the functional groups contained in the conductive polyaniline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com