Carbon coated titanium manganese sodium phosphate composite material, preparation method and application thereof in sodium-ion battery

A composite material and carbon coating technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as environmental safety side effects, environmental and human harm, and less raw material sources, to improve crystal integrity and improve coating. Uniformity, the effect of improving electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment includes the following steps:

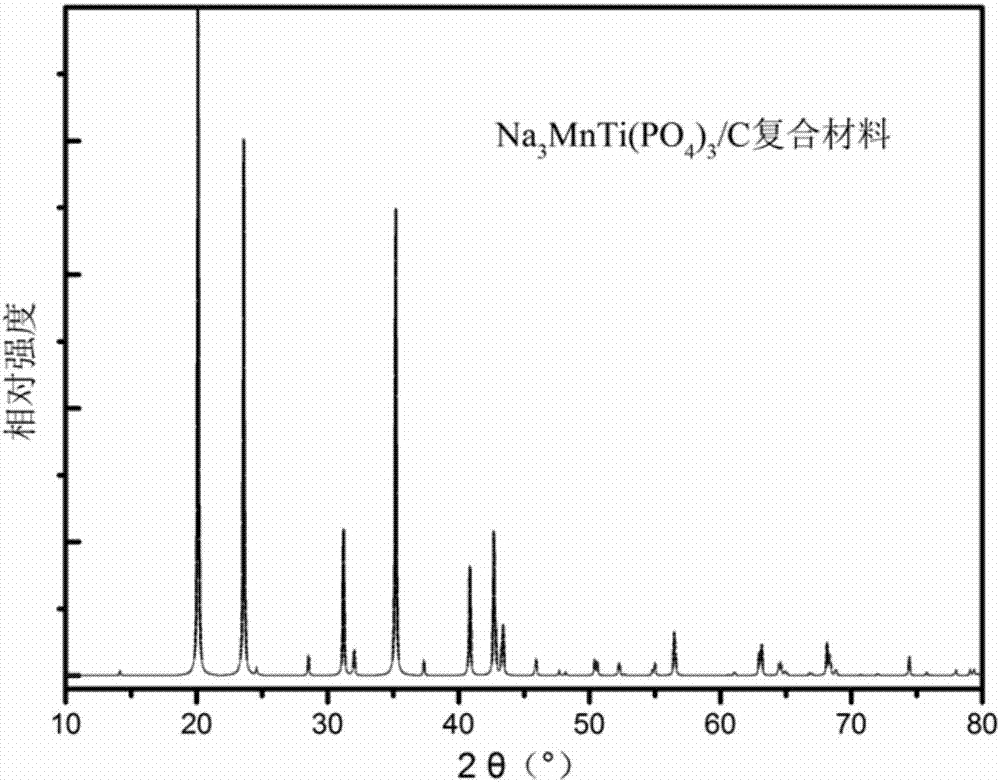

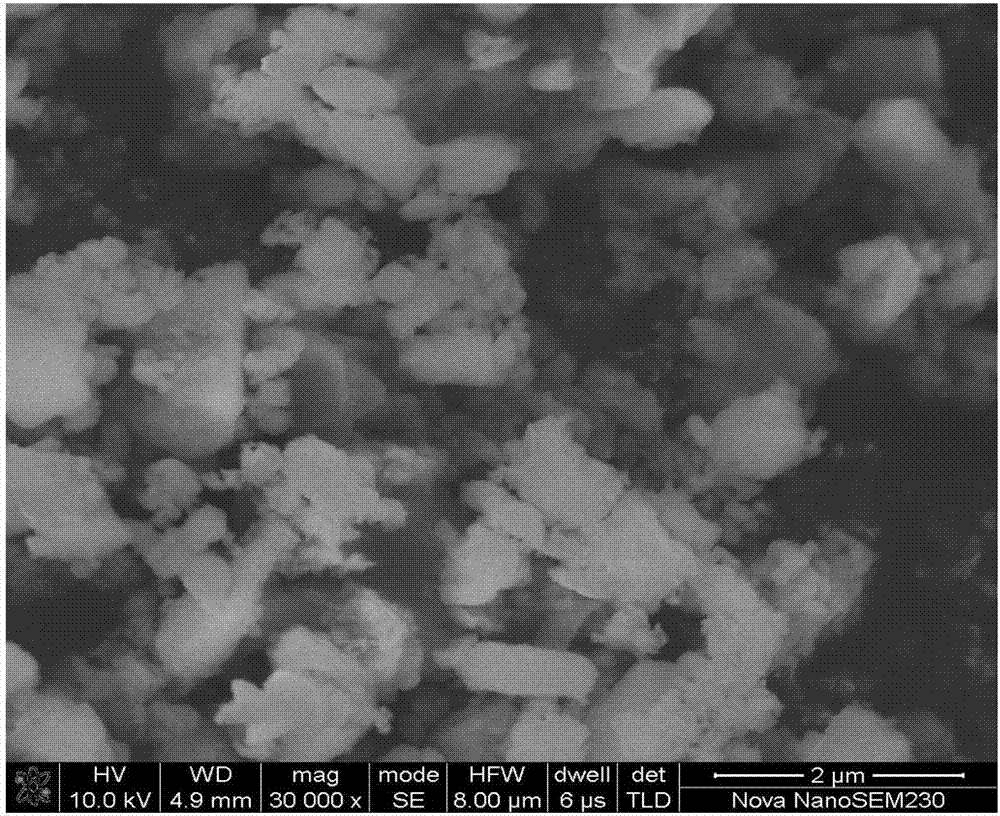

[0041] Step (1): This embodiment design generates 0.03mol target product Na 3 MnTi(PO 4 ) 3 / C composite material, 0.045mol sodium oxalate, 0.09mol ammonium dihydrogen phosphate, 0.03mol titanium dioxide, 0.03mol manganese dioxide, 1.45g glucose, add 1400g zirconia ball milling beads, and add a certain amount of acetone as the grinding medium;

[0042] Step (2): Ball milling at 800r / min for 12 hours, placed in an oven at 80°C for drying, crushed and ground, and passed through a 200-mesh sieve to obtain Na 3 MnTi(PO 4 ) 3 / C composite material precursor;

[0043] Step (3): The precursor obtained in step (2) is sintered at 350°C for 6 hours in a high-purity argon atmosphere, and then heated to 650°C for 12 hours at a heating rate of 5°C / min. Na can be obtained after natural cooling 3 MnTi(PO 4 ) 3 / C composite material;

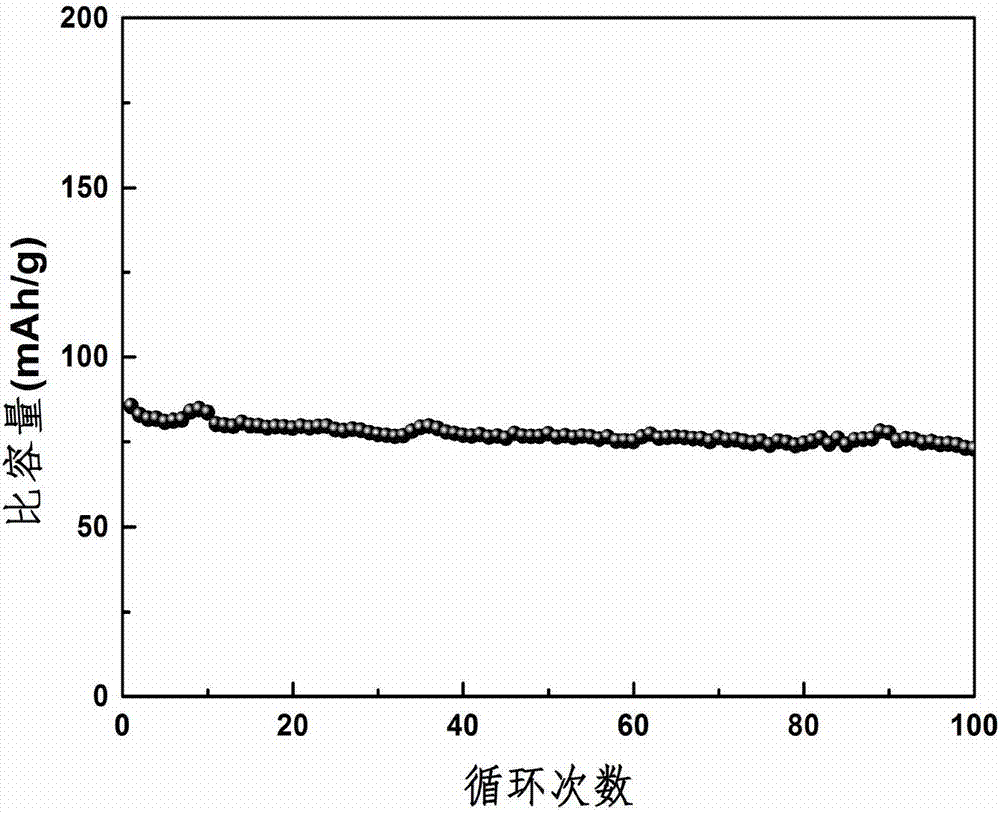

[0044] The sodium ion battery composite positive electrode material prepared in this example is...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] Step (1): This embodiment design generates 0.03mol target product Na 3 MnTi(PO 4 ) 3 / C composite material, 0.047mol sodium oxalate, 0.09mol ammonium dihydrogen phosphate, 0.03mol titanium dioxide, 0.03mol manganese dioxide, 1.45g glucose, 1400g zirconia ball milling beads were added, and a certain amount of acetone was added as the grinding medium;

[0051] Step (2): ball mill at 1000r / min for 24 hours, place in an oven at 80°C to dry, crush and grind and pass through a 100-400 mesh sieve to obtain Na 4 MnTi(PO 4 ) 3 / C composite material precursor;

[0052] Step (3): The precursor obtained in step (2) is sintered at 350°C for 6 hours in a high-purity argon atmosphere, and then heated to 750°C for 12 hours. The heating rate is 5°C / min, and Na can be obtained after natural cooling. 3 MnTi(PO 4 ) 3 / C composite material;

[0053] The battery assembly and test method of the material obtained in this embodimen...

Embodiment 3

[0055] This embodiment includes the following steps:

[0056] Step (1): This embodiment design generates 0.03mol target product Na 3 MnTi(PO 4 ) 3 / C composite material, add 0.043mol sodium oxalate, 0.09mol ammonium dihydrogen phosphate, 0.03mol titanium dioxide, 0.03mol manganese dioxide, 1.45g starch, add 1400g zirconia ball milling beads, and add a certain amount of acetone as the grinding medium;

[0057] Step (2): Ball milling at a speed of 1600r / min for 48 hours, placed in an oven at 80°C for drying, crushed and ground, and passed through a 100-400 mesh sieve to obtain Na 4 MnTi(PO 4 ) 3 / C composite material precursor;

[0058] Step (3): The precursor obtained in step (2) is sintered at 400°C for 8 hours in a high-purity argon atmosphere, and then sintered at 700°C for 18 hours. The heating rate is 5°C / min, and Na can be obtained after natural cooling. 3 MnTi(PO 4 ) 3 / C composite material;

[0059] The battery assembly and test method of the material obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com