Protein synthetic fibre spinning solution and its producing method

A technology of spinning dope and synthetic fibers, applied in the direction of cellulose/protein conjugated artificial filaments, fiber chemical characteristics, conjugated artificial filaments, etc., can solve fiber dyeability, color fastness, hot water resistance and boiling water shrinkage High color fastness, improved hot water resistance, and excellent dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

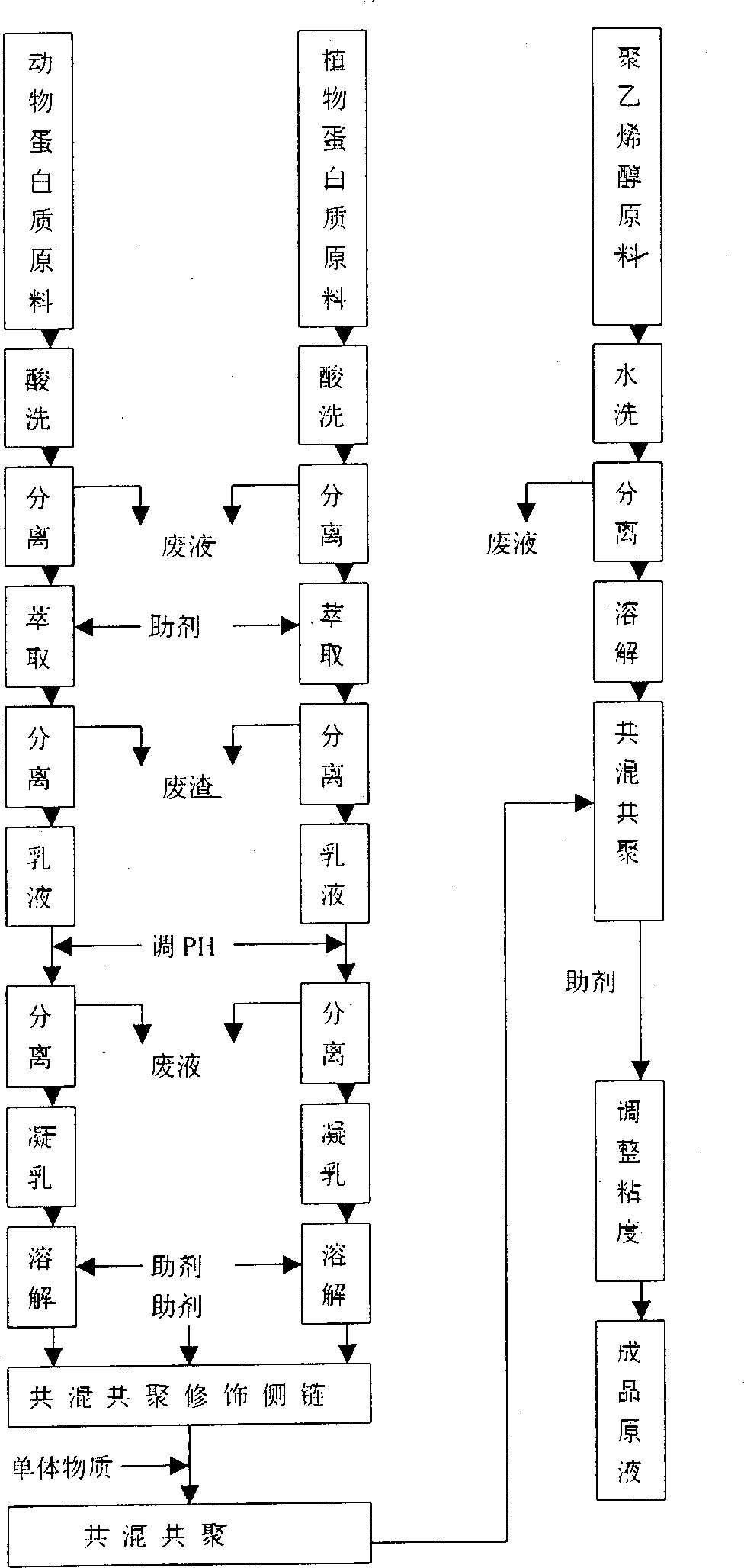

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1. animal or aquatic organism bone powder, according to the ratio of 1: 10 to water, soak in the hydrochloric acid aqueous solution of pH4.3, temperature, stir and wash 90 minutes in 30 ℃. Use a centrifuge to separate the waste liquid, and the separated raw materials are soaked in an aqueous sodium hydroxide solution with a pH of 8.5 and a temperature of 40°C according to a material-to-water ratio of 1:12, and 3% of the weight of the raw materials is added. , 0.2% ethylenediaminetetraacetic acid, 0.1% ascorbic acid, extracted for 50 minutes, and then separated to obtain protein emulsion. Then adjust the pH value to 4.7, and then separate to obtain protein curd.

Embodiment 2

[0018] Embodiment 2. Soybean meal is soaked in the ratio of 1: 11 by material-water ratio and is soaked in pH4.4, and temperature is that in the sulfuric acid aqueous solution of 33 ℃, stirring and washing for 110 minutes. Use the centrifuge to separate the waste liquid, and the soybean meal after the separation is soaked in the potassium hydroxide aqueous solution of PH9 and temperature at 45°C according to the ratio of material to water 1: 12, add 4% potassium sulfite, 0.35% potassium hydroxide respectively Ethylenediaminetetraacetic acid, 0.25% ascorbic acid, extract for 70 minutes, separate the slag to obtain a protein solution, then adjust the pH value to 4.9, and then separate to obtain a protein curd.

Embodiment 3

[0019] Embodiment 3. The sunflower kernel meal is subjected to the same process as in Example 1 or 2, and the pH value of washing is at 4.5, and the temperature is washed in water for 120 minutes in an aqueous phosphoric acid solution at 35° C. After centrifugation, the ratio of material to water is 1: 12. Soak pH9.5, temperature is 50℃, add 5% ammonium sulfite, 0.5% disodium edetate, 0.4% sodium ascorbate respectively, extract for 90 minutes, after separation, adjust pH5.2, and then separate the same Get protein curds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com