Soft wear-resistant silica gel leather and preparation method thereof

A technology of silica gel and leather, which is applied in coating, textile and paper making, etc., can solve the problem of non-abrasion of artificial leather, achieve the effect of enhancing wear resistance, soft hand feeling and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

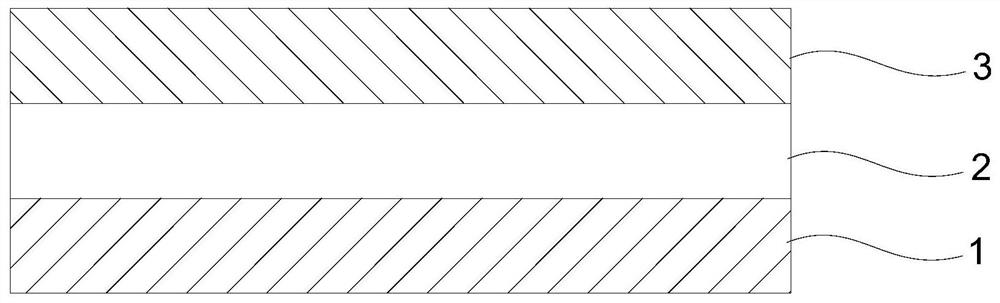

Image

Examples

preparation example Construction

[0038] The preparation method of the soft wear-resistant silicone leather provided in the embodiments of the present invention comprises the following steps:

[0039] 1) Prepare the surface layer of silica gel 3: weigh methyl vinyl silicone resin, polymethyl vinyl siloxane, fumed silica, polymethyl hydrogen siloxane, platinum catalyst and matte reinforcement according to the proportion Mix and dilute the raw materials of the silica gel surface layer 3 and the diluent according to the mass ratio of 1:1 to obtain the first mixture, electrostatically spray the proportioned amount of fluorine-containing particles on a release paper, and then place it on the release paper. Coating the first mixture on the type paper, sending it into an oven, heating and curing, and curing to form the silica gel surface layer 3, one side of the silica gel surface layer 3 is attached to the release paper, and the other side is the coating surface;

[0040]2) Preparation of middle layer silica gel lay...

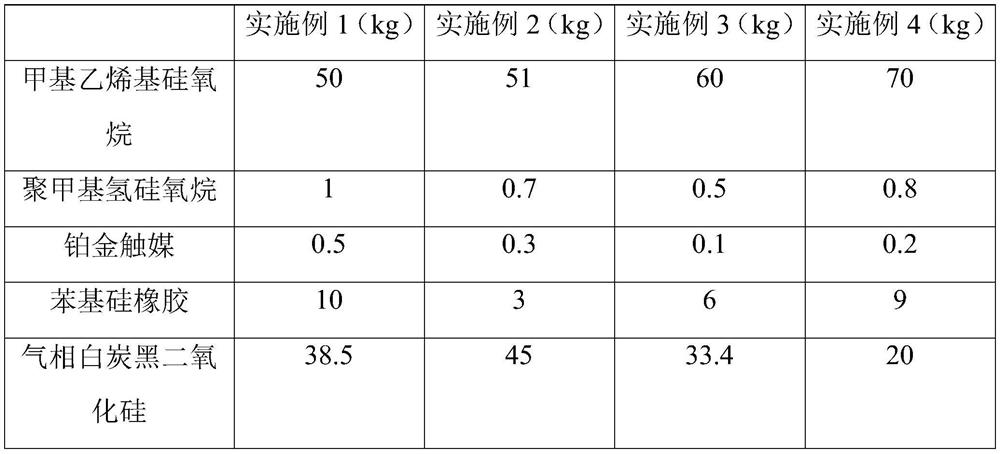

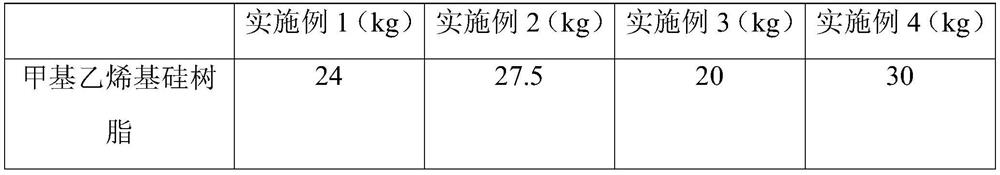

Embodiment 1-4

[0052] The preparation method of the soft type wear-resistant silicone leather of embodiment 1-4, comprises the following steps:

[0053] 1) Prepare the surface layer of silica gel 3: weigh methyl vinyl silicone resin, polymethyl vinyl siloxane, fumed silica, polymethyl hydrogen siloxane, platinum catalyst and matte reinforcement according to the proportion Mix and dilute the raw materials of the silica gel surface layer 3 and the diluent according to the mass ratio of 1:1 to obtain the first mixture, electrostatically spray the proportioned amount of fluorine-containing particles on a release paper, and then place it on the release paper. Coating the first mixture on the type paper, sending it into an oven, heating and curing, and curing to form the silica gel surface layer 3, one side of the silica gel surface layer 3 is attached to the release paper, and the other side is the coating surface;

[0054] 2) Preparation of middle silica gel layer 2: weigh methyl vinyl siloxane,...

Embodiment 5

[0078] In this embodiment, the wear resistance of the silica gel surface layer prepared in Example 1 and Comparative Examples 1-7 is tested. The test method is as follows: according to GB / T9867-1988, the GT-7012-D rubber wear tester is used for the wear test. The weight load is 2.5N. See Table 3 and Table 4 for test results.

[0079] table 3

[0080] Fluorine Resin Powder Abrasion / (cm 3 .kg -1 )

Example 1 Tetrafluoroethylene perfluoroalkyl vinyl ether copolymer resin 0.0211 Comparative example 1 / 0.1354 Comparative example 2 PTFE 0.0514 Comparative example 3 Copolymer of ethylene and tetrafluoroethylene 0.0447

[0081] It can be seen from Table 3 that the addition of fluorine-containing resin powder can indeed reduce the wear of the surface layer of silica gel and enhance its wear resistance. Among them, the wear of the surface layer of silica gel is the lowest after adding tetrafluoroethylene perfluoroalkyl vinyl ether ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com