PE spun-bonded non-woven fabric and manufacturing method thereof

A spun-bonded non-woven fabric, a manufacturing method technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of poor adhesion, etc., and achieve the effects of soft hand feeling, uniform spinning, and good thermal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

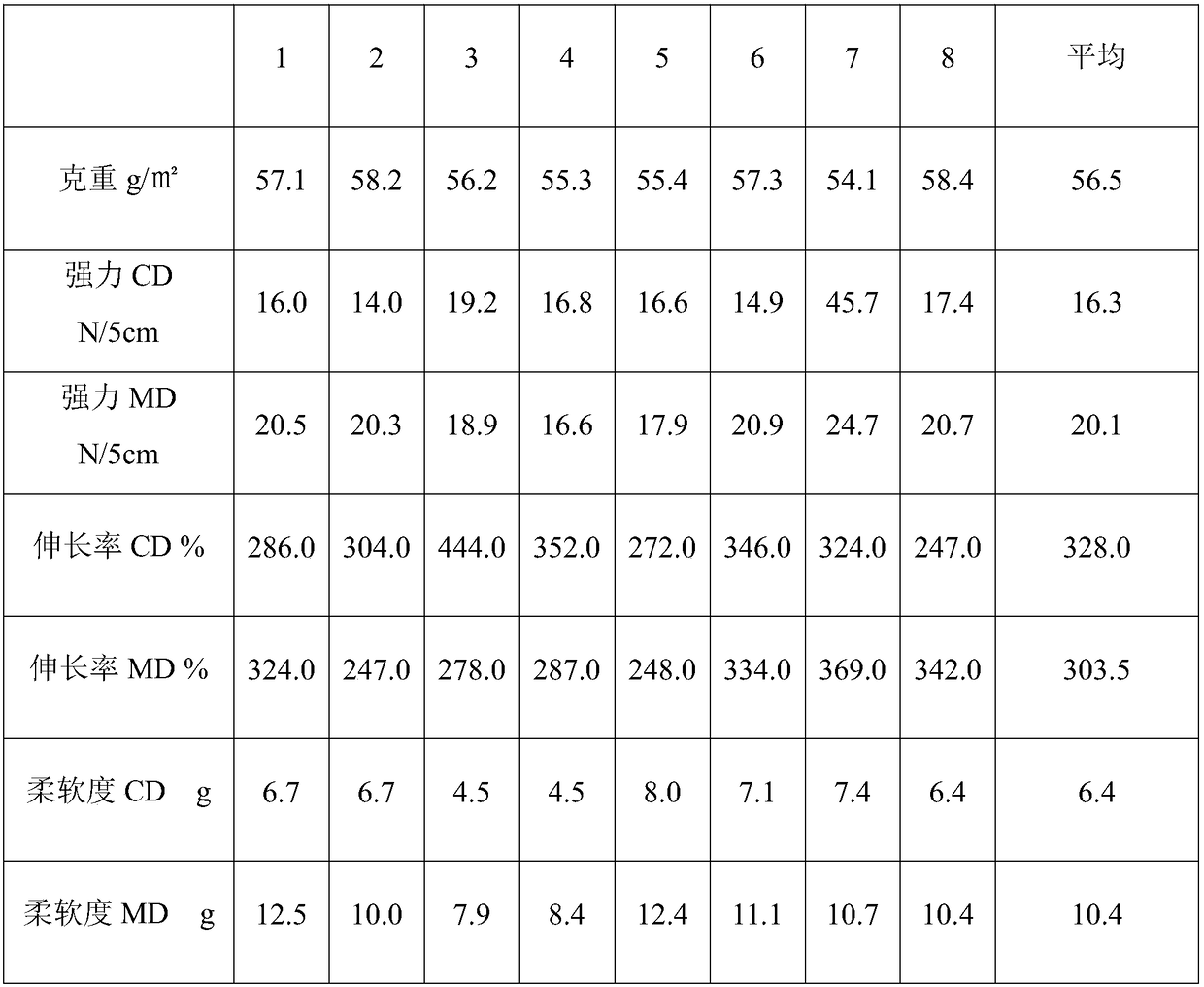

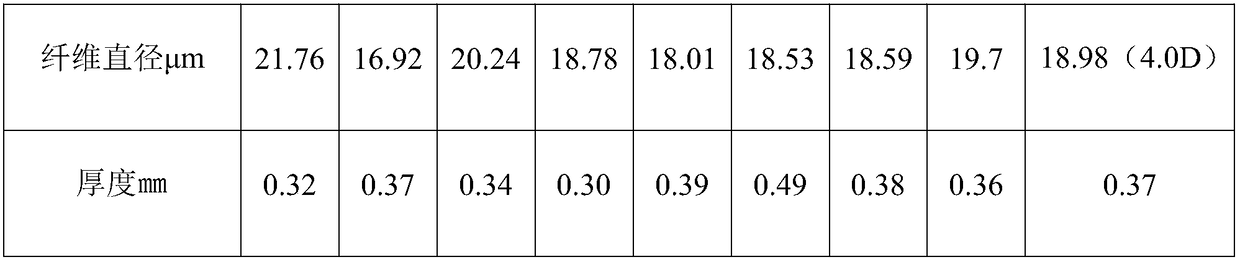

Embodiment 1

[0032] Example 1, PE raw material LL6101XR, elastomer Vistamaxx 6020FL are mixed according to the ratio of 98%: 2%

[0033] Preparation method of PE spunbond nonwoven fabric:

[0034] 1. Mix PE raw material LL6101XR and elastomer Vistamaxx 6020FL according to the ratio of 98%:2%;

[0035] 2. The mixed and stirred raw materials are extruded and melted to the screw through the feeding system (vacuum suction) to obtain a hot melt (screw melting temperature 270°C);

[0036] 3. Filter, measure and distribute the hot melt at a certain temperature and pressure (the operating temperature for filtering, measuring and distributing the hot melt is 250°C and the pressure is 10MPa);

[0037] 4. Spinning the distributed and metered hot melt, and cooling the spun silk through the side cold air to obtain primary growth filaments (the distributed and metered hot melt is spun out through a 0.8mm aperture) The silk is cooled by a cooling bellows, the temperature of the cooling bellows is 20°C,...

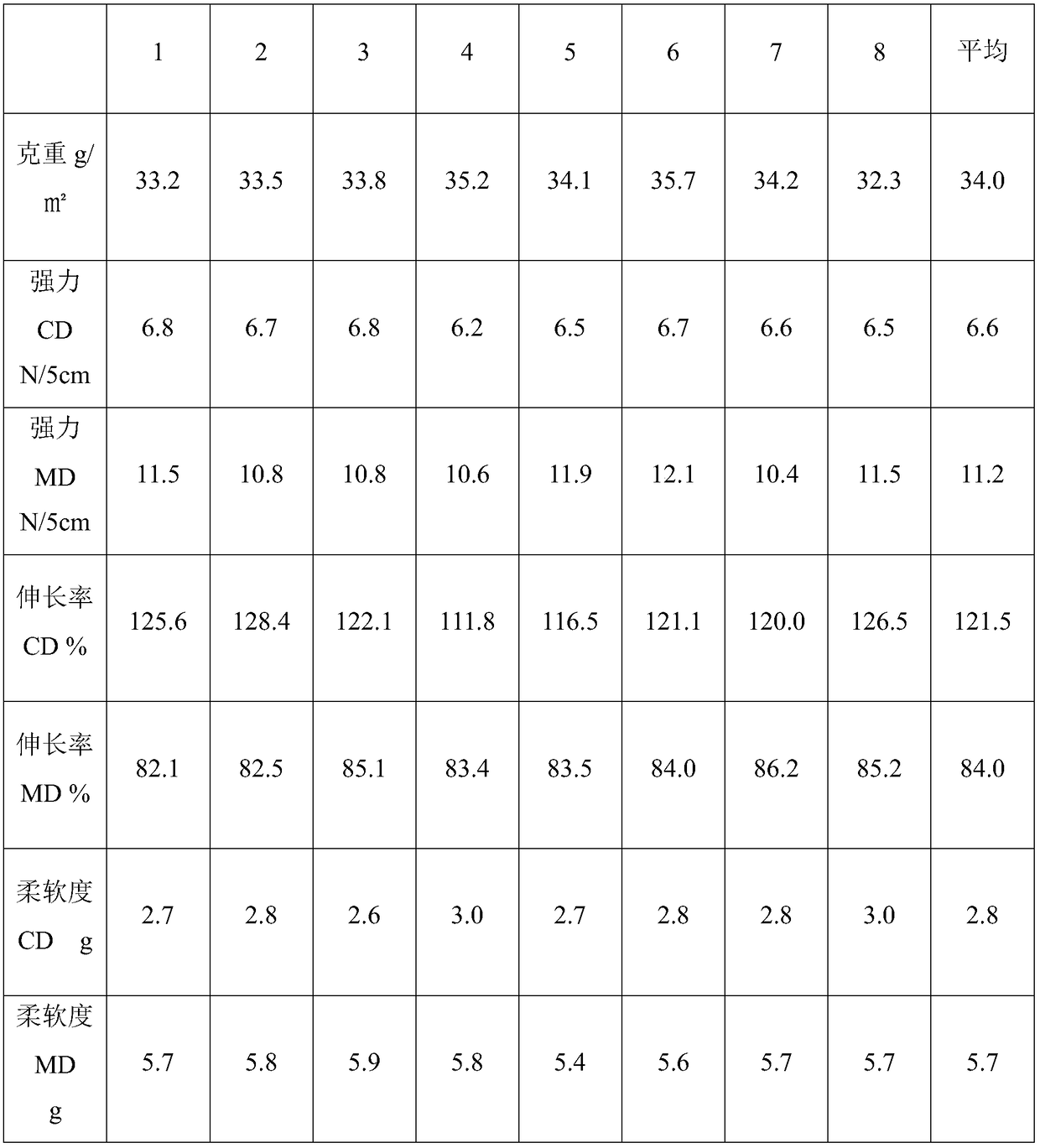

Embodiment 2

[0048] Example 2, PE raw material LL6101XR, elastomer Vistamaxx 6020FL are mixed according to the ratio of 98%: 2%

[0049] Preparation method of PE spunbond nonwoven fabric:

[0050] 1. Mix PE raw material LL6101XR and elastomer Vistamaxx 6020FL according to the ratio of 98%:2%;

[0051] 2. The mixed and stirred raw materials are extruded and melted to the screw through the feeding system (vacuum suction) to obtain a hot melt (screw melting temperature 180°C);

[0052] 3. Filter, measure and distribute the hot melt at a certain temperature and pressure (the operating temperature for filtering, measuring and distributing the hot melt is 230° C., and the pressure is 5 MPa);

[0053] 4. Spinning the distributed and metered hot melt, and cooling the spun silk through the side cold air to obtain primary growth filaments (the distributed and metered hot melt is spun out through a 0.3 mm aperture The silk is cooled by a cooling bellows, the temperature of the cooling bellows is 10°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com