Patents

Literature

55results about How to "Excellent thermal adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

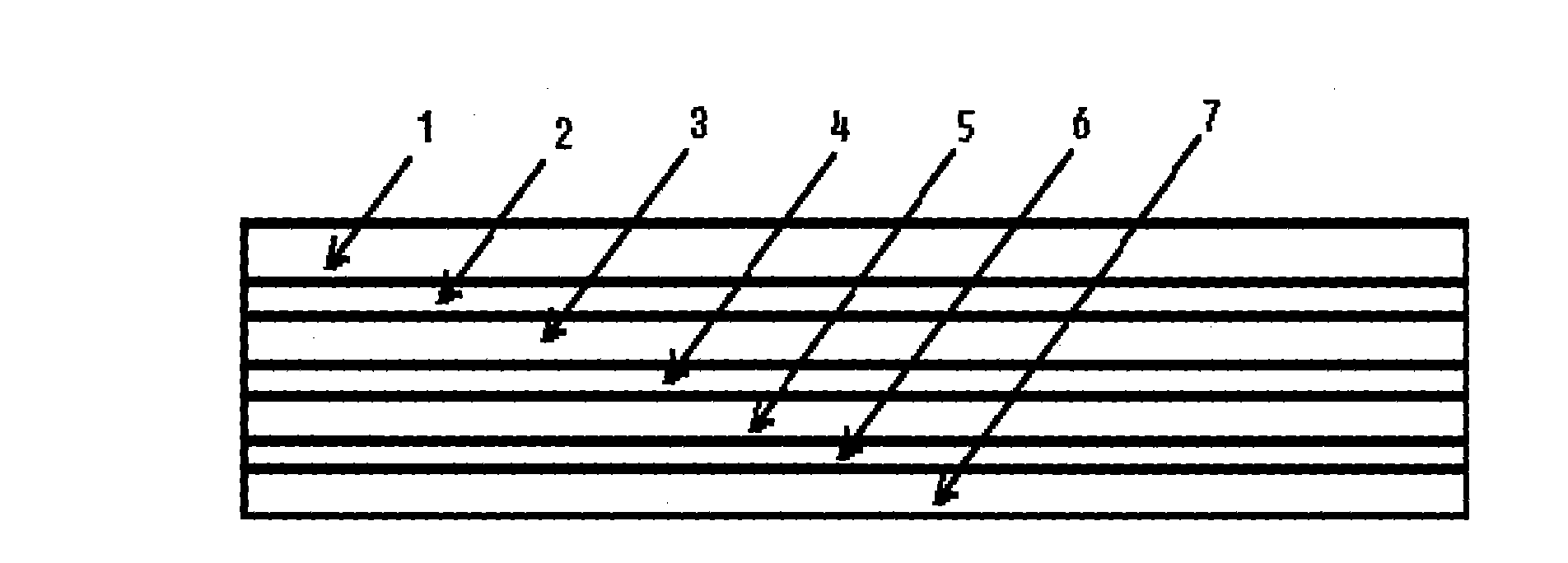

Multilayer laser-markable sheet for electronic passport and electronic passport

InactiveUS20120164419A1Improve laser marking effectIncrease contrastOther printing matterDuplicating/marking methodsEngineeringLaser light

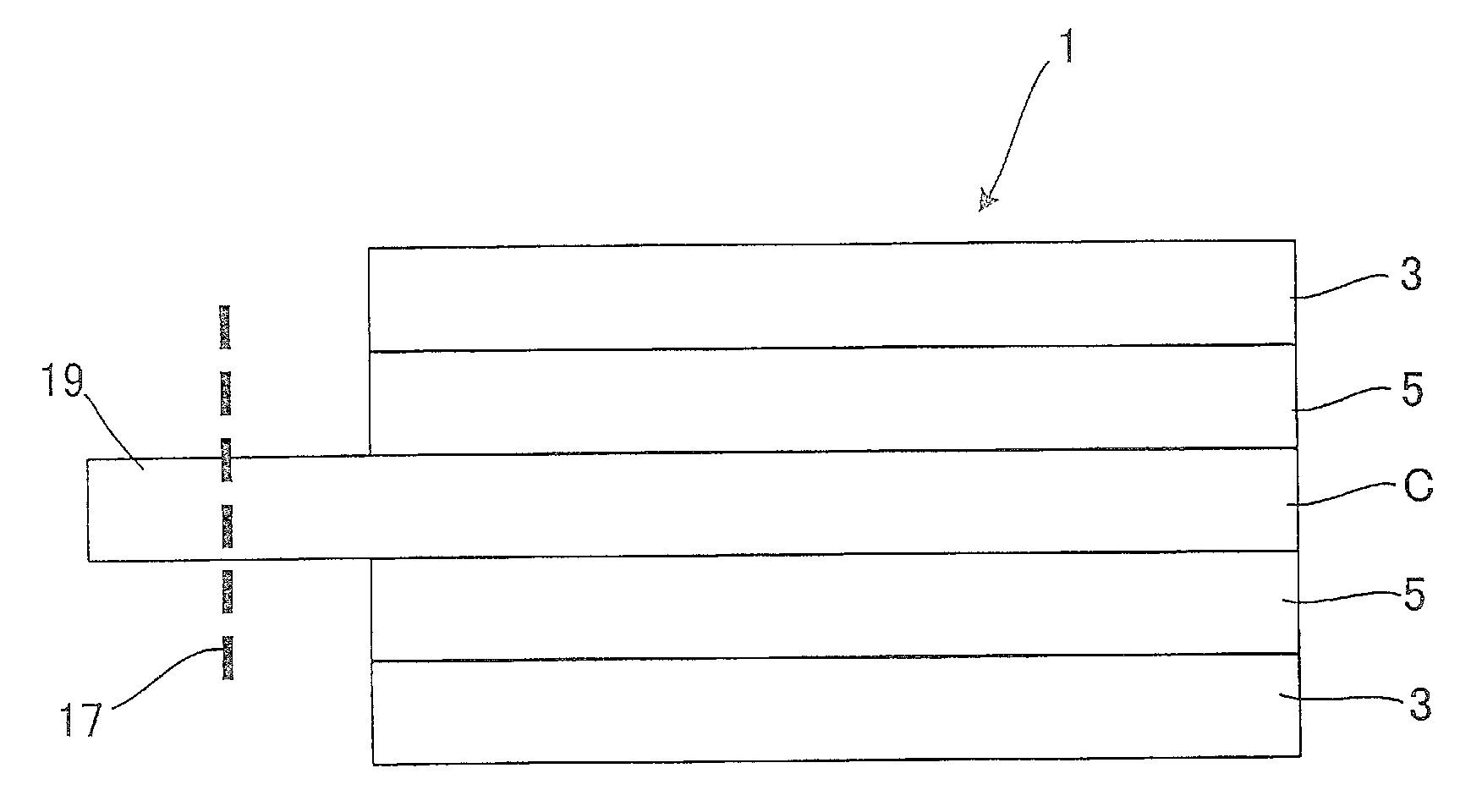

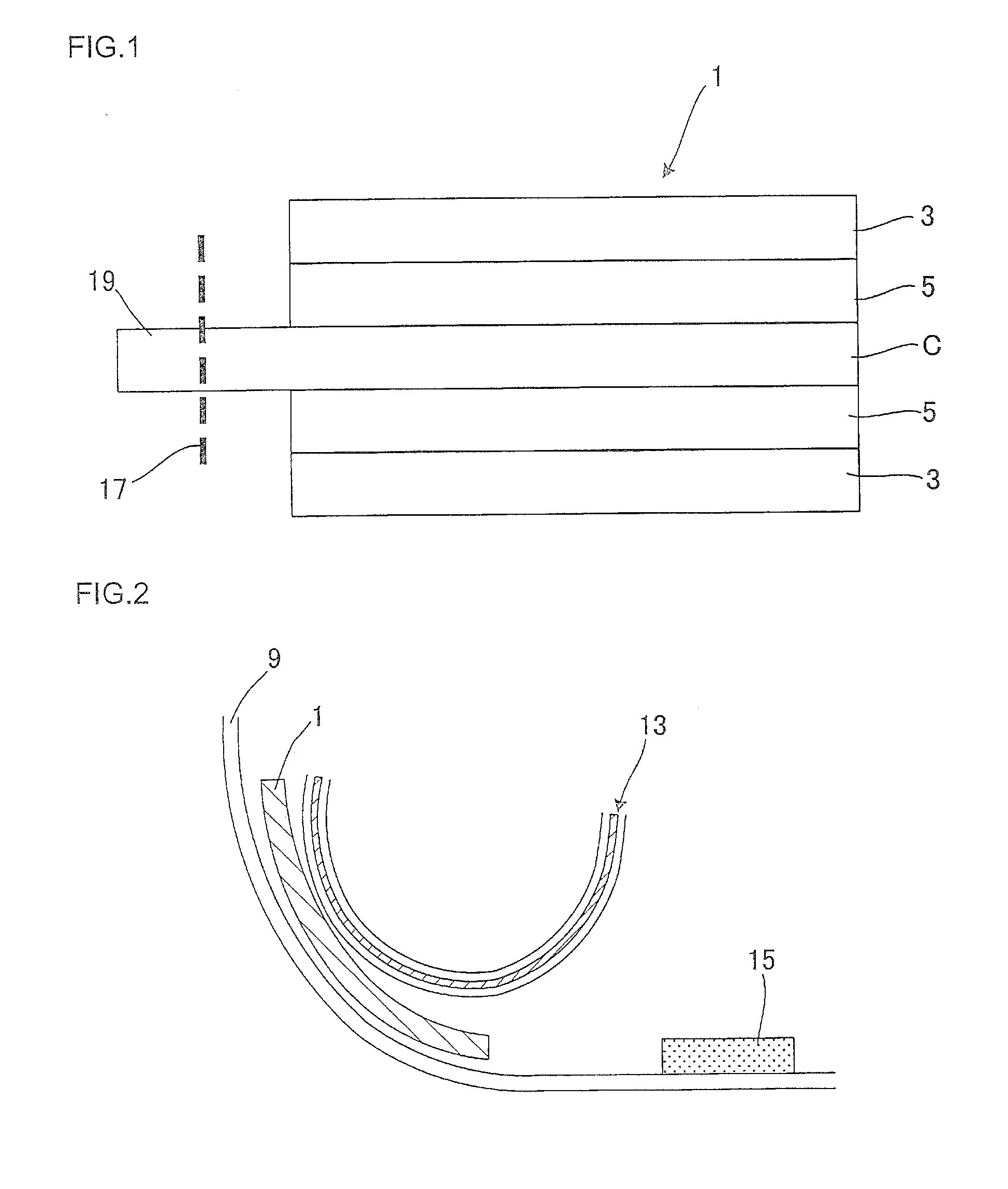

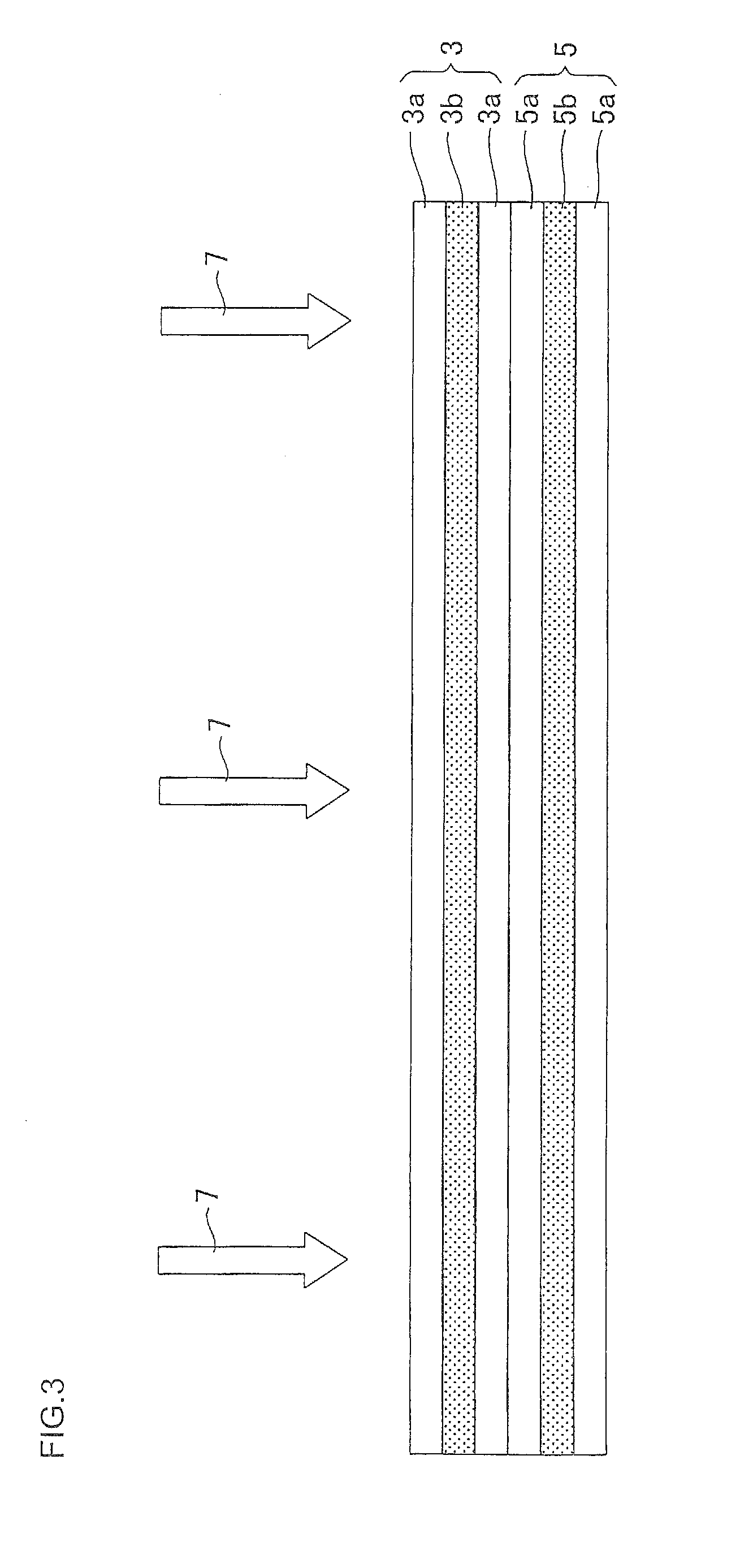

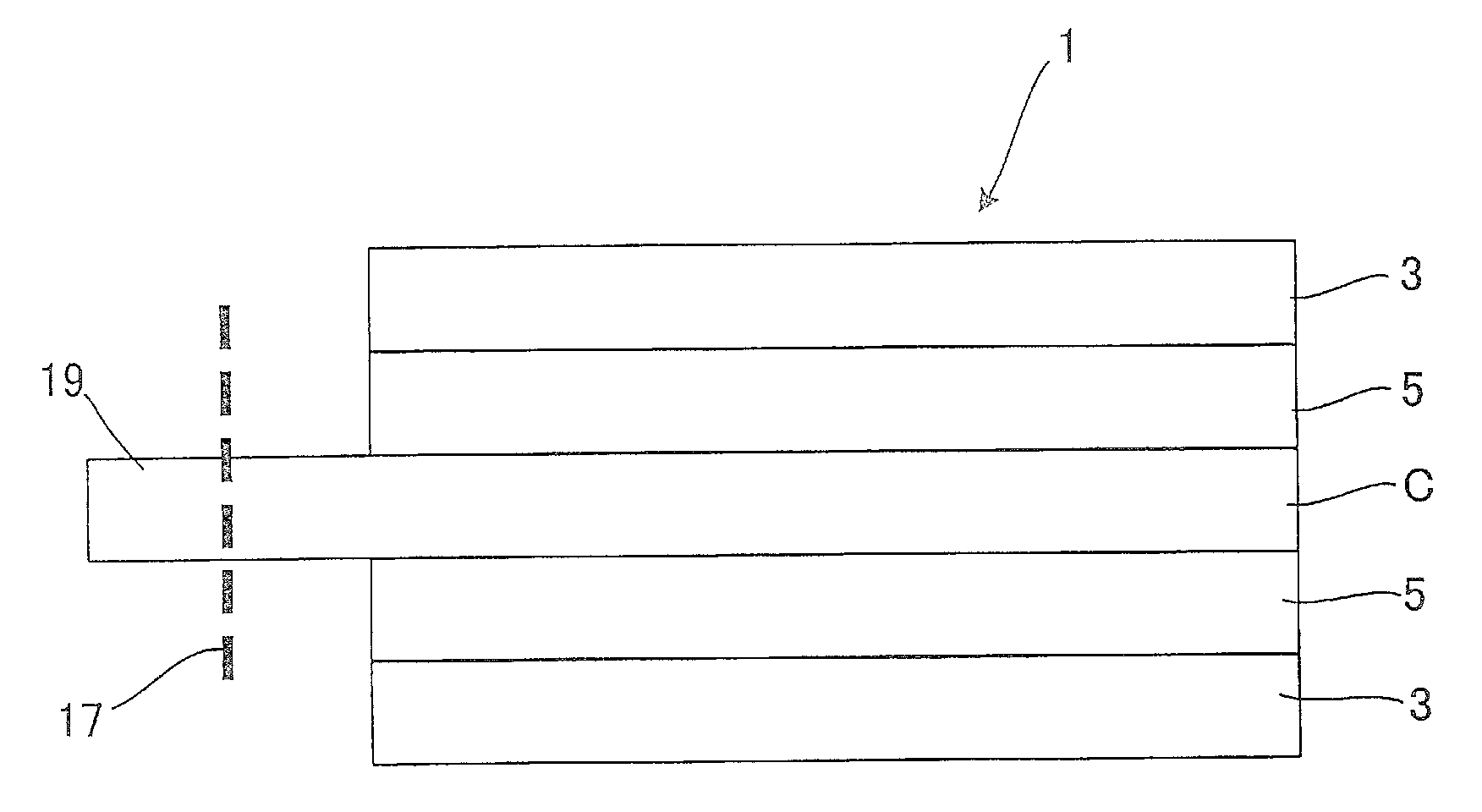

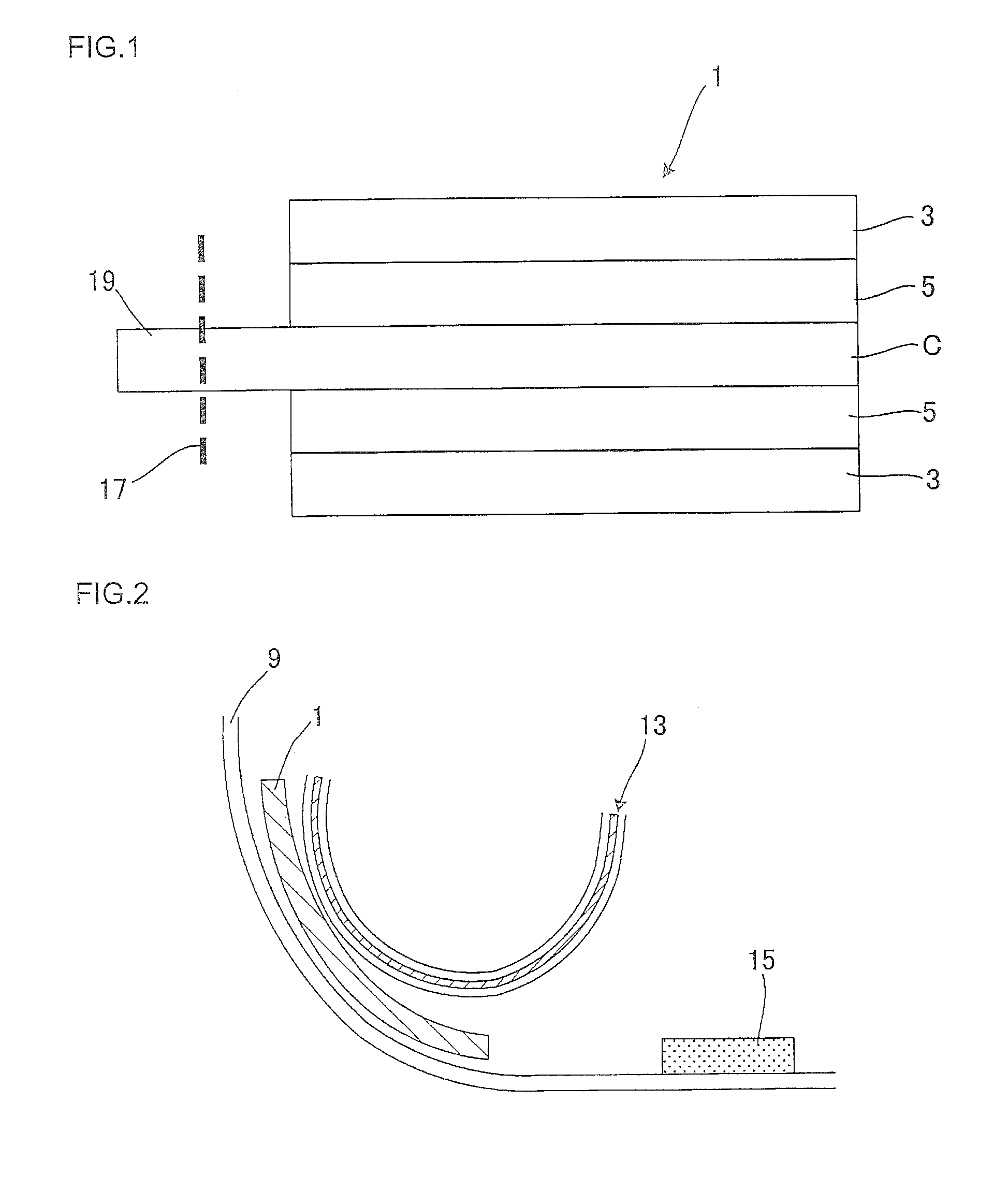

A multilayer laser-markable sheet for an electronic passport includes three sheets of a sheet A / a multilayer sheet B / a sheet C as a basic constitutional unit. The sheet A includes a transparent polycarbonate resin composition including a thermoplastic polycarbonate resin and a laser light energy absorbing agent, the multilayer sheet B includes a transparent thermoplastic resin including a thermoplastic polycarbonate resin, at least one layer of the skin layers and the core layer of the multilayer sheet B including at least one selected from a dye and a pigment. The sheet C includes a sheet or a laminate sheet. The multilayer laser-markable sheet for an electronic passport has excellent laser markability and high contrast, can achieve clear letters, symbols and images, and further has excellent thermal adhesiveness, transparency, sheet conveyance property, releasability from a die after thermal press, thermal resistance, foldability and wear resistance.

Owner:JAPAN COLORING

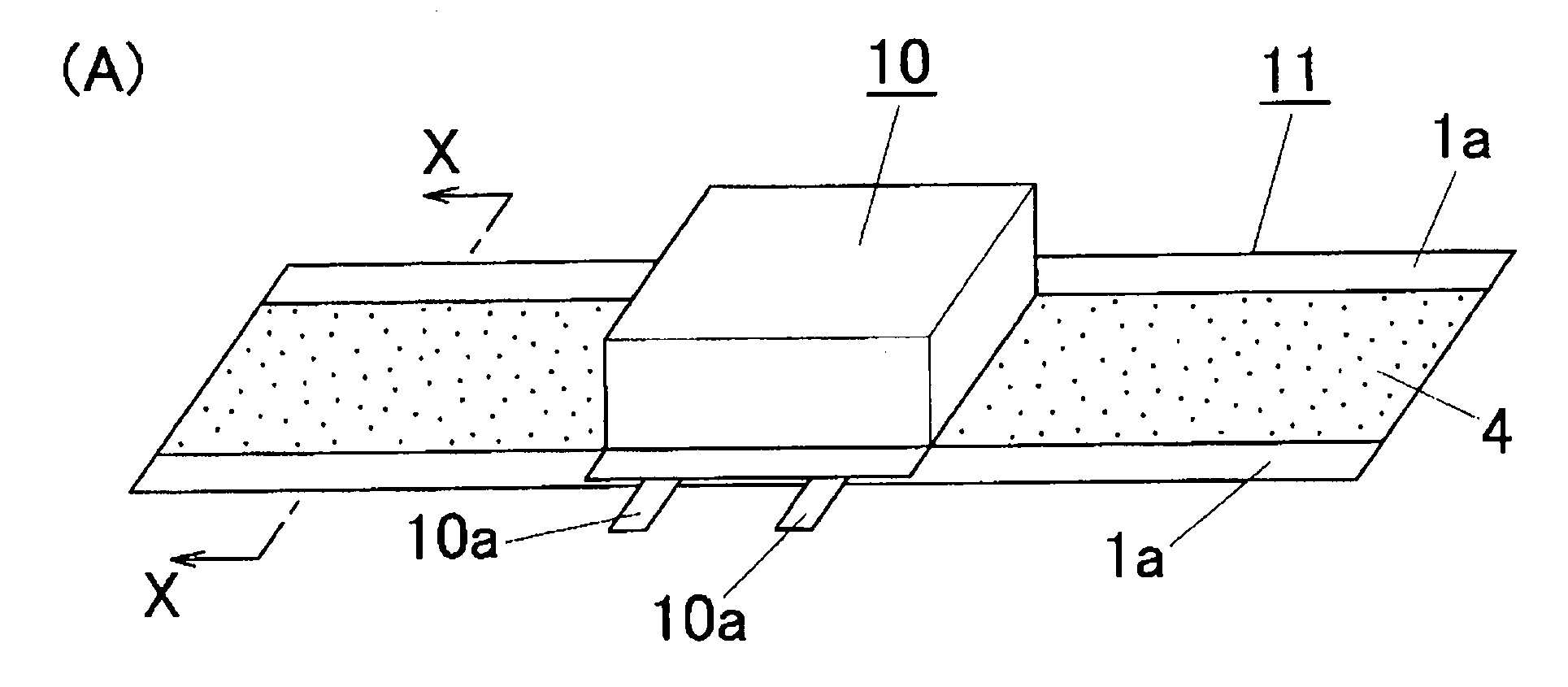

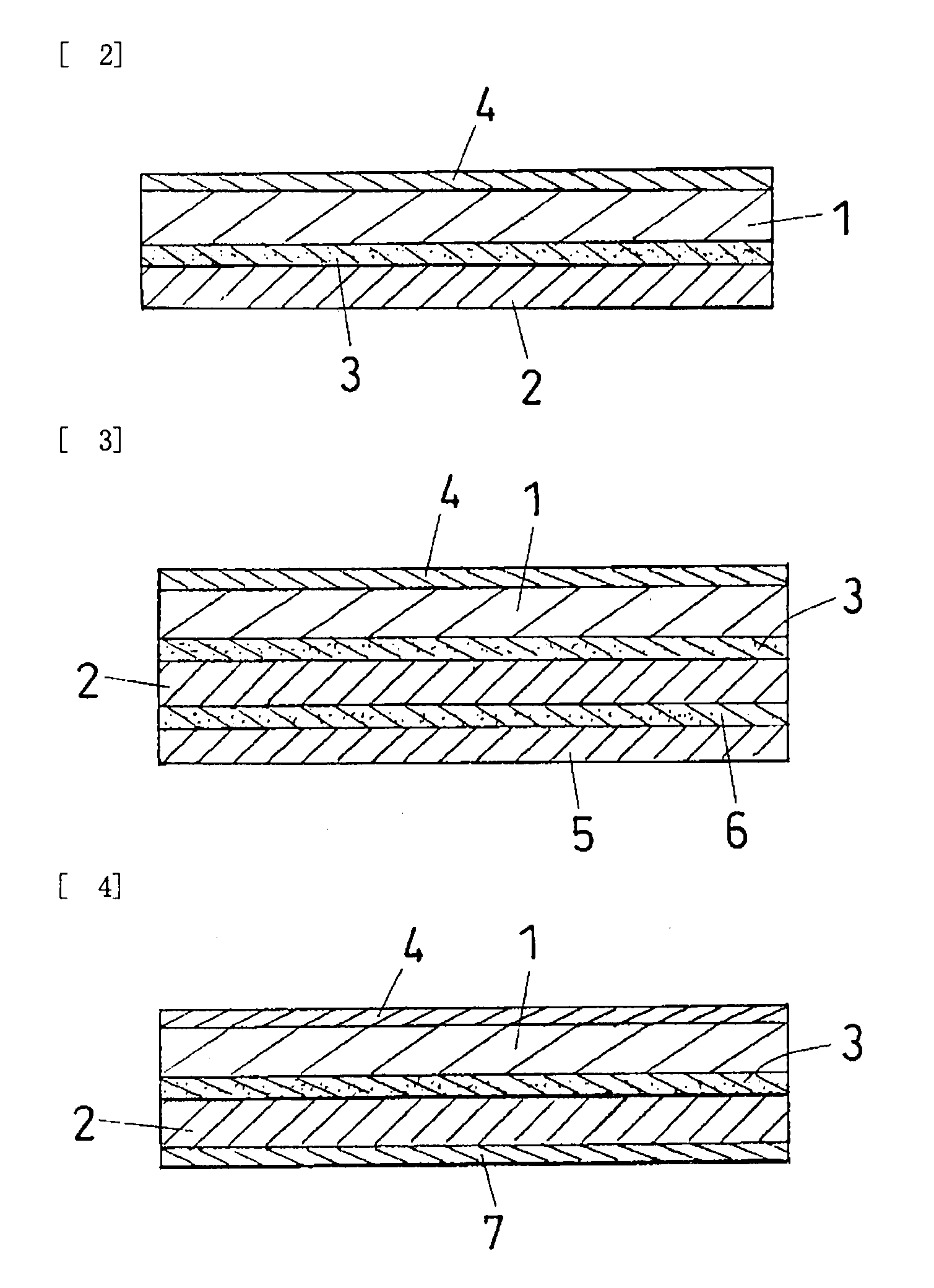

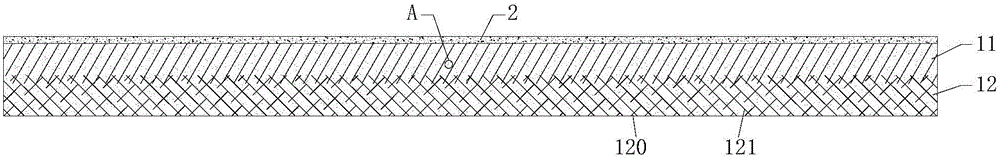

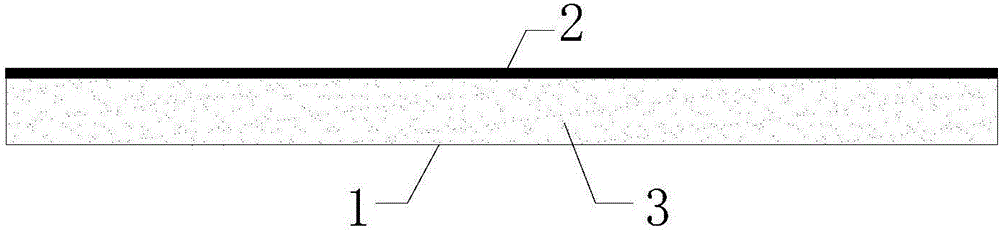

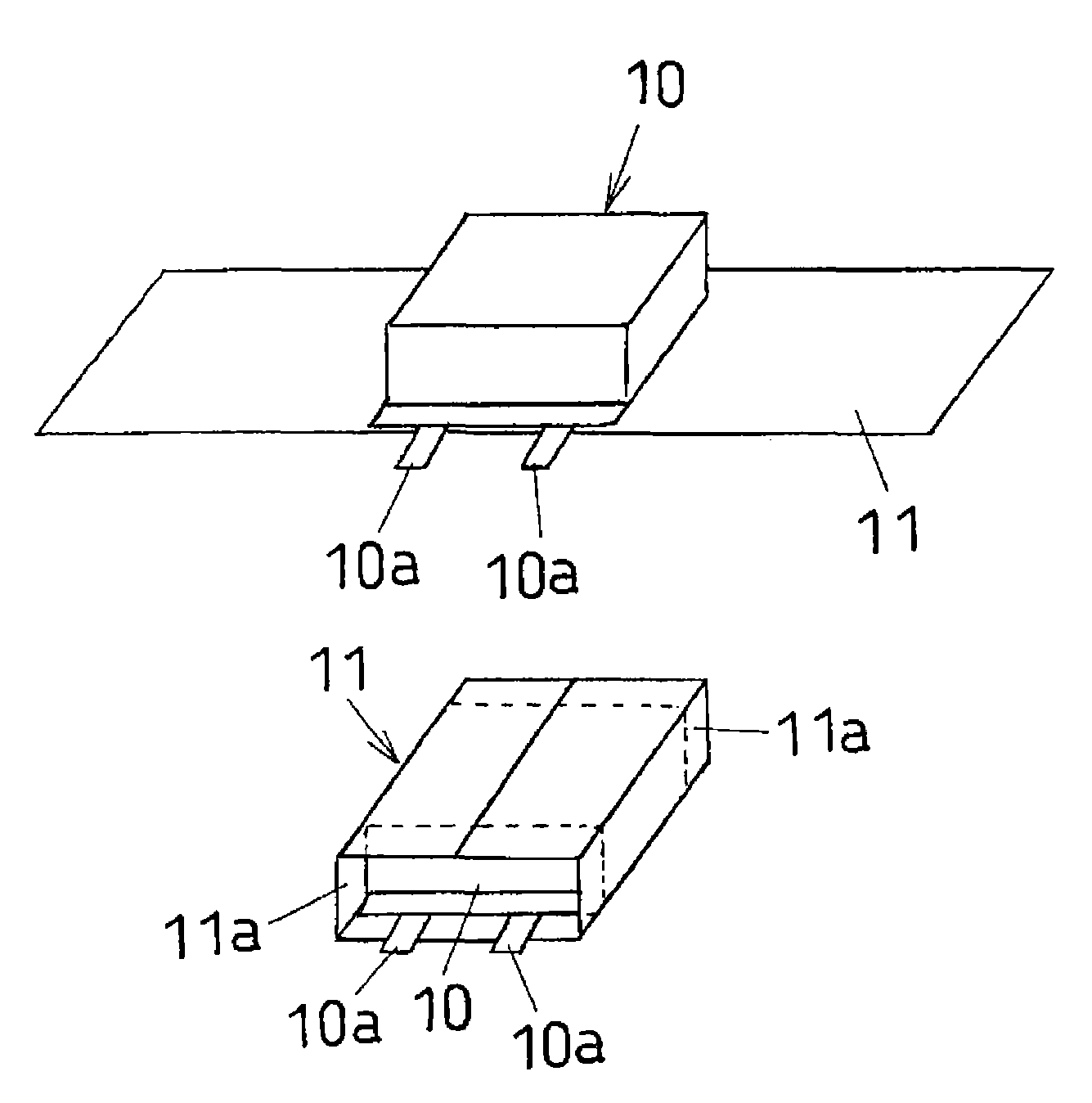

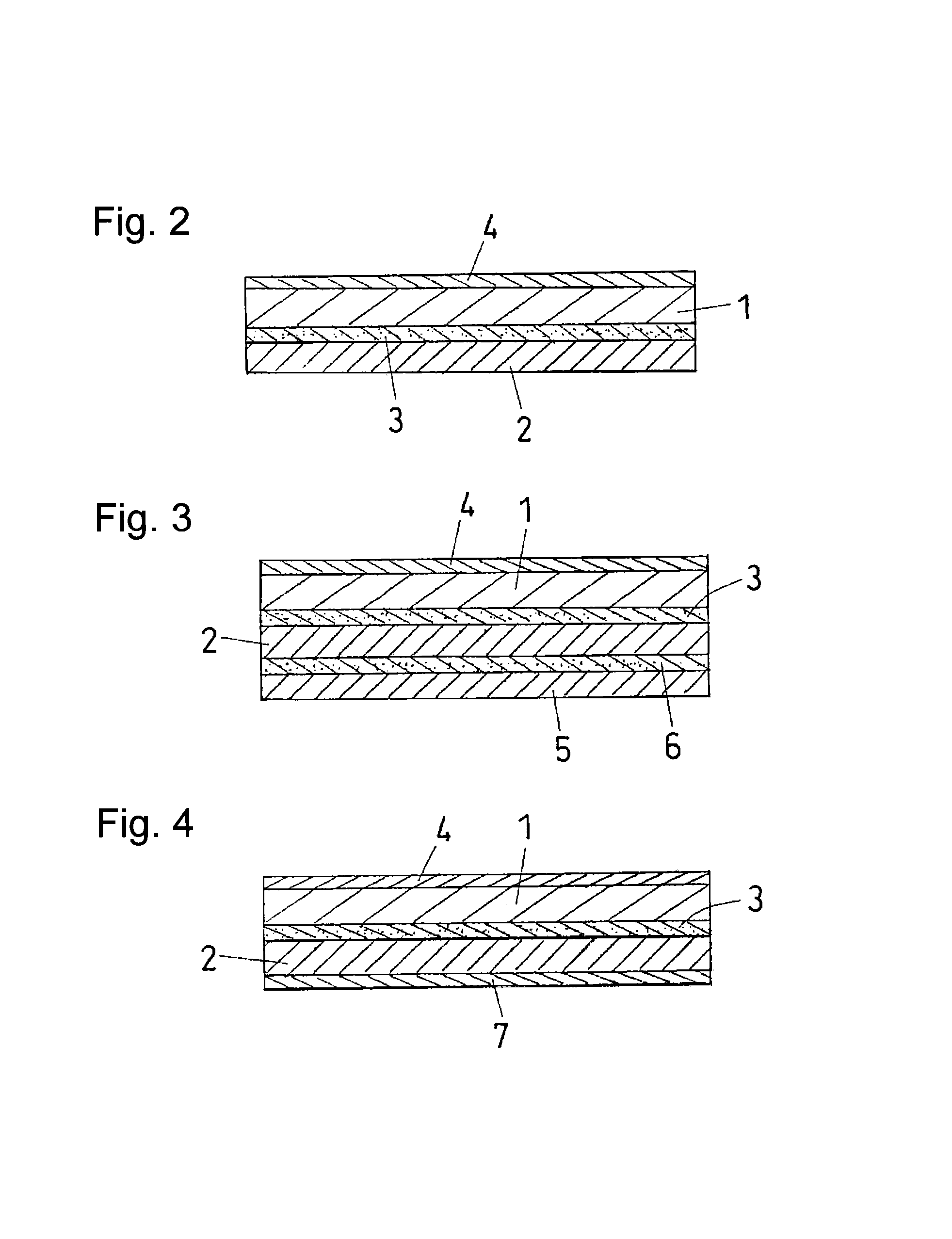

Laminate packing material for battery and laminate battery

ActiveUS20100040942A1Reduce in quantitySimplification of battery production lineSynthetic resin layered productsJackets/cases materialsMetallic foilThermal adhesive

In a laminated external packaging material for a battery according to the present invention, a metallic foil 2 is adhered to one surface side of a base film 1, and a coated film layer 4 of thermal adhesive resin having a softening point of 160° C. or below and capable of thermally bonding to a surface film of a battery main body is formed on the other surface side of the base film 1. With this laminated external packaging material for a battery, without using an adhesive tape or a hot-melt adhesive, this packaging material can be easily and assuredly bonded to the battery main body and also can be bonded firmly to an end portion reinforcing plastic component.

Owner:RESONAC PACKAGING CORP

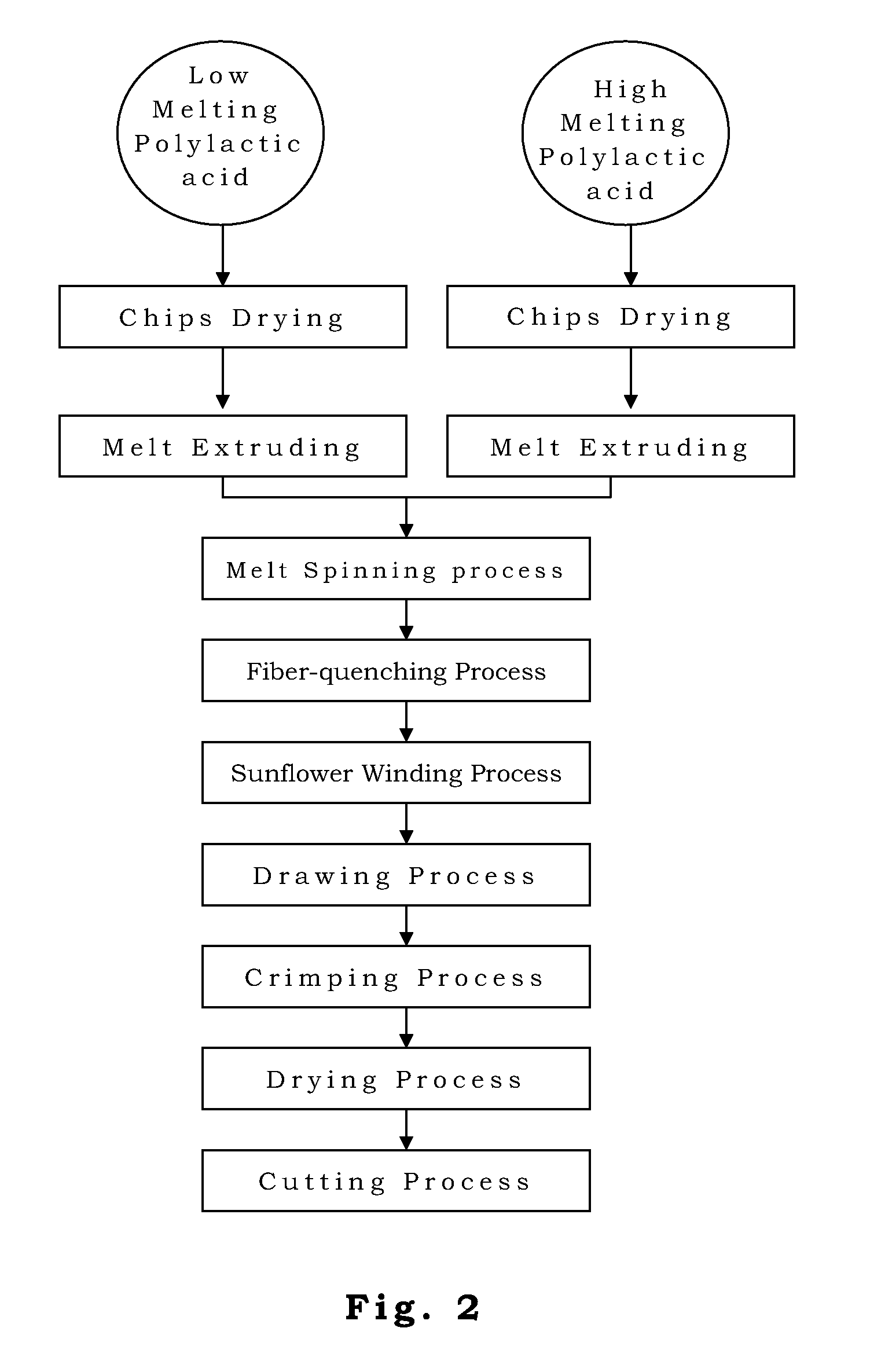

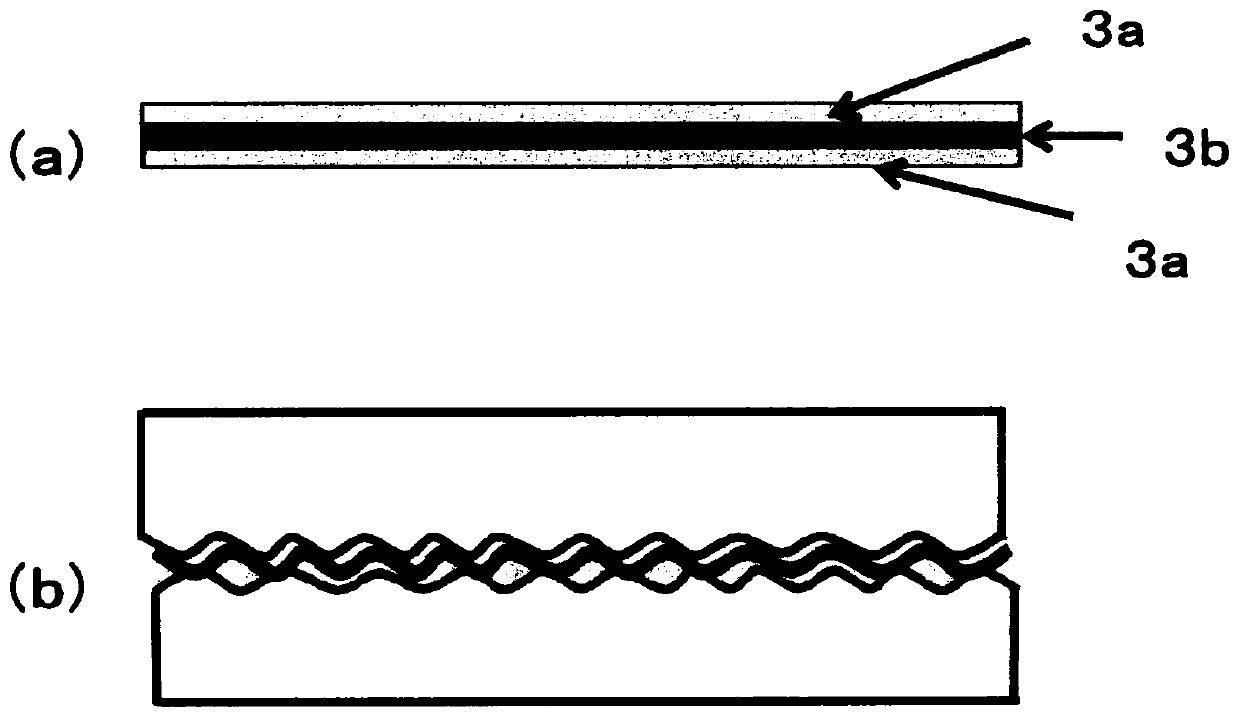

Heat adhesive biodegradable bicomponent fibers

ActiveUS7604859B2Good adhesionLow melting pointConjugated synthetic polymer artificial filamentsNon-woven fabricsCellulose fiberDicarboxylic acid

Owner:FAR EASTERN NEW CENTURY COPRRATION

High temperature resistant electrical soft composite material and manufacturing method thereof

ActiveCN101877259AMeet technical requirements for performanceImprove heat resistancePolyureas/polyurethane adhesivesSynthetic resin layered productsTransformerAdhesive

The invention discloses a high temperature resistant electrical soft composite material and a manufacturing method thereof. The invention is characterized in that: the high temperature resistant electrical soft composite material is a two-, three- or four-layer high temperature resistant electrical soft composite material comprised of a thin film layer, an adhesive layer and a synthetic fiber paper layer; the adhesive layer is prepared by mixing 115 to 230 weight parts of hydroxy-terminated prepolymer, 30 to 83 weight parts of multifunction isocyanate prepolymer, 70 weight parts of polyglycerol-modified ureido-ene resin, 150 to 300 weight parts of solvent; after an adhesive is applied on a thin film or synthetic fiber paper, the thin film or synthetic fiber paper is delivered to a drying channel to pass through an area, an area II at and an area II at 50 to 120 DEG C respectively and at a vehicle speed of 2 to 20 m / min to remove the solvent; then the thin film or synthetic fiber paper is cooled first to room temperature and then to 80 DEG C and is combined with the synthetic fiber paper or the thin film by hot rolling; the combined product is wounded and heated to 140 DEG C from room temperature for aging for 8 to 72 hours; and thus, the product is obtained. The product of the invention, which has high performance, can be used for motor element insulation, inter-winding insulation, gasket insulation and air-immersed transformer interlayer insulation.

Owner:四川东材新材料有限责任公司

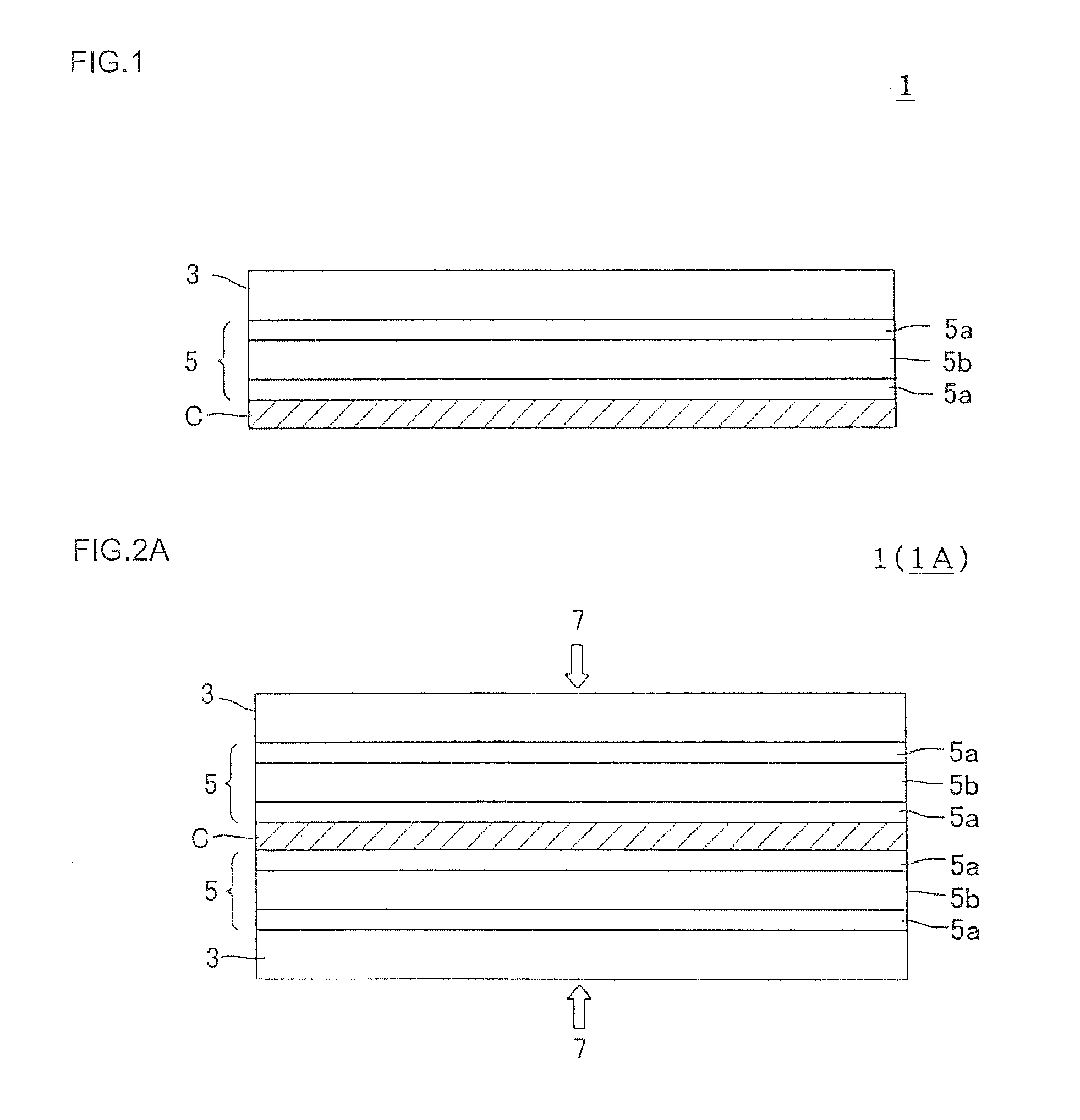

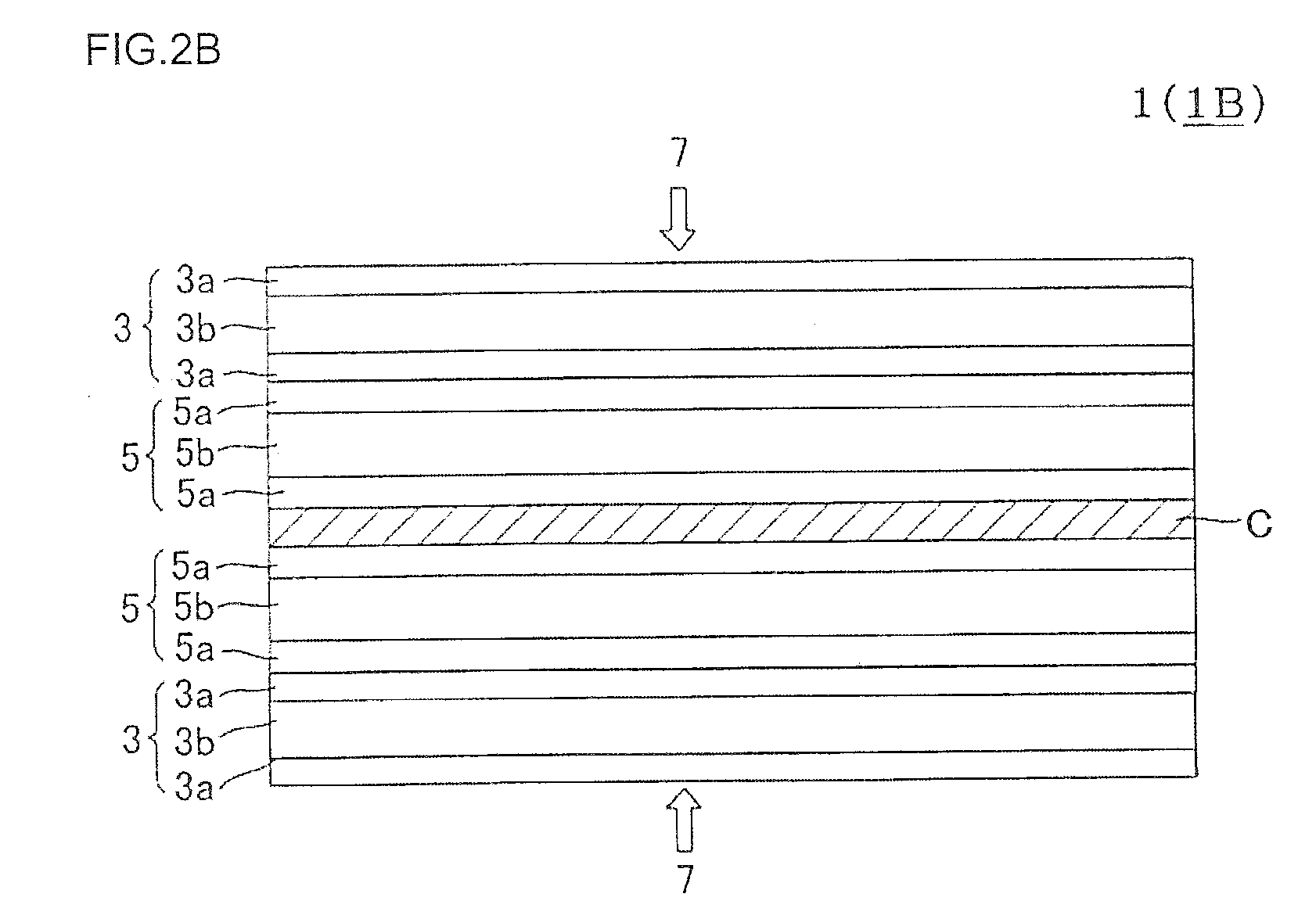

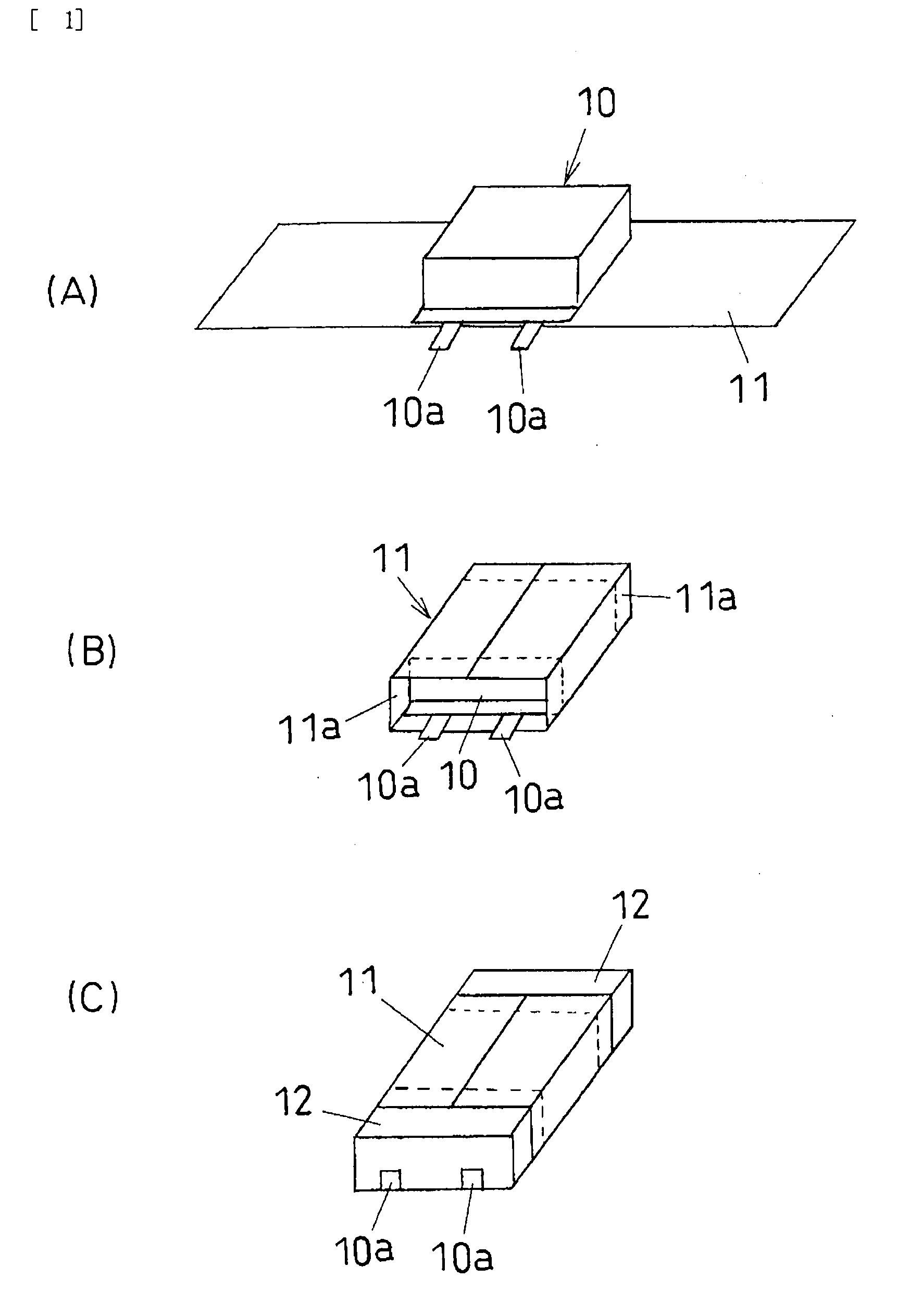

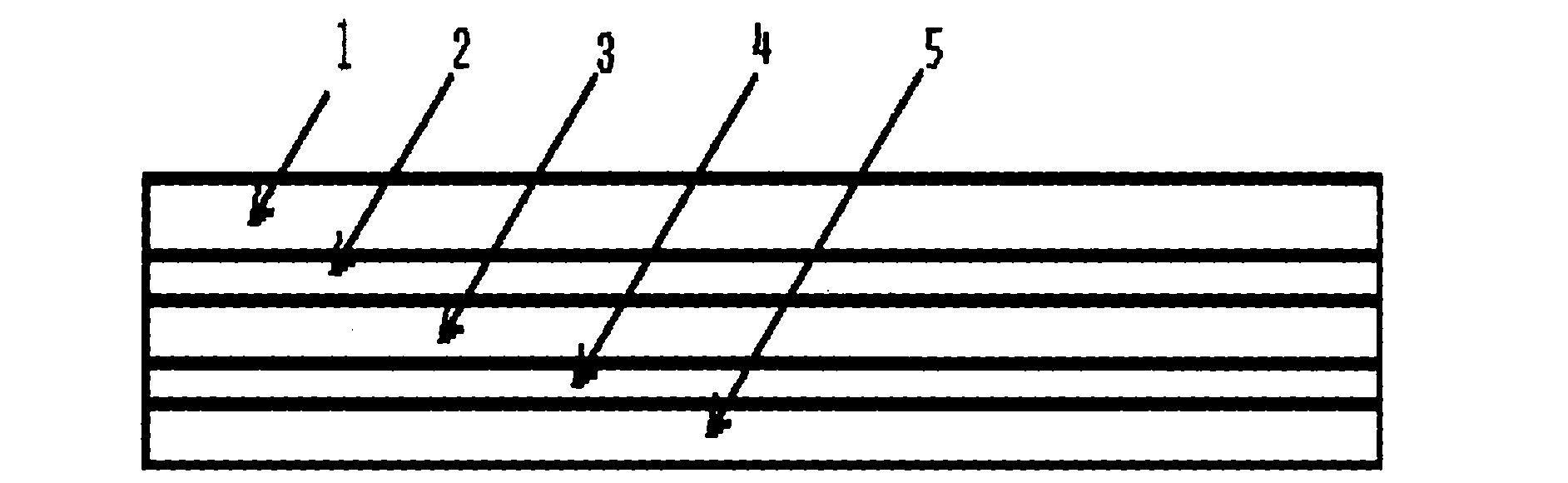

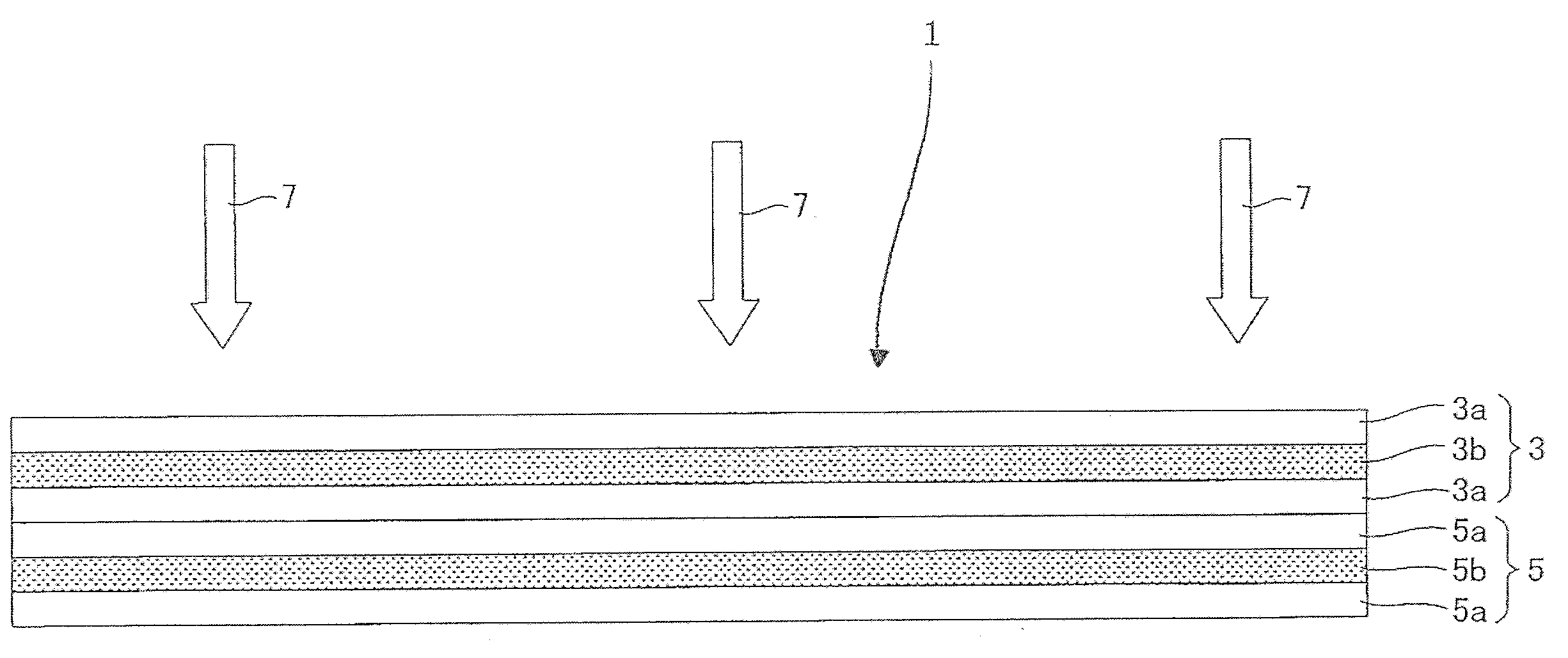

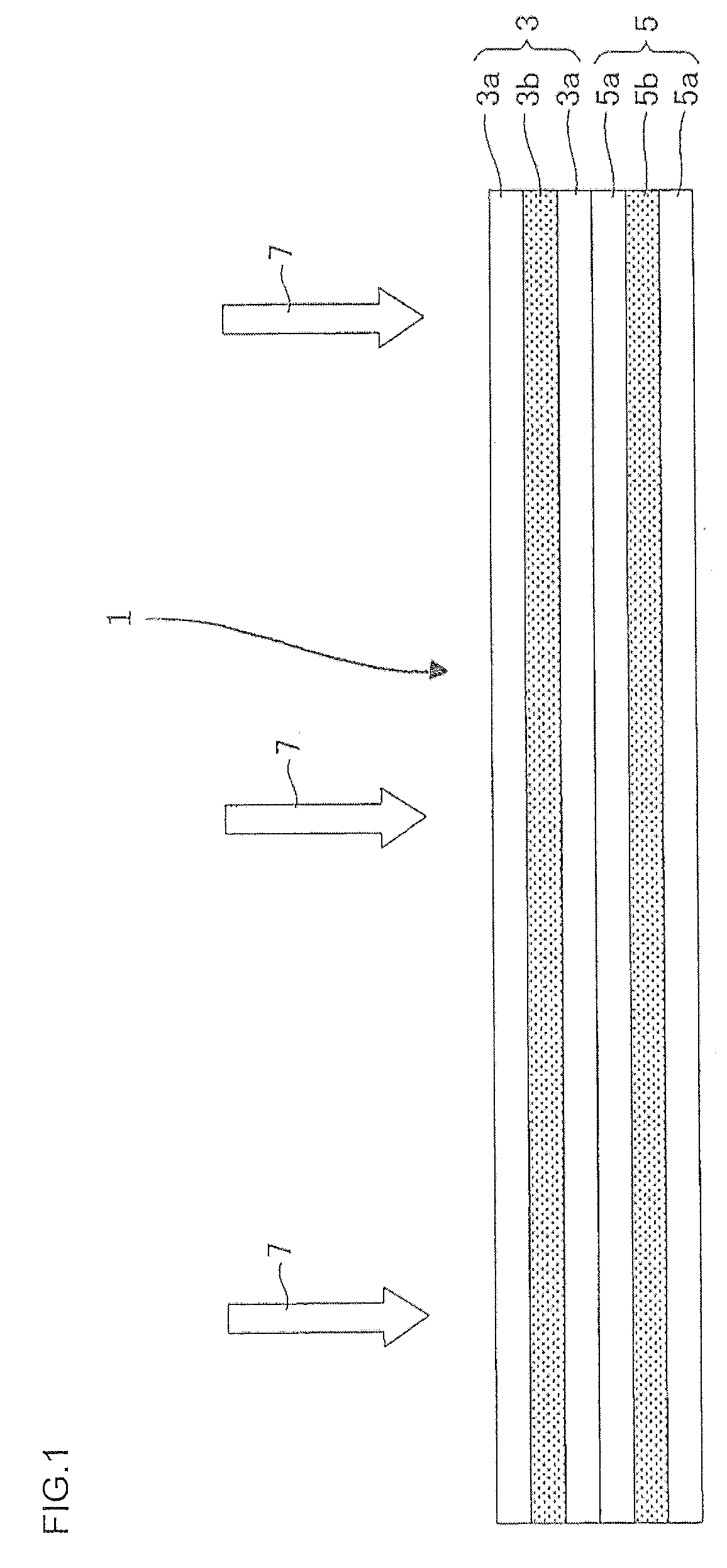

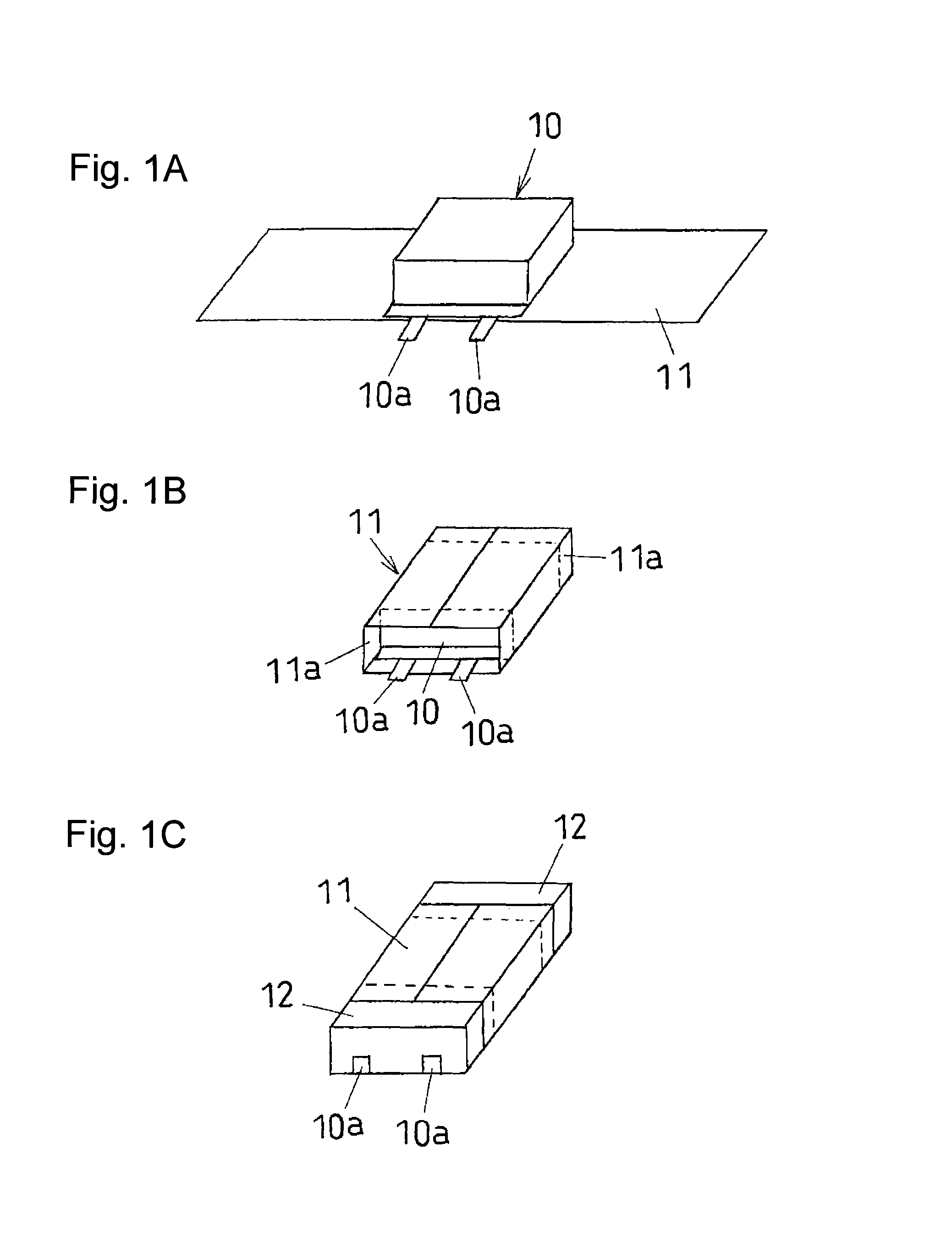

Laser-marking multilayer sheet for electronic passports, and electronic passport

ActiveUS20110069134A1Maintain good propertiesIncrease contrastPattern printingRecord information storageEngineeringLettering

There is provided a laser-marking multilayer sheet for an electronic passport formed by laminating five sheets of a multilayer sheet A / a multilayer sheet B / a film C / a multilayer sheet B / a multilayer sheet A. The multilayer sheet B is a colored laser-marking multilayer sheet. The film C is a laser-marking multilayer sheet made of a film for the electronic passport. The laser-marking multilayer sheet can have clear letters, symbols, and images, which are excellent in a laser-marking property and high in contrasts between the original surface color and the printed portions. The laser-marking multilayer sheet is excellent especially for inhibiting the falsification and forgery thereof.

Owner:MITSUBISHI CHEM CORP

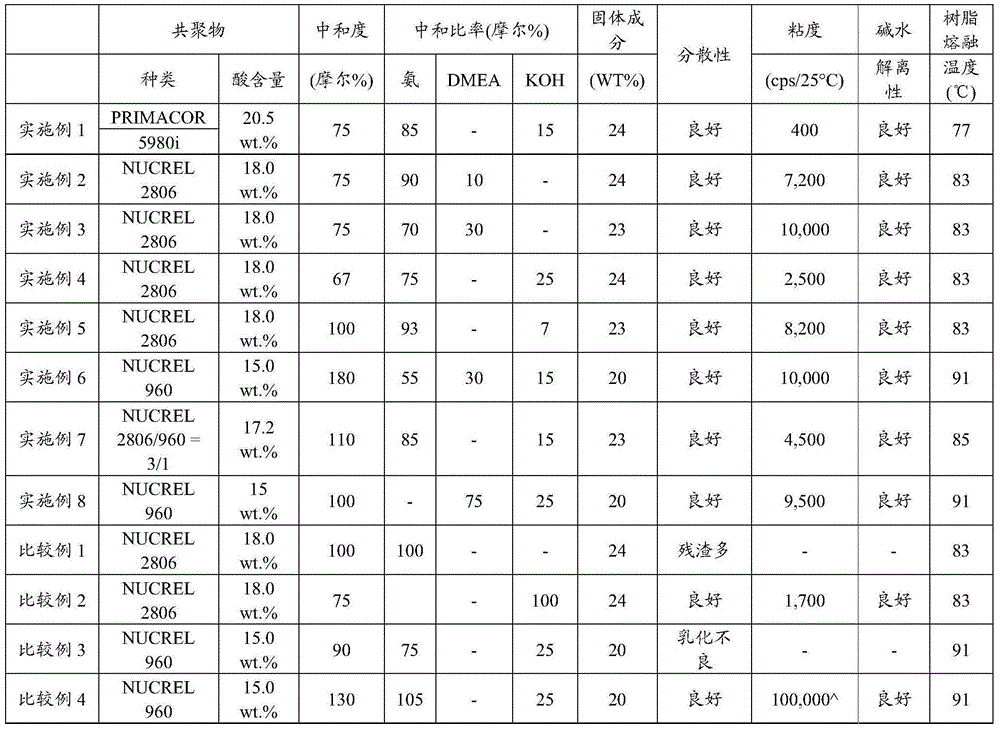

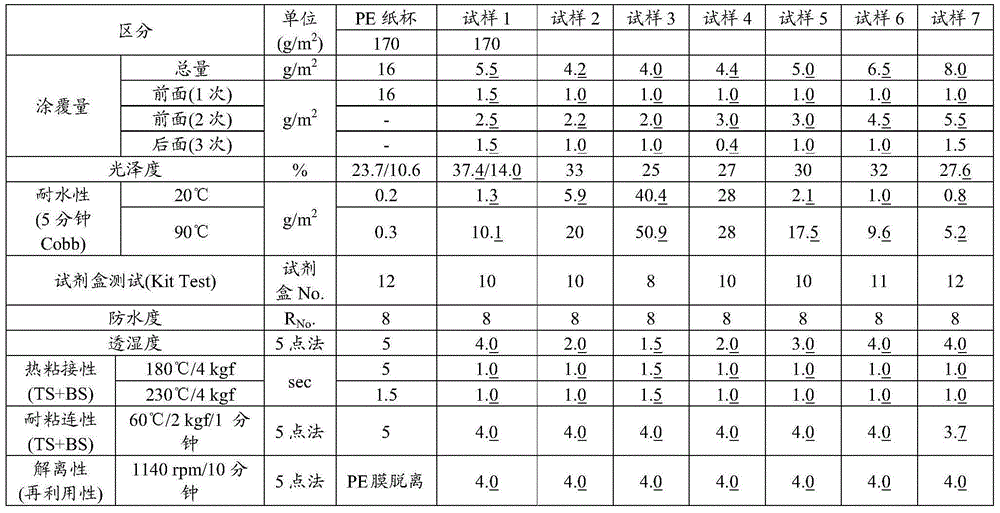

Method for preparing environmentally friendly paper coating agent by using water dispersible resin of ethylene-(meth)acrylic acid polymer, and use thereof

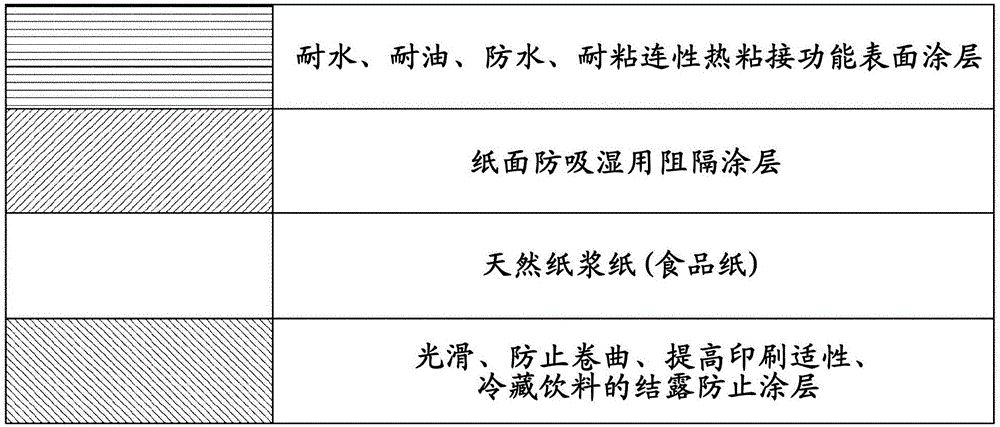

InactiveCN105102508AImprove water resistanceExcellent thermal adhesionFlexible coversWrappersMeth-Water dispersible

The present invention relates to a preparation of a paper molded product made with an environmentally friendly paper coating agent having remarkable water resistance, oil resistance, heat sealing, alkaline water dissolution and the like by using a water dispersible coating solution prepared by adding a quencher, a slipping agent, an antifoaming agent and the like, which are FDA approved, to a dispersed resin water, which is prepared by mixing an alkali metal hydroxide, an amine, ammonia water and the like with an ethylene-acrylic acid copolymer or an ethylene-methacrylic acid copolymer or a mixture thereof, and polymerizing the same in an aqueous medium.

Owner:李炳奭

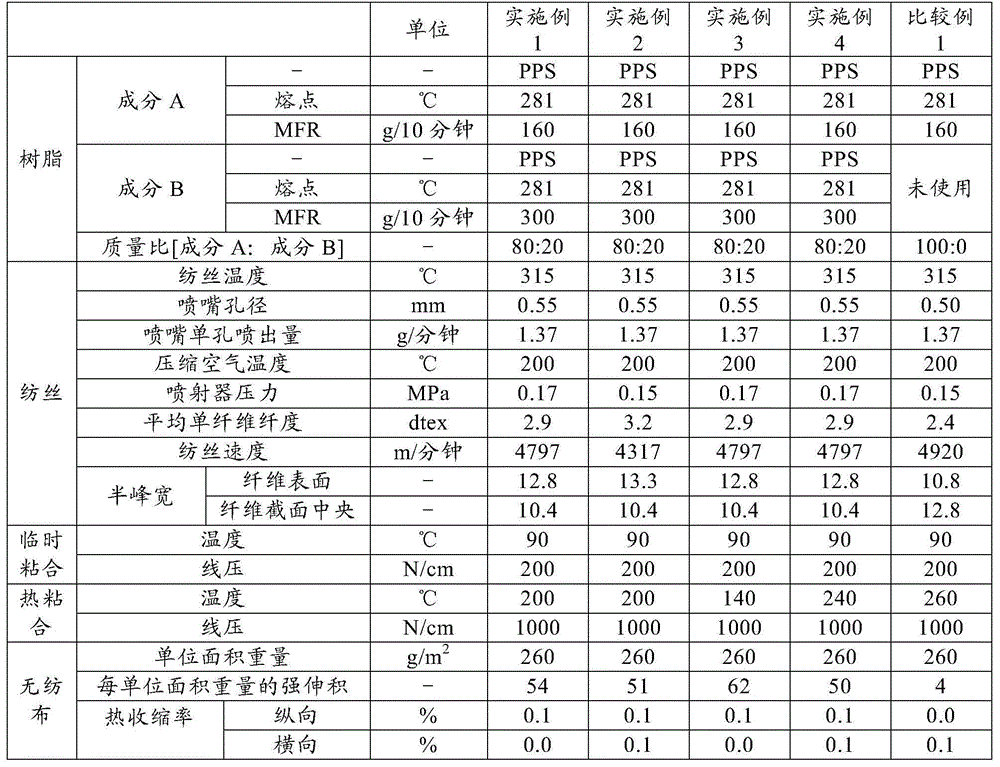

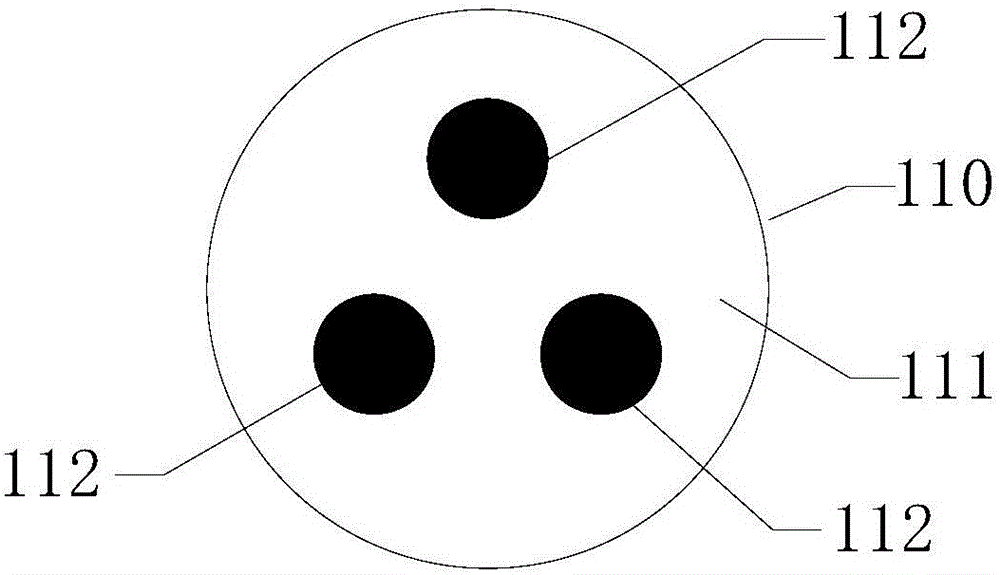

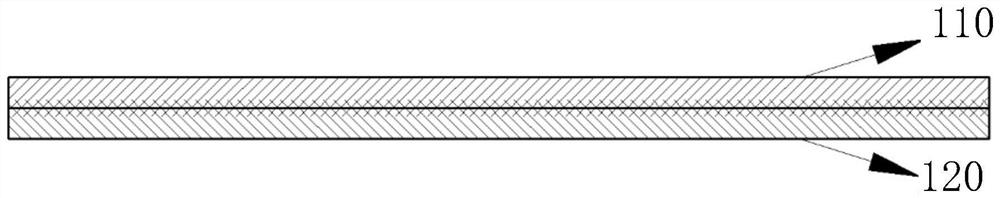

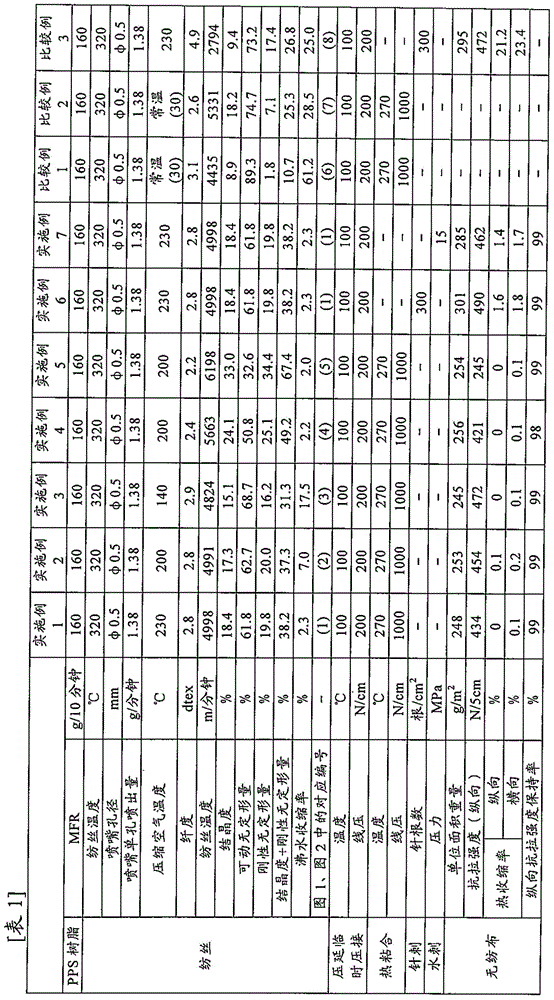

Polyphenylene sulfide composite fiber and non-woven fabric

ActiveCN104641027AThermally dimensional stableImproved thermal dimensional stabilityWoven fabricsConjugated synthetic polymer artificial filamentsNonwoven fabricInorganic sulfide

Provided are: a composite fiber which comprises a resin containing polyphenylene sulfide as the main component and has excellent thermal adhesion properties while keeping thermal dimensional stability thereof; and a non-woven fabric. A composite fiber mainly composed of a component (A) and a component (B), wherein the component (A) is a resin containing polyphenylene sulfide as the main component and the component (B) is a resin containing polyphenylene sulfide as the main component and having a higher melt flow rate than that of the component (A), and wherein at least a part of the surface of the fiber is formed from the component (B).

Owner:TORAY IND INC

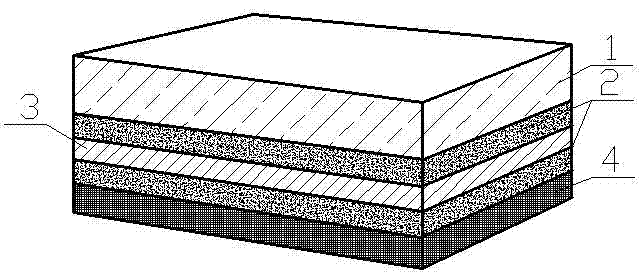

Composite membrane with high barrier property

InactiveCN104512068ANo destructive effectGood printabilityFlexible coversWrappersSurface layerCrystal structure

A disclosed composite membrane with high barrier property comprises an outer surface layer (1), a middle layer (3) and an inner layer (4); the outer surface layer (1) is paper, the middle layer (3) is aluminium foil, and the inner layer (4) is polyethylene; the paper outer surface layer (1) is a printing layer, the aluminium-foil middle layer (3) is nontoxic and odorless and is of a highly-compact metal crystal structure and has good moisture resistance, gas barrier property and shading property; and adhesive layers are arranged between the outer surface layer (1) and the middle layer (3), and between the middle layer (3) and the inner layer (4), and the inner layer (4) polyethylene is thermally bonded with a substrate. The composite membrane has small environmental pollution and does not influence of properties of a medicine self.

Owner:谢超

Laser-marking multilayer sheet for electronic passports, and electronic passport

ActiveUS8322752B2Maintain good propertiesIncrease contrastOther printing matterSynthetic resin layered productsEngineeringLettering

There is provided a laser-marking multilayer sheet for an electronic passport formed by laminating five sheets of a multilayer sheet A / a multilayer sheet B / a film C / a multilayer sheet B / a multilayer sheet A. The multilayer sheet B is a colored laser-marking multilayer sheet. The film C is a laser-marking multilayer sheet made of a film for the electronic passport. The laser-marking multilayer sheet can have clear letters, symbols, and images, which are excellent in a laser-marking property and high in contrasts between the original surface color and the printed portions. The laser-marking multilayer sheet is excellent especially for inhibiting the falsification and forgery thereof.

Owner:MITSUBISHI CHEM CORP

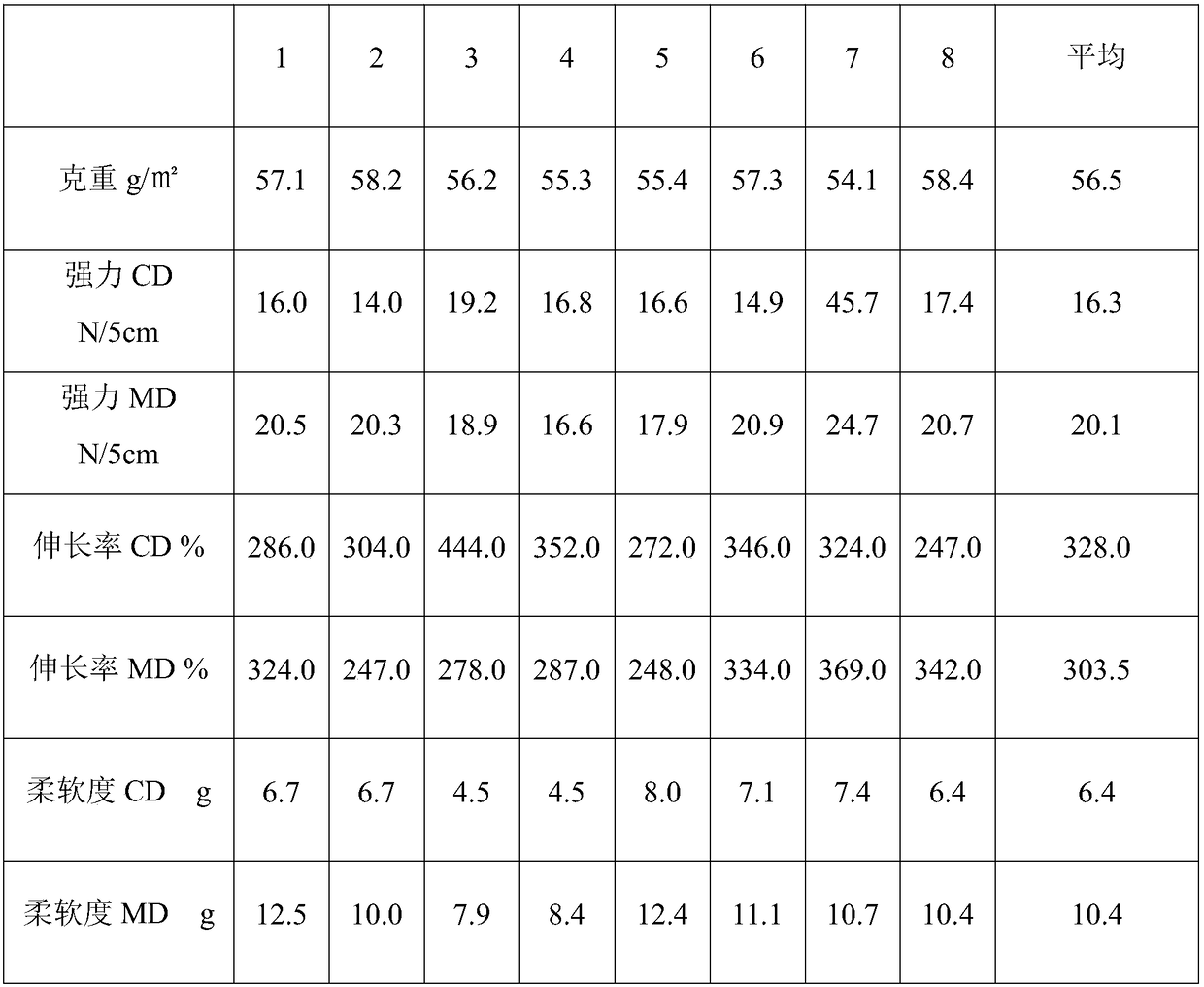

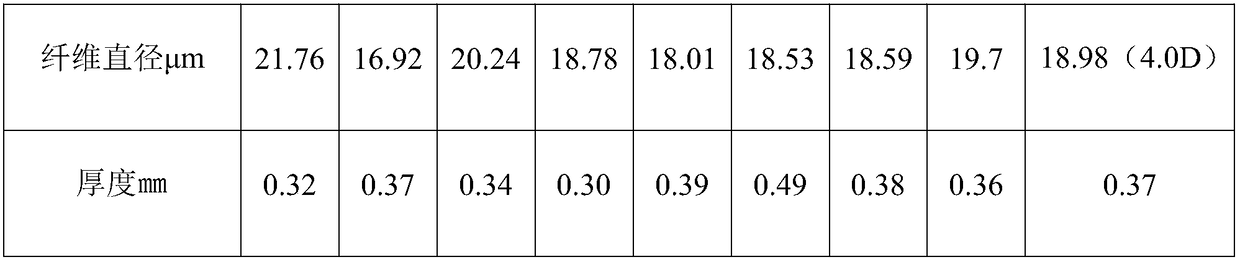

PE spun-bonded non-woven fabric and manufacturing method thereof

The invention relates to a PE spun-bonded non-woven fabric which is composed of PE raw material and elastomer mixed at a ratio of 98%: 2%. The elastomer is VISTAMAXX 6020FL, and the PE raw material isLL6101XR. A manufacturing method of the PE spun-bonded non-woven fabric is further disclosed. A bottom film product for composite air permeable films is produced by using the PE raw material insteadof the conventional PP raw material. The composite bottom film of the conventional PP spun-bonded non-woven fabric needs to be bonded by adhesive. The novel PE spun-bonded non-woven fabric has good adhesion, and can be directly composited with an air permeable film after heating without adding adhesive materials. On the other hand, the PE spun-bonded non-woven fabric can be used in wallpaper without gluing.

Owner:山东恒鹏卫生用品有限公司

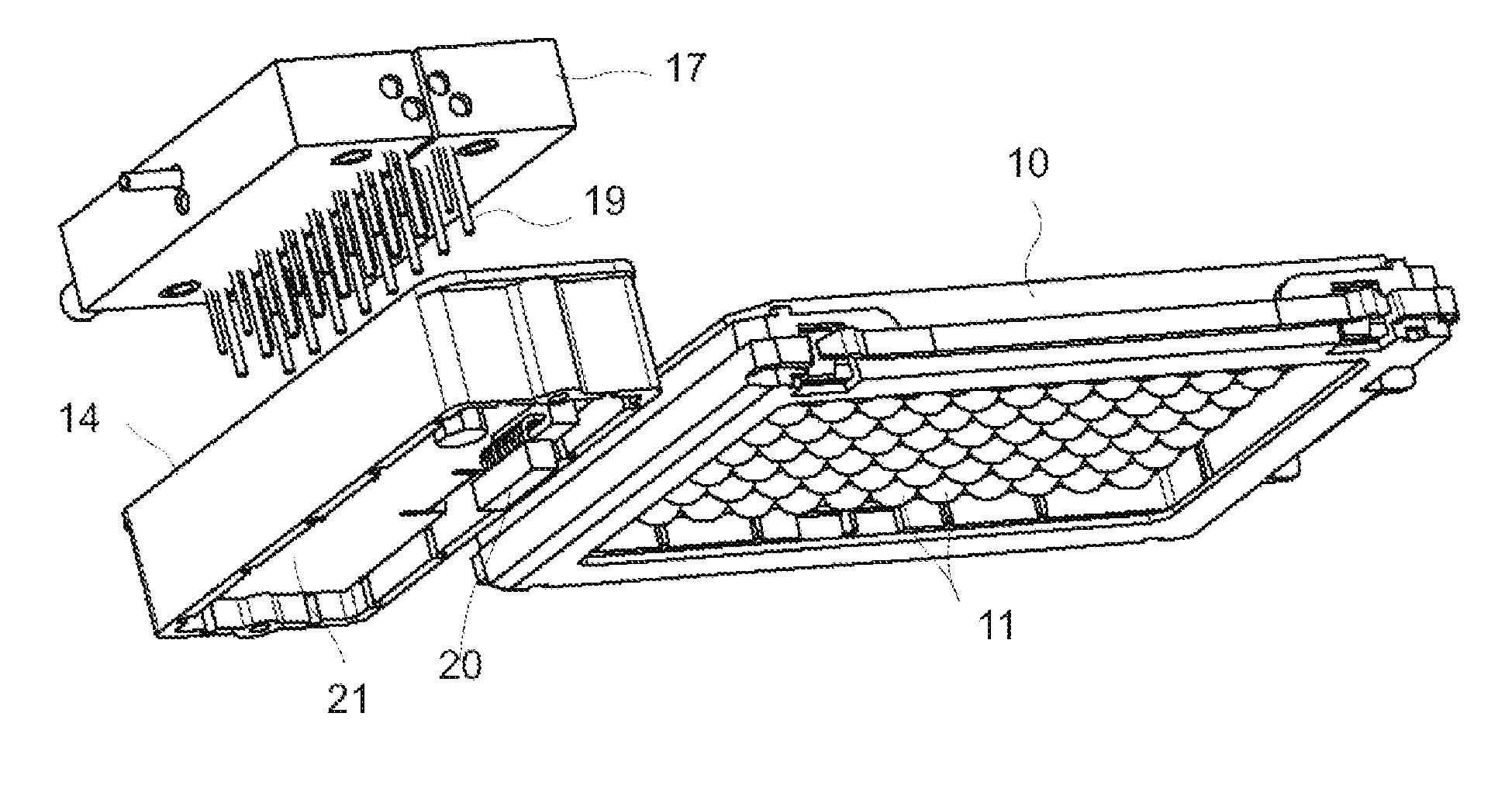

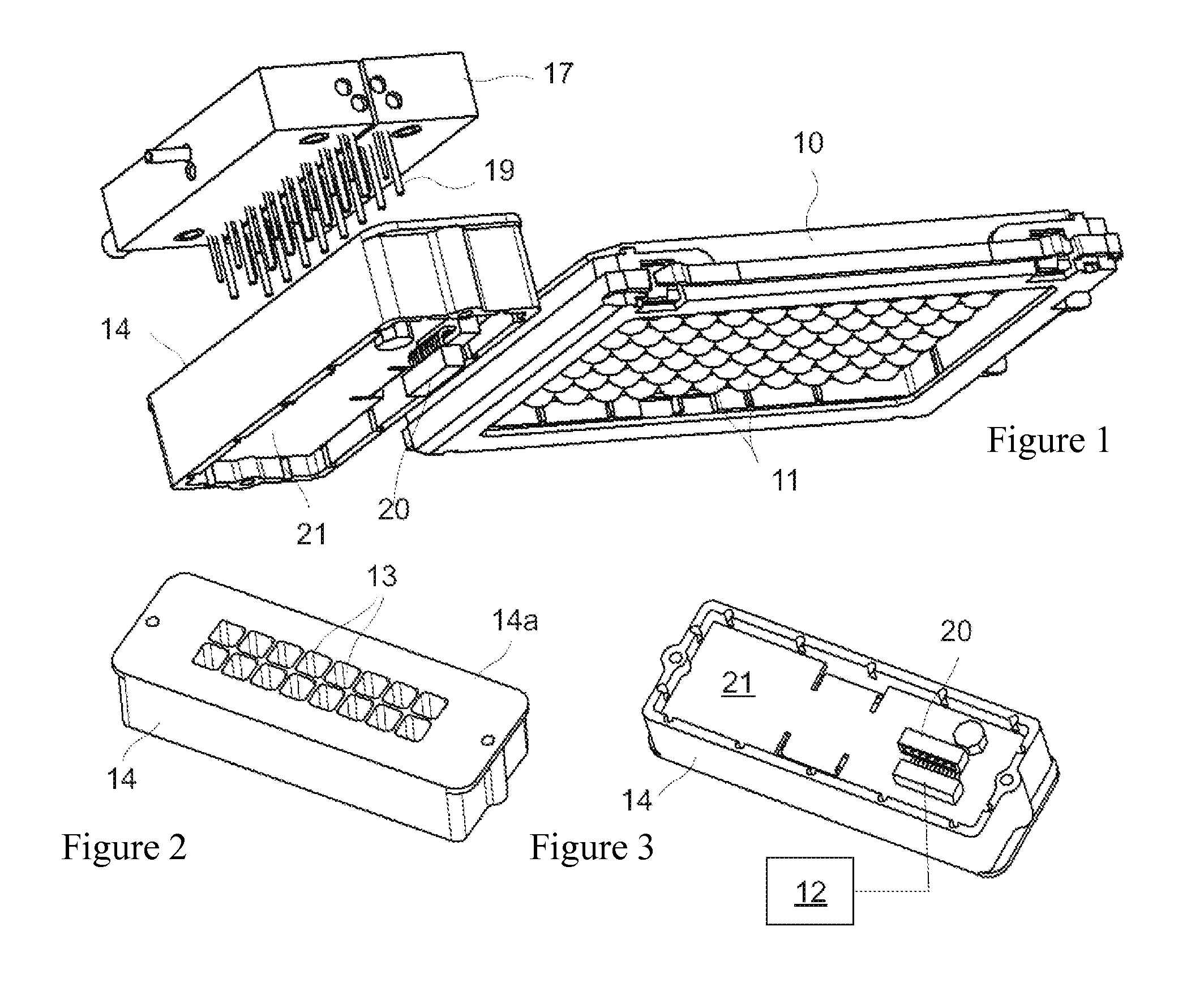

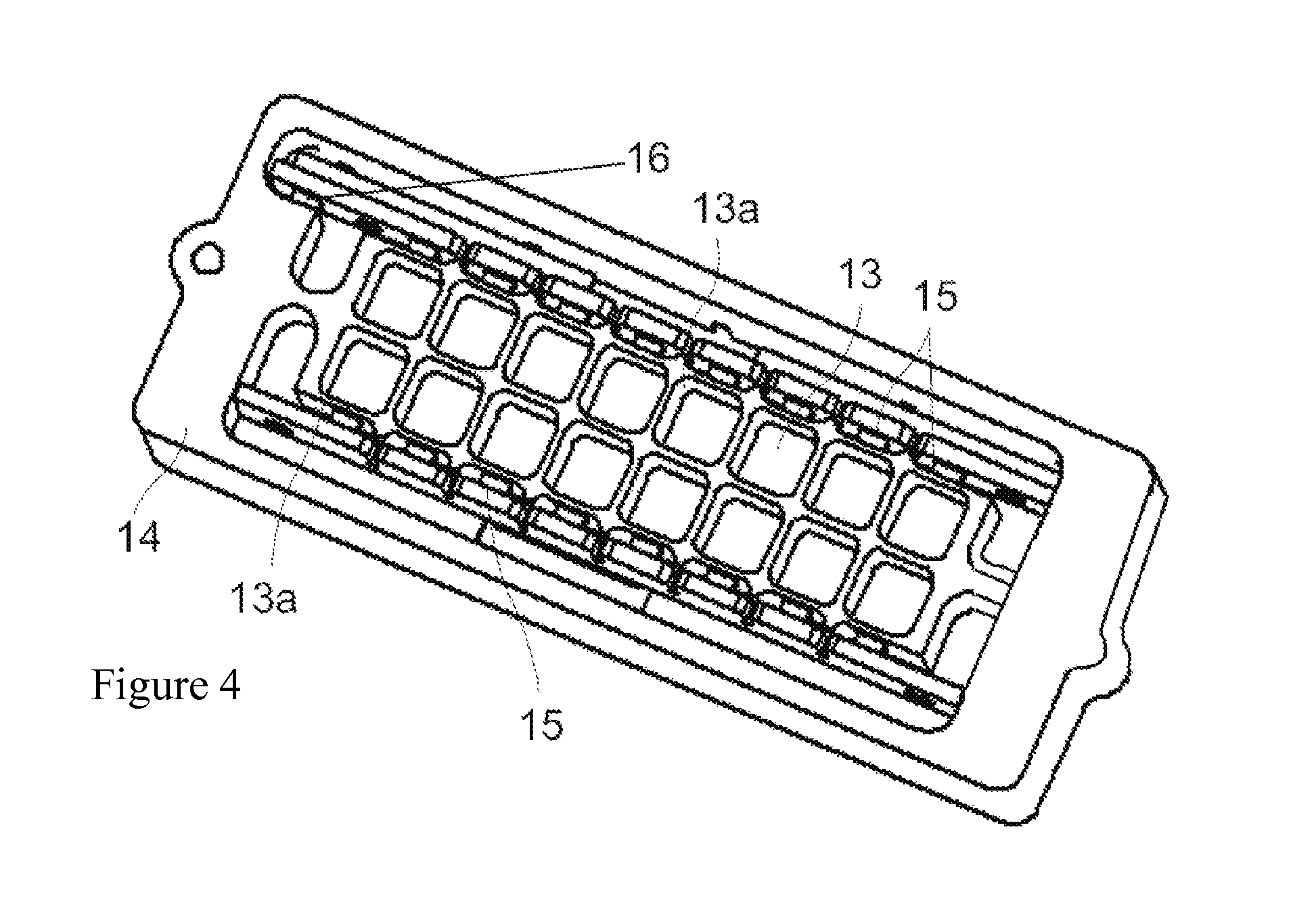

Method and apparatus for detecting the level of a liquid in monitoring a dispense/aspirate process

ActiveUS8689625B2Excellent thermal adhesionImprove responseChemical analysis using titrationMaterial heat developmentLevel sensorThermistor

Owner:STRATEC BIOMEDICAL AG

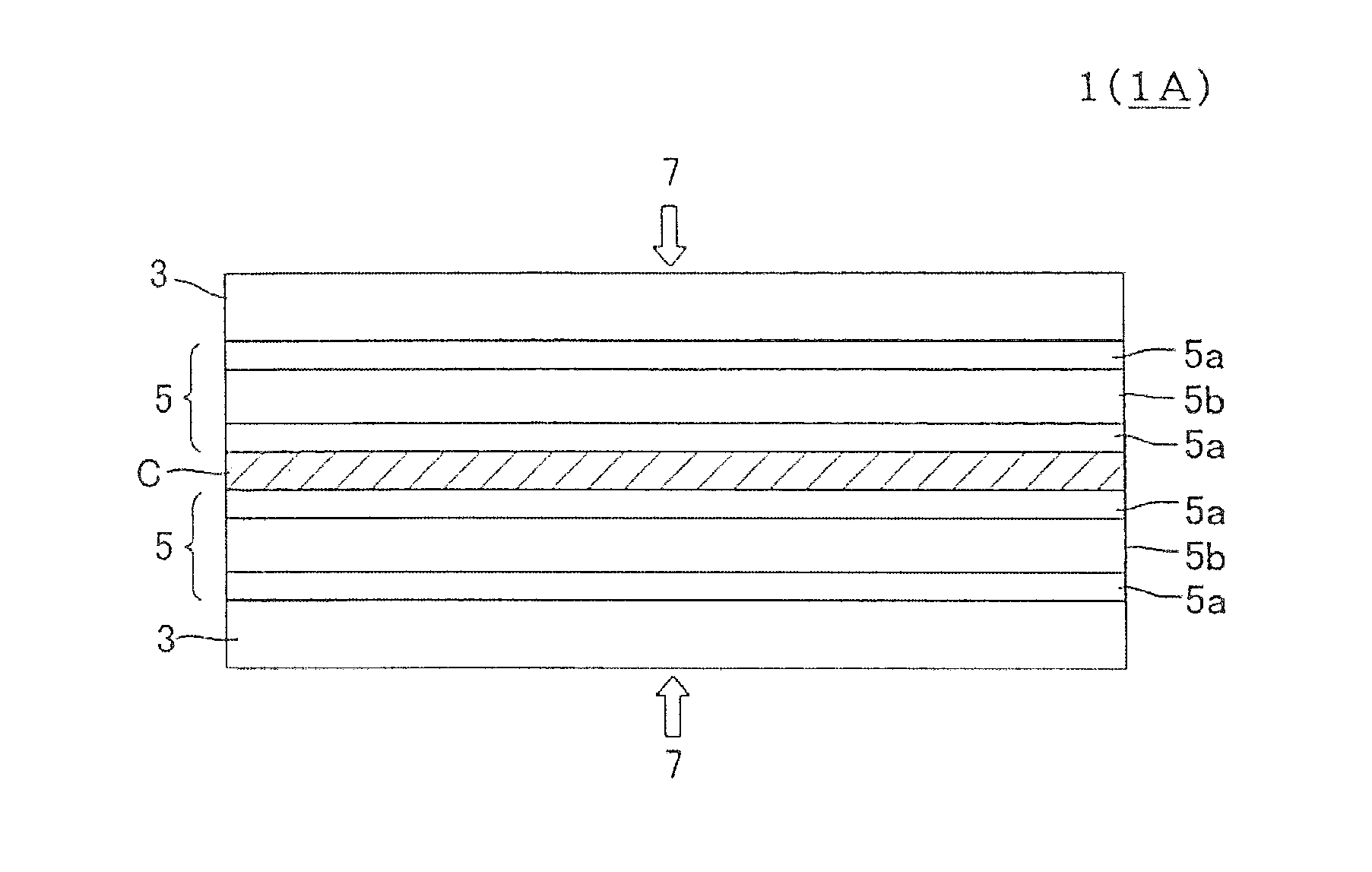

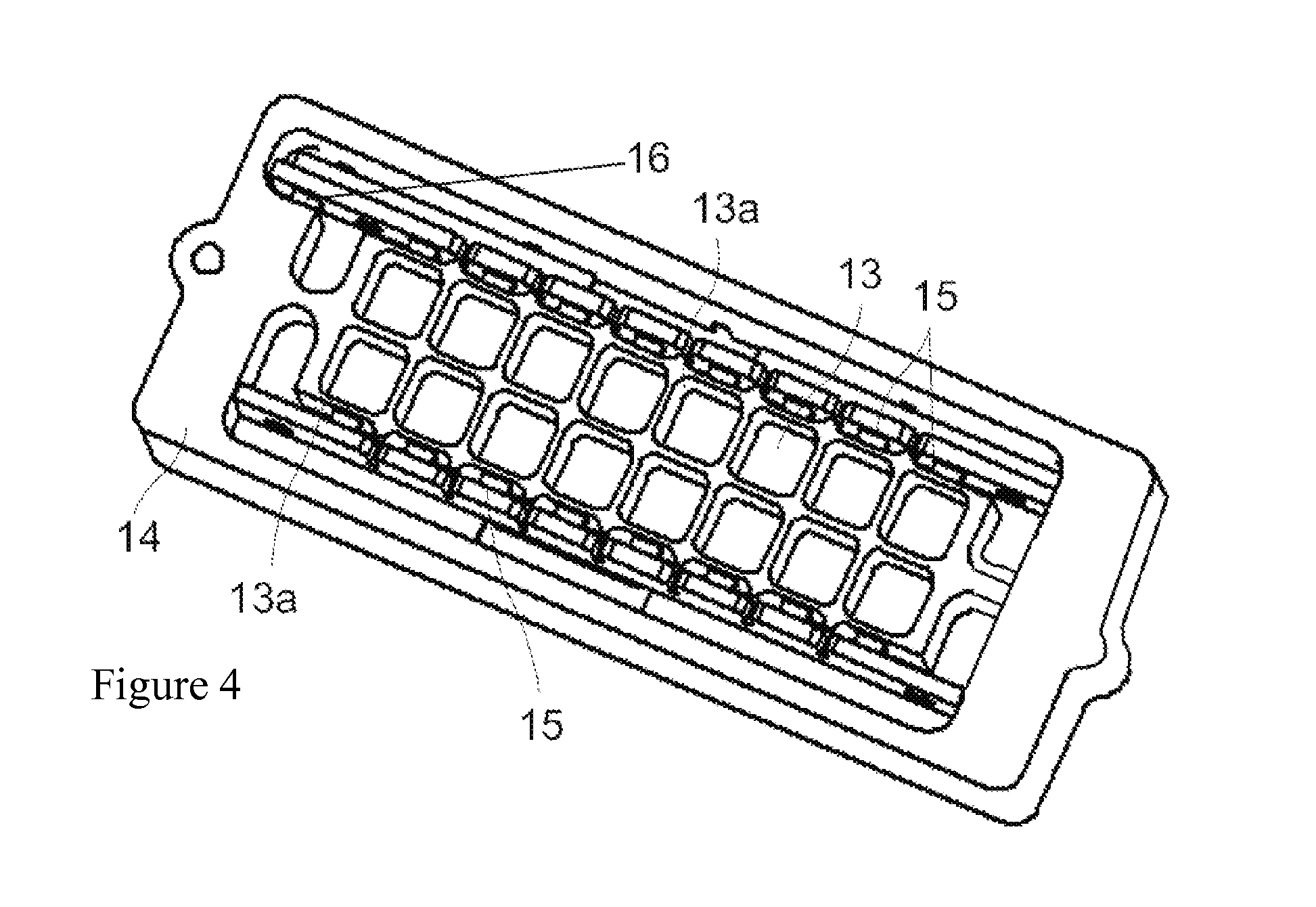

Multilayer sheet for laser marking

ActiveUS8603633B2Excellent thermal adhesionIncrease contrastSynthetic resin layered productsRecord information storagePolyester resinOptoelectronics

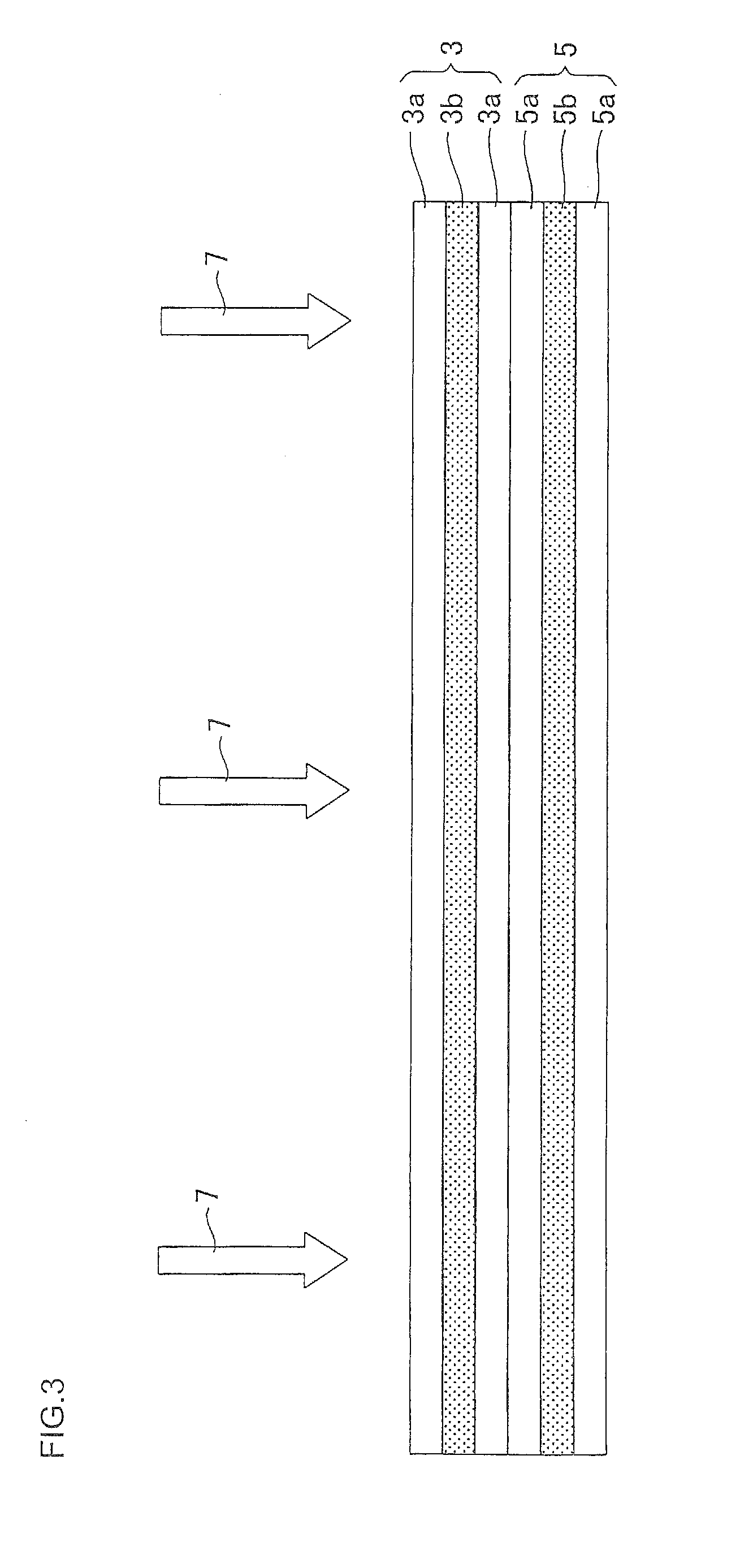

A laser marking multilayer sheet includes a multilayer sheet A, and a multilayer sheet B that is stacked under the multilayer sheet A. The multilayer sheet A is a transparent laser marking multilayer sheet. A skin layer that forms each outermost layer of the multilayer sheet A is formed of a noncrystalline aromatic polyester resin composition, and a core layer of the multilayer sheet A is formed of a polycarbonate resin composition. The multilayer sheet B is a colored laser marking multilayer sheet. A skin layer that forms each outermost layer of the multilayer sheet B is formed of a noncrystalline aromatic polyester resin composition, and a core layer of the multilayer sheet B is formed of a polycarbonate resin composition.

Owner:JAPAN COLORING

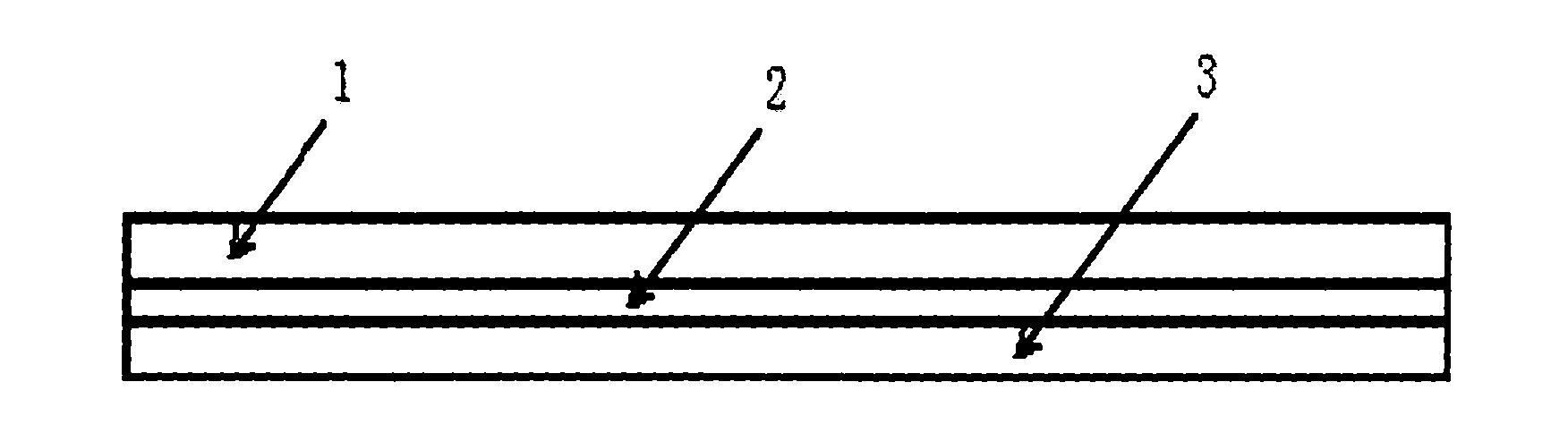

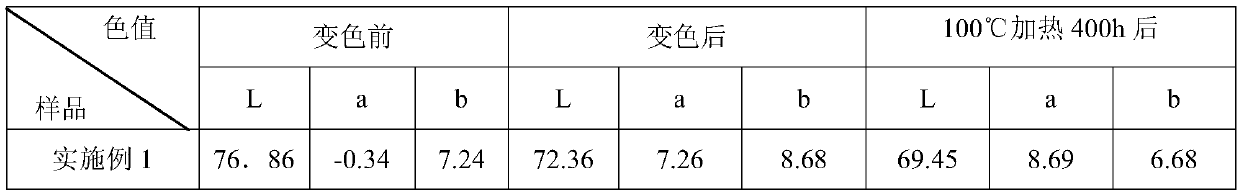

Thermochromic low-melting-point polyester film and preparation method thereof

ActiveCN111098577AExtended use timePrevent loss of functionSynthetic resin layered productsPolymer scienceCopolyester

The invention discloses a thermochromic low-melting-point polyester film and a preparation method thereof, and belongs to the field of polyester. The method comprises the following steps: taking terephthalic acid, 1, 4-butanediol or ethylene glycol as raw materials, adding aliphatic dibasic acid, polyester diol and a monohydroxy end-capping reagent by adopting a direct esterification method, and carrying out esterification and polymerization reactions to prepare the PBT or PET modified copolyester, crushing PET or PBT slices, uniformly mixing the crushed PET or PBT slices with a thermochromicmaterial, a heat stabilizer and an antioxidant in a high-speed mixer, and carrying out melt blending and pelletizing by using a double-screw extruder to obtain thermochromic low-melting-point polyester master batch; and using the prepared thermochromic low-melting-point polyester master batch as an intermediate layer and low-melting-point polyester as an outer layer to prepare three layers of thethermochromic low-melting-point polyester film. The prepared thermochromic polyester film is low in modulus, good in hand feeling, low in crystallinity, good in thermal adhesiveness and good in colorchanging performance, and can be widely applied to the fields of automobiles, buildings, heat-seal packaging films and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chloroprene rubber composition for ultra low temperature sealing arrangement

ActiveCN101412824AMeet the requirementsExcellent thermal adhesionOther chemical processesPolymer scienceNeoprene

The invention provides a neoprene composition for an ultra low temperature sealing device, wherein neoprene, carbon black, ZnO and accelerant are evenly mixed and placed in a rubber mixing machine for mixing. The neoprene composition has good process performance and metal heat bonding performance; and at an ultra low temperature of 196 DEG C below zero, the neoprene composition has good medium compatibility and reliable sealing performance, and the pressure resisting range reaches between 0.1 below zero to 35MPa.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

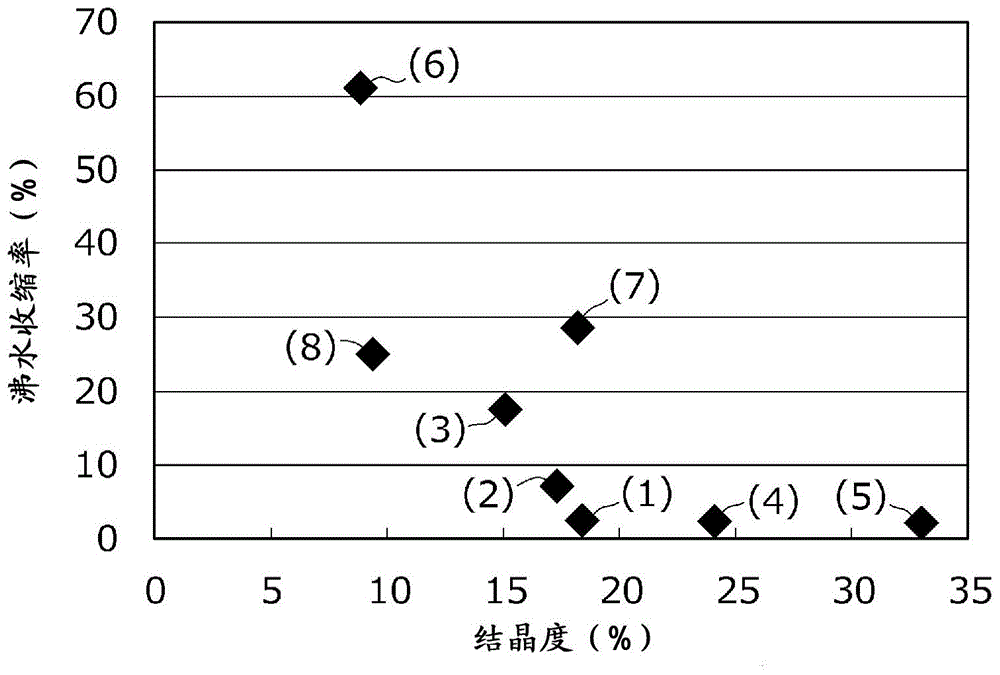

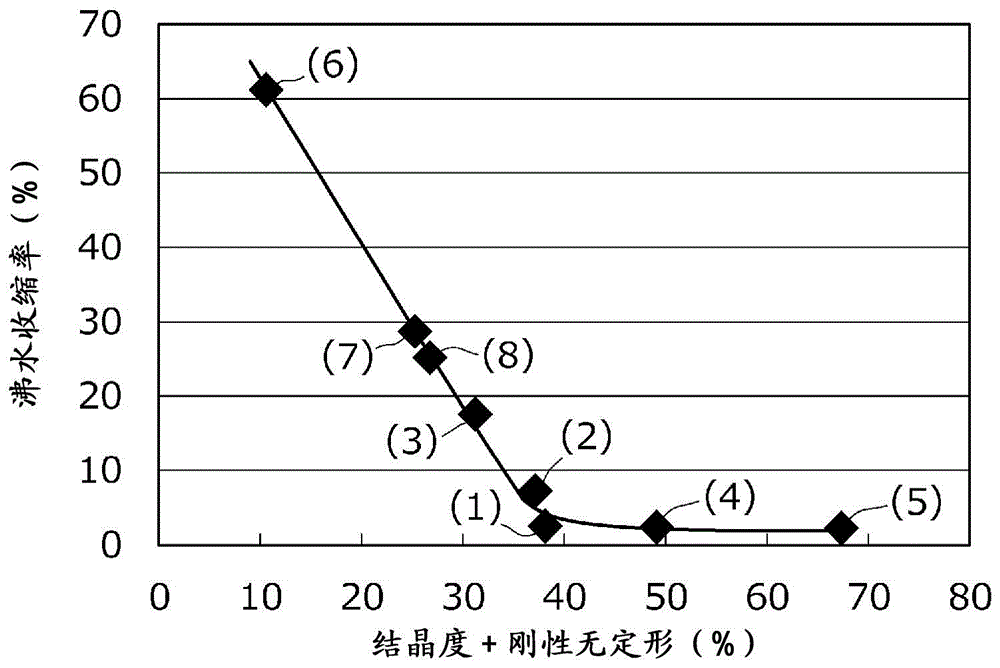

Polyphenylene sulfide composite fiber and nonwoven fabric

InactiveCN103328704BHeat resistantImprove heat resistanceWoven fabricsConjugated synthetic polymer artificial filamentsHeat resistanceNonwoven fabric

A polyphenylene sulfide composite fiber which consists primarily of component A and component B, the component A being a resin primarily containing polyphenylene sulfide made from p-phenylene sulfide as a primary unit, the component B being a resin primarily containing a copolymerized polyphenylene sulfide made from at least one kind of copolymerization unit other than p-phenylene sulfide, characterized in that at least one part of a fiber surface is made of component B. A thermally adhesive composite fiber and a nonwoven fabric which are made of a resin consisting primarily of polyphenylene sulfide and are excellent in heat resistance, flame retardancy and chemical resistance can be provided.

Owner:TORAY IND INC

Thermal interface material, interface thermal coupling method, and production method for thermal interface material

PendingCN110249424AExcellent thermal adhesionLess pressure dependentCarbon compoundsFilm/foil adhesivesPhysical chemistryGraphite

The present invention achieves: a graphite-based thermal interface material that exhibits excellent thermal resistance properties even when used between members having uneven surfaces; and a production method for such a thermal interface material. This thermal interface material comprises a flexible or fluid substance (A) and a graphite film (B), wherein the graphite film has a thickness falling within the range of 100 nm to 15 [mu]m, a density falling within the range of 1.20-2.26 g / cm<3>, and a thermal conductivity in the film surface direction of at least 500 W / mK, and the weight ratio (A / B) between (A) and (B) falls within the range of 0.08-25.

Owner:KANEKA CORP

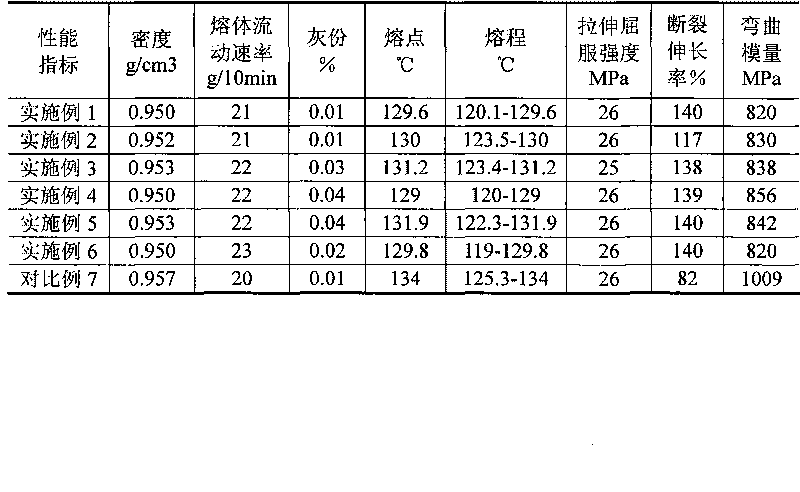

High-density polyethylene composition

InactiveCN101698721AImprove performanceGood flexibilityConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolymer scienceHigh density

The invention discloses a high-density polyethylene composition, which contains ethylene-1-butenyl copolymer with the flow rate of melt between 20g / 10min and 24g / 10min, which is suitable for the production of a sheath of PE / PP composite fiber, and which has extremely excellent spinnability, thermal bonding property and softness. The nonwoven fabric which is produced by using the composition has excellent softness and good physical and mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP

Degradable environment-friendly non-woven adhesive lining containing bamboo activated carbon powder and preparation method thereof

ActiveCN106072936AImprove environmental performanceGood stabilityFibre treatmentGarmentsChemistrySkin core

The invention discloses a degradable environment-friendly non-woven adhesive lining containing bamboo activated carbon powder and a preparation method thereof. The degradable environment-friendly non-woven adhesive lining comprises a base cloth and a hot melt adhesive layer, wherein the base cloth has a double-layer structure; the upper layer is a skin core compound fiber net layer; the lower layer is an anti-microbial moisture-absorbing fiber net layer; the skin core compound fiber net layer is composed of skin core double-component cellosilk; the skin core double-component cellosilk is formed by compounding a polylactic acid fiber layer with a polypropylene fiber core layer; the anti-microbial moisture-absorbing fiber net layer is composed of chitosan fiber chopped strands and chitin fiber filaments at a certain weight ratio; one side of the skin core compound fiber net layer is connected with the anti-microbial moisture-absorbing fiber net layer; a hot melt adhesive layer is coated on the other side of the skin core compound fiber net layer; the bamboo activated carbon powder is fixed on the base cloth. The degradable environment-friendly non-woven adhesive lining containing bamboo activated carbon powder adopts PLA / PP compound fiber, chitosan fiber and chitin fiber with biological degradability as manufacturing fibers, has the advantages of excellent environmental protection, stability, elasticity, antimicrobial activity and moisture absorption and also has the effects of purifying air, eliminating peculiar smell, absorbing moisture and preventing mold.

Owner:CHANGXING SHENGFAN TEXTILE

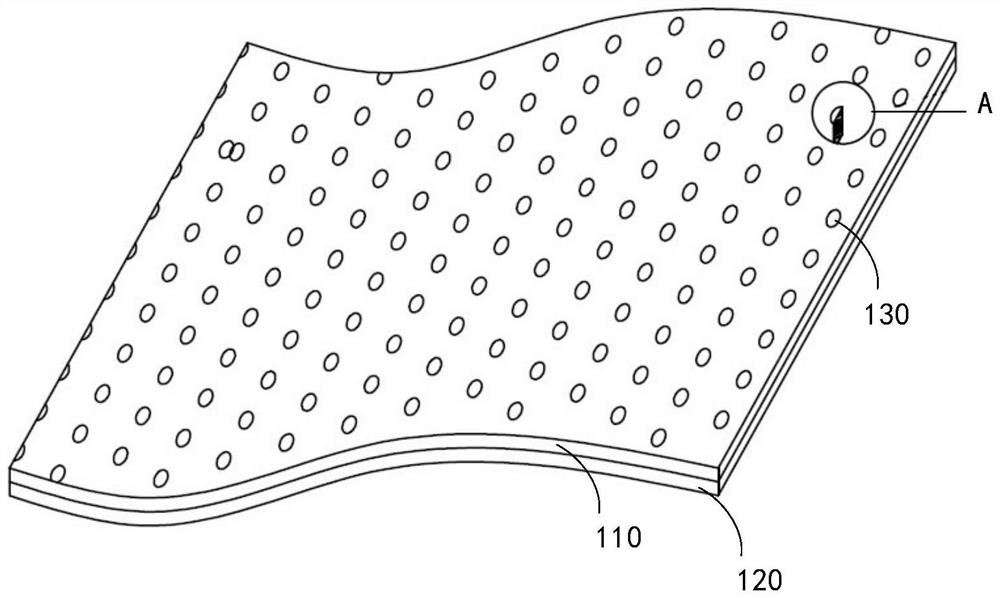

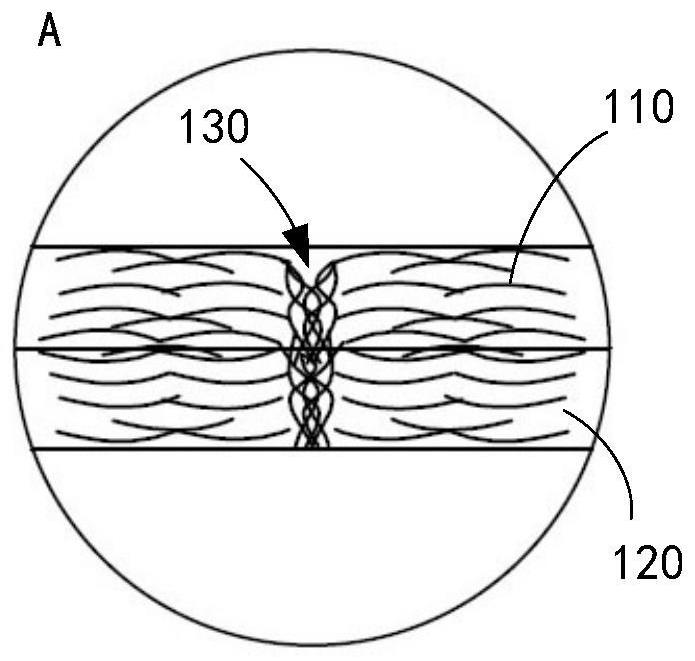

Spunlace non-woven fabric, composite non-woven fabric and sanitary absorption product

PendingCN114481444AReduce thicknessEasy to heat bondSanitary towelsBaby linensPolymer scienceCotton fibre

The invention relates to a spunlace non-woven fabric, which is provided with a plurality of spunlace points, and comprises an upper surface fiber layer, a lower surface fiber layer, an upper surface fiber layer and a lower surface fiber layer, and a lower surface fibrous layer, the upper surface fibrous layer and the lower surface fibrous layer entangled with each other at the plurality of spunlace points of the spunlace nonwoven fabric, the lower surface fibrous layer comprising bi-component staple fibers. According to the spunlace non-woven fabric, the skin feeling of a wearer is dry and comfortable, and meanwhile the cotton fibers and the bi-component short fibers are contained in the fiber mixing layer; the spunlace non-woven fabric with the upper surface fiber layer and the lower surface fiber layer which are mutually entangled at the spunlace points has better bonding performance, especially heat bonding or ultrasonic bonding performance on the lower surface fiber layer side, so that the spunlace non-woven fabric can be better compounded with other materials or can be more conveniently formed into a sanitary absorbing product; meanwhile, the fiber layer of the lower surface layer is made of bi-component short fibers, so that the dryness of the sanitary absorption product can be improved.

Owner:江苏锦琪昶新材料有限公司

Aromatic melt-blown non-woven fabric having low ventilation resistance, planar mask with melt-blown non-woven fabric and manufacturing method of planar mask

InactiveCN112080859AImprove filtering effectIncrease contentNon-woven fabricsProtective garmentLinear low-density polyethylenePolymer science

The invention discloses an aromatic melt-blown non-woven fabric having low ventilation resistance, a planar mask with the melt-blown non-woven fabric and a manufacturing method of the planar mask. Theplanar mask is prepared from the following raw materials in parts by weight of 80-90 parts of polypropylene melt-blown non-woven fabric slices, 10-13 parts of maleic anhydride grafted polypropylene,5-7 parts of metallocene catalyzed linear low-density polyethylene, 1.8-2.2 parts of mesoporous silica, 2.5-3 parts of nano bismuth stearate, 1.5-1.8 parts of 3-[3-(benzotriazole-2-yl)-5-tert-butyl-4-hydroxyphenyl] methyl propionate, 3-3.8 parts of 2,6-dimethylphenylphthalimide, 2-2.5 parts of oleamide and 0.6-0.9 part of erucamide. The aromatic melt-blown non-woven fabric having low ventilation resistance is good in filtering effect and excellent in electret charge storage performance, the filtering efficiency of the non-woven fabric is still good after the non-woven fabric is stored for 3 months under the high-temperature and high-humidity conditions, and the prepared planar mask is good in filtering effect and good in protection effect. The mask is good in air permeability, low in ventilation resistance, and not liable to cause discomfort such as oxygen deficit when being worn.

Owner:怡佳(福建)卫生用品股份有限公司

Polyphenylene sulfide fibers and nonwoven fabric

ActiveCN103562446AHeat resistantImprove heat resistanceMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceHeat resistance

Owner:TORAY IND INC

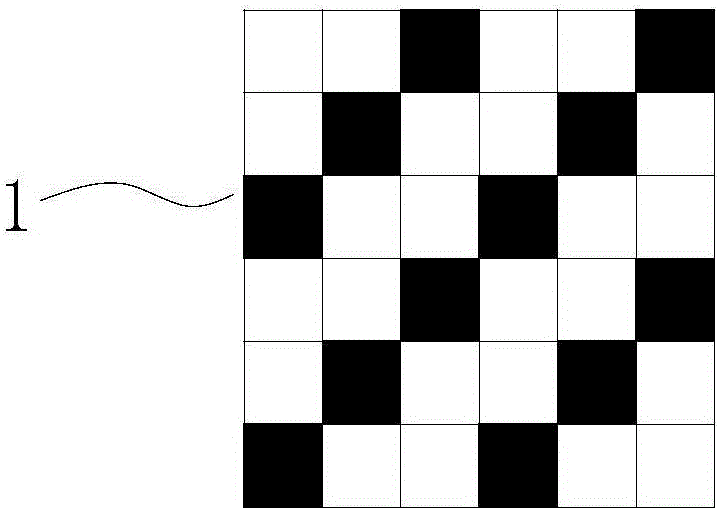

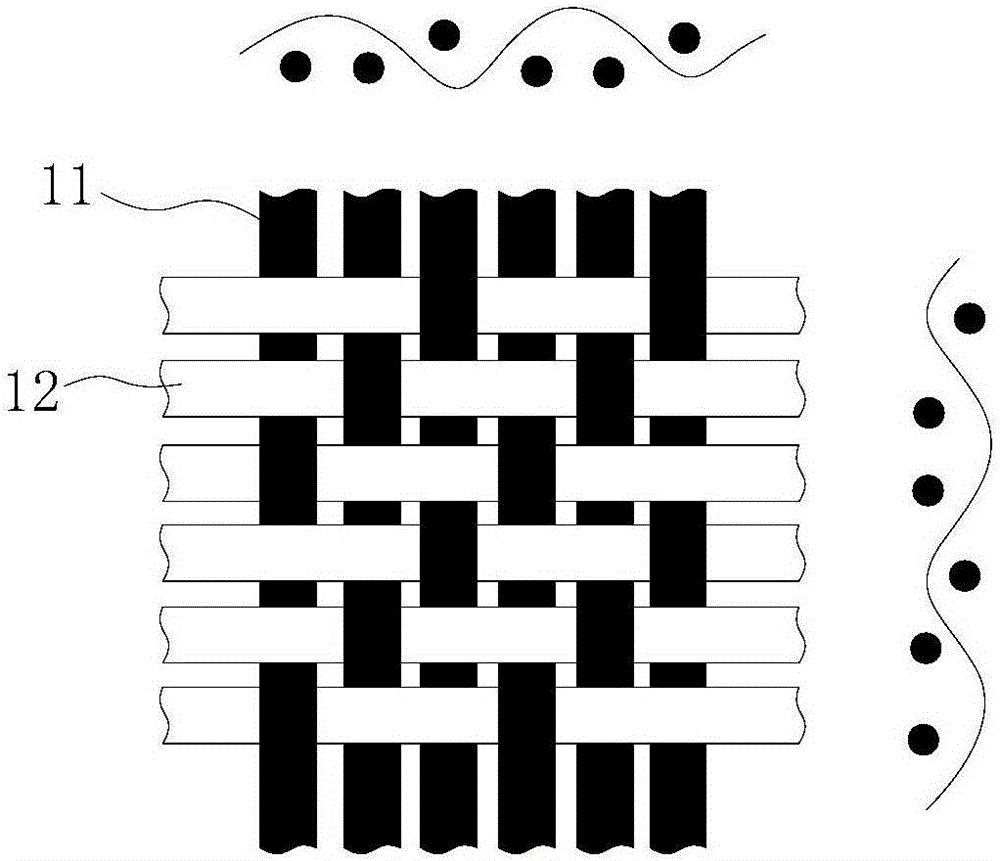

Degradable environment-friendly adhesive lining containing bamboo activated carbon powder and preparation method of adhesive lining

The invention discloses a degradable environment-friendly adhesive lining containing bamboo activated carbon powder. The adhesive lining comprises base cloth and a gluing layer, wherein the base cloth is a sine-cosine curve-shaped stable overlying structure formed by up-down alternate contact between a warp yarn and a weft yarn, the warp yarn is formed by the twisting of a plurality of skin core compound fiber filaments, the skin core compound fiber filaments are formed by the compounding of PLA fiber skin layers and PP fiber core layers, and the weft yarn is formed by the twisting of a plurality of chitin fiber filaments; bamboo activated carbon powder is fixed in the base cloth, and one of two surfaces of the base cloth are coated with the gluing layers. The invention further provides a preparation process of the degradable environment-friendly adhesive lining containing the bamboo activated carbon powder. By utilizing biodegradable PLA / PP skin core compound fiber filaments and chitin fiber filaments as manufacturing fibers of woven lining cloth, the adhesive lining has the advantages of environmental friendliness, antimicrobial activity, hygroscopicity and the like; by virtue of fixation of the bamboo activated carbon powder, the adhesive lining has the effects of purifying air, eliminating peculiar smell, absorbing moisture, preventing mold, inhibiting bacteria and killing pests.

Owner:CHANGXING SHENGFAN TEXTILE

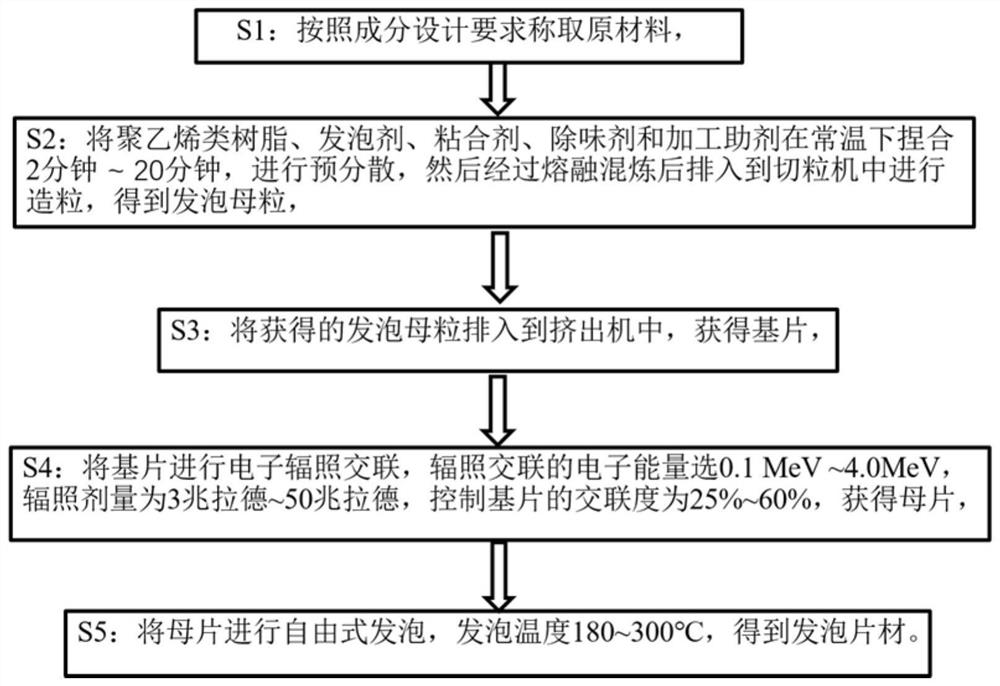

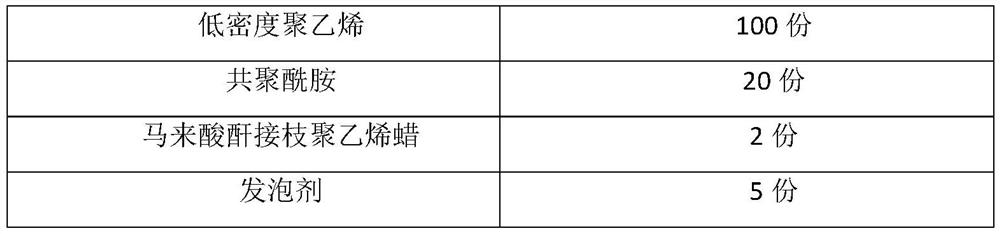

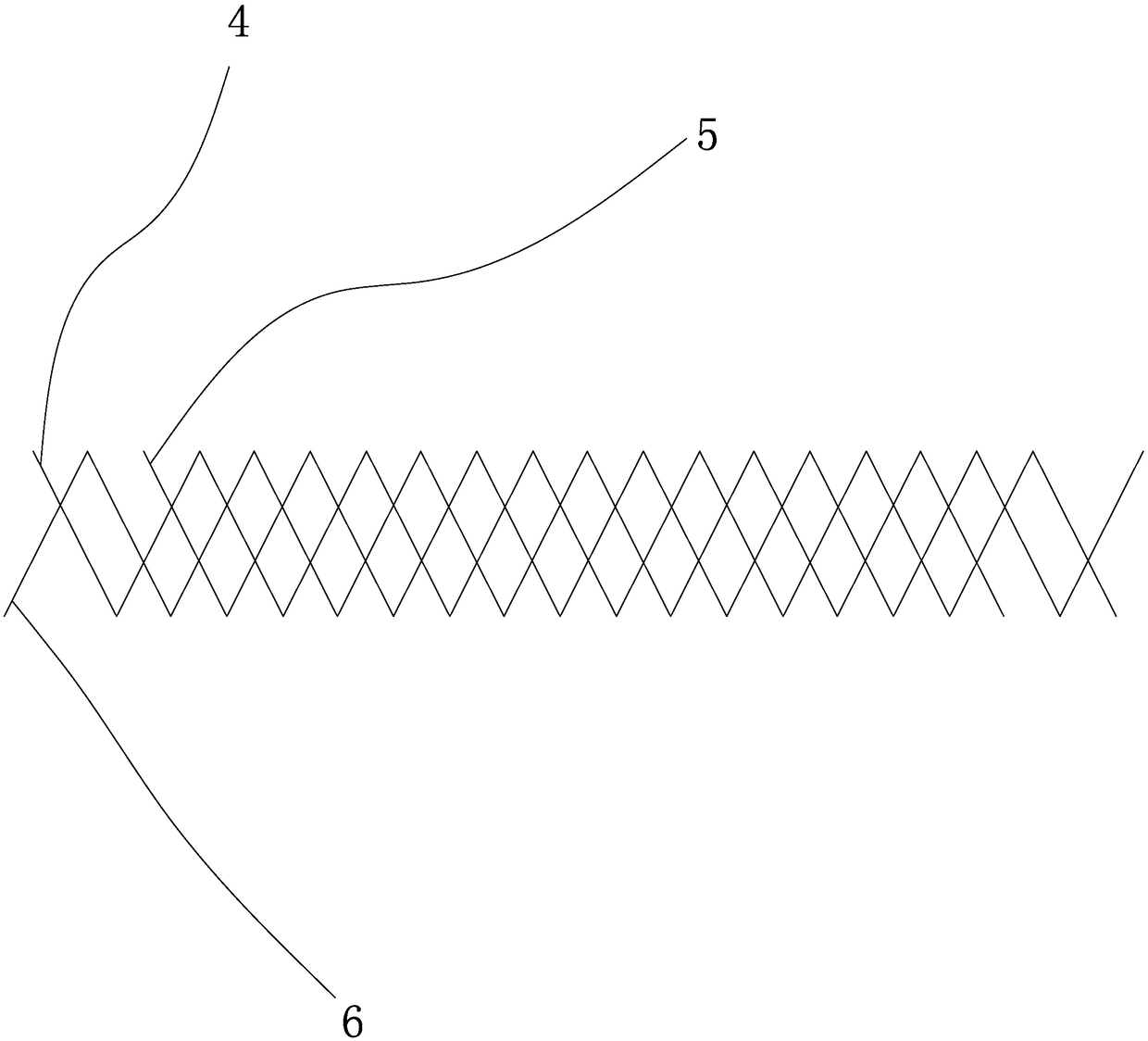

Low-odor polyethylene foam material with thermal bonding performance and preparation method thereof

The invention provides a low-odor polyethylene foam material with thermal bonding performance and a preparation method thereof, and belongs to the field of polyethylene foam materials. The density of the material is 0.05-0.18 g / cm<3>, and the hardness of the material is represented as 30-70 according to Shore C. The low-odor polyethylene foam material has uniform thermal bonding performance from inside to outside. After the low-odor polyethylene foam material is bonded with an external fabric, the peel strength is 1.5-2.6 N / mm. The odor grade of the low-odor polyethylene foam material is not greater than 2.5. The polyethylene foam material has no adhesive property at the temperature of 100-130 DEG C and has adhesive property at the temperature of higher than 180 DEG C. The polyethylene resin is resin obtained by polymerizing polyethylene monomers or polymerizing a polyethylene monomer with other monomers. The invention also provides a method for preparing the polyethylene foam material. The material provided by the invention has the advantages of thermal bonding performance, good processing technology and no pungent smell, and can be well compounded with fabrics made of other materials.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

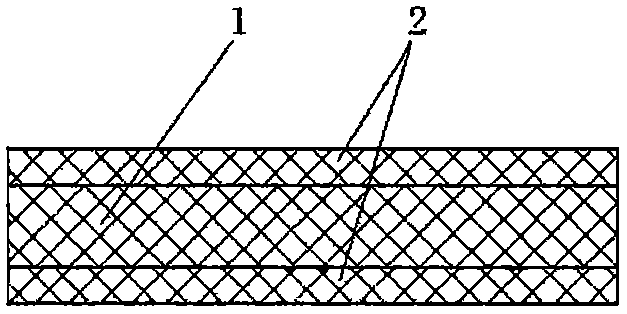

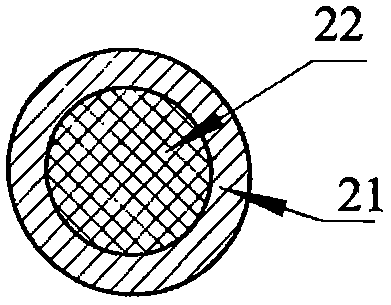

Insulation reinforcing mat for cable and preparing method thereof

InactiveCN104078103AAvoid bondingReduce usagePlastic/resin/waxes insulatorsInsulated cablesFiberGlass fiber

The invention relates to an insulation reinforcing mat for a cable and a preparing method thereof. The mat is formed by mixing 80-92% of glass fiber water drawing wires and 8-20% of CO-PET / PET fiber by weight. The preparing method comprises the steps of raw material beating, mixing, matching, forming and finished product collecting. In the adopted material and in the machining process, no adhesive is added, and therefore the insulation reinforcing mat for the cable has the advantages of being uniform in thickness and mass area ratio, high in insulating coefficient, good in heat-bonding effect and the like.

Owner:JIANGSU CHANGHAI COMPOSITE MATERIALS CO LTD

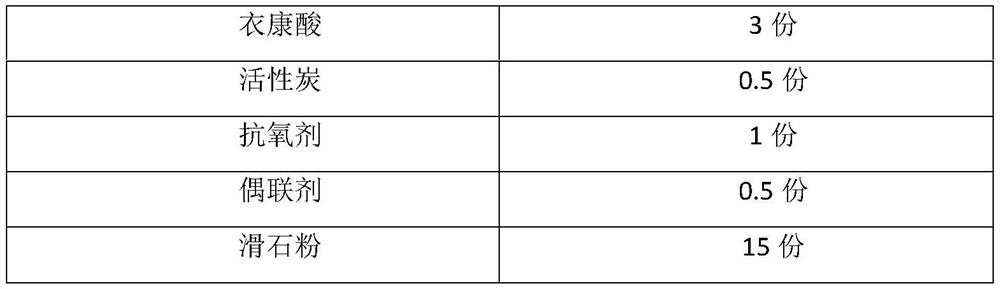

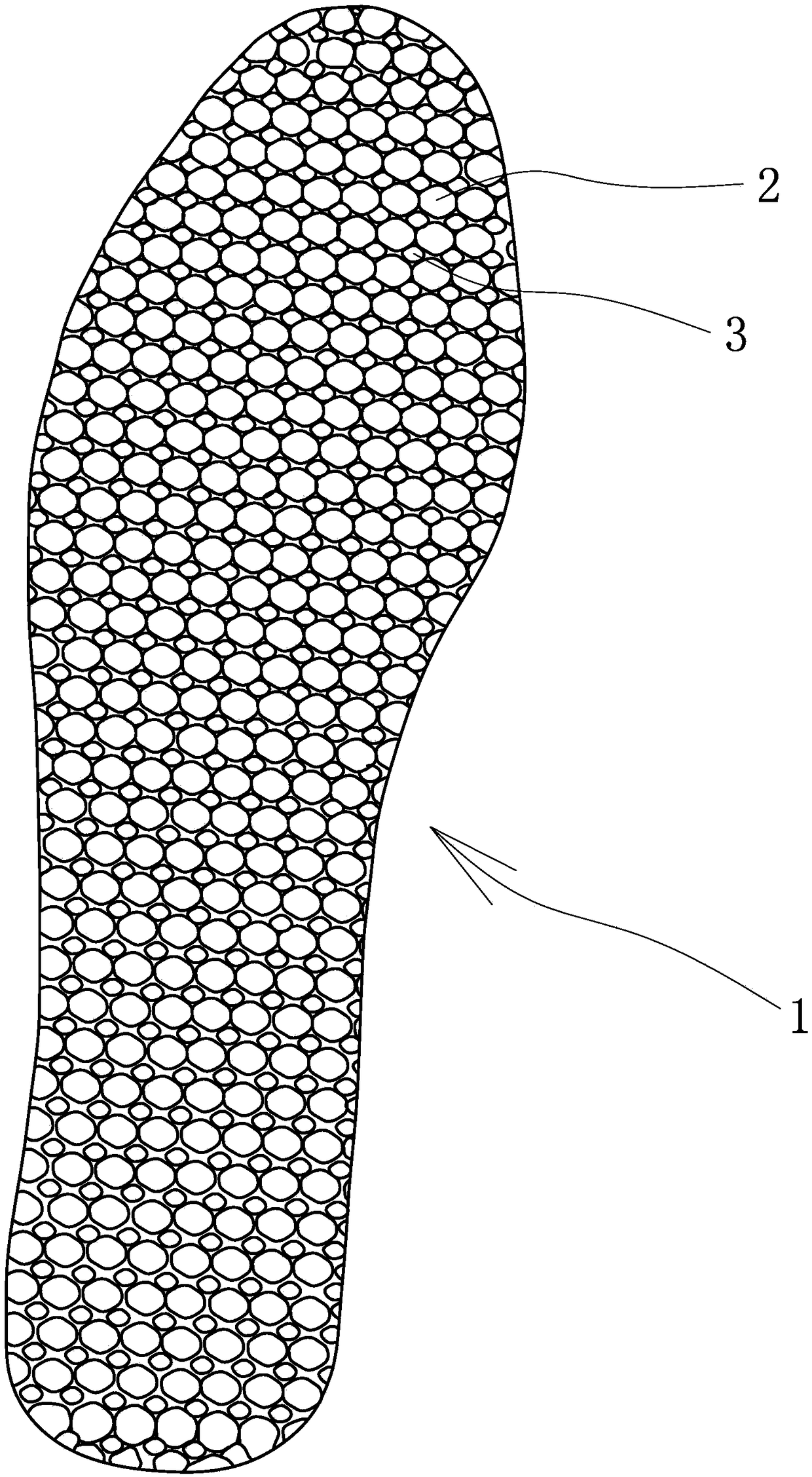

Deodorizing and sterilizing insole and manufacturing method thereof

InactiveCN108968233AThe hybrid connection is firm and not easily deformedMassage is good for health careInsolesNon-woven fabricsReticular fiberPolyester

The invention provides a deodorizing and sterilizing insole and a manufacturing method thereof, belongs to the technical field of daily supplies and solves the problems of short service life and poorhealthcare effects of an existing insole. According to the manufacturing method of the deodorizing and sterilizing insole, raw materials including, in percent, 40%-50% of copper polyester fibers, 10%-20% of wood pulp fibers and 40%-50% of low melting point fibers are placed into a mixer and mixed into mixed fibers, the mixed fibers are placed into a fiber bale opener for bale opening, enter an opener for debonding, are sucked into a reserve box and treated into bobbin cotton, the bobbin cotton is placed into a carding machine, carded into a single-fiber state, placed into a lapping machine, uniformly folded and laid into needed width, a folded reticular fiber thin layer is repeatedly needled by seven needling machines, and fibers in the reticular fiber thin layer are drawn close and compressed, then enter a hot mill with the high temperature of 250 DEG C and are formed. The deodorizing and sterilizing insole has the advantages of low cost, simplicity in manufacture, strong deformationresistance and long service life.

Owner:浙江易立洁日用品科技有限公司

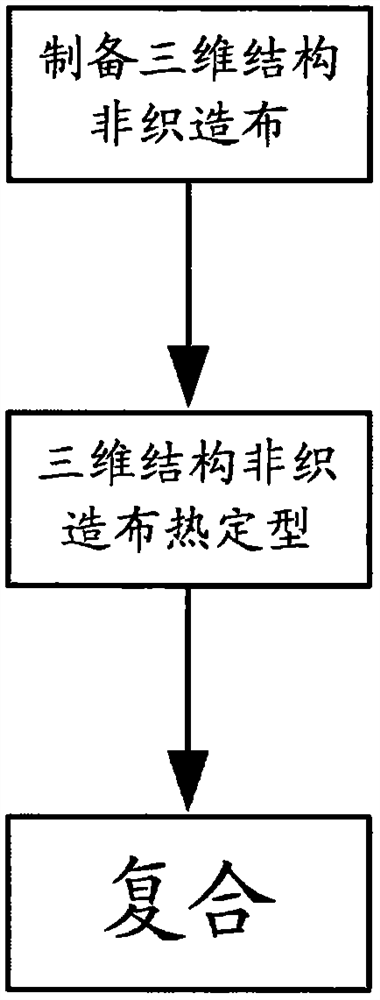

Composite waterproof roll as well as preparation method and application thereof

PendingCN112497874AImprove the top threeImprove environmental adaptabilityRoof covering using flexible materialsSynthetic resin layered productsFiberThermal bonding

The invention discloses a composite waterproof roll as well as a preparation method and application thereof. The composite waterproof coiled material comprises a coiled material core layer and non-woven fabrics distributed on the upper surface and the lower surface of the core layer, the non-woven fabrics are made of double-component fibers of a skin-core structure, and a fiber skin layer of the outer layer of the double-component fibers of the skin-core structure and the coiled material core layer are thermally bonded into a whole in the compounding process. The fiber core layer of the innerlayer of the skin-core structure double-component fiber is completely wrapped. According to the waterproof coiled material obtained through the special preparation process, the non-woven fabric and the coiled material core layer are thermally bonded into a whole, fibers are wrapped in the non-woven fabric all the time, the three strengths of the coiled material are improved, and meanwhile the environmental adaptability of the coiled material is improved.

Owner:秦皇岛市松岩建材有限公司

Collagen fiber mattress lining and preparation method thereof

ActiveCN105350176ADoes not pollute the environmentThe processing technology is easy to realizeLiquid/gas/vapor removalCarding machinesComposite materialSynthetic fiber

The invention relates to a collagen fiber mattress lining and a preparation method thereof, and belongs to the field of novel home textile materials. The method comprises following steps: performing physical slicing, rewetting, softening, tearing, debonding, opening and impurity removing processes on wet blue waste materials so as to obtain collagen fibers; opening low-melting-point and bi-component fibers; conveying the collagen fibers and the low-melting-point and bi-component fibers to the same former for air laying through pipe air flow so as to obtain a synthetic fiber web; and pre-pressure-heating, thermoforming and cutting the synthetic fiber web so as to obtain the collagen fiber mattress lining. By employing the method, the collagen fibers are extracted from the wet blue waste materials through a simple environment-friendly dry manner, a problem that a conventional collagen fiber extraction process is complex and is not environment-friendly is solved, the process for extracting the collagen fibers is environment-friendly and is simplified, and the manufactured collagen fiber mattress lining is fluffy, can remove moisture, is ventilated, is flame resistant, is warm in winter and cool in summer, and has high sound-absorbing performance.

Owner:JIAXING UNIV

Polyphenylene sulfide composite fiber and nonwoven fabric

InactiveCN103328704AHeat resistantImprove heat resistanceWoven fabricsConjugated synthetic polymer artificial filamentsPolymer scienceHeat resistance

Provided is a polyphenylene sulfide composite fiber which consists mainly of a component (A) and a component (B), the component (A) being a resin mainly comprising poylphenylene sulfide that comprises p-phenylene sulfide as the main units and the component (B) being a resin mainly comprising a copolyphenylene sulfide that contains at least one kind of comonomer units besides p-phenylene sulfide, characterized in that at least some of the surface of the fiber is constituted of the component (B). The composite fiber, which is constituted of resins that comprise polyphenylene sulfide as a main component, is heat-bondable and is excellent in terms of heat resistance, flame retardancy, and chemical resistance. Also provided is nonwoven fabric.

Owner:TORAY IND INC

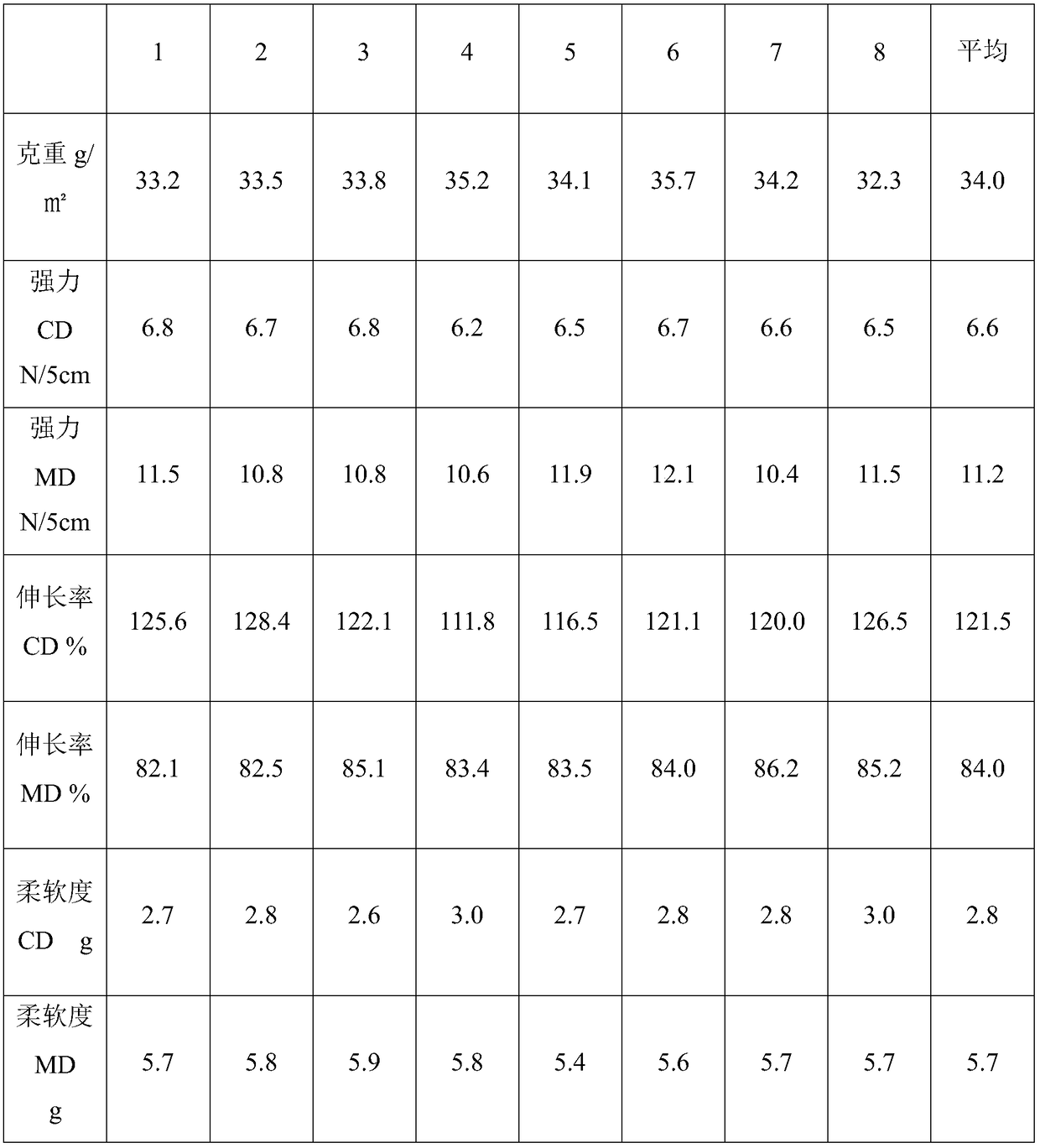

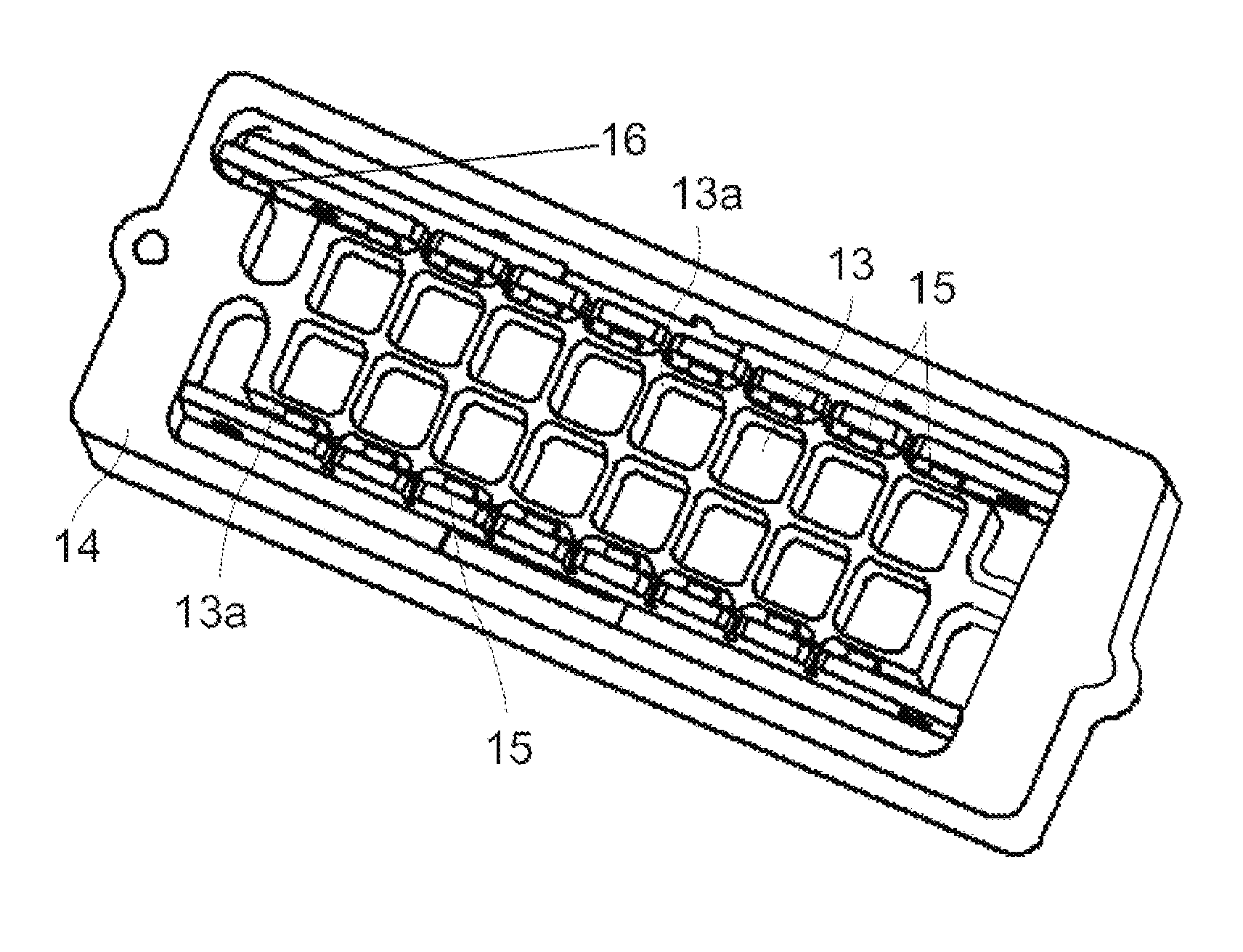

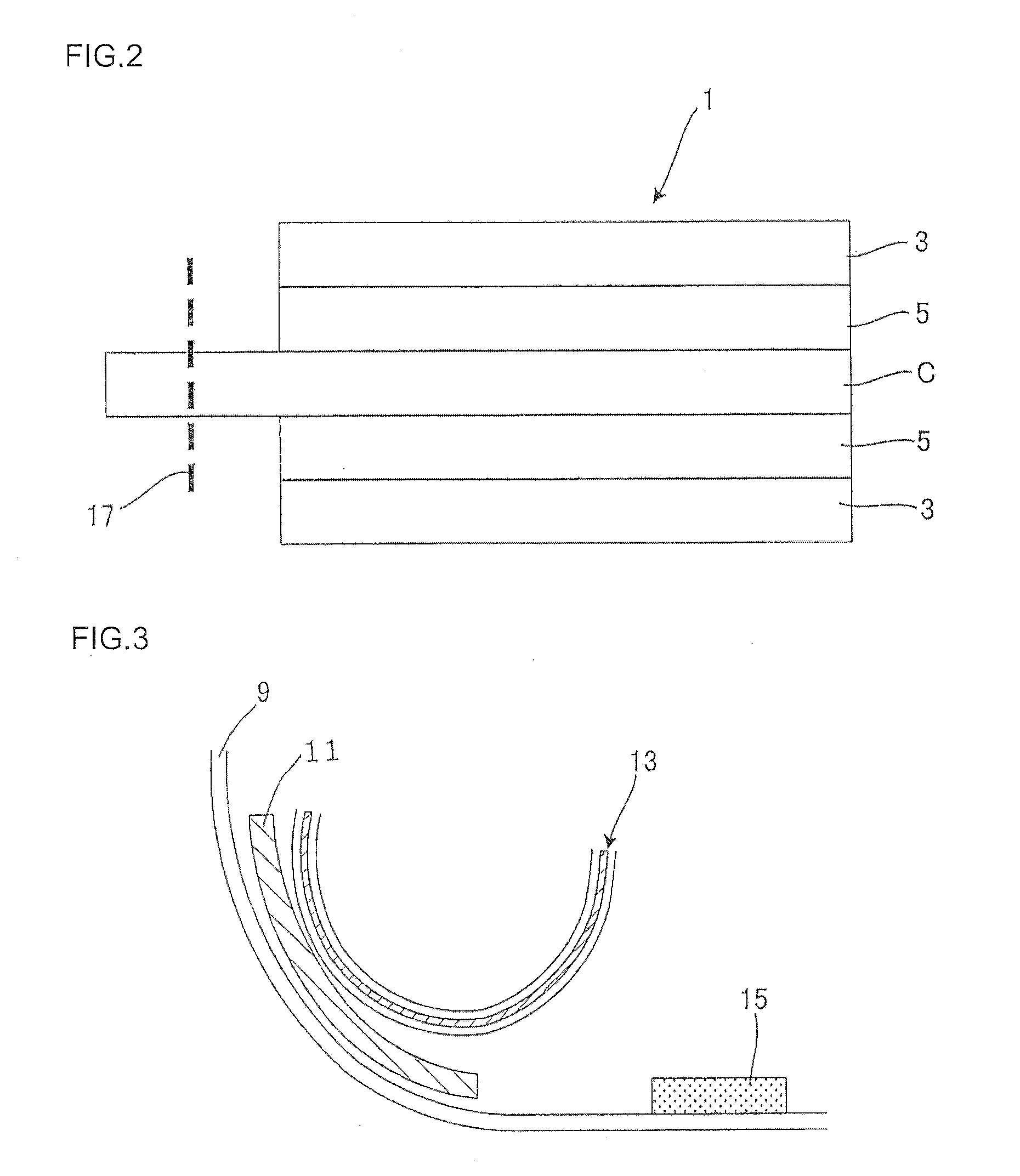

Method and Apparatus for Detecting the Level of a Liquid in Monitoring a Dispense/Aspirate Process

ActiveUS20120096940A1Excellent thermal adhesionImprove responseLaboratory glasswaresMachines/enginesElectrical resistance and conductanceLevel sensor

A device and a method are used for measuring the filling level of a fluid for monitoring a dispense / aspirate process in reaction vessels, including at least one cavity for dispensing and aspirating the fluid, where the cavity is provided with a filling level sensor whose signals, transmitted to an evaluation unit, are evaluated to determine the filling level, the at least one cavity is assigned a receiving body which is closed at the bottom and is separated from the cavity for receiving the fluid, the filling level sensor is at least one thermistor extending along the outside of a wall of the receiving body without coming in contact with the fluid he the evaluation unit evaluates the temperature influence of the thermistor in dispensing, aspirating and in retention of the fluid in the receiving body to detect the filling level, in this way the process monitoring in washing the reaction vessels is improved.

Owner:STRATEC BIOMEDICAL AG

Laminate packing material for battery and laminate battery

ActiveUS8323827B2Reduce in quantitySimple processSynthetic resin layered productsJackets/cases materialsMetallic foilEngineering

In a laminated external packaging material for a battery according to the present invention, a metallic foil 2 is adhered to one surface side of a base film 1, and a coated film layer 4 of thermal adhesive resin having a softening point of 160° C. or below and capable of thermally bonding to a surface film of a battery main body is formed on the other surface side of the base film 1. With this laminated external packaging material for a battery, without using an adhesive tape or a hot-melt adhesive, this packaging material can be easily and assuredly bonded to the battery main body and also can be bonded firmly to an end portion reinforcing plastic component.

Owner:RESONAC PACKAGING CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com