Low-odor polyethylene foam material with thermal bonding performance and preparation method thereof

A polyethylene foaming and low-odor technology, applied in the field of polyethylene foaming materials, can solve the problems affecting the application scenarios of polyethylene foaming materials, restricting application fields, and limited composite effects, etc., achieving simple and convenient application, wide application, Appropriate hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

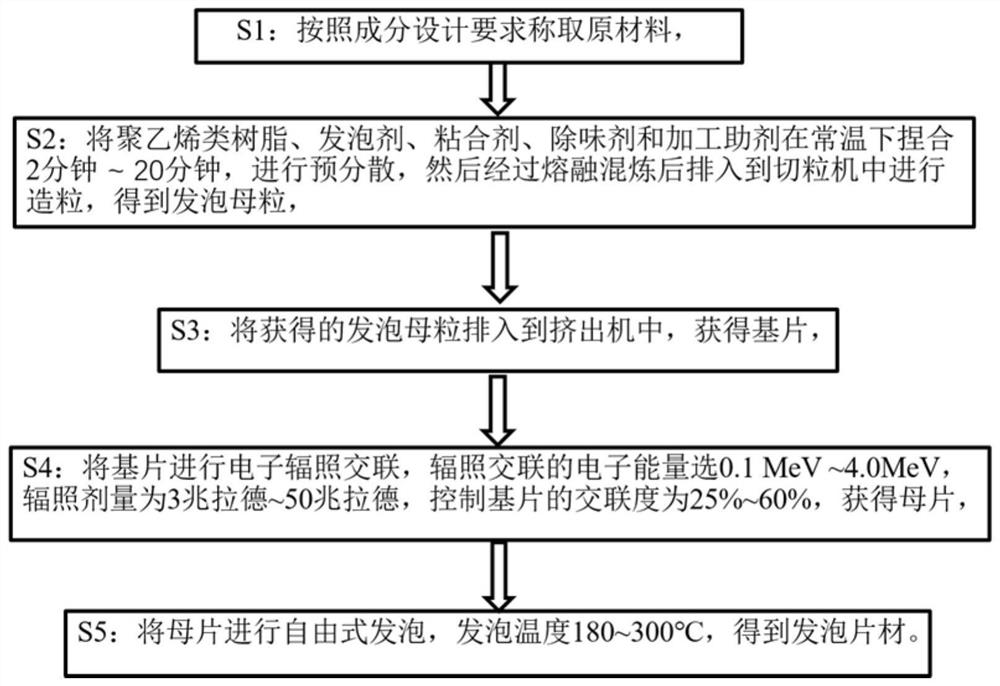

[0038] The preparation methods in actual engineering are, for example:

[0039] (1) Weighing: Weigh 100 parts of low-density polyethylene resin, 10-50 parts of adhesive, 1-15 parts of foaming agent, 0.7-15 parts of deodorant, 1-20 parts of Processing aids;

[0040] (2) Granulation: knead low-density polyethylene resin, foaming agent, adhesive, deodorant, and processing aid at room temperature for 2 to 20 minutes. This stage is the pre-dispersion stage, and then after melt kneading Discharge into the water ring granulator for granulation to obtain foam masterbatch;

[0041] (3) Extrusion: the obtained foaming masterbatch is discharged into the screw extruder to obtain a sheet, which is replaced by a base sheet below;

[0042] (4) Electron irradiation cross-linking: the substrate is subjected to electron irradiation cross-linking, the electron energy of irradiation cross-linking is selected as 0.1-4.0 MeV, the irradiation dose is 3-50 Mrad, and the degree of cross-linking of t...

Embodiment 1

[0049] Polyethylene foam sheet 1 component and weight ratio:

[0050] Low-density polyethylene 100 copies Ethylene-vinyl acetate copolymer 10 copies Copolyamide 10 copies Maleic anhydride grafted polyethylene wax 1 copy Foaming agent 5 copies itaconic acid 3 copies activated carbon 0.5 parts antioxidant 1 copy coupling agent 0.3 parts talcum powder 10 copies

[0051] The melt index of low-density polyethylene resin is 2.0g / 10min (test condition 190℃ / 2.16KG), and the density is 0.923g / cm 3 ,The VA content in the ethylene-vinyl acetate copolymer is 48%, the melt index of the copolyamide is 30g / 10min (test condition 160℃ / 2.16KG), the melting range is 115~120℃, and the blowing agent is azodimethoxane Amide (ADC), the particle size D50 value is 17.5 μm, the gas generation capacity of the foaming agent is 230ml / g, the particle size D50 value of itaconic acid and activated carbon is 10 μm, and the particle...

Embodiment 2

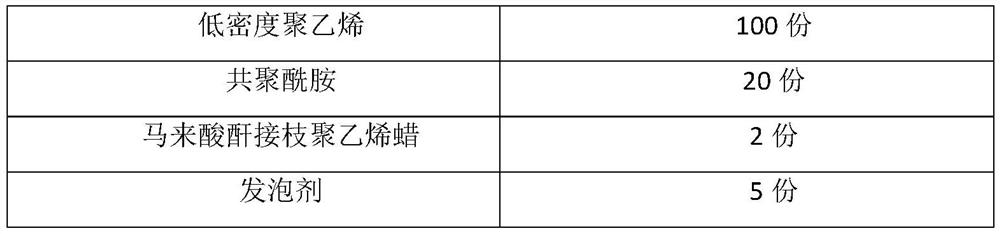

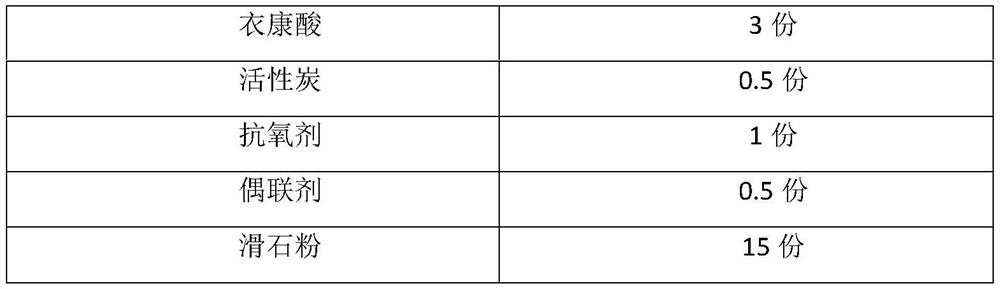

[0061] Polyethylene foam sheet 2 components and weight ratio:

[0062]

[0063]

[0064] The melt index of low-density polyethylene resin is 2.0g / 10min (test condition 190℃ / 2.16KG), and the density is 0.923g / cm 3 , The melt index of copolyamide is 50g / 10min (test condition 160℃ / 2.16KG), the melting range is 120~125℃, the foaming agent is azodicarbonamide (ADC), the particle size D50 value is 25μm, and the foaming The gas generation amount of the agent is 240ml / g, the particle size D50 value of itaconic acid and activated carbon is 10 μm, and the particle size D50 value of talcum powder is 20 μm.

[0065] The preparation method of polyethylene foam sheet 2:

[0066] S1: Weigh low-density polyethylene, copolyamide, maleic anhydride grafted polyethylene wax, foaming agent, itaconic acid, activated carbon, antioxidant, coupling agent, talcum powder according to the above weight ratio;

[0067] S2: Knead low-density polyethylene, copolyamide, maleic anhydride grafted polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com