Spunlace non-woven fabric, composite non-woven fabric and sanitary absorption product

A spunlace non-woven fabric and non-woven fabric technology, applied in the field of fiber products, can solve the problems of easy delamination, high cost, and poor bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This example provides a method for preparing pure cotton fiber and bicomponent short fiber spunlace nonwoven fabric.

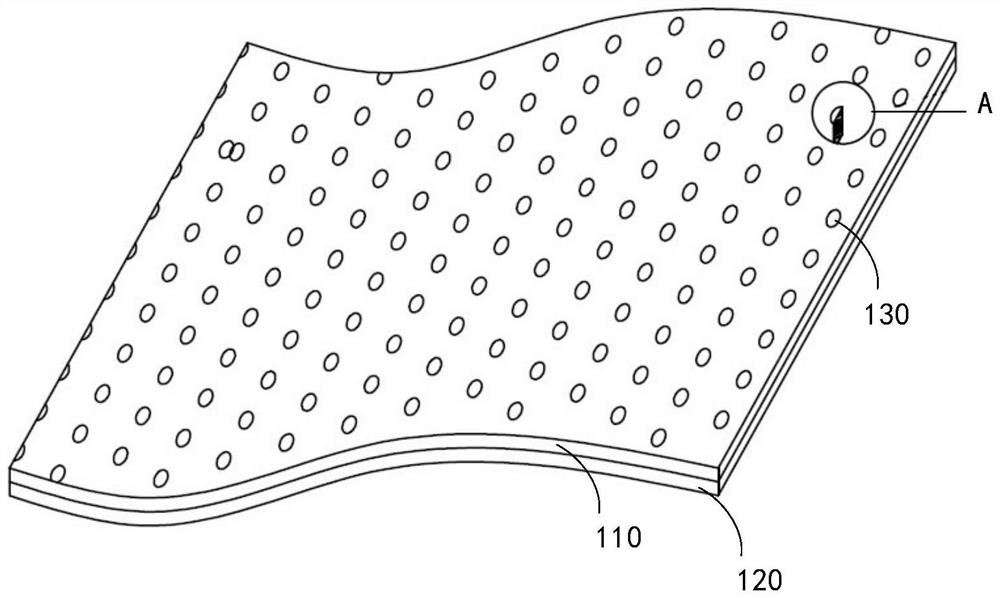

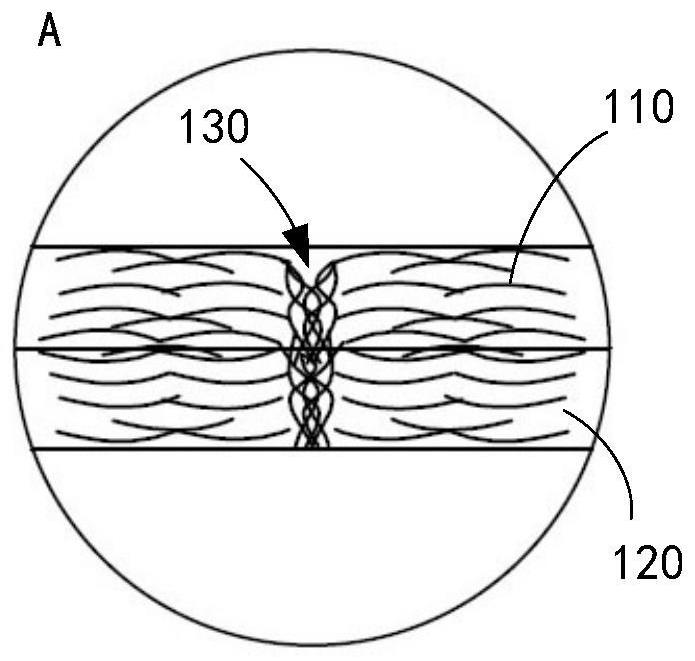

[0067] Such as figure 1 As shown, the upper surface fiber layer 110 is a 100% bleached absorbent cotton fiber layer. As a preference, the pure cotton fiber is selected from Xinjiang cotton, European cotton, Australian cotton or American cotton, and the pure cotton fiber is opened, mixed, After carding, the web is laid and formed. The carding method of the fiber layer 110 on the upper surface is to use continuously arranged cover plates to card the fibers, and the number of cover plates (carding units) is 25-40. The fiber length of cotton fiber is 33mm-39mm, and the fineness of cotton fiber is 1.1dtex-1.4dtex.

[0068] The lower surface fiber layer 120 is formed by using about 100% bi-component short fibers, preferably: the bi-component short fibers are selected from sheath-core type composite fibers, the skin layer is PE (melting point is 126~129 ° C)...

Embodiment 2

[0077] This example provides a method for preparing a spunlace nonwoven fabric containing cotton fibers and bicomponent short fibers.

[0078] Such as figure 1 As shown, the upper surface fiber layer is 100% bleached absorbent cotton fiber layer, as preferably, the cotton fiber is selected from Xinjiang cotton, European cotton, Australian cotton or American cotton, and the cotton fiber is laid after opening, mixing and carding. Web forming.

[0079] The lower surface fiber layer is formed by blending about 20% of the bleached absorbent cotton fiber and about 80% of the two-component staple fiber, preferably: the cotton fiber is selected from Xinjiang cotton, European cotton, Australian cotton or American cotton ; As a preference: the bicomponent short fiber is selected from sheath-core type composite fiber, the cortex is PE (melting point is 126~129 ℃), the core layer is PP (melting point is 163~170 ℃), fiber fineness is 2.5D, fiber length The fiber is 38mm, the number of cr...

Embodiment 3

[0083] This embodiment provides a double-layer composite non-woven fabric, such as Figure 4 shown.

[0084] The first layer of the double-layer composite non-woven fabric is selected from the spunlace non-woven fabric of Example 1.

[0085] The second layer of the double-layer composite non-woven fabric is made of hot-air non-woven fabric, which is made of 100% bi-component short fibers through opening, mixing, carding, hot-air reinforcement, ironing, and winding. , as a preference: bi-component short fibers are selected from sheath-core composite fibers, the skin layer is PE (melting point is 126-129°C), the core layer is PP (melting point is 163-170°C), the fiber fineness is 4.0D, and the fiber length The fiber is 51mm, the oil content is 0.45%, the number of crimps is 18 / inch, the fiber is weak acid fiber, and the basis weight of the hot-air non-woven fabric is 18g / m 2 .

[0086] The double-layer composite non-woven fabric is made by spunlace non-woven fabric through rh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com