Collagen fiber mattress lining and preparation method thereof

A collagen fiber and inner lining technology, applied in the field of collagen fiber mattress inner lining and its preparation, can solve the problems of collagen fiber length and thickness, low utilization rate, complex production process, etc., and achieve easy and good processing technology Usable strength and the effect of many pores between fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In step 101, the waste wetblue leather is cut into (8-10)×(8-10) cm strip-shaped wetblue leather waste pieces, and the wetblue leather waste pieces are rewetted to be soft, torn and loosened. After decomposing, opening and impurity removal processes, the collagen fibers are obtained, and the collagen fibers are transported to the former through the pipeline air flow, and the delivery amount of the collagen fibers is controlled so that every 1m in the pipeline 3 The amount of fiber carrying the collagen fiber / s air volume is 135-475g, and the collagen fiber is further opened and separated under the air blowing in the pipeline.

[0039] In step 102, the low-melting-point bi-component fiber is fed into a licker-in roller opener for rough opening, and the low-melting point bi-component fiber is transported to the former through a pipeline airflow, Control the delivery rate of the low melting point bicomponent fiber, so that every 1m in the pipeline 3 The amount of fiber ca...

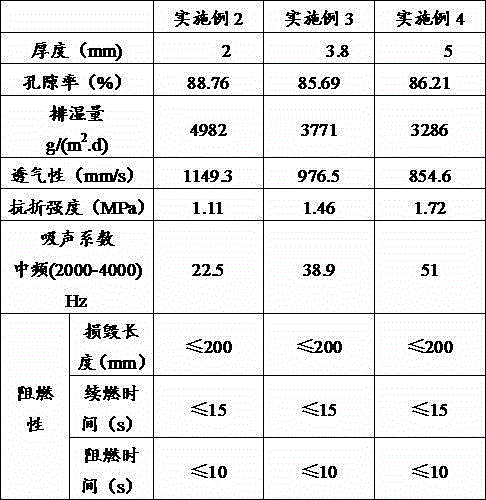

Embodiment 2

[0049] 1. Extraction and opening of collagen fibers

[0050] Cutting: cutting the wet blue hide waste into 8×8cm strips of wet blue hide waste with a cutting machine;

[0051] Moisture soft:

[0052] a. Preparation of remoistening softening solution; according to the ratio of castor oil phosphate: Tween-80: softening enzyme: hydrophilic silicone softener: preservative: water: 6: 0.8: 0.2: 4: 1: 88 Wet softening liquid, the pH value of the solution is adjusted to 6.5 with lactic acid, the temperature of the control solution is 40°C, and the preservative used is sodium sorbate;

[0053] b. Spray the wet blue leather waste evenly with the prepared re-moisture softening liquid, so that the re-moisture softening liquid accounts for 45% of the waste, and then cover it with plastic cloth and stack it at room temperature for 20 hours, and finally make the wet blue leather The moisture content of the waste block is 25%;

[0054] c. Softening and puffing treatment: use a stainless st...

Embodiment 3

[0074] 1. Extraction and opening of collagen fibers

[0075] Cutting: cutting the wet blue hide waste into 9×10cm strips of wet blue hide waste with a cutting machine;

[0076] Moisture soft:

[0077] a. Preparation of re-moisture softening solution; according to the ratio of castor oil phosphate: Tween-80: softening enzyme: hydrophilic silicone softener: preservative: water: 8:1:0.5:6:2.5:82 Wet softening liquid, the pH value of the solution is adjusted to 5.5 with lactic acid, and the temperature of the control solution is 45°C, wherein the preservative used is ethylparaben;

[0078] b. Spray the wet blue leather waste evenly with the prepared re-moisture softening solution, so that the re-moisture softening solution accounts for 50% of the waste, then cover it with plastic cloth and pile it up at room temperature for 22 hours, and finally make the wet blue leather The moisture content of the waste is 30%;

[0079] c. Softening and puffing treatment: use a stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com