Process for treating radioactive wastewater

A radioactive and technological technology, applied in the field of radioactive saline wastewater treatment, can solve the problems of large investment, discharge of radioactive substances, damage to animals and plants, etc., and achieve the effects of increasing evaporation area, increasing absorption rate, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

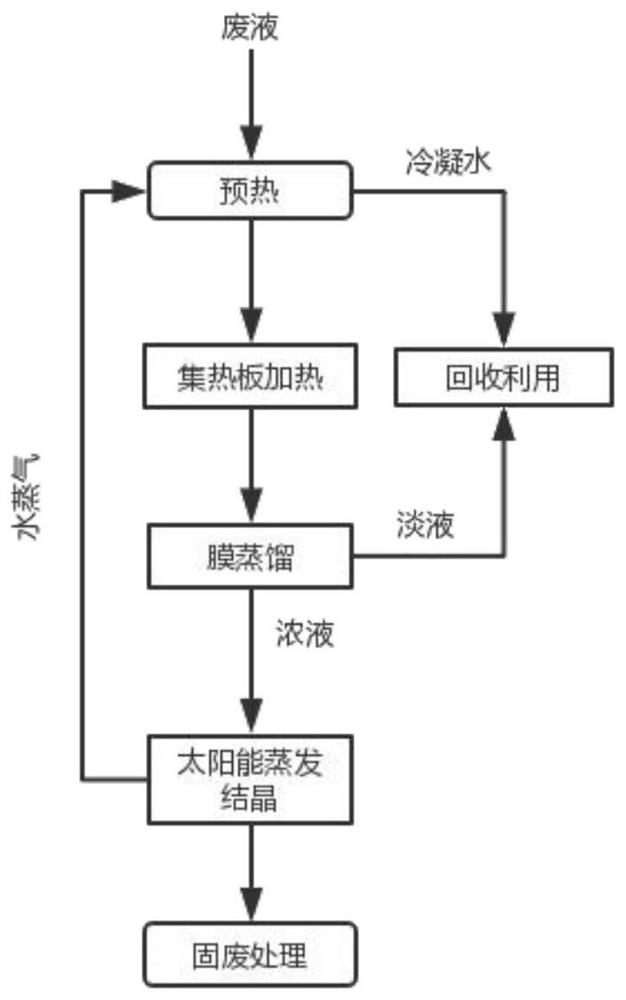

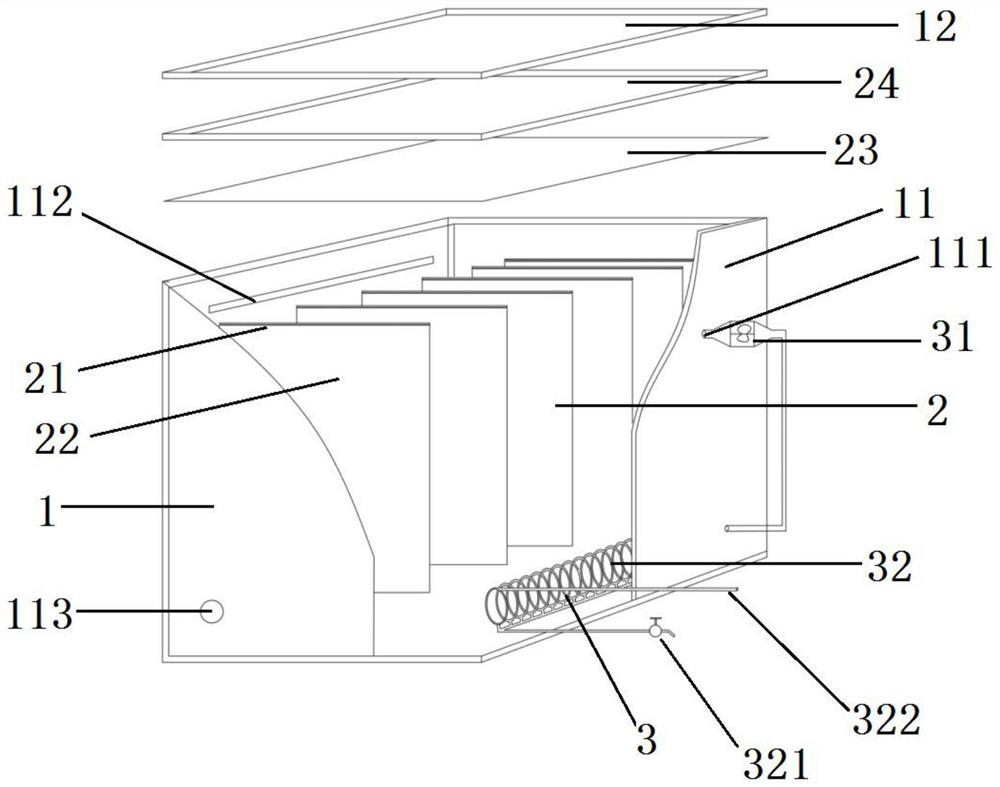

[0052] The wastewater treatment process in this embodiment is as follows: figure 1 As shown, the evaporation and salt collection device used is as figure 2 as shown,

[0053] The evaporating salt-collecting device includes an evaporating chamber 1, an evaporating salt-collecting device 2, and a condensing liquid-collecting device 3; the evaporating chamber 1 includes a side wall surrounded by a shroud 11 and a top cover formed by a cover 12, and the shroud 11 has a Air introduction port 111, air inlet port 112 and waste water inlet port 113;

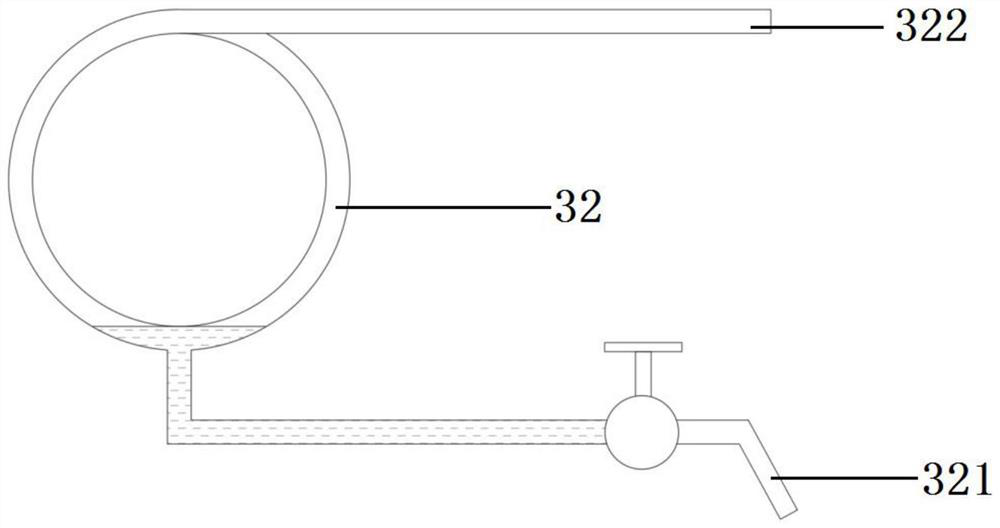

[0054] The evaporation salt collection device 2 is located inside the evaporation chamber 1, and it includes a water-absorbing component beam 21, a water-absorbing component 22, a heat collecting plate 23 and a heat insulating plate 24; the heat insulating plate 24 is located below the cover plate 12 and Close to the cover plate 12, the heat collecting plate 23 is located below the heat insulating plate 24 and is close to the heat in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com