Preparation method of sodium alginate-based photo-thermal distilled water gel

A technology of sodium alginate and distilled water, which is applied in the field of photothermal distillation hydrogel preparation, can solve the problems that cannot be applied to the field of photothermal water treatment, the shape cannot be kept stable, and the water absorption and evaporation performance is weak, so as to achieve good light absorption performance and mechanical properties Excellent effect with less production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: In this embodiment, a preparation method based on sodium alginate-based photothermal distillation hydrogel is carried out according to the following steps:

[0026] 1. Oxidation reaction:

[0027] ①. Add dopamine hydrochloride solution, potassium persulfate solution and sodium bicarbonate solution to sodium alginate solution in sequence to obtain a mixed solution;

[0028] ②. Under the condition of stirring speed of 180r / min~240r / min and temperature of 60℃~80℃, oxidize for 20min~30min, then at room temperature and stirring speed of 180r / min~240r / min, Continue stirring until cooled to room temperature;

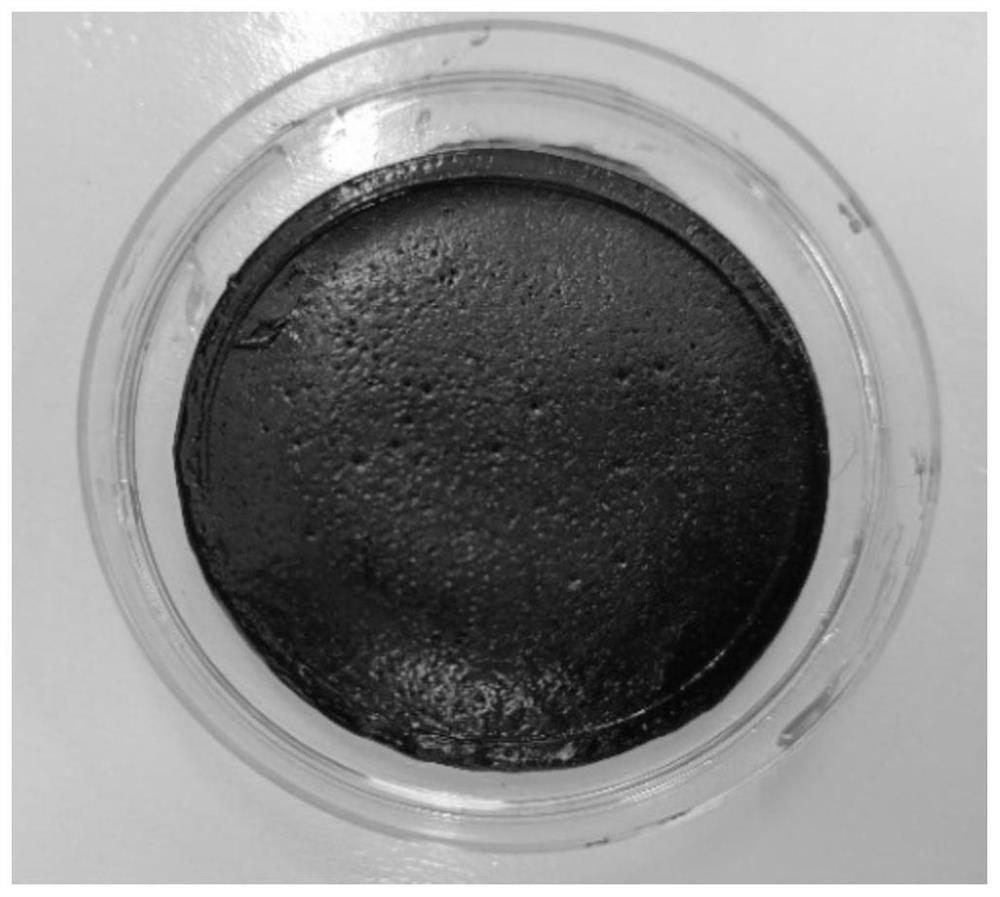

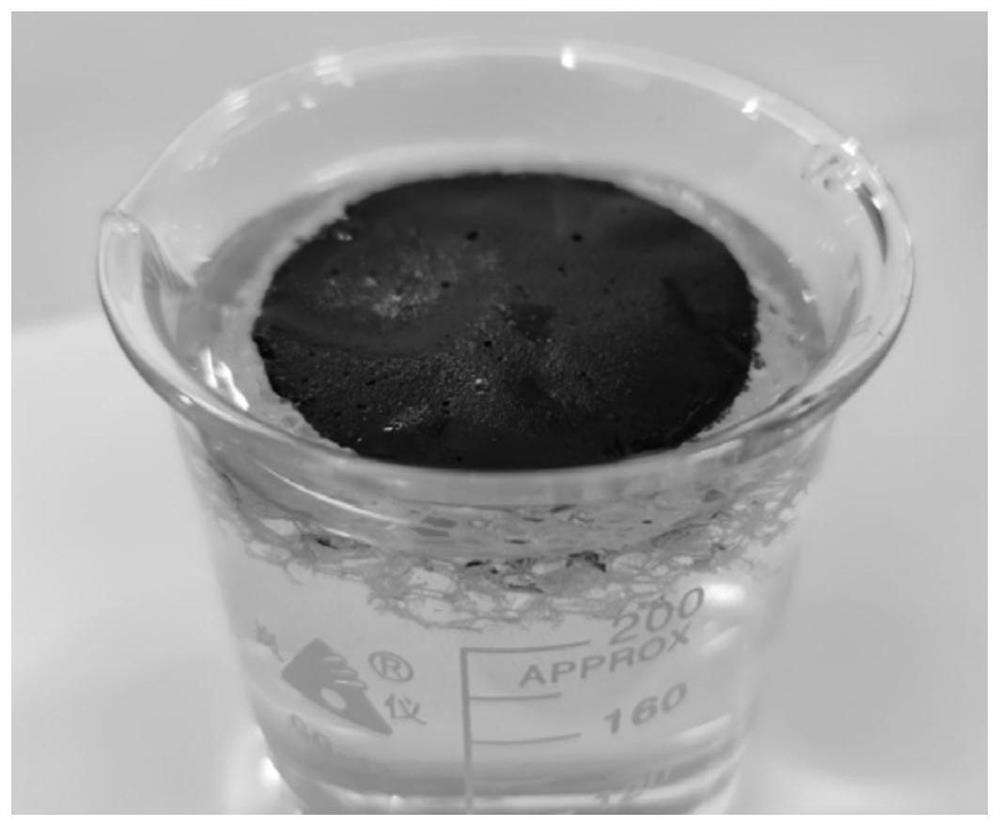

[0029] ③. Repeat steps 1 and ② until the solution is black and thick with a viscosity of 2000cP to 3000cP, then add sodium bicarbonate powder and stir evenly to obtain a raw material solution;

[0030] 2. Forming:

[0031] Spread anhydrous calcium chloride powder on the bottom of the container, then pour the raw material liquid evenly into the...

specific Embodiment approach 2

[0045] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the sodium alginate solution described in step 1.1 is prepared according to the following steps: sodium alginate is added to deionized water, and the stirring speed is 180r Stir until the sodium alginate is dissolved at 70°C to 80°C at a temperature of 240r / min to 240r / min to obtain a sodium alginate solution; the mass percentage of the sodium alginate solution is 2.0% to 2.8%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass percent of the dopamine hydrochloride solution described in step one 1. is 9%~10%; The mass percent of potassium solution is 4%~4.8%; The mass percent of the sodium bicarbonate solution described in step one 1. is 9.00%~9.50%; The volume of the dopamine hydrochloride solution and potassium persulfate solution described in step one 1. The ratio is 1:(1~1.2); the volume 1:(1.8~2.2) of the dopamine hydrochloride solution and the sodium bicarbonate solution described in the step one 1. step; the dopamine hydrochloride solution and the sodium alginate solution described in the step one 1. The volume ratio is 1:(39~41); the quality of the sodium bicarbonate powder described in step one 3. is the 1.5%~2.0% of the raw material liquid quality that step one 3. prepares. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

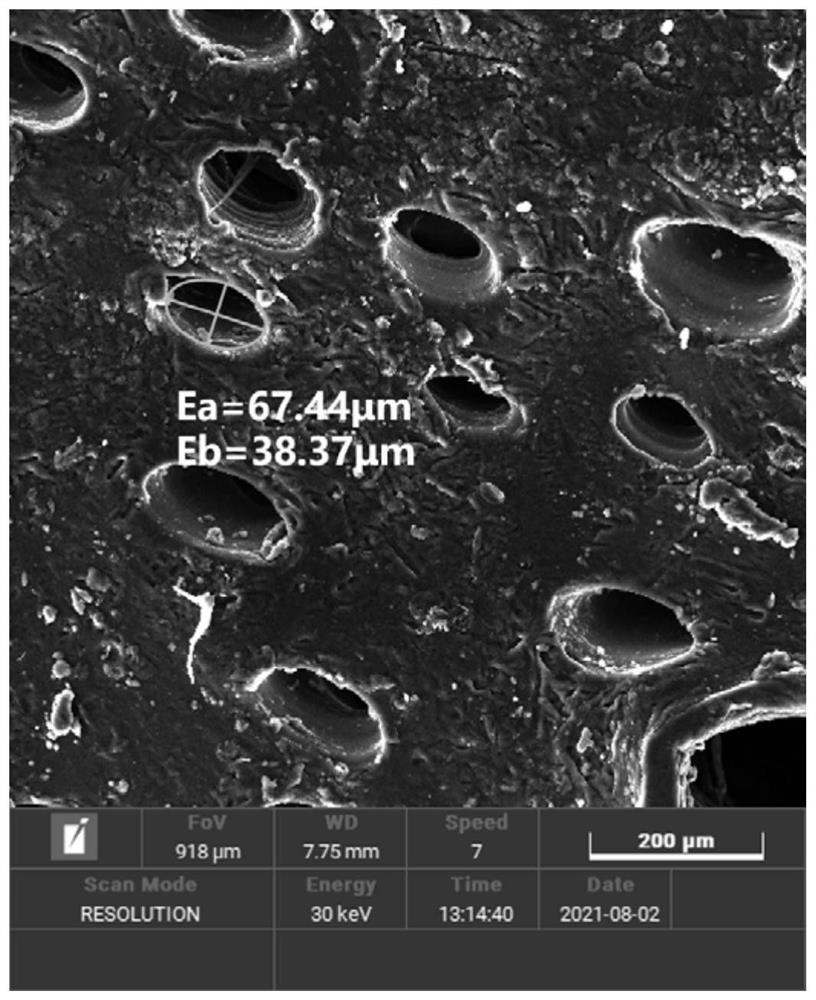

| Aperture size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com