Dysprosium ion doped barium tantalum tungstate and preparation method and application thereof

A technology of barium tungstate tantalate and dysprosium ions, which is applied in the field of dysprosium ion-doped barium tungstate tantalate and its preparation, can solve the problems of unstable performance, complex preparation process, and insufficient luminous brightness of green phosphors, and achieve low production costs , High light conversion efficiency, good light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of dysprosium ion-doped barium tungstate tantalate comprises:

[0031] (1) According to the chemical formula Ba 6-6x Dy 6x Ta 2 WO 14 The stoichiometric ratio of each element in the formula was weighed to contain barium ions (Ba 2 + ) compounds containing dysprosium ions (Dy 3+ ) compounds containing tantalum ions (Ta 5+ ) compounds and containing tungsten ions (W 6+ )compound of.

[0032] Among them, containing Ba 2+ The compound is selected from barium oxide (BaO), barium carbonate (BaCO 3 ) and barium nitrate Ba(NO 3 ) 2 One of. It can be understood that in the preparation of the dysprosium ion-doped barium tungstate tantalate, containing Ba 2+ The compound can use BaO alone, or BaCO alone 3 , you can also use Ba(NO 3 ) 2 . It can also be understood that containing Ba 2+ The compound can use BaO and BaCO 3 A mixture of BaO and Ba(NO 3 ) 2 A mixture of BaCO can also be used 3 and Ba(NO 3 ) 2 mixture. It can also be under...

Embodiment 1

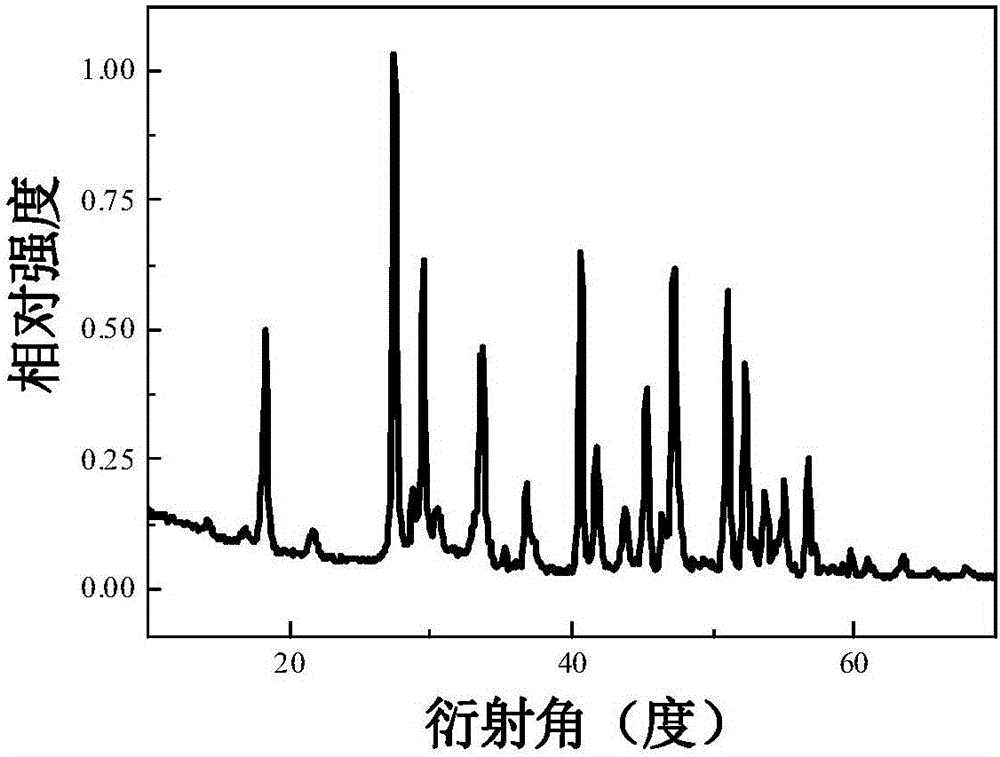

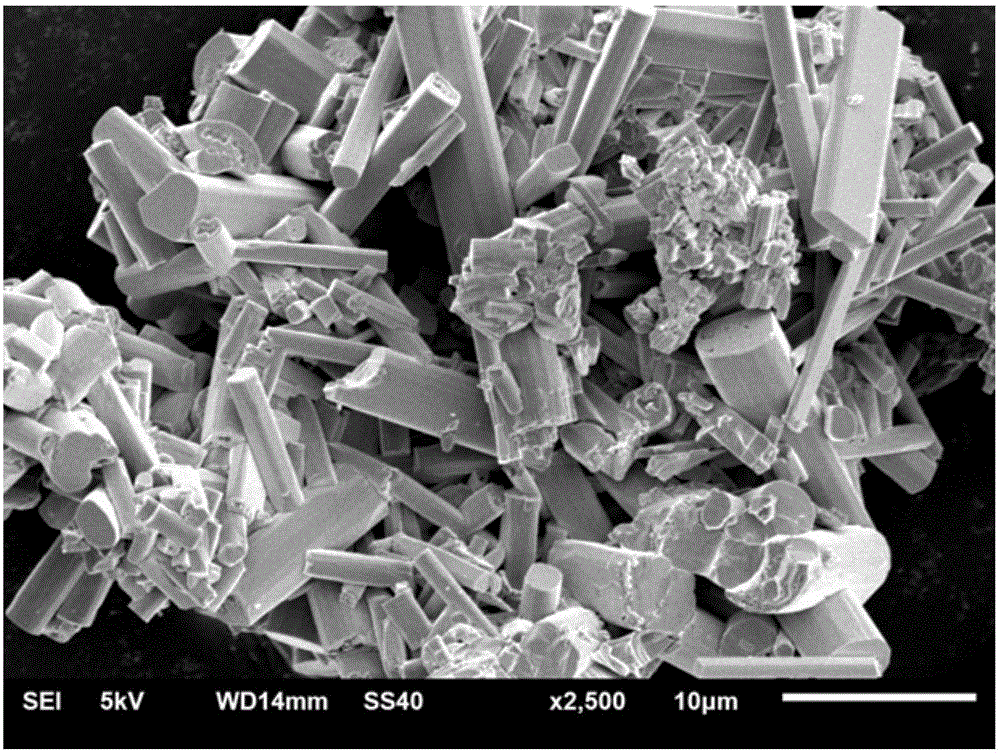

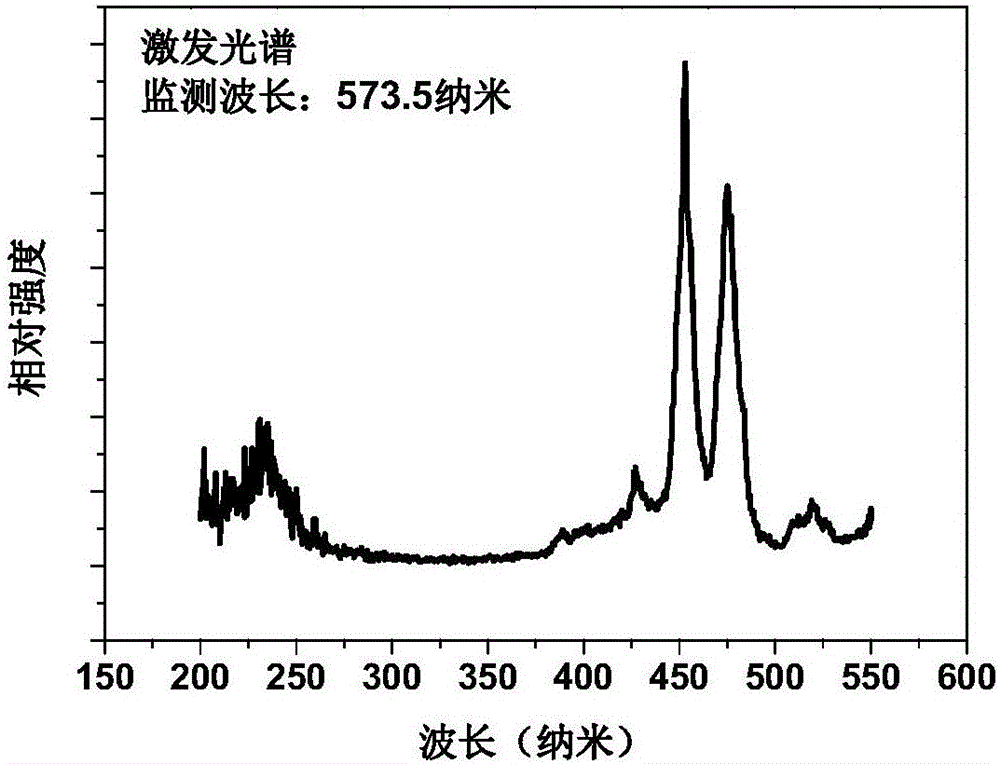

[0044] According to the chemical formula Ba 5.4 Dy 0.6 Ta 2 WO 14 For the stoichiometric ratio of each element, weigh 2.6641g of BaCO 3 , 0.3010g of Dy 2 o 3 , 1.105g Ta 2 o 5 and 0.6339g of (NH 4 ) 10 W 12 o 41 . The above-mentioned various compounds are grinded for the first time and mixed uniformly to obtain a mixture. The obtained mixture was calcined for the first time in a muffle furnace, that is, in an air atmosphere, and calcined at a calcining temperature of 1100° C. and a calcining time of 1 h. Then, after natural cooling, the second grinding is carried out to obtain the pre-product. The pre-product was again placed in the muffle furnace for the second calcination, that is, calcination was performed under an air atmosphere at a calcination temperature of 1300° C. and a calcination time of 3 h. Then, it is ground for the third time after natural cooling again, and what is obtained after uniform grinding is dysprosium ion-doped barium tungsten tantalate. ...

Embodiment 2

[0054] According to the chemical formula Ba 5.994 Dy 0.006 Ta 2 WO 14 For the stoichiometric ratio of each element, weigh 2.2977g of BaO and 0.0068g of Dy(NO 3 ) 3 ·6H 2 O, 1.105g of Ta 2 o 5 and 0.5796g of WO 3 . The above-mentioned various compounds are grinded for the first time and mixed uniformly to obtain a mixture. The obtained mixture was calcined for the first time in a muffle furnace, that is, under an air atmosphere, and calcined at a calcining temperature of 600° C. and a calcining time of 15 h. Then, after natural cooling, the second grinding is carried out to obtain the pre-product. The pre-product was again placed in the muffle furnace for the second calcination, that is, calcination was performed under an air atmosphere at a calcination temperature of 1150° C. and a calcination time of 4 h. Then, it is ground for the third time after natural cooling again, and what is obtained after uniform grinding is dysprosium ion-doped barium tungsten tantalate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com