Electric heating mechanical type micro-oil-gasification combustor

A technology of burners and gasifiers, which is applied in the direction of burners, burners burning powder fuel, and combustion methods, etc., can solve the problems of oil dripping, black smoke, etc., achieve no pollution to the environment, high combustion efficiency, and solve Easy to drip oil and black smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

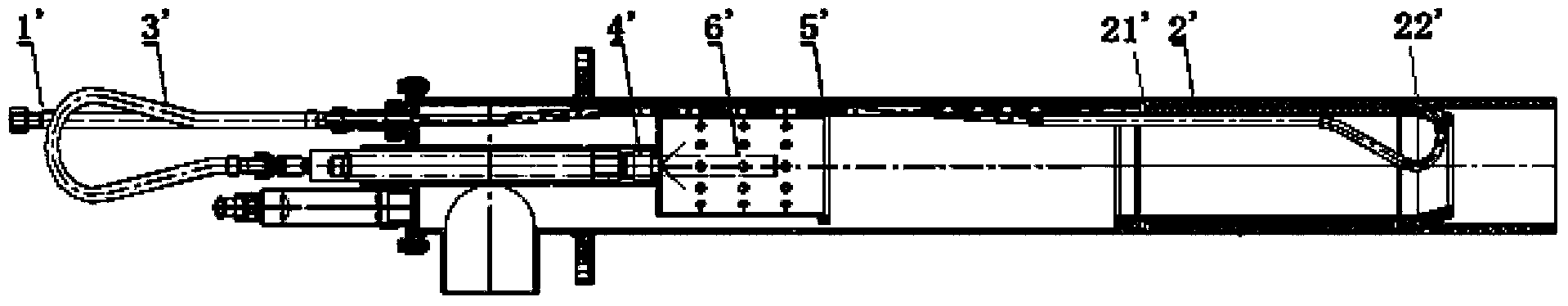

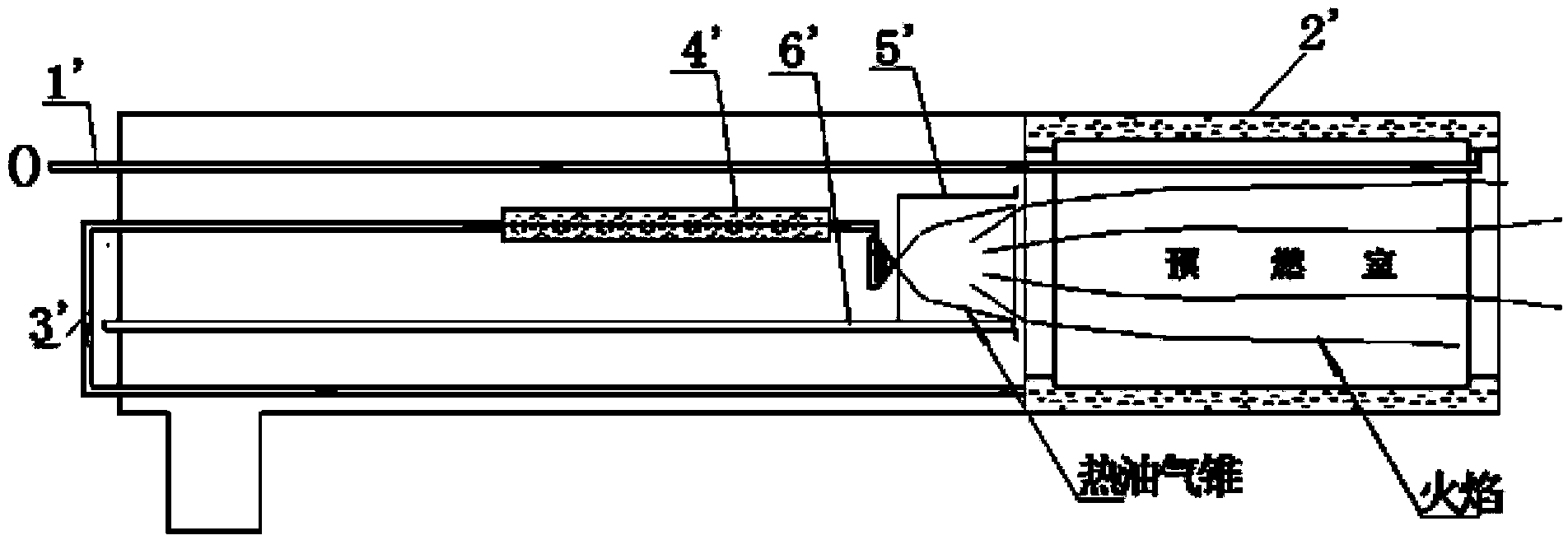

[0042] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

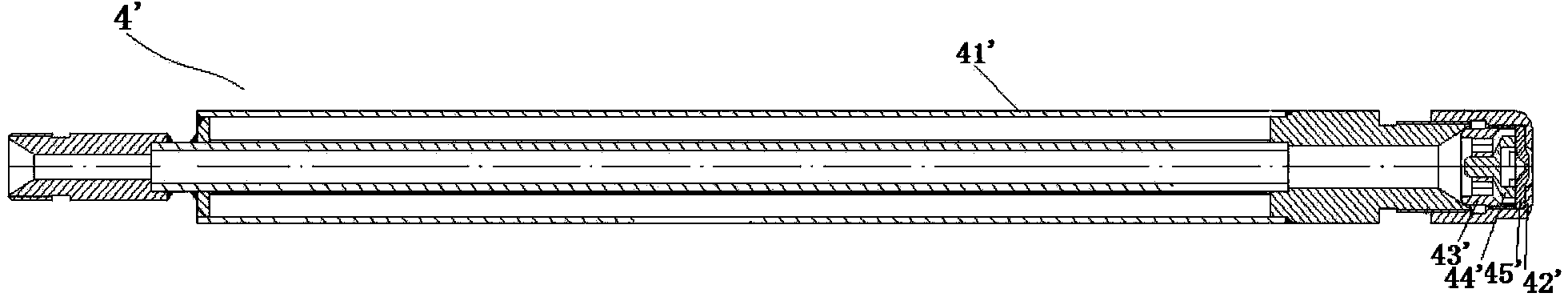

[0043] Figure 5 Shown is a schematic structural view of the micro-oil gasification burner in the present invention; Image 6 Shown is Figure 5 Schematic diagram of the working principle. Such as Figure 5 , Image 6 , Figure 14As shown, the micro-oil gasification burner provided by the present invention has the same structural parts as the micro-oil gasification burner in the prior art, including a four-head spiral groove gasifier 1, an air distribution tube 2, a burner 3, and an ignition gun 4. Mechanical atomizing oil gun 5, first oil inlet pipe 6 and second oil inlet pipe 7, wherein:

[0044] The right end of the air distribution cylinder 2 is adapted and docked with the left end of the four-head spiral groove gasifier 1, the ignition gun 4 and the mechanical atomization oil gun 5 are both assembled in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com