Patents

Literature

219 results about "Pipeline.air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

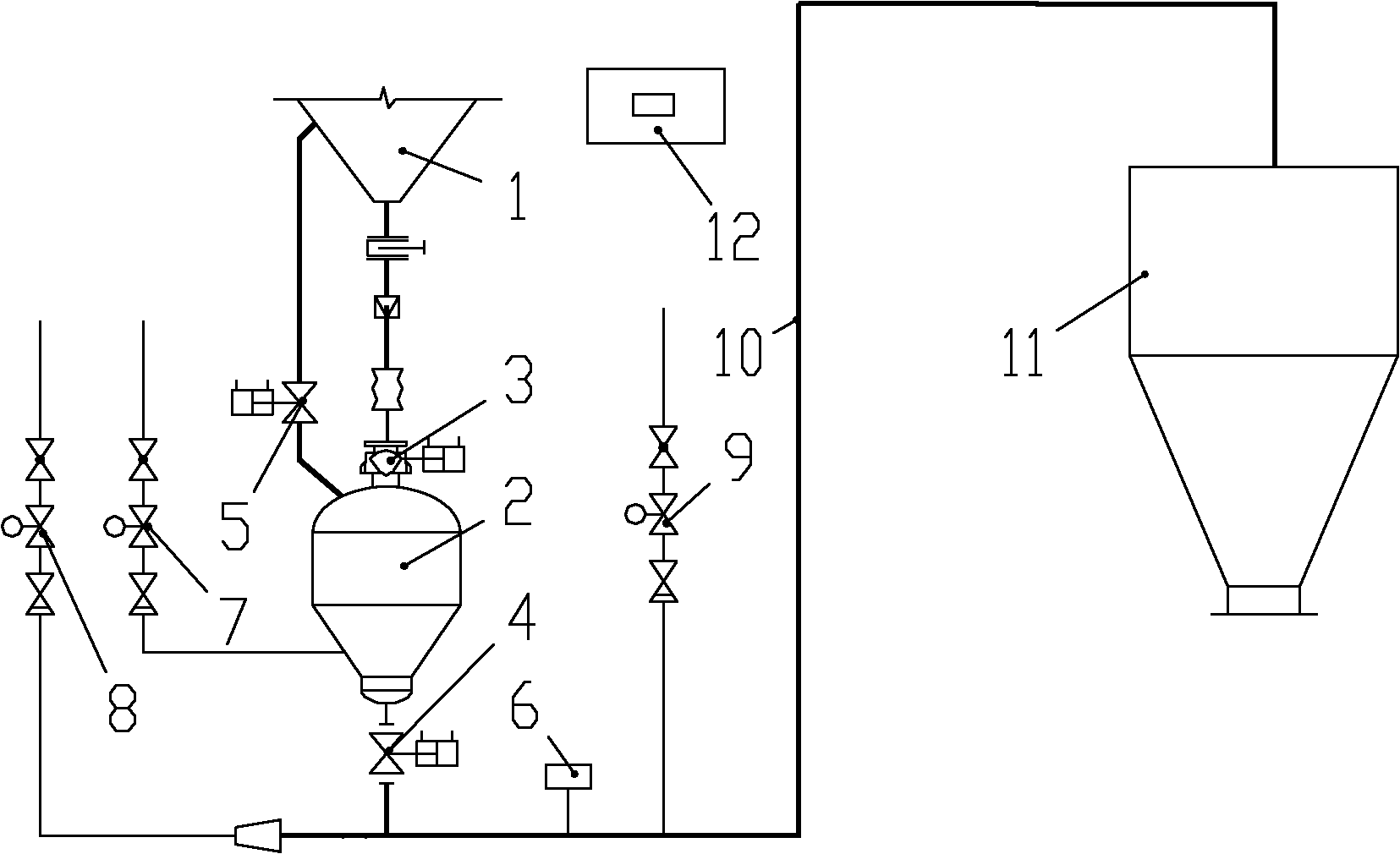

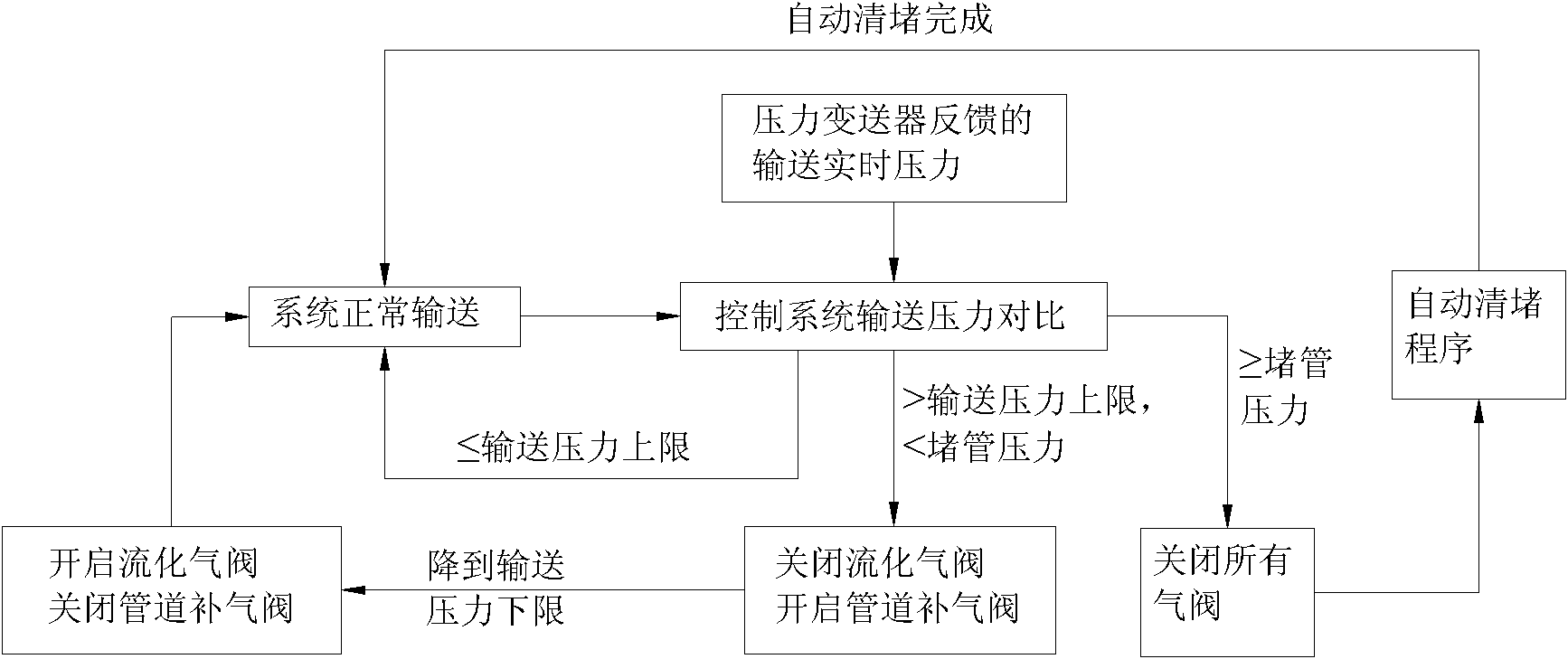

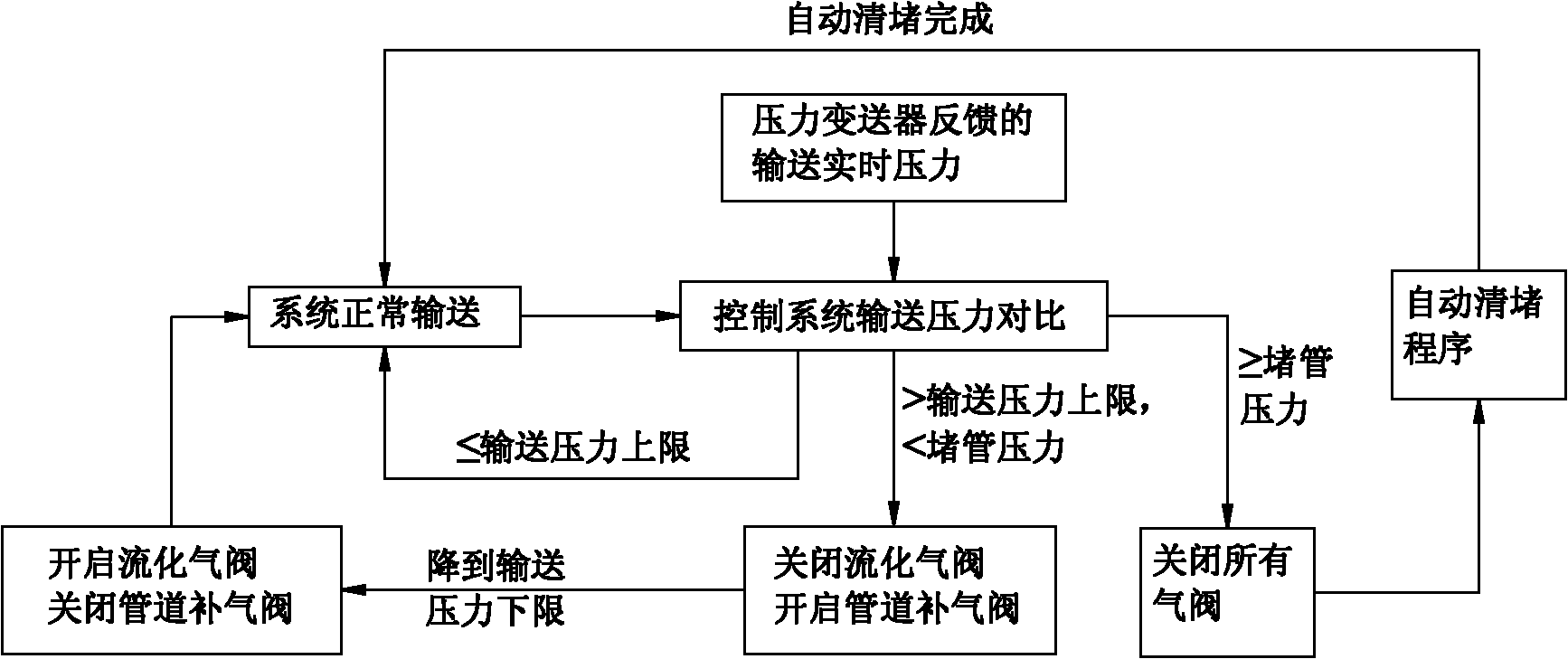

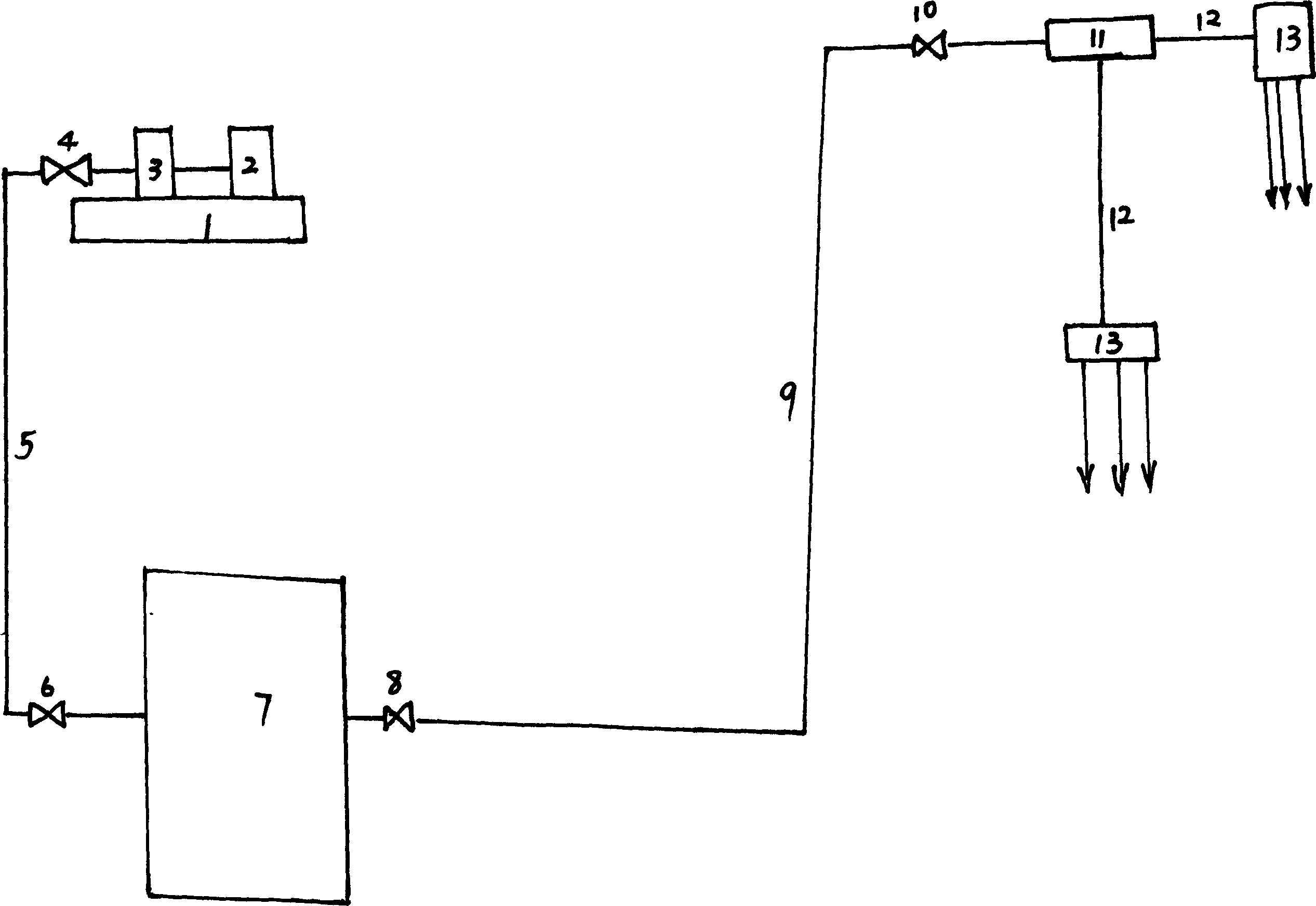

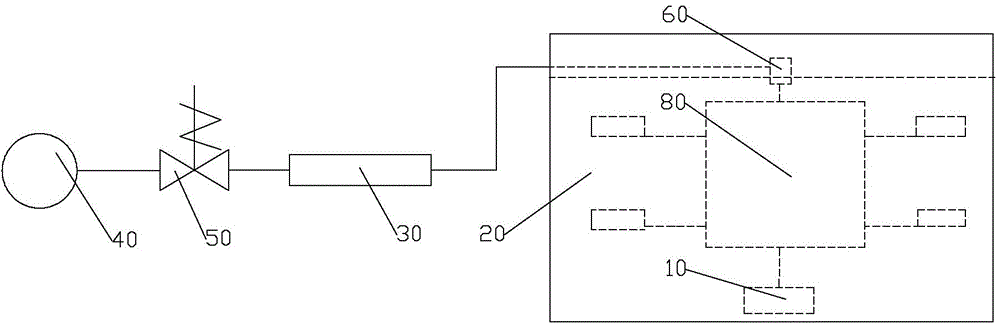

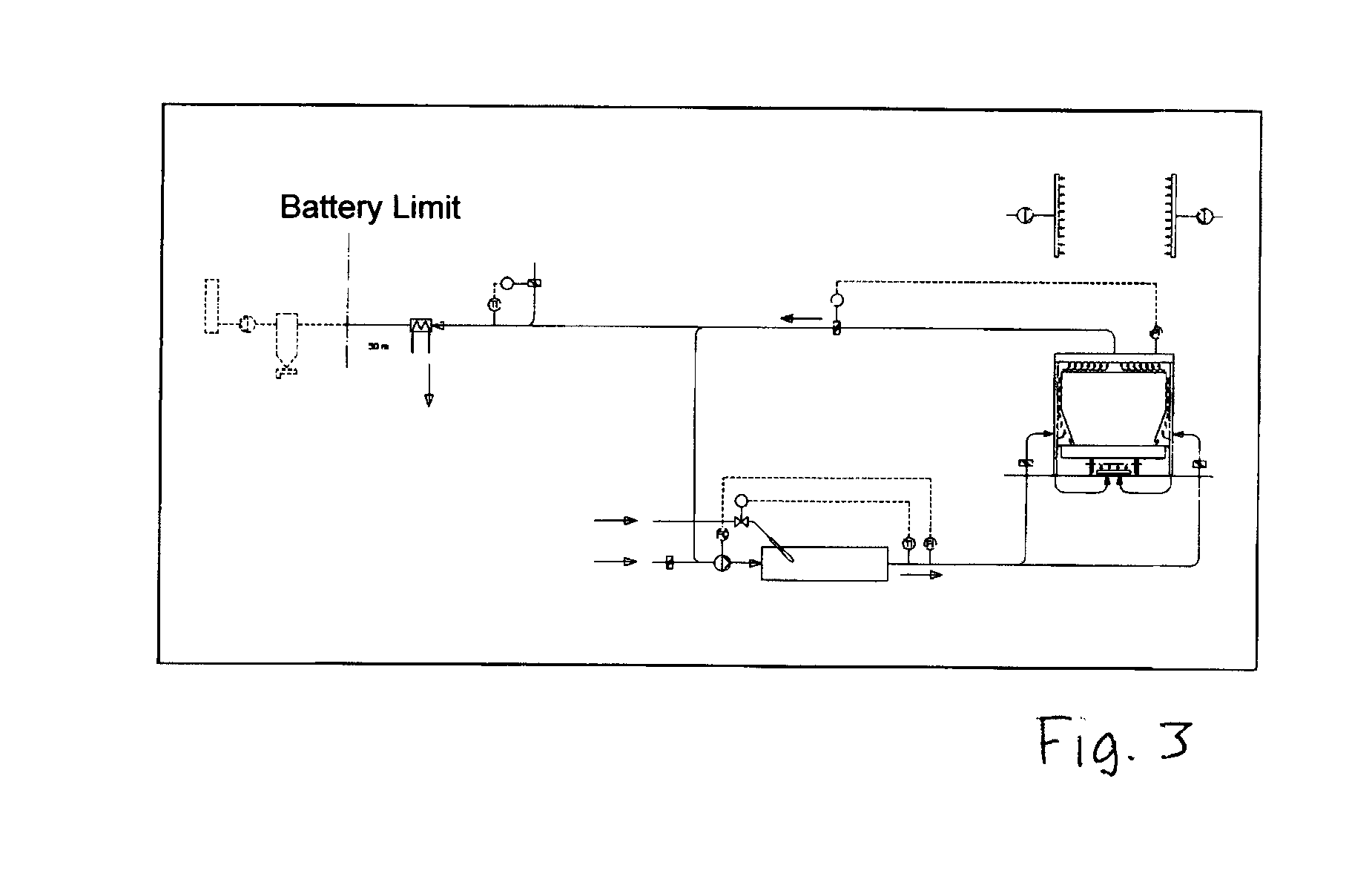

Conveying control method for pneumatic conveying system

The invention provides a conveying control method for a pneumatic conveying system. The conveying control method comprises the following steps of: 1) opening a fluidifying air valve, closing a pipeline air supply valve, comparing conveying real-time pressure with a conveying pressure upper limit, and normally conveying when the conveying real-time pressure is less than or equal to the conveying pressure upper limit, transferring to step 2) when the conveying real-time pressure is more than the conveying pressure upper limit and less than a blockage pressure set value, and transferring to step3) when the conveying real-time pressure is more than or equal to the blockage pressure set value; 2) closing the fluidifying air valve, opening the pipeline air supply valve, and transferring to thestep 1) when the conveying real-time pressure is reduced to a conveying pressure lower limit; and 3) closing all the air valves, transferring to an automatic blockage clearing program, and transferring to the step 1) after the blockage clearing is completed. In the conveying control method, the logic judgment is added on a control system, corresponding air valves are controlled to be opened and closed according to judgment results, the blockage phenomenon is effectively avoided, the time for blockage clearing of the system is shortened, the abrasion and the energy consumption of the system are reduced, and the reliability of the pneumatic conveying system is improved.

Owner:FUJIAN LONGKING

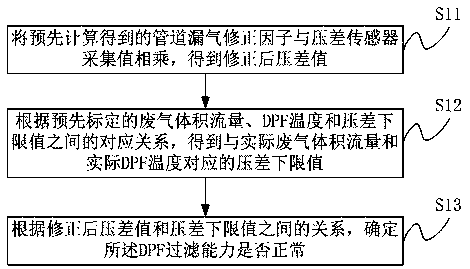

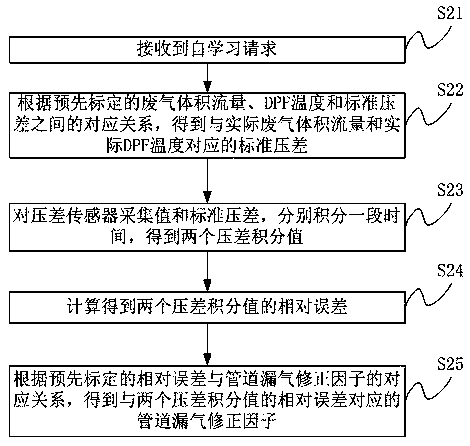

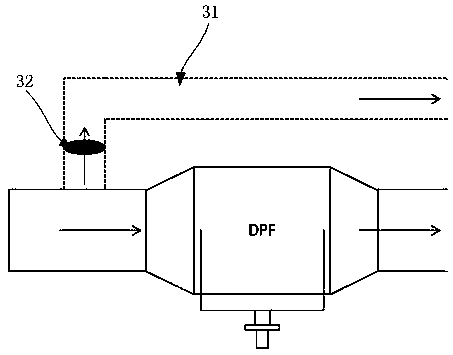

Method and device for detecting filtering capacity of DPF

ActiveCN110725738AImprove robustnessThe test result is accurateInternal combustion piston enginesExhaust apparatusPipeline.airDifferential pressure

The invention provides a method and device for detecting the filtering capacity of a DPF. The method comprises the steps that a pipeline air leakage correction factor is pre-calculated and obtained, adifferential pressure sensor collected value is corrected through the pipeline air leakage correction factor, and a corrected differential pressure value is obtained. Due to the fact that the corrected differential pressure value corrects differential pressure influence caused by pipeline air leakage, whether the filtering capacity of the DPF is normal or not is determined according to the relation between the corrected differential pressure value and a differential pressure lower limiting value, so that the detecting result is more accurate, the fault false alarm rate caused by the pipelineair leakage is reduced, and the robustness of a detecting strategy is improved. Furthermore, by setting differential pressure self-learning conditions, when a vehicle meets the differential pressure self-learning condition, the pipeline air leakage correction factor is calculated, and the workload of pre-calibrating the corresponding relation among the waste volume flow rate, DPF temperature and standard differential pressure and the corresponding relation between a relative error and the pipeline air leakage correction factor is reduced.

Owner:WEICHAI POWER CO LTD

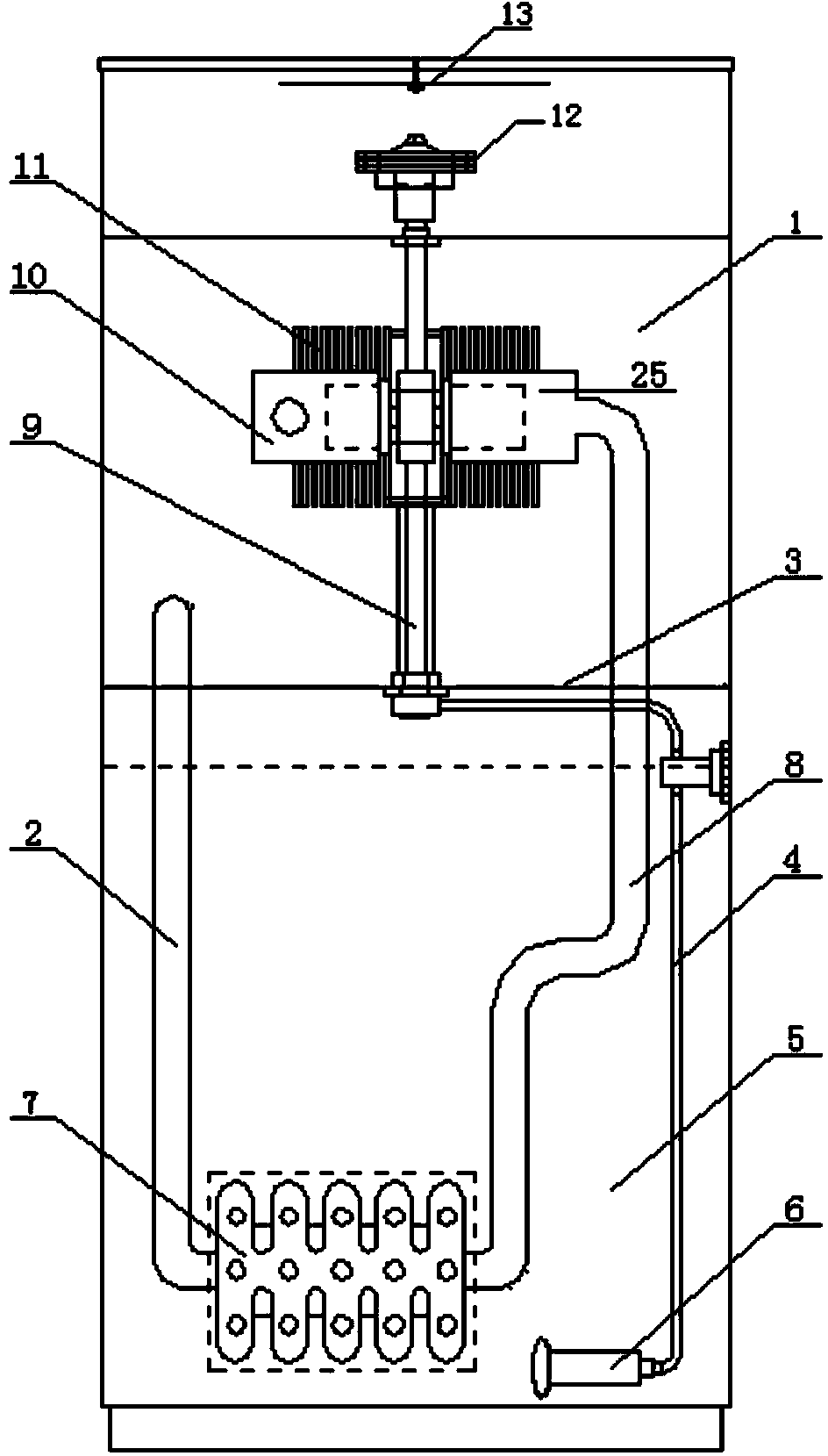

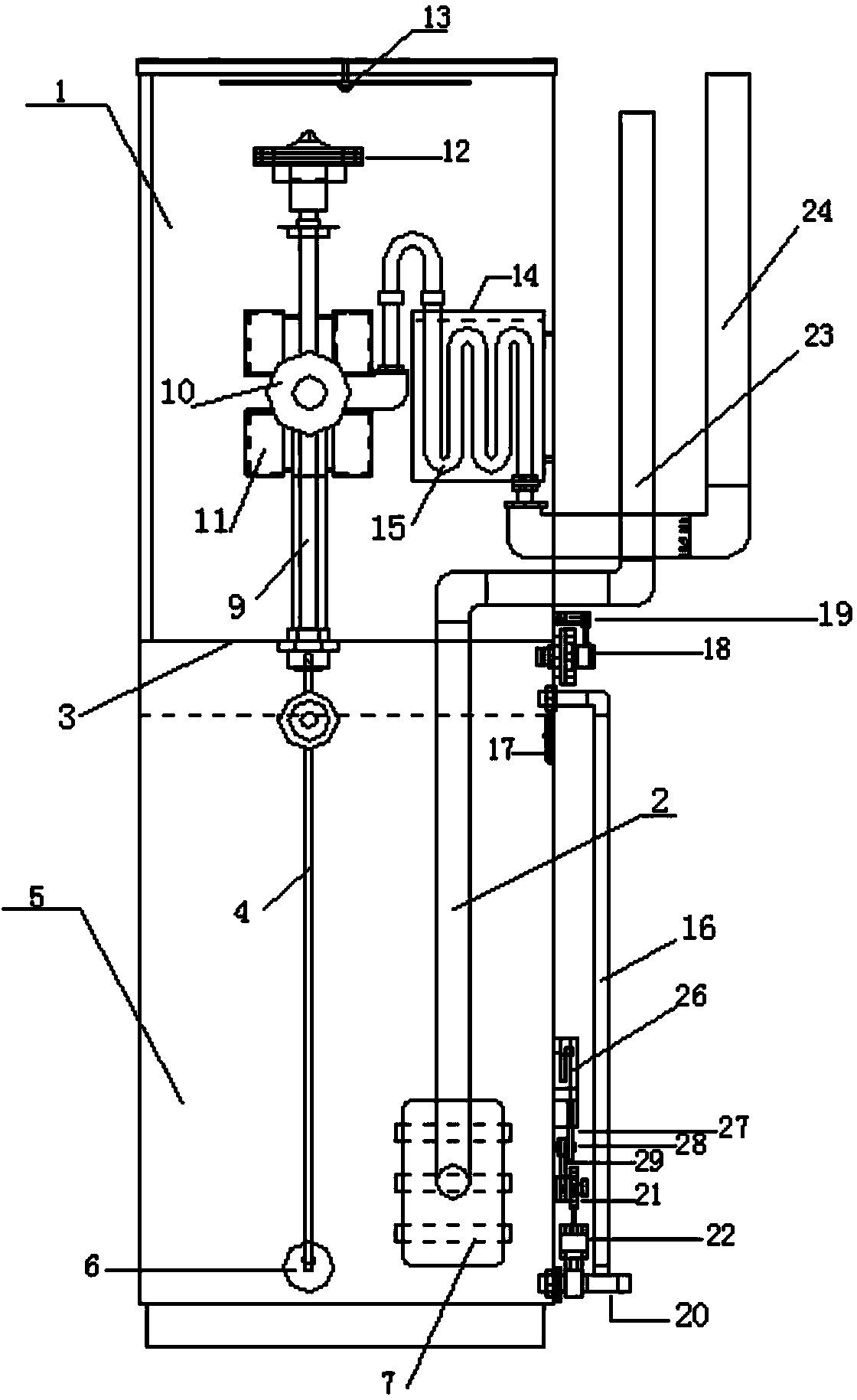

Water air-conditioning system coupling cooling spray device water circulation with air current cooler

InactiveCN103411283ANo pollutionImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusPipeline.airWater circulation

The invention discloses a water air-conditioning system coupling cooling spray device water circulation with an air current cooler. The system comprises a cooling water tank and a cooling spray tank, wherein a multi-hole top plate is arranged between the cooling water tank and the cooling spray tank, the cooling water tank contains cooling spray water, and the air current cooler is placed in the cooling spray water; a cooling spray device, an ice pack water tank and a winding quick cooler are arranged at the inner part of the cooling spray tank, an inner pipeline air bag is installed at the inner part of the cooling spray device, the ice pack water tank is fixed on the inner part of the cooling spray tank by virtue of a support, the quick cooler is arranged at the inner part of the ice pack water tank, one end of the inner pipeline air bag is connected with the air current cooler in the cooling water tank through a second cooling transition pipe, the other end of the inner pipeline air bag is connected with one end of the quick cooler, and the other end of the quick cooler is connected with an exhaust fan pipeline. Compared with the existing air conditioner, the system disclosed by the invention has the advantages of good refrigeration effect, low fabrication cost, small power consumption and no pollution and the like.

Owner:SOUTHEAST UNIV

Heating and ventilation equipment hard pipeline air leakage detection device

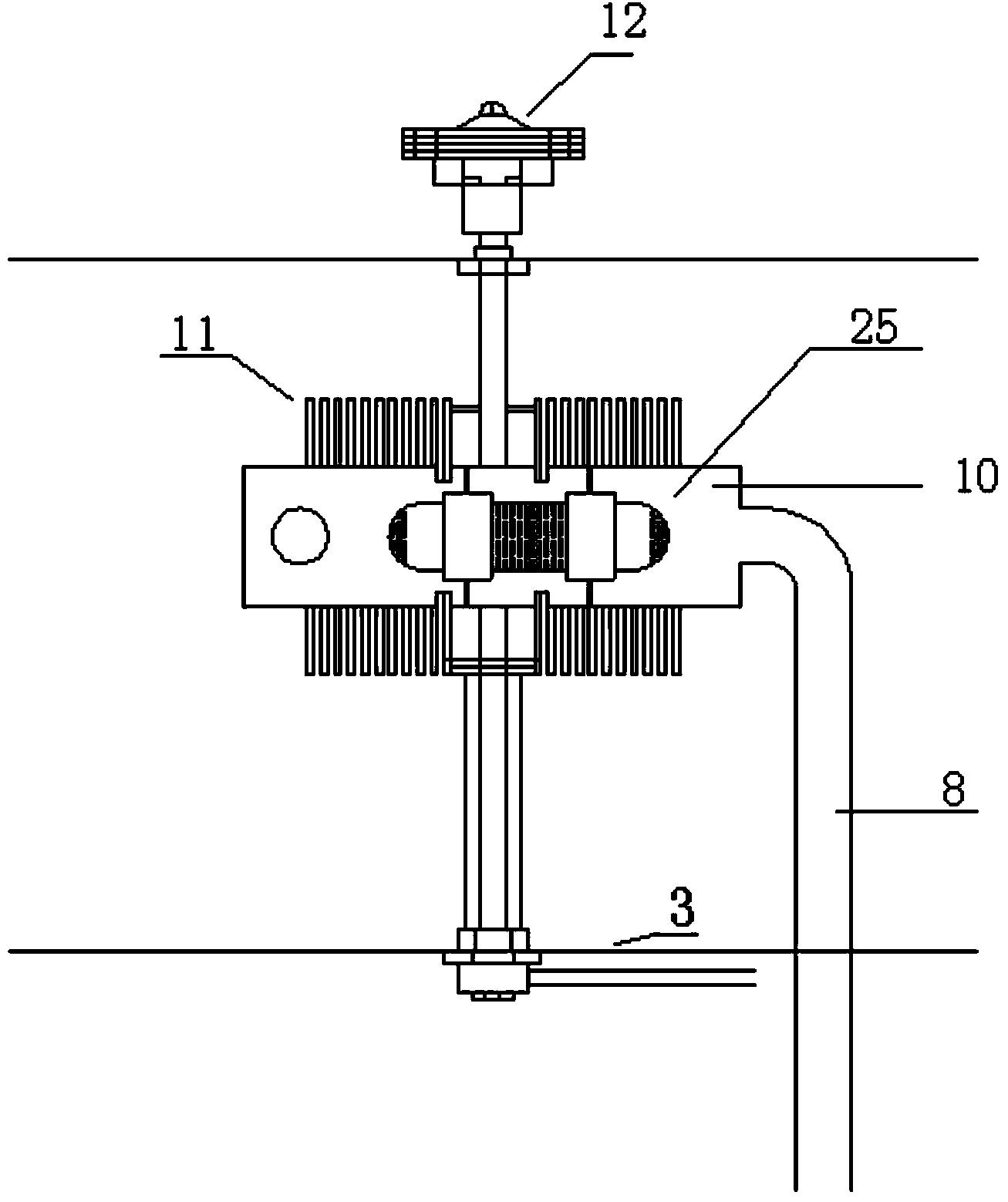

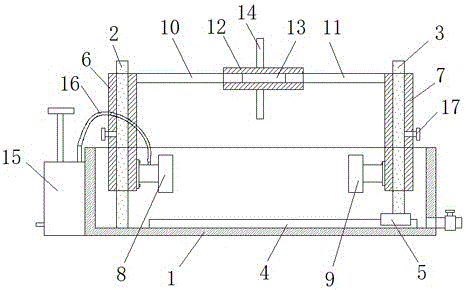

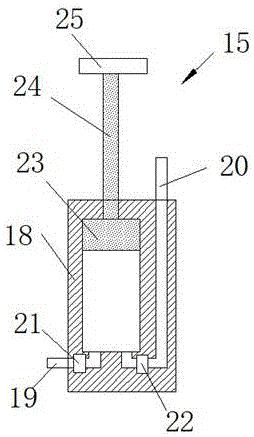

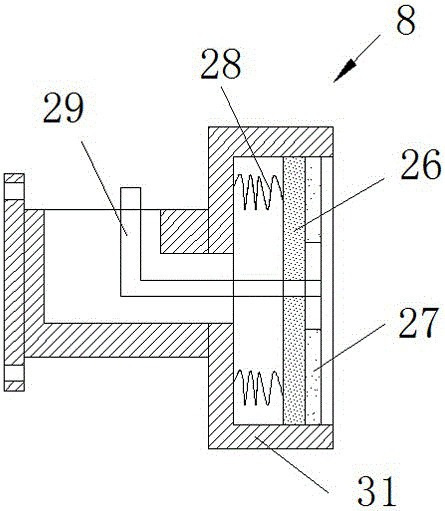

PendingCN106768676ALow costEasy to operateDetection of fluid at leakage pointPipeline systemsPipeline.airEngineering

The invention discloses a heating and ventilation equipment hard pipeline air leakage detection device, which comprises a first sleeve and a second sleeve, wherein the right side bottom of the first sleeve and the left side bottom of the second sleeve are respectively provided with a first connector and a second connector; the right side top of the first sleeve and the left side top of the second sleeve are respectively connected with a connecting sleeve through a first threaded rod and a second threaded rod; a threaded hole is formed inside the connecting sleeve; the first threaded rod and the second threaded rod are respectively connected at the left side and the right side inside the threaded hole through screw threads; an inflating device is arranged at the left side of the outer part of a water tank, and communicates with the first connector through a hose. The device has the advantages that a hard pipe is connected in a sealed way through the first connector and the second connector, and is then put into water; the inside of the hard pipe is inflated through the inflating device; whether air leakage exists or not is judged through judging whether bubbles are generated in the clear water or not, so that whether the hard pipe is qualified or not can be detected. The cost of the device is low; the operation is simple; the mass production is easy.

Owner:JIANGSU RES INST OF BUILDING SCI

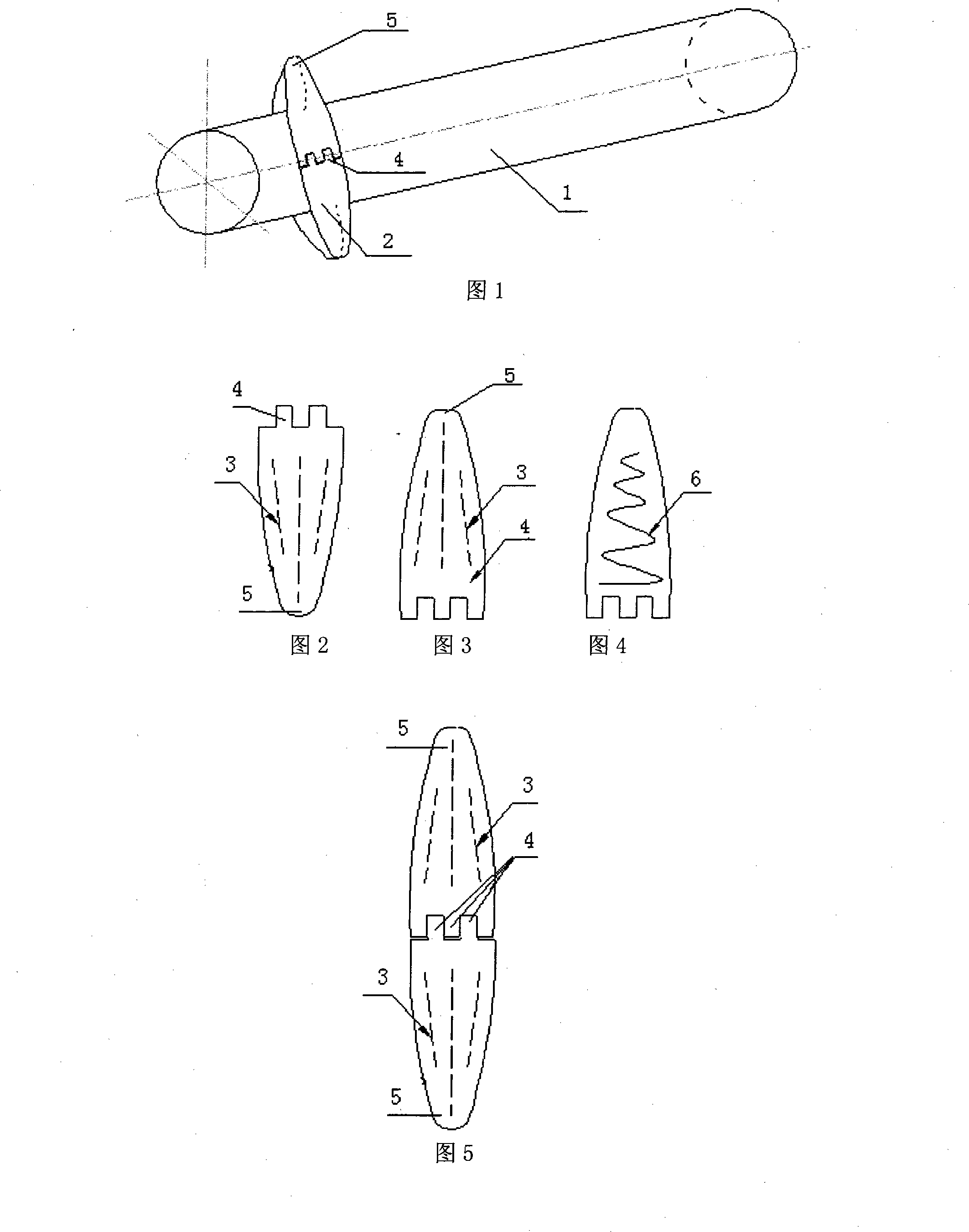

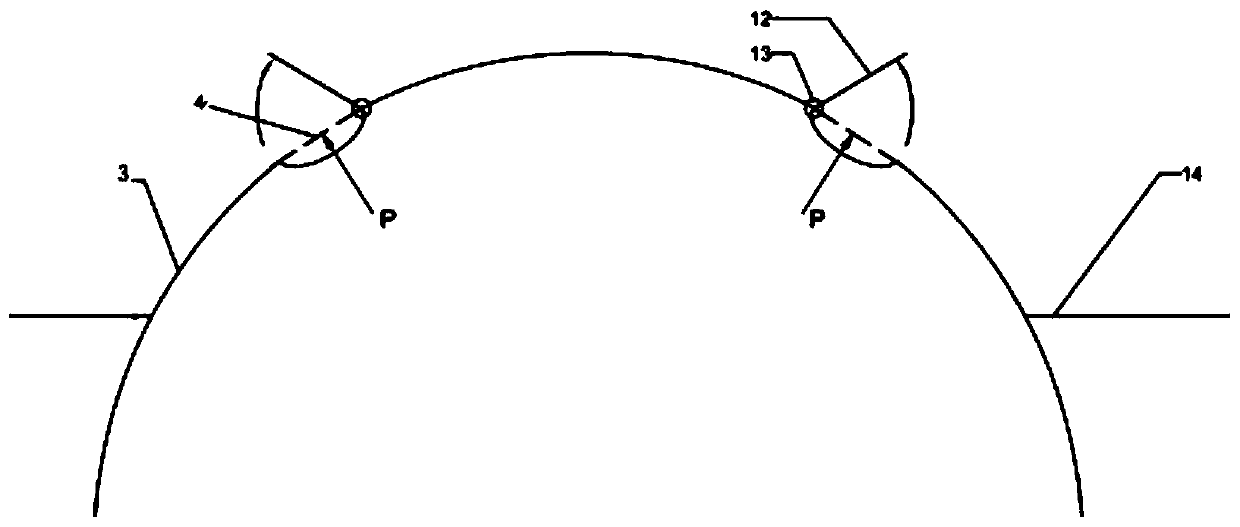

Submerged pipeline air guide sleeve and its production and fixing method

InactiveCN101220887AReduce the possibility of resonanceReduce adverse effectsPipe laying and repairOcean bottomPipeline.air

The invention relates to an undersea pipeline guide cover which is a symmetrical shell which is connected by two convex tops in the middle. The invention is spliced by four tongue-shaped guide pieces which has the same size and bending radian; each guide piece is gradually thinned from the bottom edge to the top; the bottom edge is provided with a square-wave incision; the external wall of the guide piece is fixed with a Z-shaped torrent wire; the square-wave incision of each guide piece is matched with the square-wave incision of the guide piece which is spliced by the square-wave incision of the guide piece at the bottom edge. The invention also relates to a manufacture and fixing method of the guide cover. The manufacture and fixing method of the undersea pipeline guide cover which is provided by the invention effectively controls a vortex-induced vibration, has moderate complexity of the construction process, keeps the construction cost in an acceptable range, and realizes the optimization between the factors of process complexity, manufacture cost, the restriction effect of the vortex-induced vibration, etc.

Owner:TIANJIN UNIV

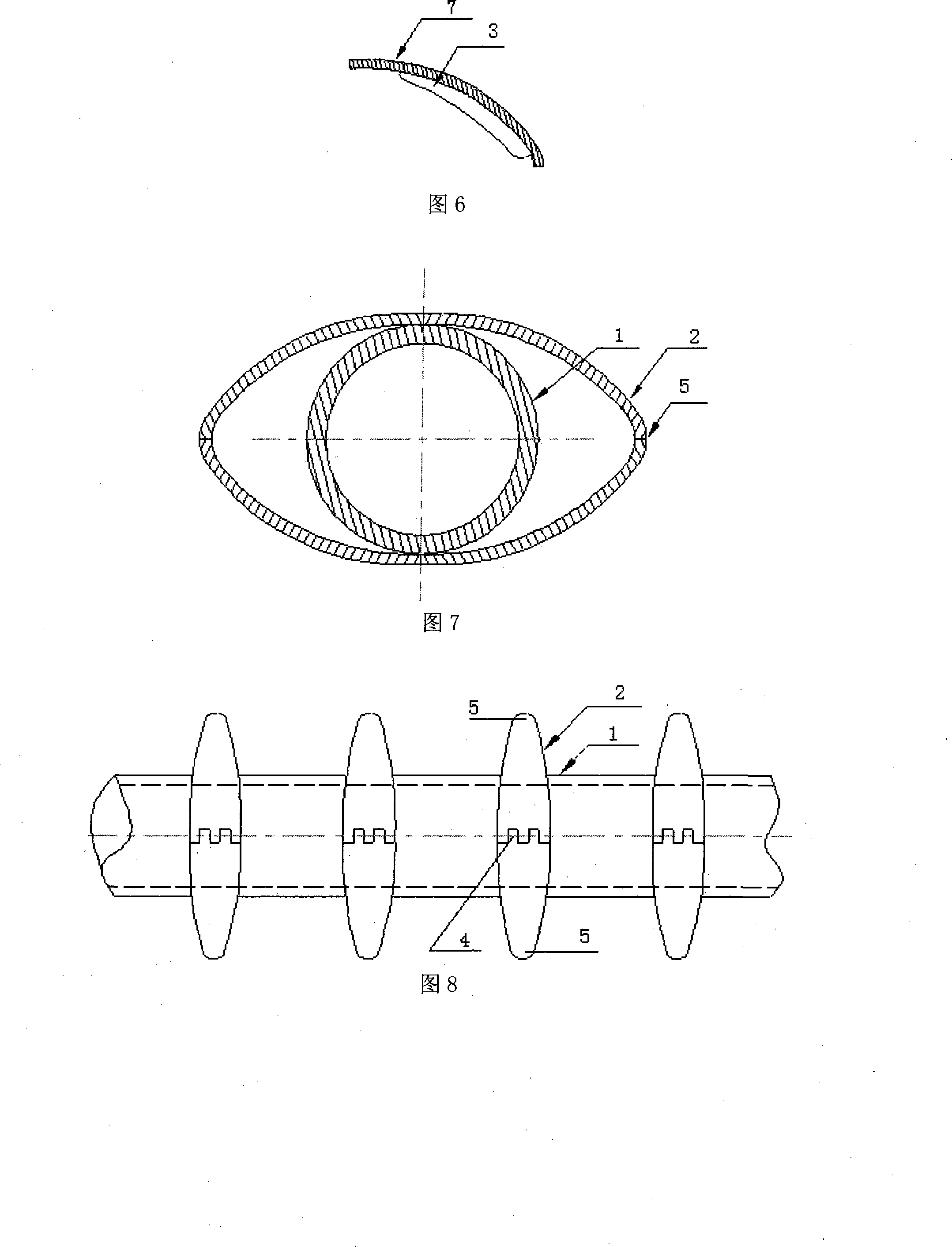

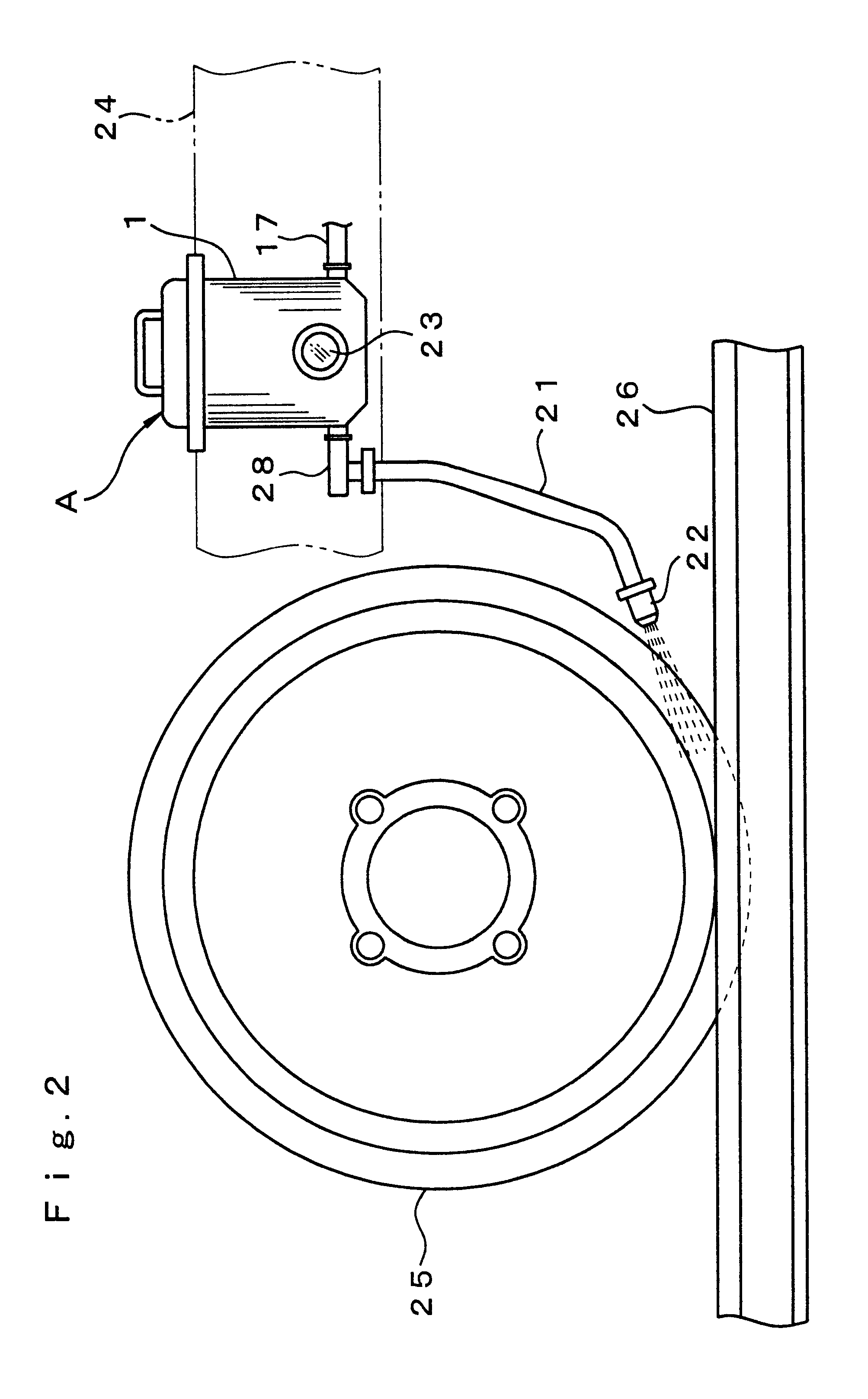

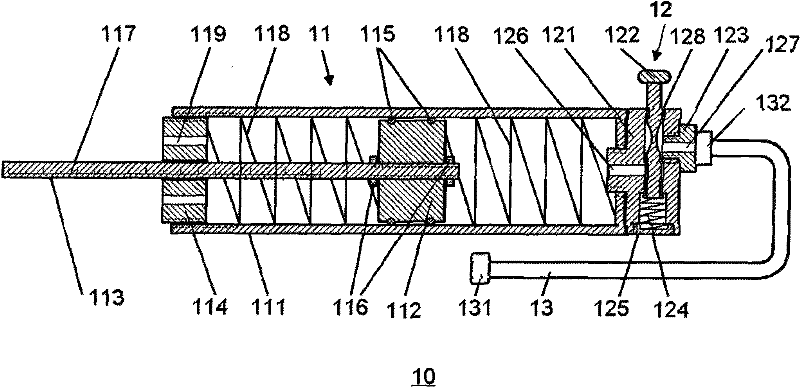

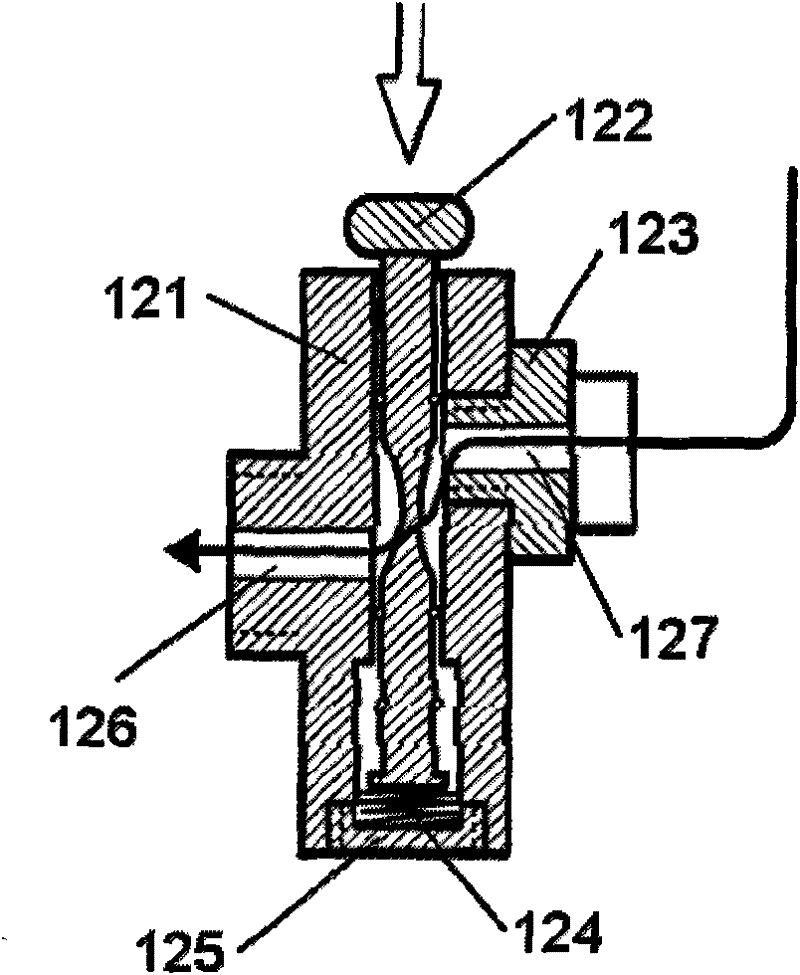

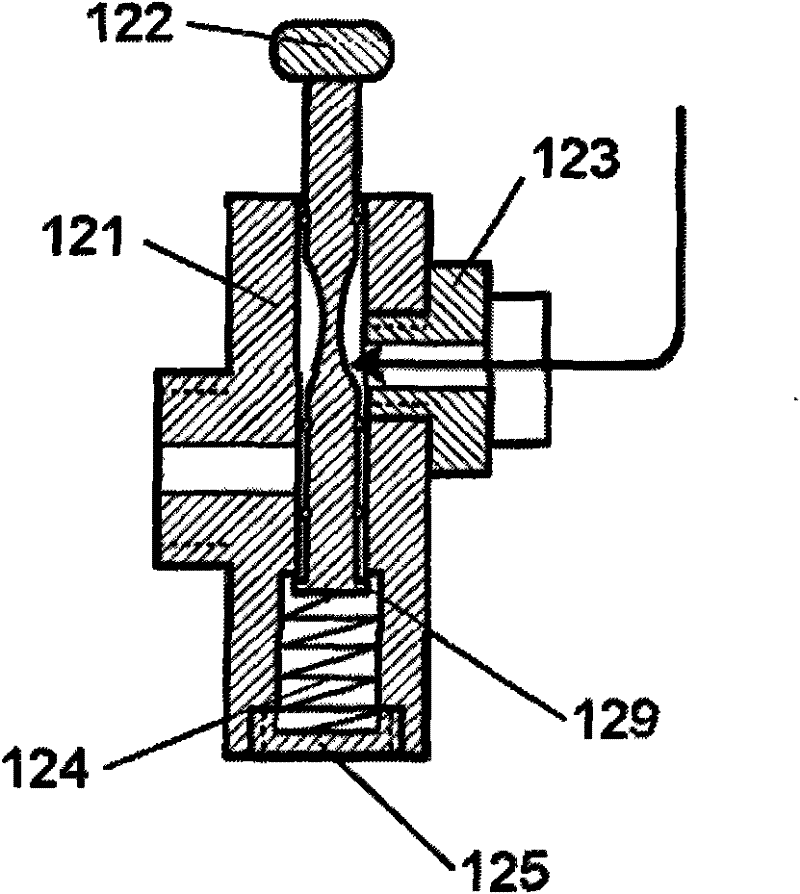

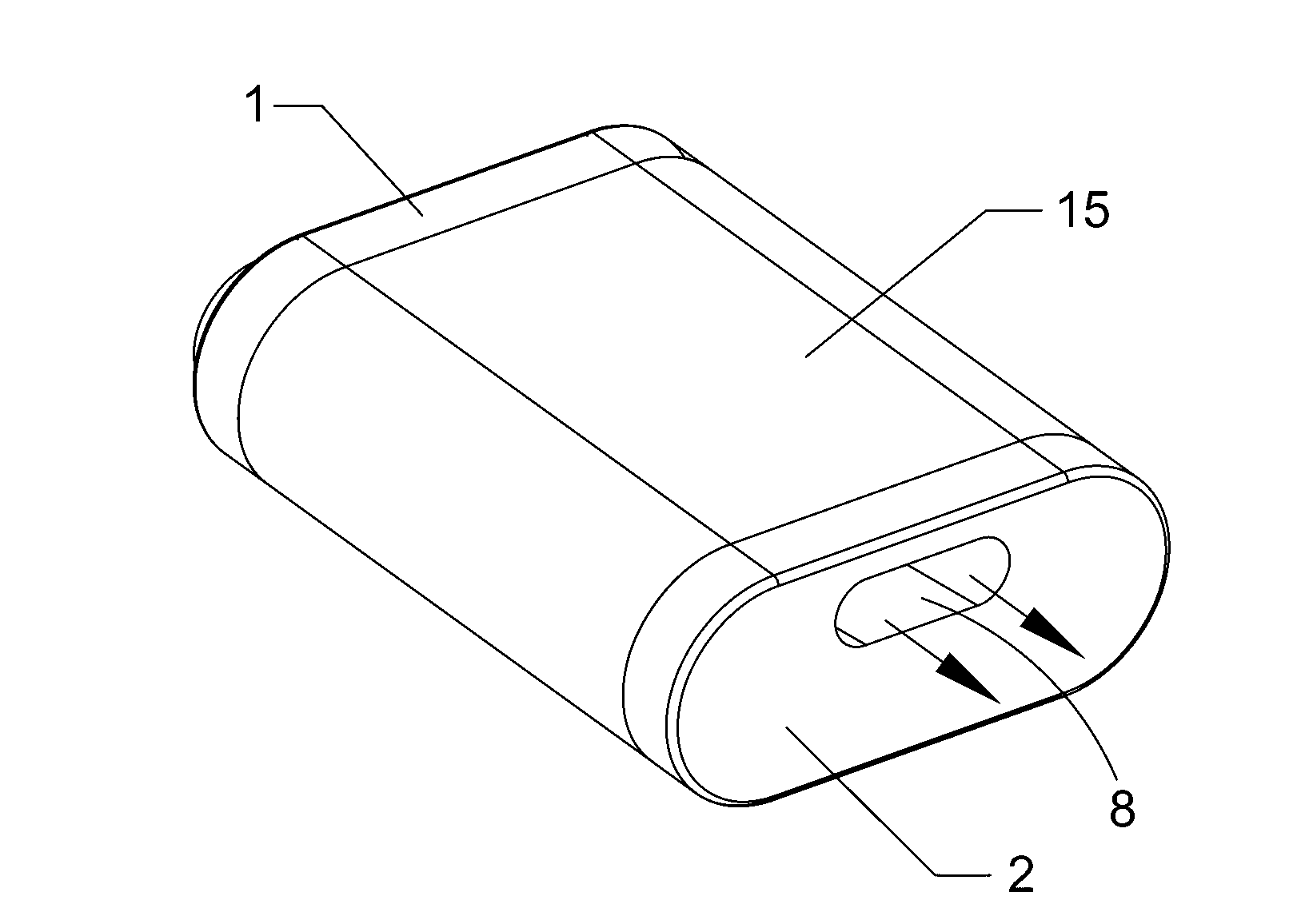

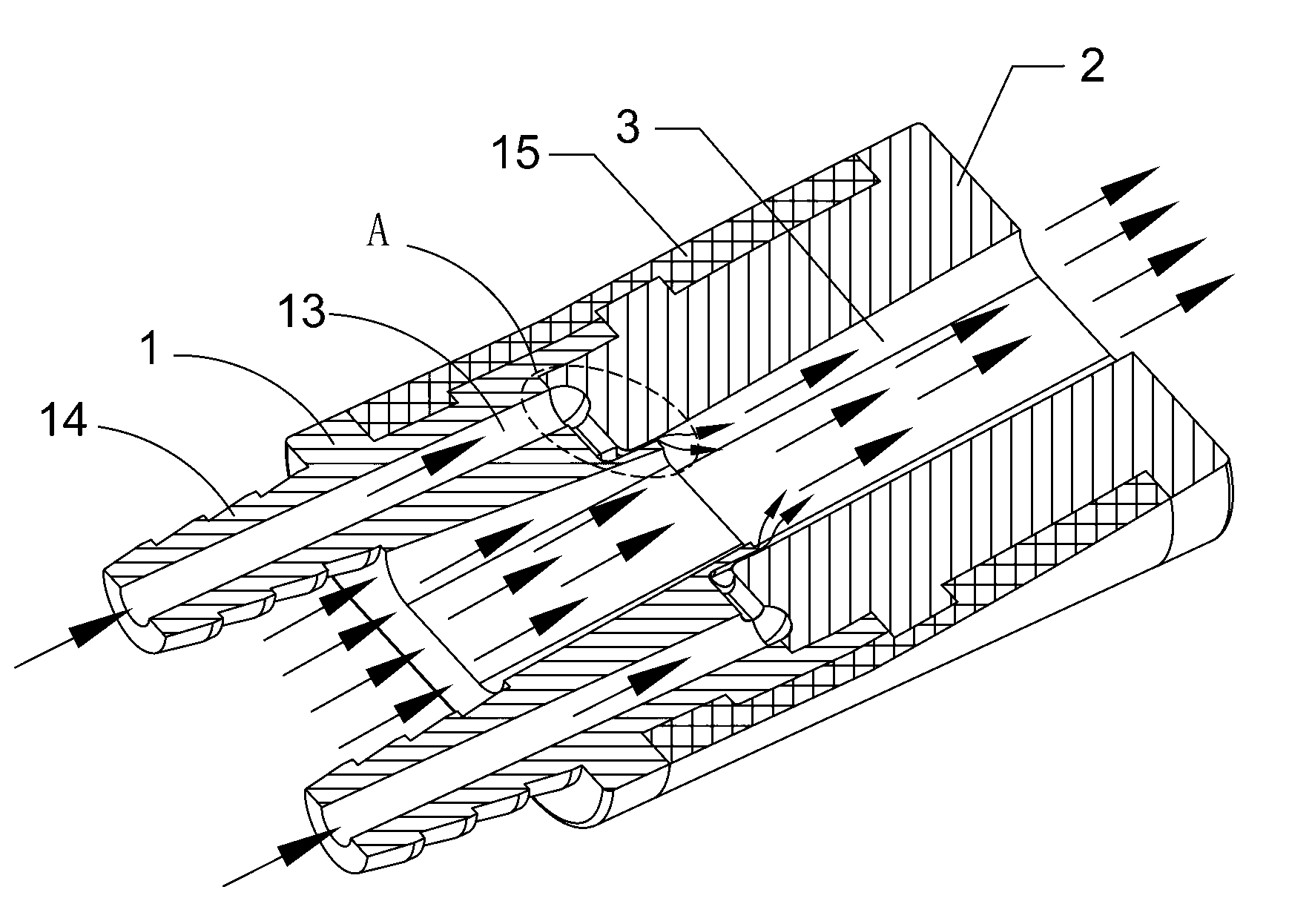

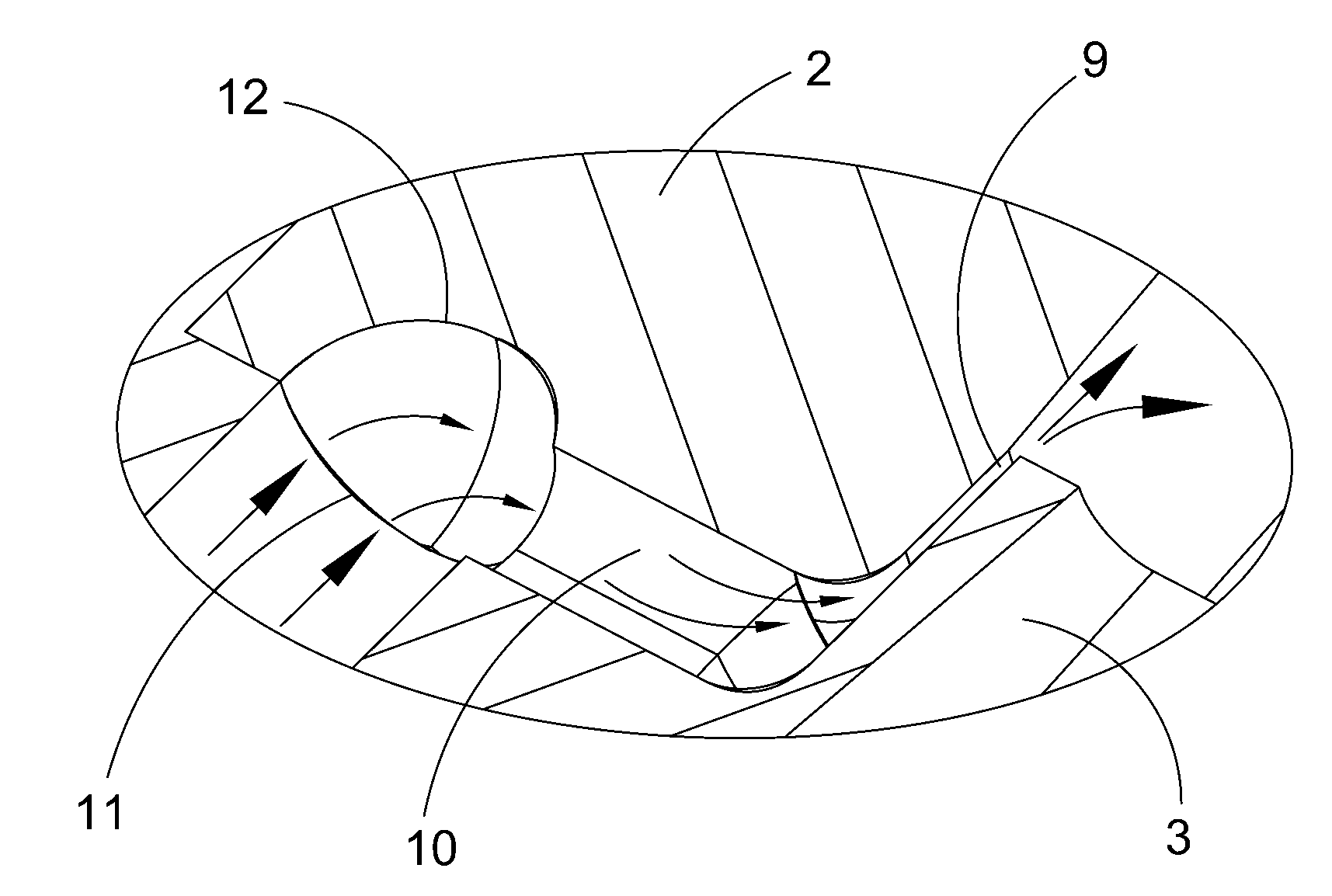

Slip prevention particle injection device

InactiveUS6722589B1Simple structureImprove cost efficiencyFertiliser distributersManure distributersPipeline.airParticle injection

Problems are posed by slip prevention particle injection devices by wheels of railway rolling stock. Namely, if the injected quantity of slippage-preventing particles is adjusted so as not to be excessive and to be a suitable quantity, it is not possible to obtain a predetermined injection pressure and it is not possible to inject the particles at the target location. The injector device of the present invention is constituted by providing an air through-flow duct 5 inside a particle retainer tank 1, and connecting an air supply duct 17 to this air through-flow duct 5. In the above mentioned tank 1, in addition to an air inflow duct 6 being provided in the vicinity of the inlet side of the air through-flow duct 5, an air discharge duct 18 is provided in the vicinity of the outlet side of the air through-flow duct 5. This air inflow duct 6 and air discharge duct 18 are connected to the air through-flow duct 5 and one end of these ducts 6 and 18 is open into the tank 1. Further, in addition to a mixing chamber 15 and a smaller-diameter air passage section 9 being provided in the air through-flow duct 5, a particle introduction hole 16 is provided in the mixing chamber 15, and an injector duct 21 that injects a fluid mixture of slippage-preventing particles and compressed air is provided at the outlet side of the air through-flow duct 5.

Owner:RAILWAY TECH RES INST +1

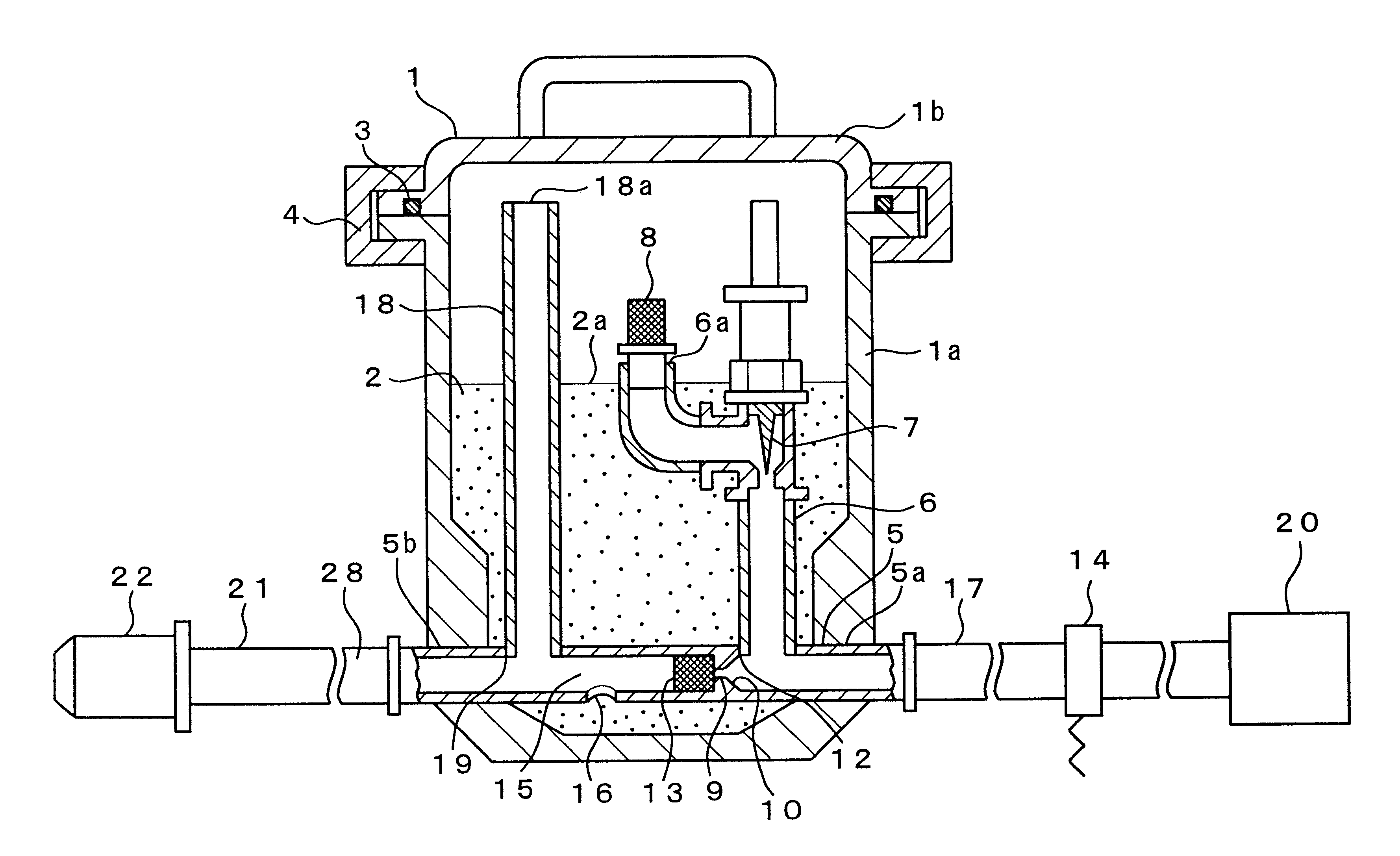

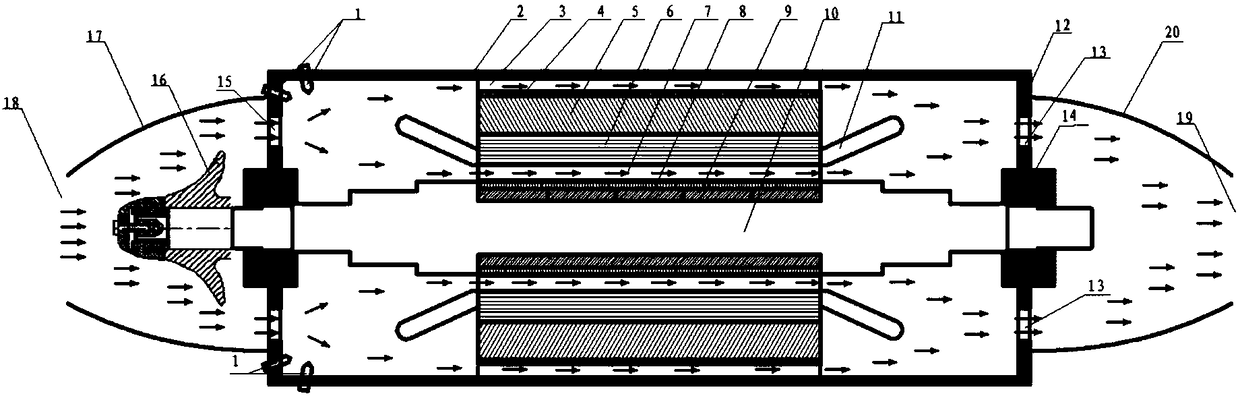

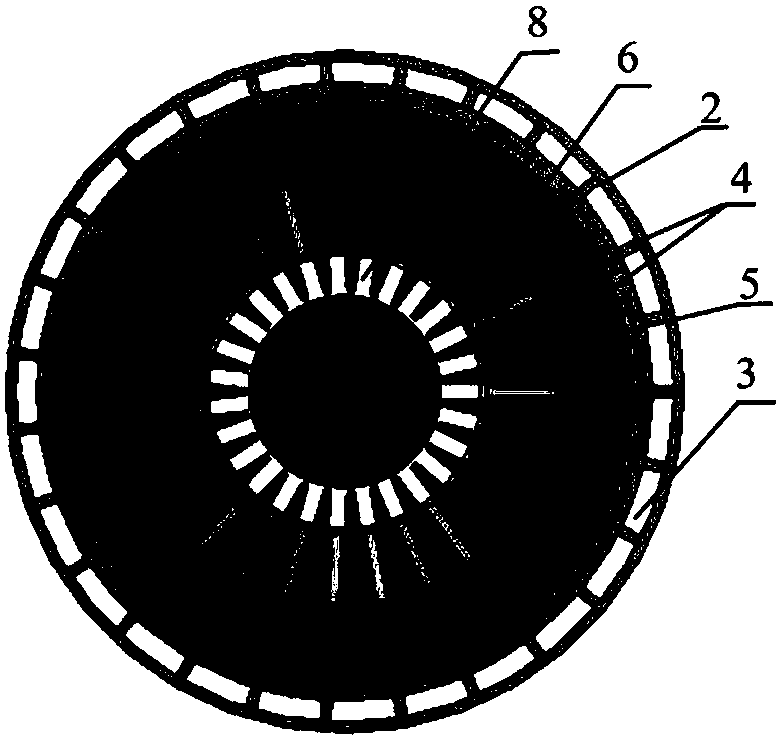

Total-closed high-speed permanent magnet motor using liquid jet to be cooled

ActiveCN108258849AImprove reliabilityIncreased operating lifeMagnetic circuit rotating partsMagnetic circuit stationary partsLiquid jetPipeline.air

The invention belongs to the technical field of motors, and discloses a total-closed high-speed permanent magnet motor using liquid jet to be cooled. The permanent magnet motor comprises a motor shell, a stator, a rotor and end covers, wherein the stator and the rotor are arranged in the motor shell, the end covers are arranged at the front and back ends of the motor shell, the end covers at the front and back ends of the motor shell are both provided with wind gap shells, the wind gap shells at the front and back ends are respectively provided with a pipeline air inlet and a pipeline air outlet, the end covers at the front and back ends of the motor shell are correspondingly provided with an air passage inlet and an air passage outlet, the pipeline air outlet is communicated with the pipeline air inlet to form the circulation flow of gas in the motor, in addition, the side face of the front end of the motor shell is provided with multiple liquid jet ports distributed around the external circumference of the motor shell, the liquid jet ports are used for cooling the entered gas from the air passage inlet, and the cooling liquid ejected from the liquid jet ports is Freon, R123, R245or R141. According to the total-closed high-speed permanent magnet motor using liquid jet to be cooled, the temperature of the motor is effectively reduced, and the problems that the total-closed high-speed permanent magnet motor has high temperature, difficult heat dissipation and too-high local temperature rising of the stator and rotor are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

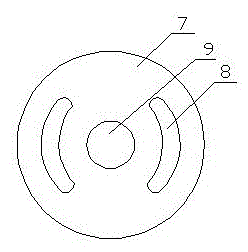

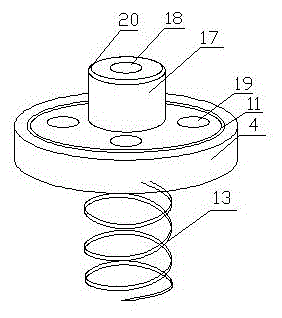

Pipeline air pressure on-line detector and detection method

ActiveCN102221437AImprove measurement accuracyImprove efficiencyFluid pressure measurement using pistonsPipeline.airEngineering

The invention discloses a pipeline air pressure on-line detector, comprising detection parts, a hand valve and an air inlet pipe. The detection parts comprise a piston housing, a piston and a piston rod, wherein one end of the housing is provided with a chamber cover, one end of the piston rod passes through the chamber cover, the piston rod is provided with a scale and both sides of the piston are respectively provided with a detection spring. The invention also discloses another pipeline air pressure on-line detection method. Under the conditions that the air inlet pipe communicates with the pipeline to be detected and the hand valve is opened, the piston moves under the effect of pipeline air pressure and the piston rod is driven to stretch. The air pressure state value of the pipeline can be detected through the reading of the scale. Therefore, the measuring apparatus has advantages such as high measurement accuracy, on-line detection option, positive and negative air pressure detection option, simple and convenient operation, high efficiency and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

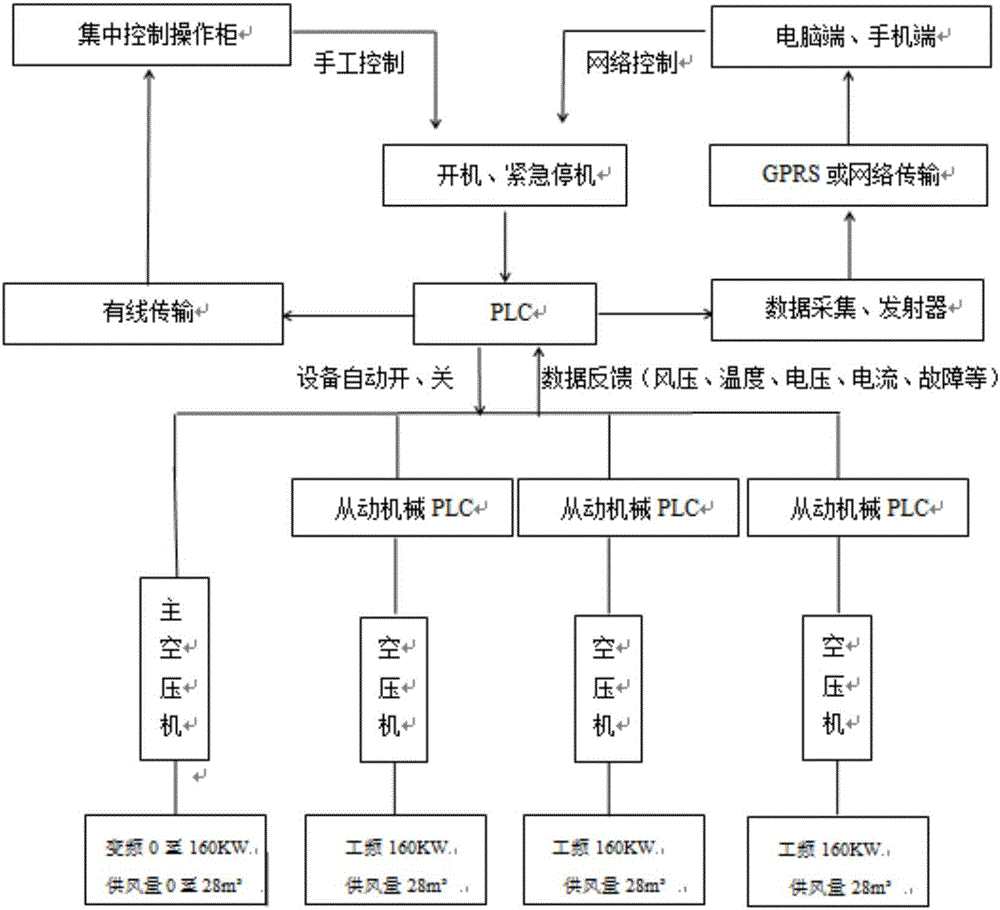

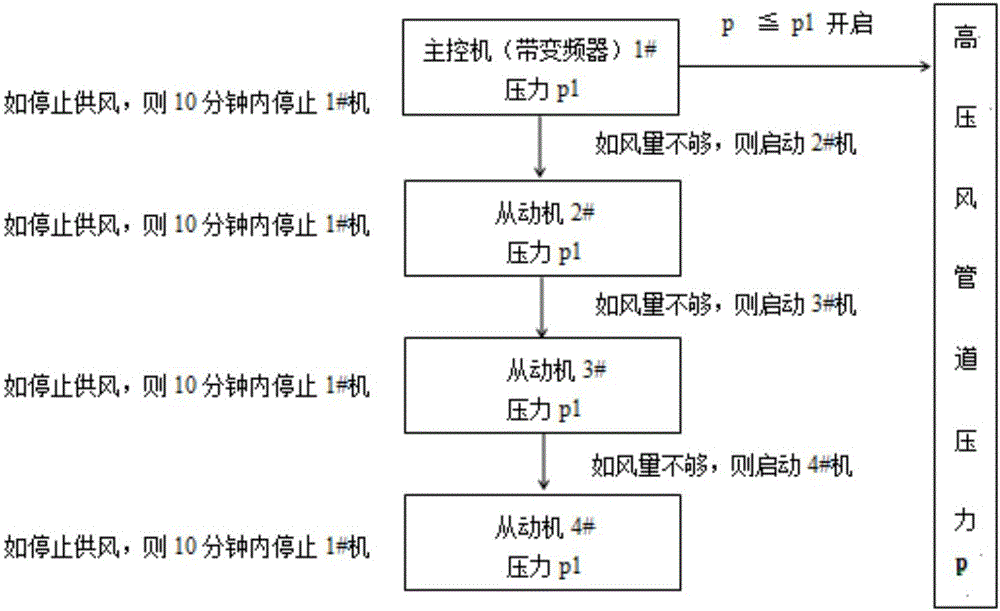

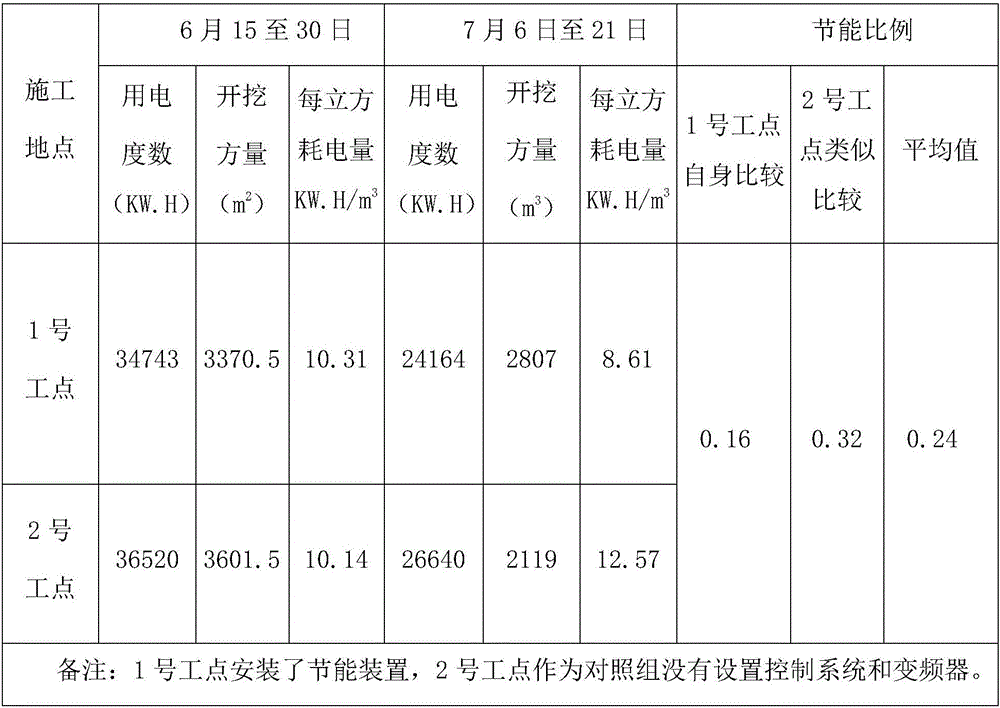

Energy-saving control system and control method for screw type electric air compressor set

ActiveCN106704193ARealize energy-saving controlRealize joint controlMachines/enginesFrequency changerPipeline.air

The invention discloses an energy-saving control system for a screw type electric air compressor set. The energy-saving control system comprises a main control machine and multiple driven machines. The main control machine comprises a first screw electric air compressor, a frequency converter connected with the first screw electric air compressor, a first controller connected with the frequency converter and a first air pressure sensor, wherein the first air pressure sensor is connected with a high-pressure air conveying pipeline and used for transmitting detected pipeline air pressure data to the first controller. Each driven machine comprises a second screw electric air compressor, a power frequency controller connected with the second screw electric air compressor and a second air pressure sensor, wherein the second air pressure sensor is connected with the high-pressure air conveying pipeline and used for transmitting detected pipeline air pressure data to the power frequency controller. The power frequency controller is connected with the first controller. The first controller acquires the pressure values detected by the first air pressure sensor and the second air pressure sensor, and the frequency converter is controlled and the frequency of the motor and start and stop of the driven machines are controlled according to the set PID control. The energy-saving control system has the beneficial effects that energy saving is achieved, and the start is skipped to automatically when a failure happens.

Owner:中铁隧道局集团建设有限公司

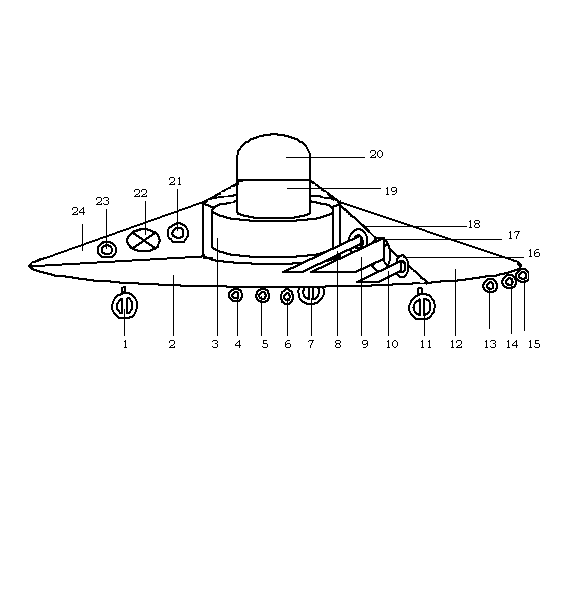

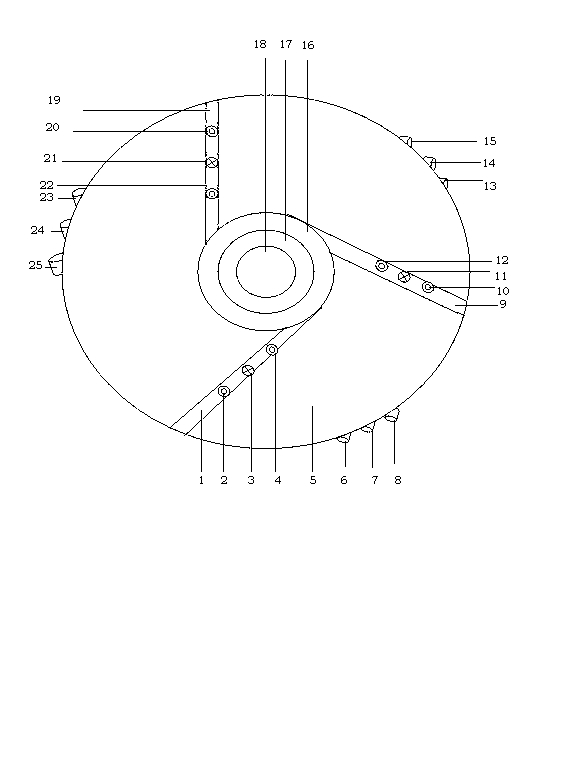

Flying saucer spacecraft

InactiveCN103253372AReduce gravityReduced effectivenessJet type power plantsAircraftsAviationRocket launch

The invention provides a flying saucer spacecraft, and relates to the spaceflight, aviation and rocket launching fields. A satellite, a missile and a spaceship are launched through combining rocket and space shuttle technologies and utilizing a flying saucer principle and an aerodynamic principle. The flying saucer spacecraft is composed of a central low-portion fuel tank, a central control system, an upper-portion launch silo (a satellite silo, a missile silo, a space ship silo), a rocket engine air inlet and an air pipeline air inlet which are arranged at the upper layer of the flying saucer spacecraft, a rocket engine air outlet and an air pipeline air outlet which are arranged at the lower layer, a rocket engine and an air pipeline which are arranged at the middle layer, and a first tire, a second tire and a third tire which are arranged at the bottom layer of the flying saucer spacecraft. The flying saucer spacecraft has the advantages of high speed, far range, repeated use, substantial reduction of the space activity cost, and the like, and is suitable for launching satellites, missiles and spaceships.

Owner:罗才德

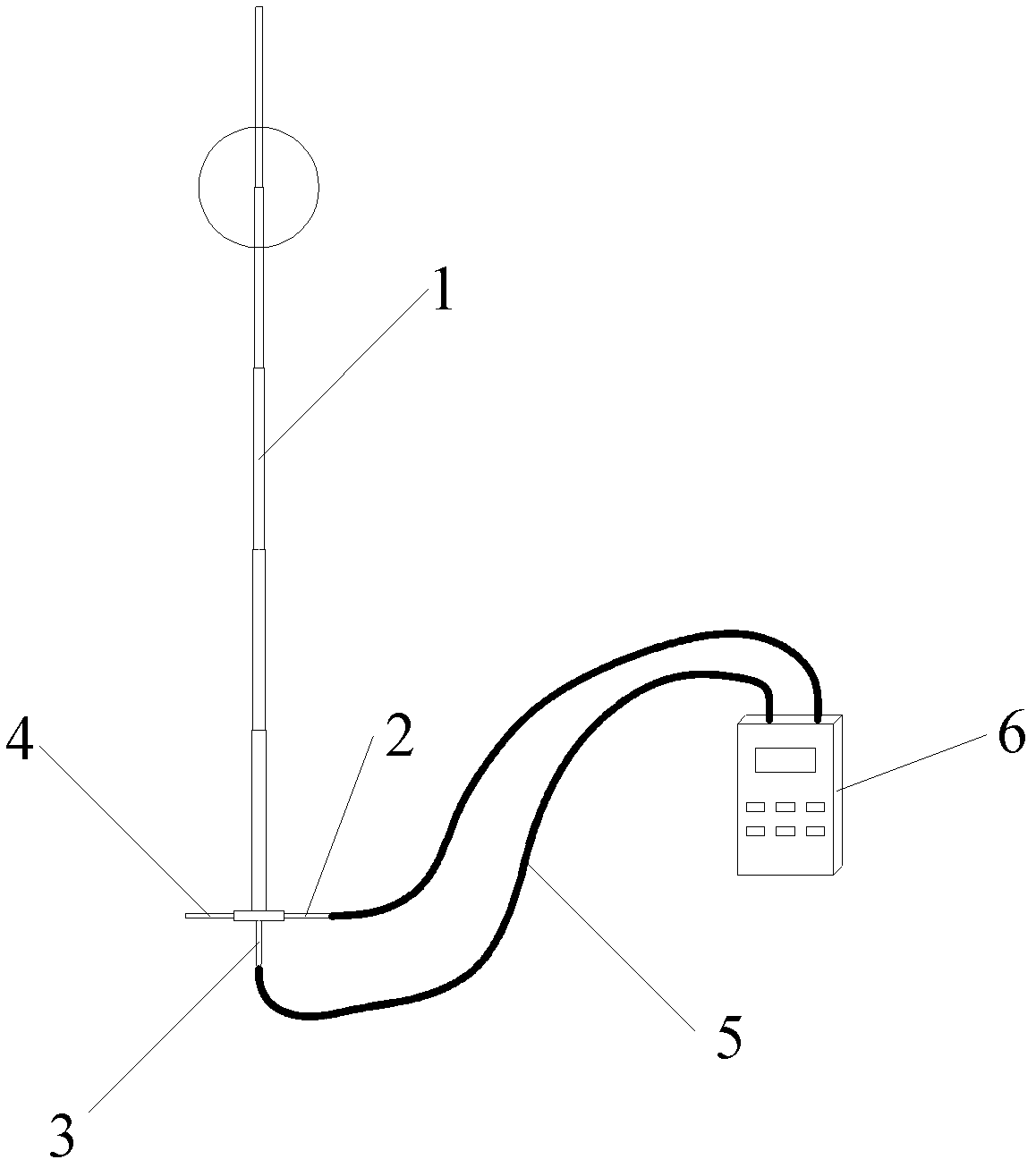

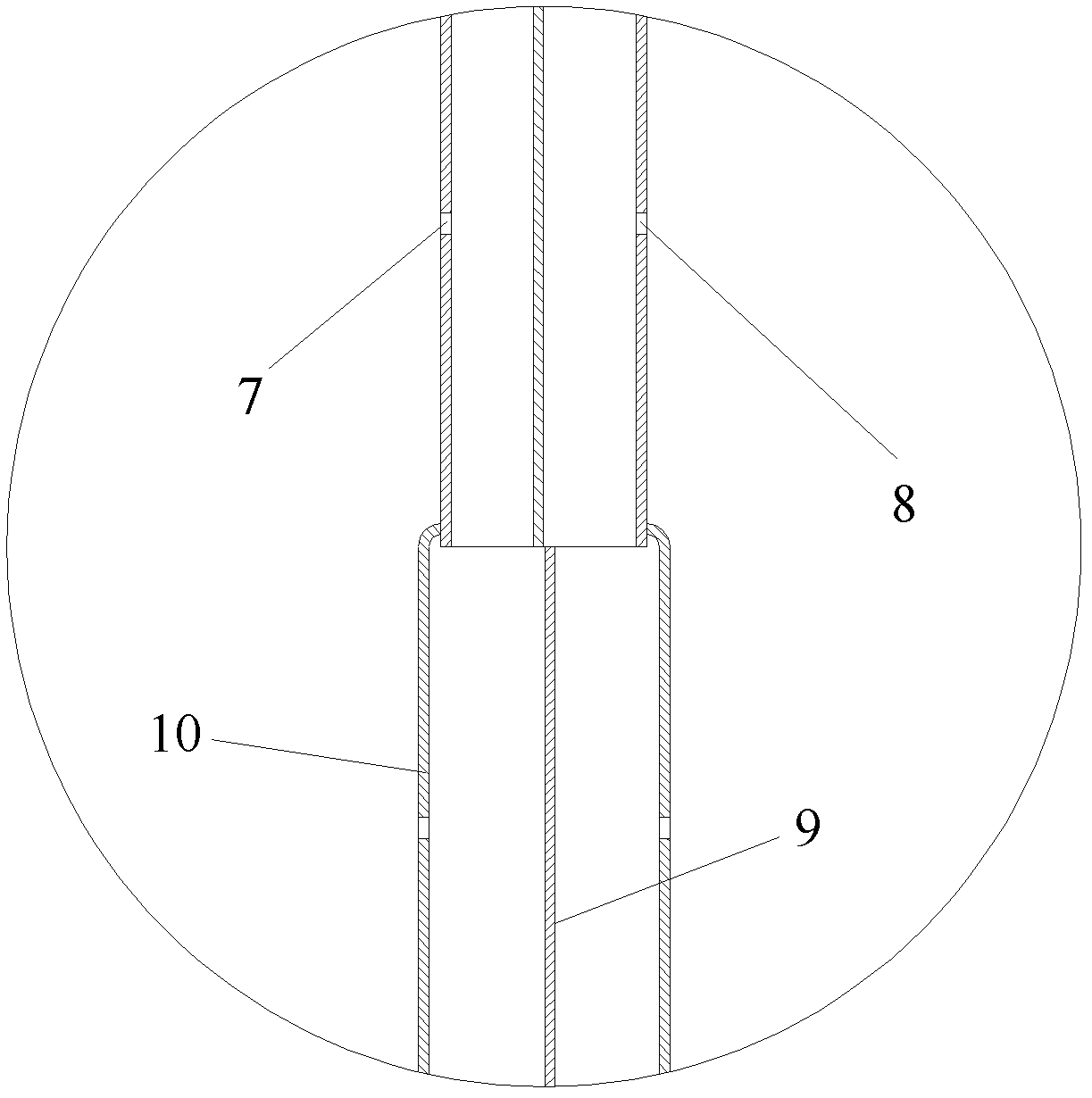

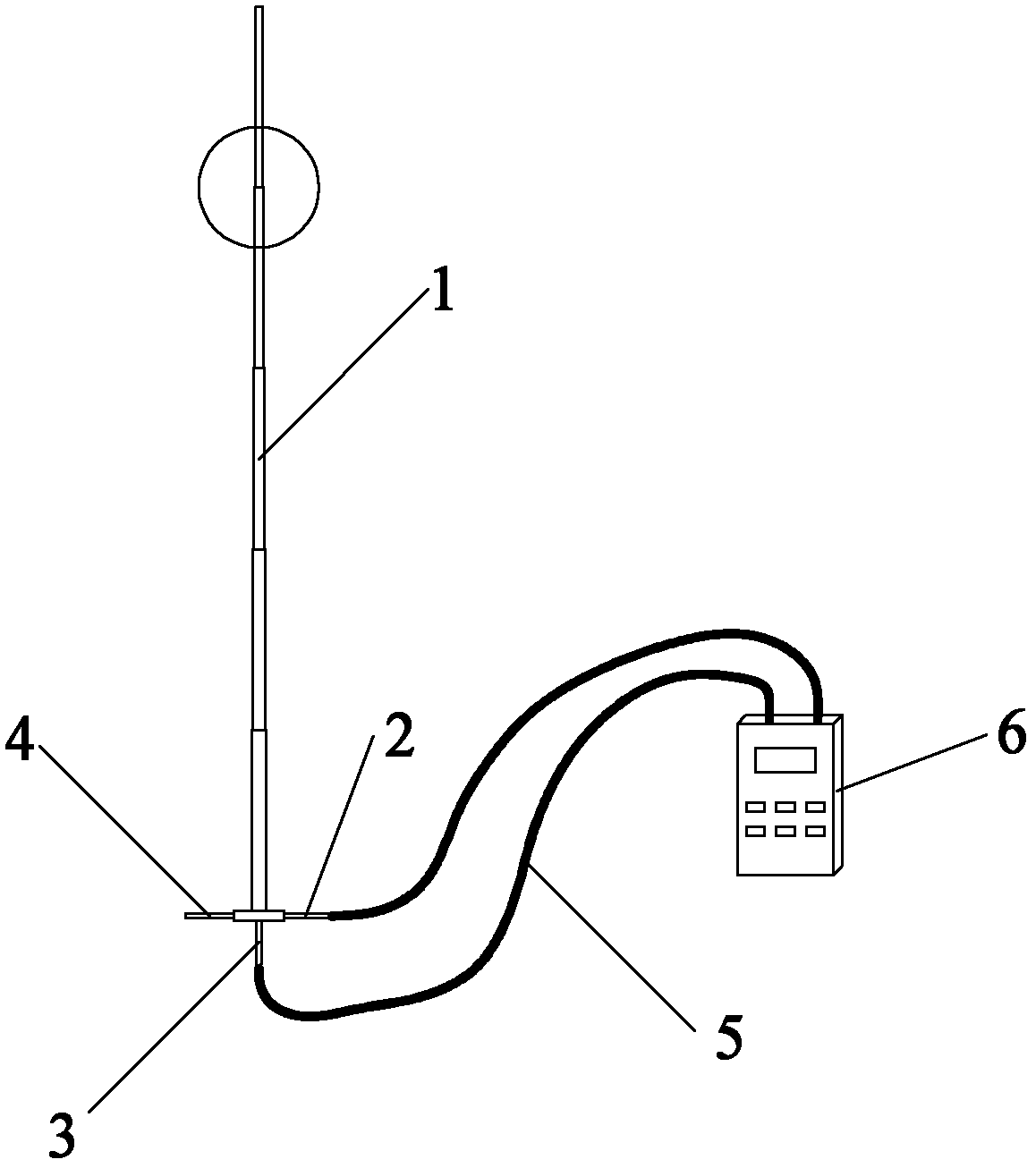

Portable air speed measuring apparatus of pipeline

InactiveCN102495232AGuaranteed synchronicityImprove test accuracyFluid speed measurement using pressure differencePipeline.airTest efficiency

The invention discloses a portable air speed measuring apparatus of a pipeline. The air speed measuring apparatus comprises a detection bar, a static pressure bar, a total pressure bar and an air speed digital display, wherein the length of the detection bar is adjustable and the detection bar is connected with the air speed digital display respectively through the static pressure bar and the total pressure bar. According to the portable air speed measuring apparatus of the pipeline, disclosed by the invention, an air speed detecting element is composed of a plurality of circular equal pressure pipes in a sleeve joint manner, so as to realize the test of a pipeline air speed, greatly improve the testing efficiency and have the synchronism of testing; the detection bar can be adjusted according to the size of an air pipe so that an applicable range is enlarged; by utilizing a digital display mode, the pipeline air speed can be directly displayed and the field numerical reading can be realized. Compared with other similar test devices, the air speed measuring apparatus has the advantages of high measurement efficiency, accuracy, convenience and fastness and the like, has a very strong real meaning in engineering practice, and has great promotion effects on the development in fields of ventilation and air conditioner, particularly a testing technology of the air speed in the pipeline.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

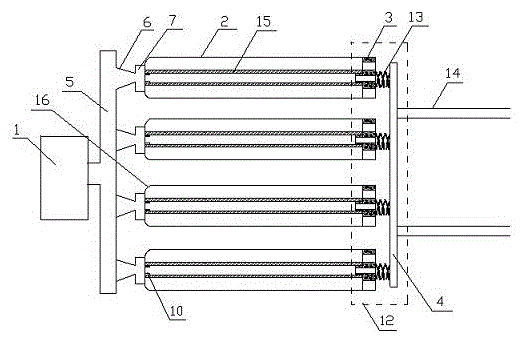

Steam cleaning device for high-pressure oil pipe

ActiveCN104984957AImprove cleaning qualityNo secondary pollutionHollow article cleaningCleaning using liquidsPipeline.airAir separation

The invention discloses a steam cleaning device for a high-pressure oil pipe. The steam cleaning device comprises a high-pressure steam cleaner, three to eight cleaning boxes, three to eight sealing plates and a limiting plate. The cleaning box is a hollow cylinder. The high-pressure steam cleaner is communicated with an air distribution chamber at the front end of each cleaning box through a pipeline air outlet. The cleaning boxes are communicated with the air separation chambers through vent holes outside the pipe and vent hole inside the pipe. Supporting pipes are arranged on the inner sides of the vent holes inside the pipe. The sealing plates are arranged at the rear ends of the cleaning boxes through circular grooves. Steam outlets are arranged on the sealing plates. A water collection box is arranged below the steam outlets. A spring is arranged at the rear end of each sealing plate. The limiting plate is arranged at the rear ends of the springs. The lower portion of the limiting plate is communicated with a track through a roller. The traditional cleaning technology is changed, and the inner and outer walls of the high-pressure oil pipe can be cleaned simultaneously at high temperature, so that the cleaning quality of the high-pressure oil pipe is improved; steam generates no other scales, so that no secondary pollution is generated; and a plurality of oil pipes can be cleaned at the same time, so that the working efficiency is high.

Owner:ZHANGJIAGANG CITY SHENGDINGYUAN PIPE MAKING

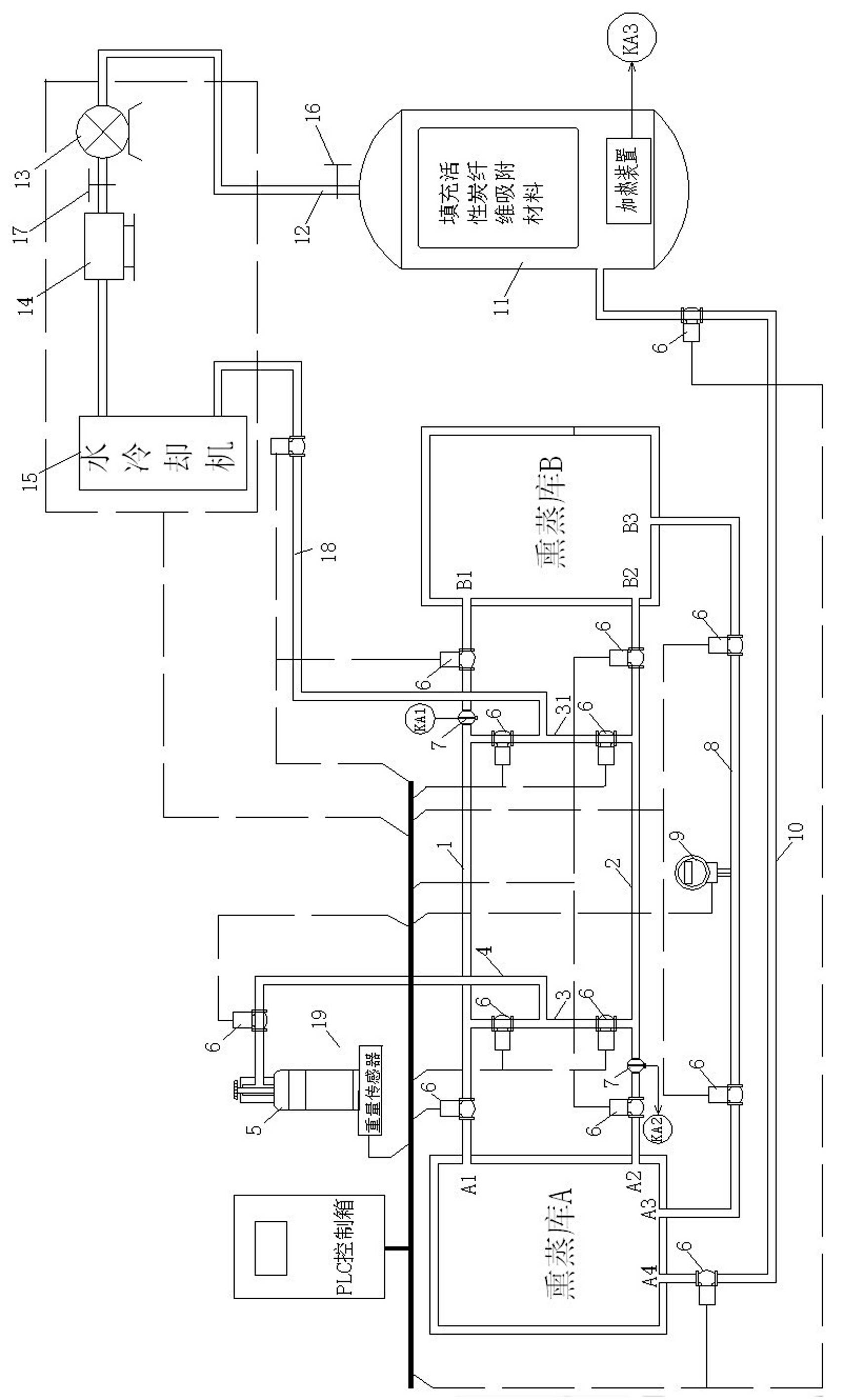

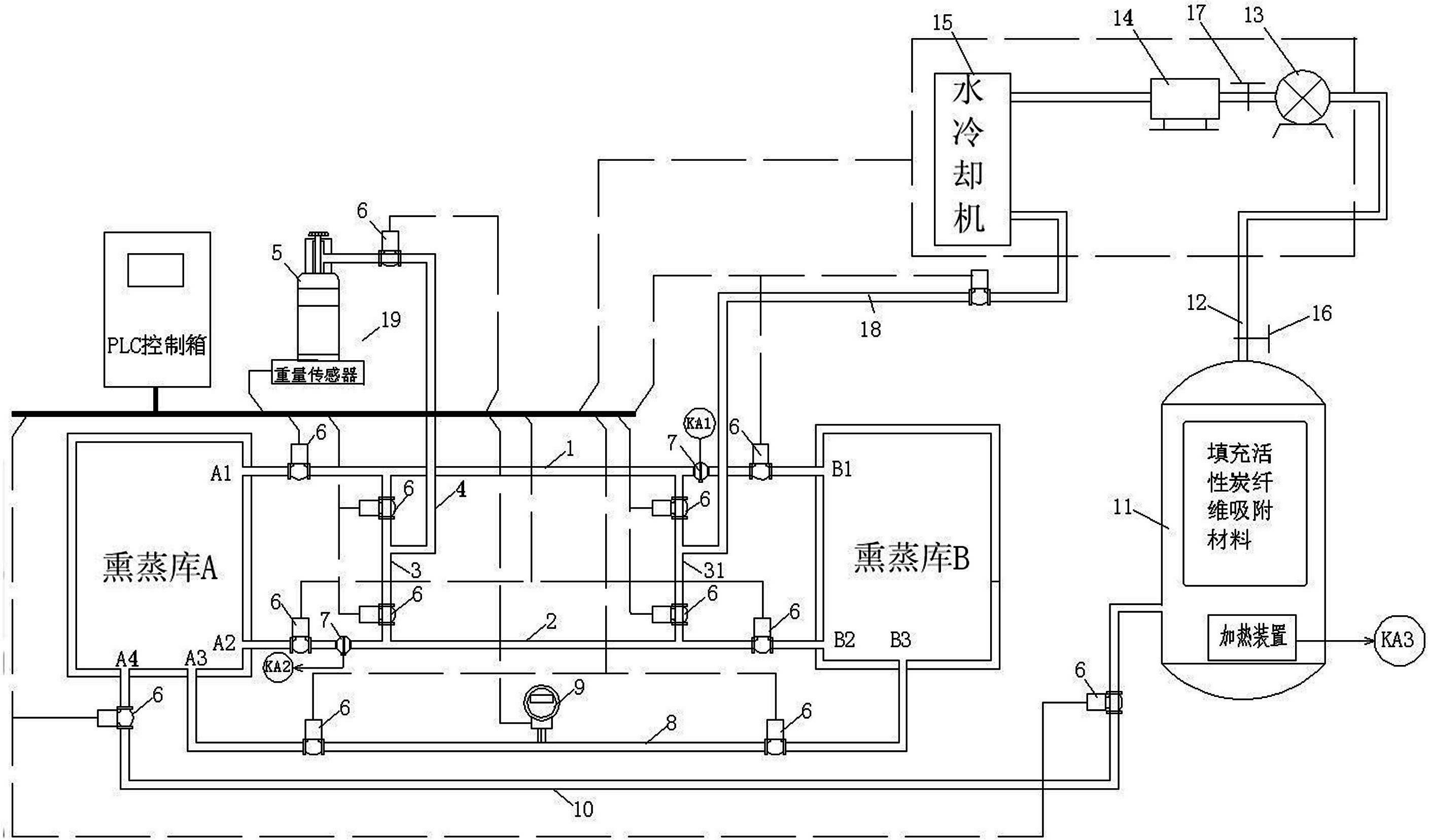

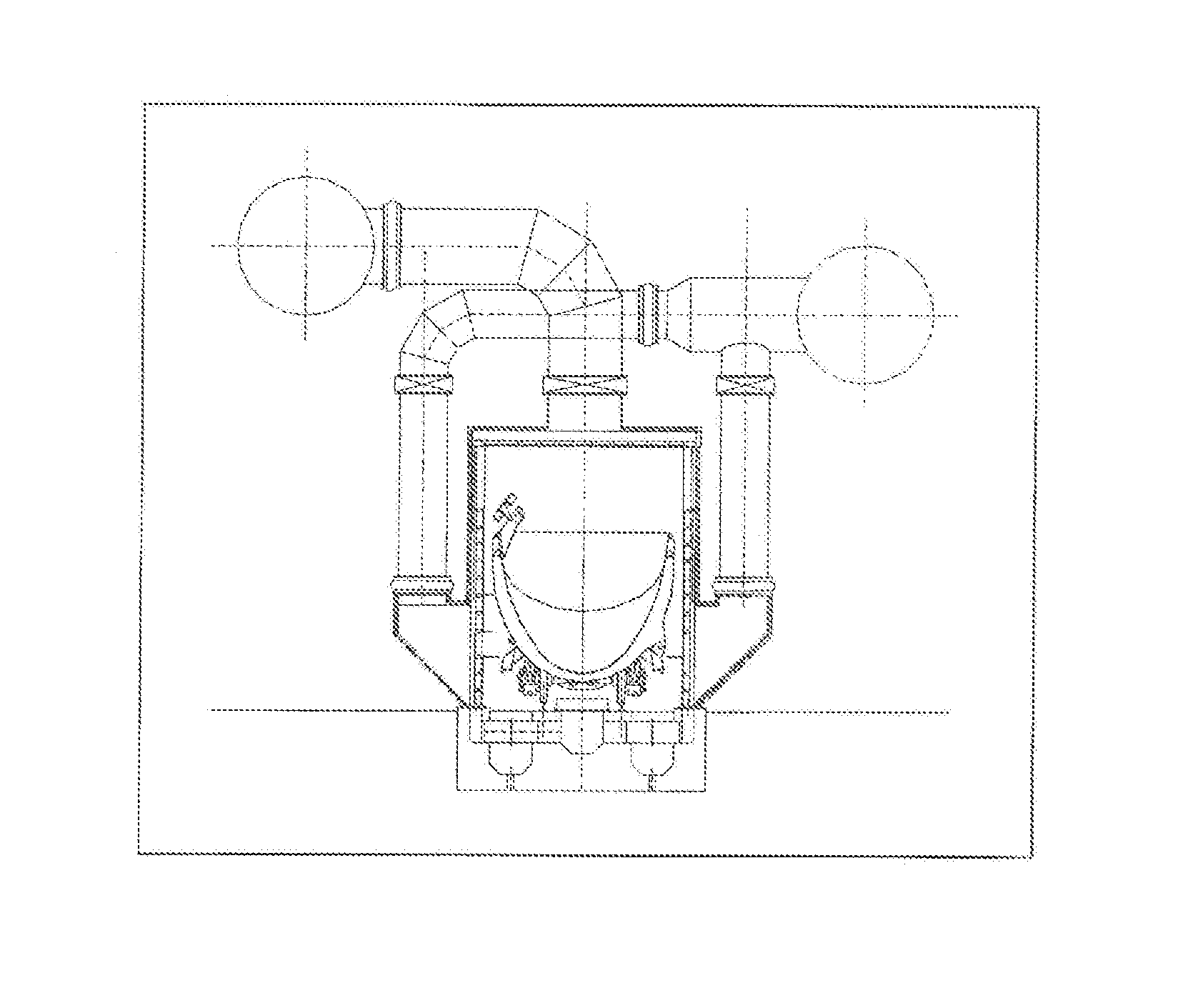

Circular dosing and fumigating system and method

ActiveCN102687712AHave the ability to controlAchieve emission reductionFumigatorsChemicalsPipeline.airAutomatic control

The invention relates to a circular dosing and fumigating system and method.. The circular dosing and fumigating system comprises two fumigating chambers; the fumigating chamber A is connected with a fumigating chamber B through two parallel pipelines; a dosing pipeline is connected through a parallel-connection pipeline A, and a fumigation agent recovery device is connected through a parallel-connection pipeline B; the amount of a fumigation agent is set by a program of a PLC (Programmable Logic Controller); the weight of the fumigation agent is collected by a weight sensor; the concentration of the fumigation agent is collected by a fumigation agent detector; and states of each solenoid valve and each pipeline air blower in a system pipeline are controlled by the PLC, so that the fumigation agent is circularly dosed and used between two fumigating chambers in a sealed fumigating system, and therefore the emission reduction of the fumigation agent can be realized, and the circular utilization of the residual fumigation agent can be further sufficiently used. Meanwhile, the circular dosing and fumigating system has no damage on humans and animals and no pollution to an environment. The circular dosing and fumigating system has regulation and control capability through automatic control. By utilizing the circular dosing and fumigating system, the concentration can be dynamically adjusted according to the using condition of the fumigation agent, so that the current situation that the conventional fumigating system causes environmental pollution is changed.

Owner:黄庆林 +2

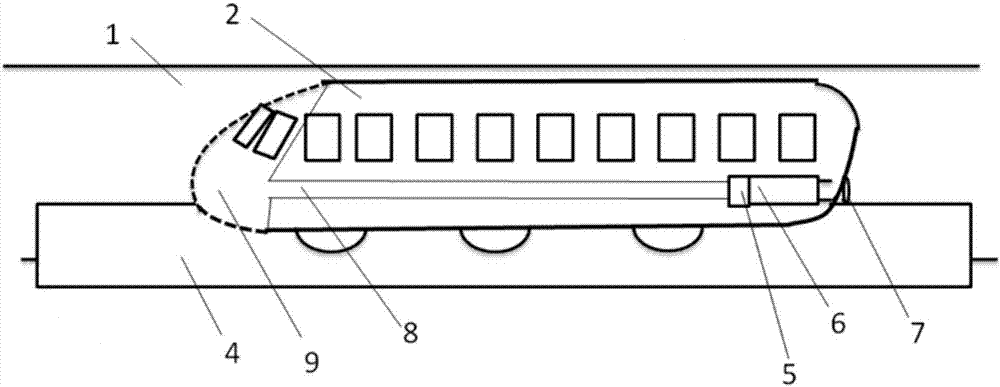

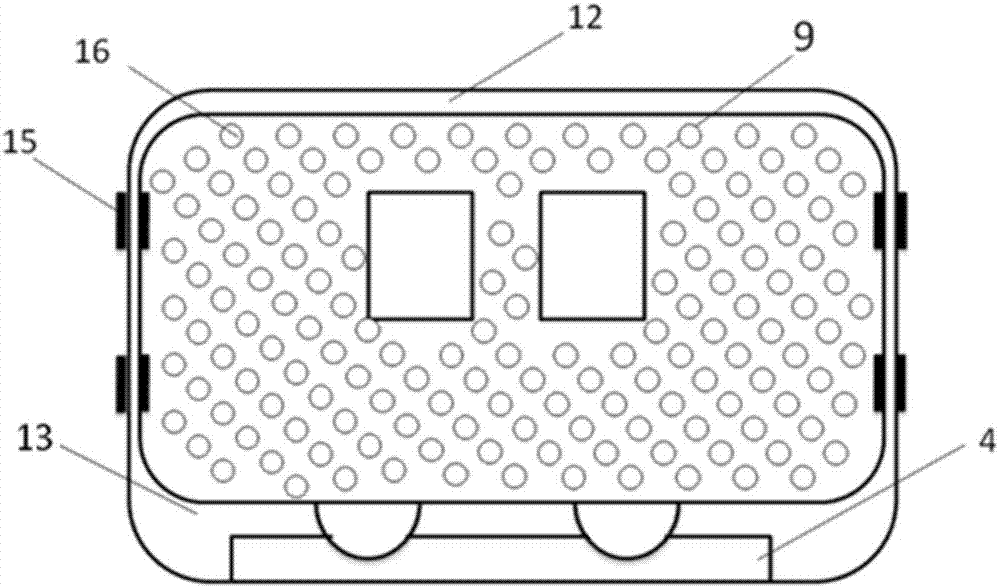

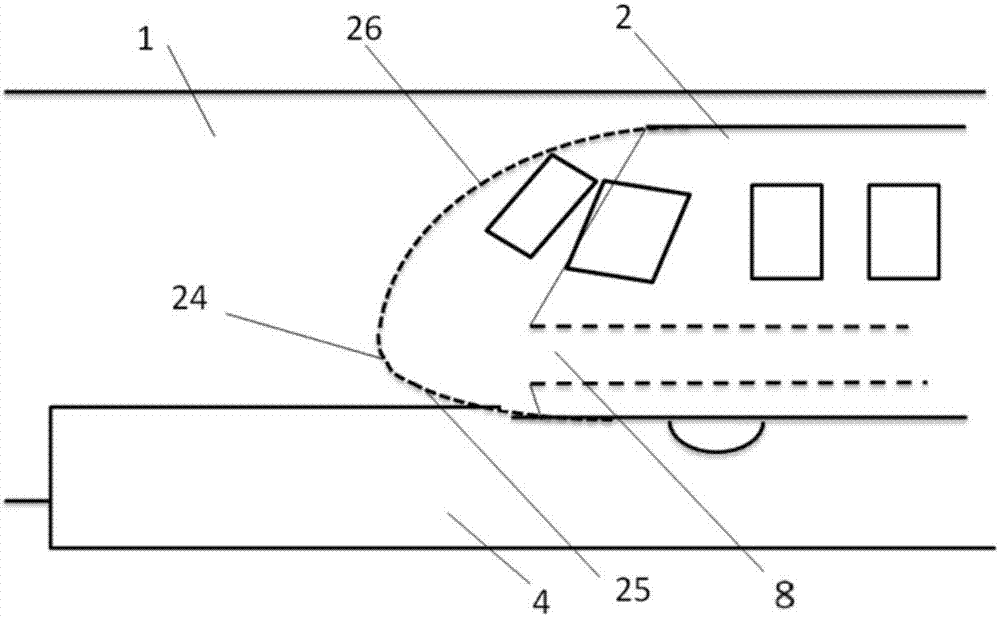

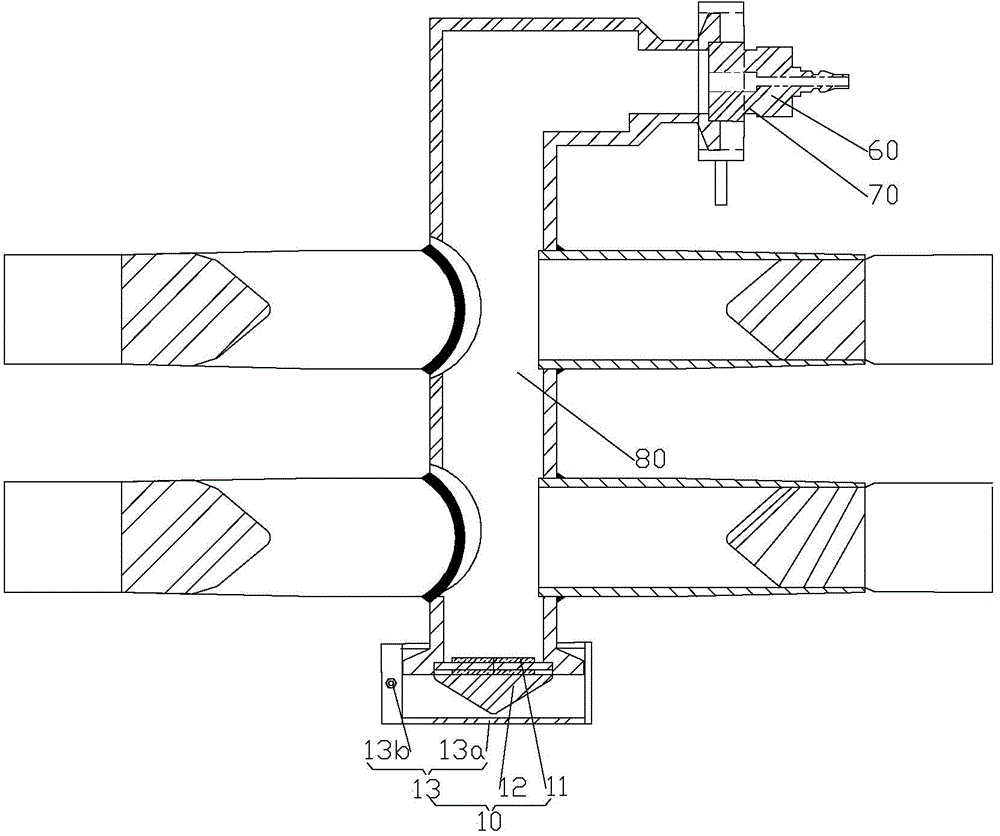

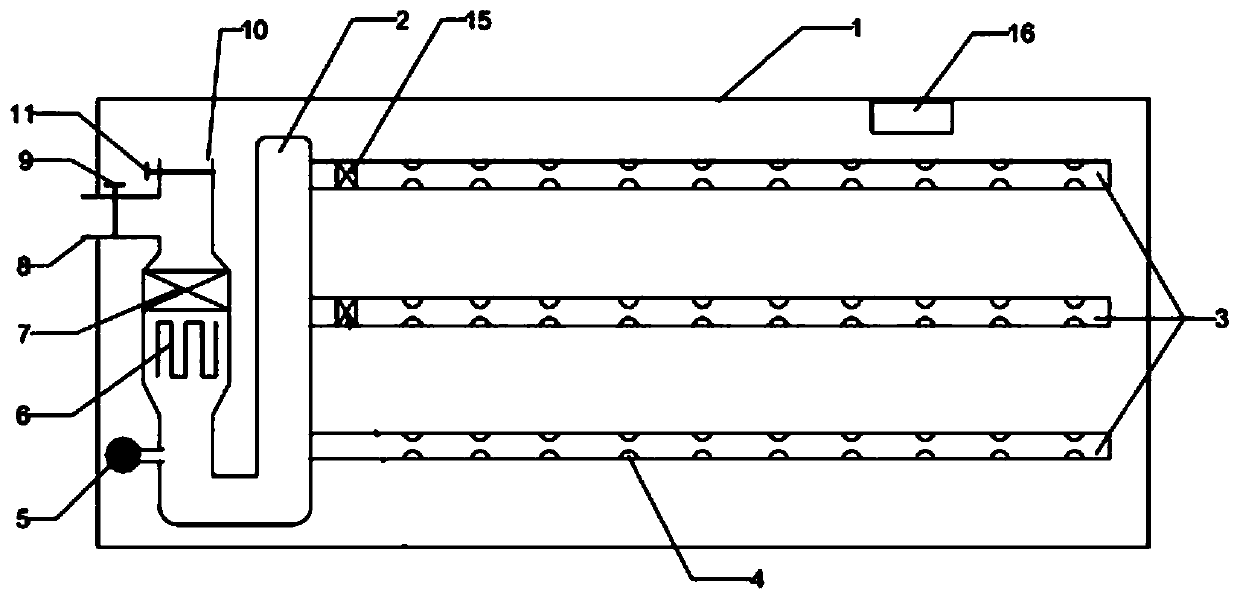

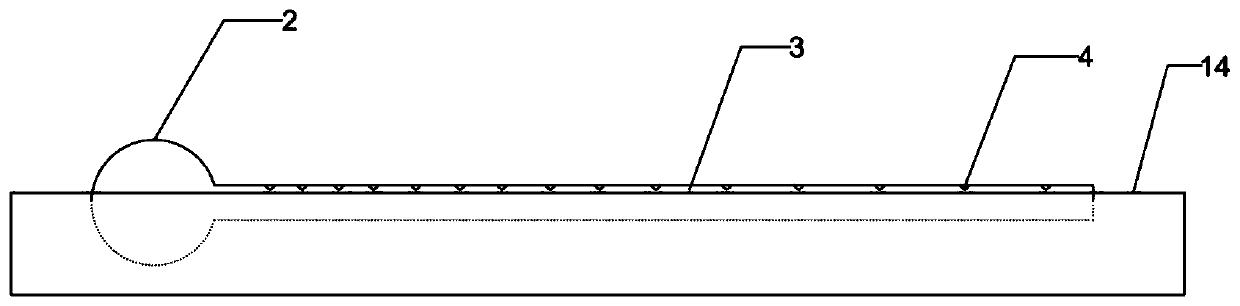

Pipeline air-suspending transportation device

InactiveCN107097801AAvoid influenceImprove operational efficiencyRailway tunnelsPipeline.airEngineering

The invention provides a pipeline air-suspending transportation device which is characterized by comprising a running pipeline, wherein a running guide rail is disposed on the bottom face inside the running pipeline, and a carrying device runs on the running guide rail; the carrying device has a carriage structure; and an air-breathing engine is disposed inside the carrying device, an output end of the air-breathing engine is connected to an air vent disposed on the rear end of the carrying device, and an input end of the air-breathing engine is connected to a second-stage air inlet structure which is disposed on the front end of the carrying device by an air inlet pipeline.

Owner:BEIJING KANGHUAYUAN SCI TECH CO LTD

Duct system of sea wind (air) air conditioner by deep sea water cooling

InactiveCN1786597AImprove working environmentImprove the living environmentLighting and heating apparatusAir conditioning systemsOcean bottomEngineering

Owner:孙洪福

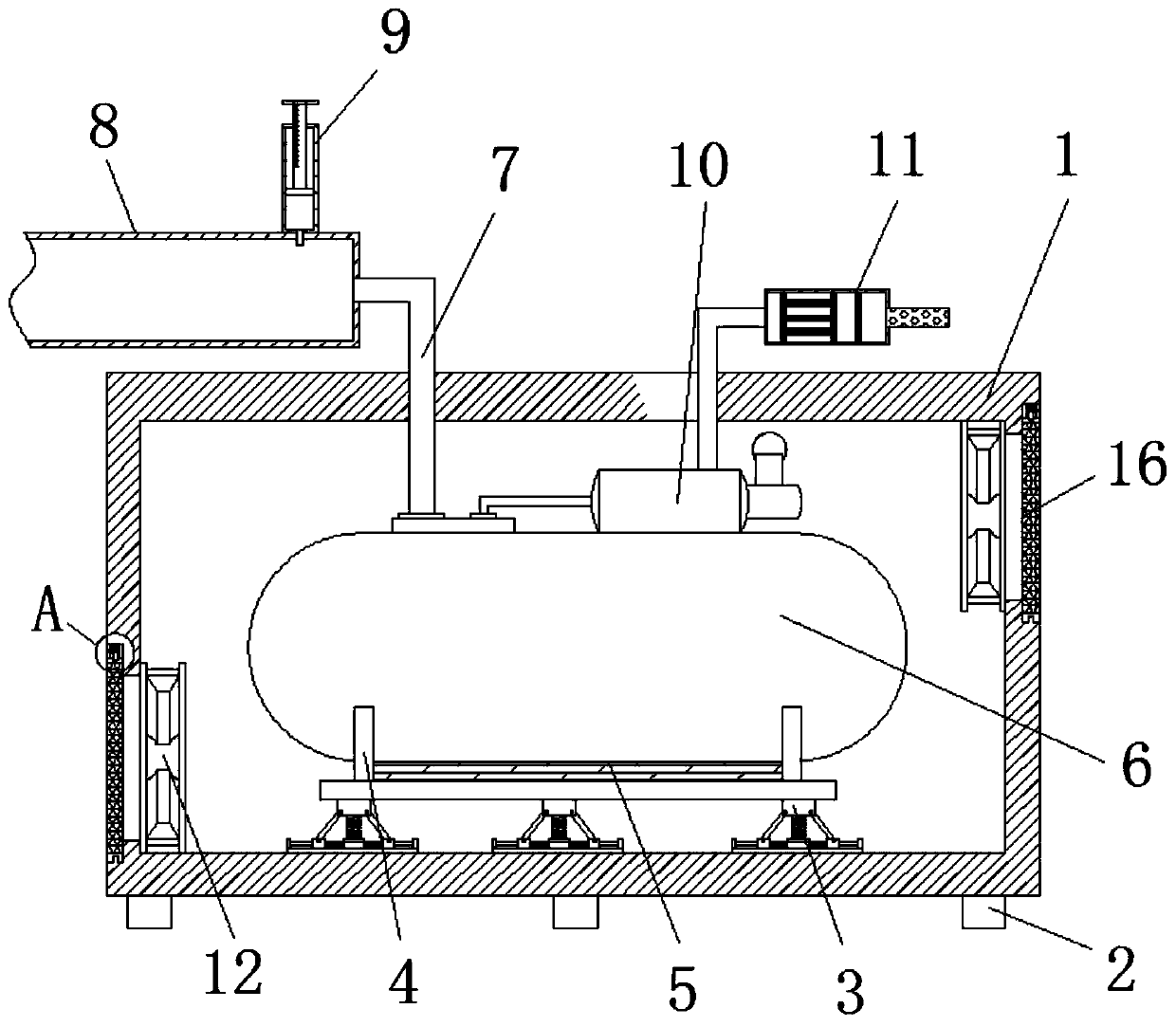

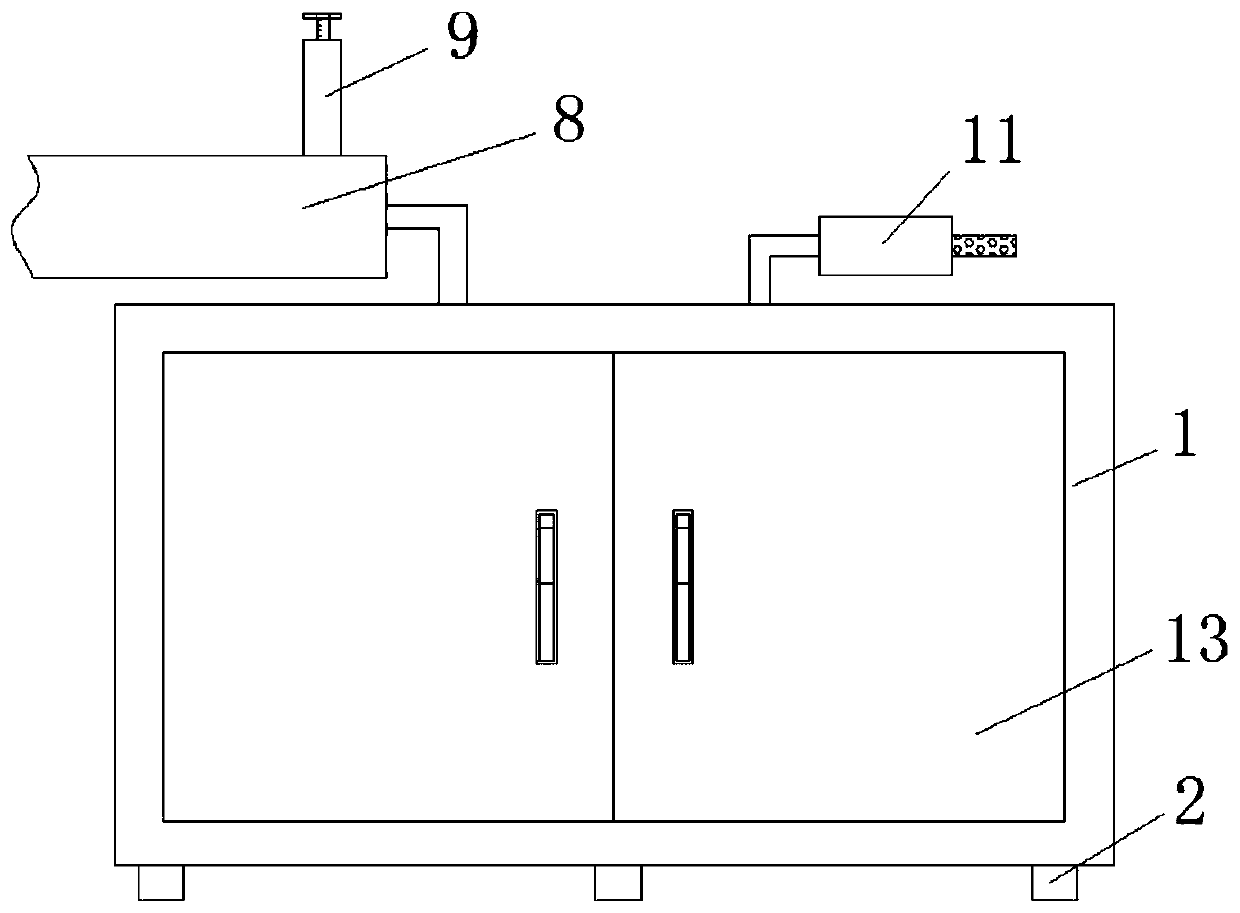

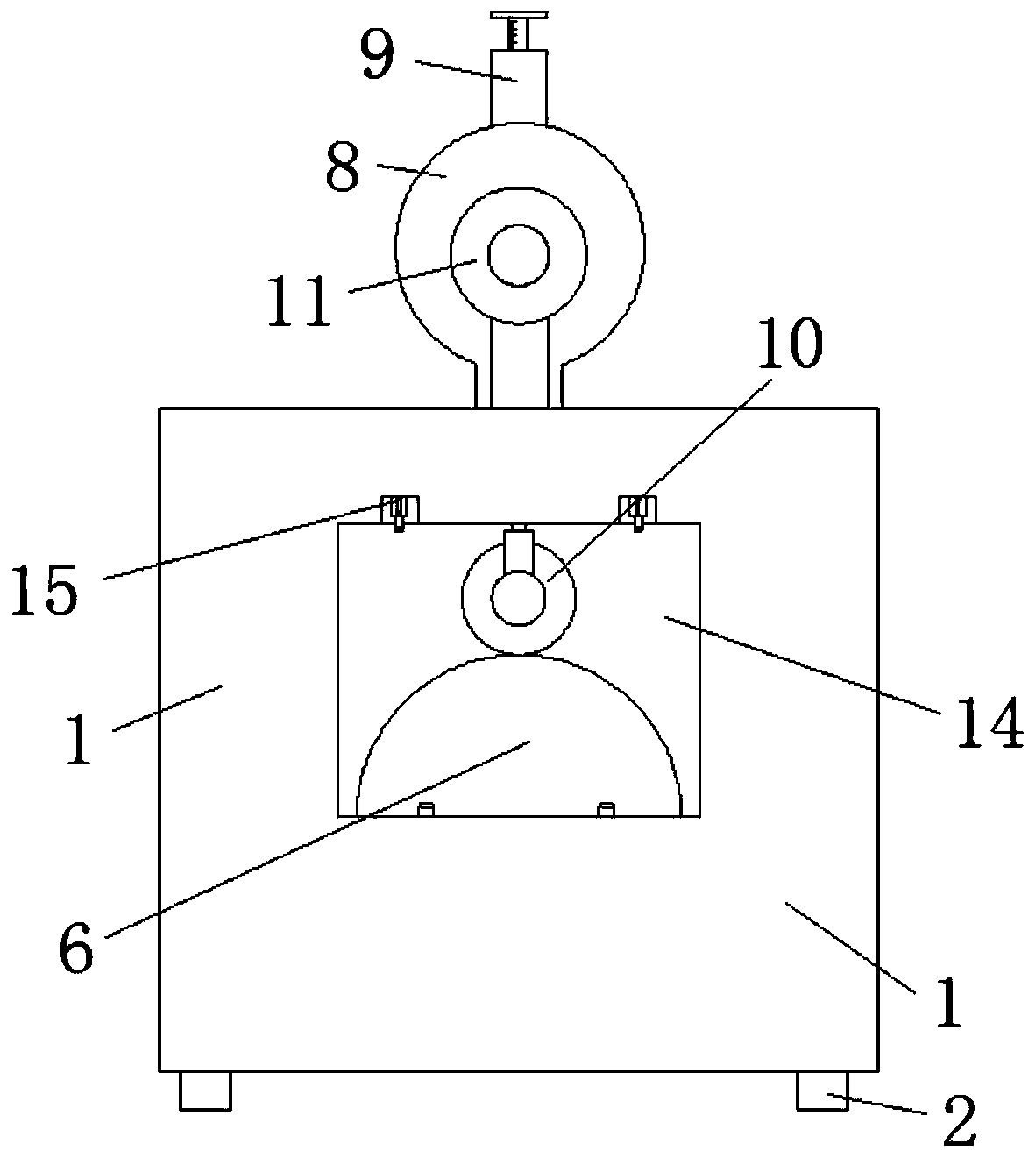

Air compressor with pipeline air tightness detection

InactiveCN110985355AEasy dischargeEasy to cleanPositive displacement pump componentsPump controlPhysicsPipeline.air

The invention discloses an air compressor with pipeline air tightness detection. The air compressor comprises a box body, wherein the lower surface of the box body is fixedly connected with a bottom column, the front surface of the box body is hinged with a box door, the lower surface in the box body is fixedly connected with a damping assembly, the damping assembly is fixedly connected with a fixing frame, an air storage tank is fixedly connected with the fixing frame, the upper surface of the air storage tank is fixedly connected with an output pipe, the output pipe penetrates through the box body longitudinally, the other end of the output pipe is fixedly connected with a pipeline, the top end of the pipeline is fixedly connected with an air tightness detection assembly, the top end, corresponding to one side of the output pipe, of the air storage tank is fixedly connected with an air compressor, the output end of the air compressor is connected with the air storage tank through anair pipe, the input end of the air compressor is fixedly connected with an air inlet device through the air pipe, and openings are formed in the lower end of one side of the box body and the upper endof the other side of the box body. The air compressor has the function of detecting air tightness of the pipeline, has a good heat dissipation effect, and has a better shock absorption effect, and afilter screen is convenient to disassemble, clean and replace.

Owner:南京拓新冷暖科技有限公司

Pipeline air tightness detection device

InactiveCN104697722AGuaranteed reliabilitySimple structureDetection of fluid at leakage pointPipeline.airEngineering

The invention provides a pipeline air tightness detection device comprising a plugging portion, a water box and an air inlet pipe. The plugging portion is used for sealing an air outlet of a pipeline to be detected. The plugging portion and the pipeline to be detected are arranged below the liquid level in the water box. The air inlet pipe is communicated with an air inlet of the pipeline to be detected. In use, the worker feeds air in the pipeline to be detected through the air inlet pipe and observes whether or not air leakage occurs to the pipeline to be detected, especially connectors; if no bubbles occur in the water box, air tightness of the pipeline to be detected is proved to be good and applicable to evacuation; if the air entering the pipeline to be detected becomes the bubbles on the water, the pipeline to be detected is proved to be poor in air tightness and fails to be used for evacuation. By sealing the air outlet of the pipeline to be detected by the plugging portion, the air never flees out of the air outlet of the pipeline to be detected, accordingly guaranteeing user reliability of the pipeline air tightness detection device.

Owner:GREE ELECTRIC APPLIANCES INC

Treatment method of cooling water leakage in vacuum circulating degassing furnace vacuum chamber

The invention provides a treatment method of cooling water leakage in a vacuum circulating degassing furnace vacuum chamber. Under the circumstance of a small water leakage, the method includes: stopping oxygen blowing, raising a top lance to a standby position, and reducing the insert tube blowing strength to 0.16-0.28Nm<3> / ht; and closing a vacuum valve, introducing a gas to conduct system vacuum breaking, and when the pressure in a vacuum chamber reaches over 90kPa, transferring the top lance and a camera lens out of the vacuum chamber, and closing a water inlet valve. Under the circumstances of a large water leakage, the method includes: stopping oxygen blowing, raising the top lance to the standby position, shutting an insert tube lifting gas and the top lance or a camera lens water inlet valve, reducing the vacuum pressure to less than 1kPa, making use of a vacuum pump to eliminate water vapor, and when a normal vacuum pressure is achieved in the vacuum chamber, normal pipeline air or nitrogen is utilized to conduct system vacuum breaking, and when the pressure in the vacuum chamber reaches over 90kPa, moving the top lance and the camera lens out of the vacuum chamber. The invention can effectively reduce the harm of water leakage, and lower the risk of explosion, thus avoiding personal injury, equipment damage and other serious accidents.

Owner:ANGANG STEEL CO LTD

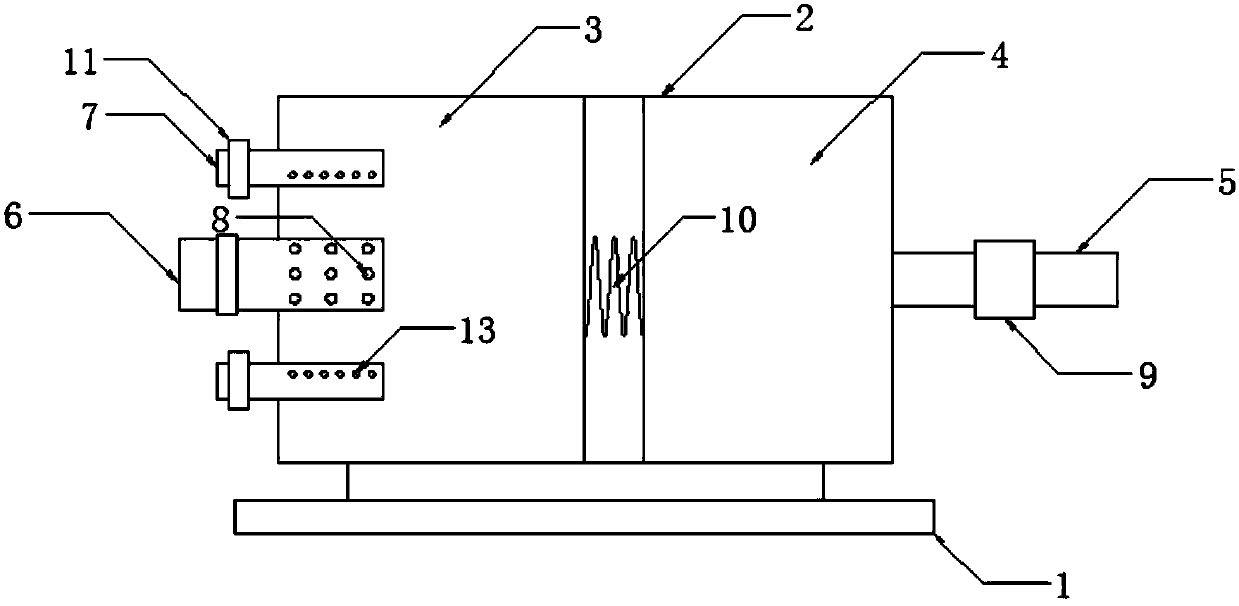

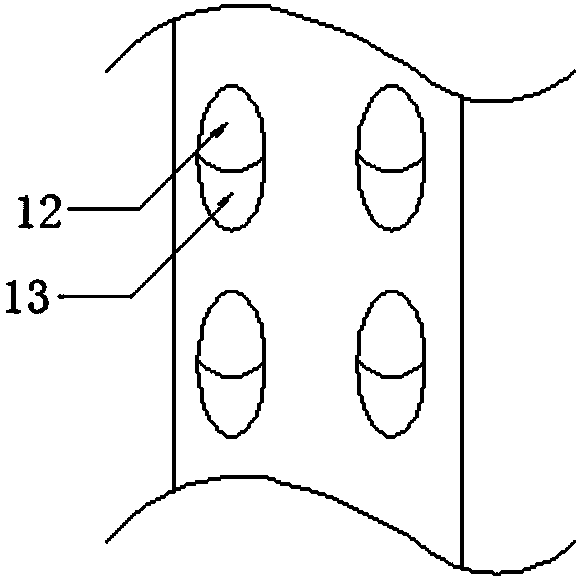

Device and method for de-icing railway trucks and ore concentrate in railway trucks

InactiveUS20150101640A1Overcome problemsSpeed up the processLighting and heating apparatusCleaning apparatus for railwaysOre concentrateTruck

The invention relates to an arrangement for de-icing railway trucks and ore concentrate in railway trucks. The arrangement comprises a tunnel (2) having a number of discharge openings (3) for heated air which is used for de-icing and at least one exhaust opening (4) for used air. An air heater (5) is in communication with the discharge openings (3) through a supply air duct (6). The arrangement further comprises a water supply device arranged to supply water to the air heater (5) and / or the supply air duct (6). The capacity of the air heater (5) is high enough to heat the air to a temperature sufficient for vaporizing at least a portion of the water. The invention also relates to a corresponding method for de-icing.

Owner:EPN SOLUTIONS

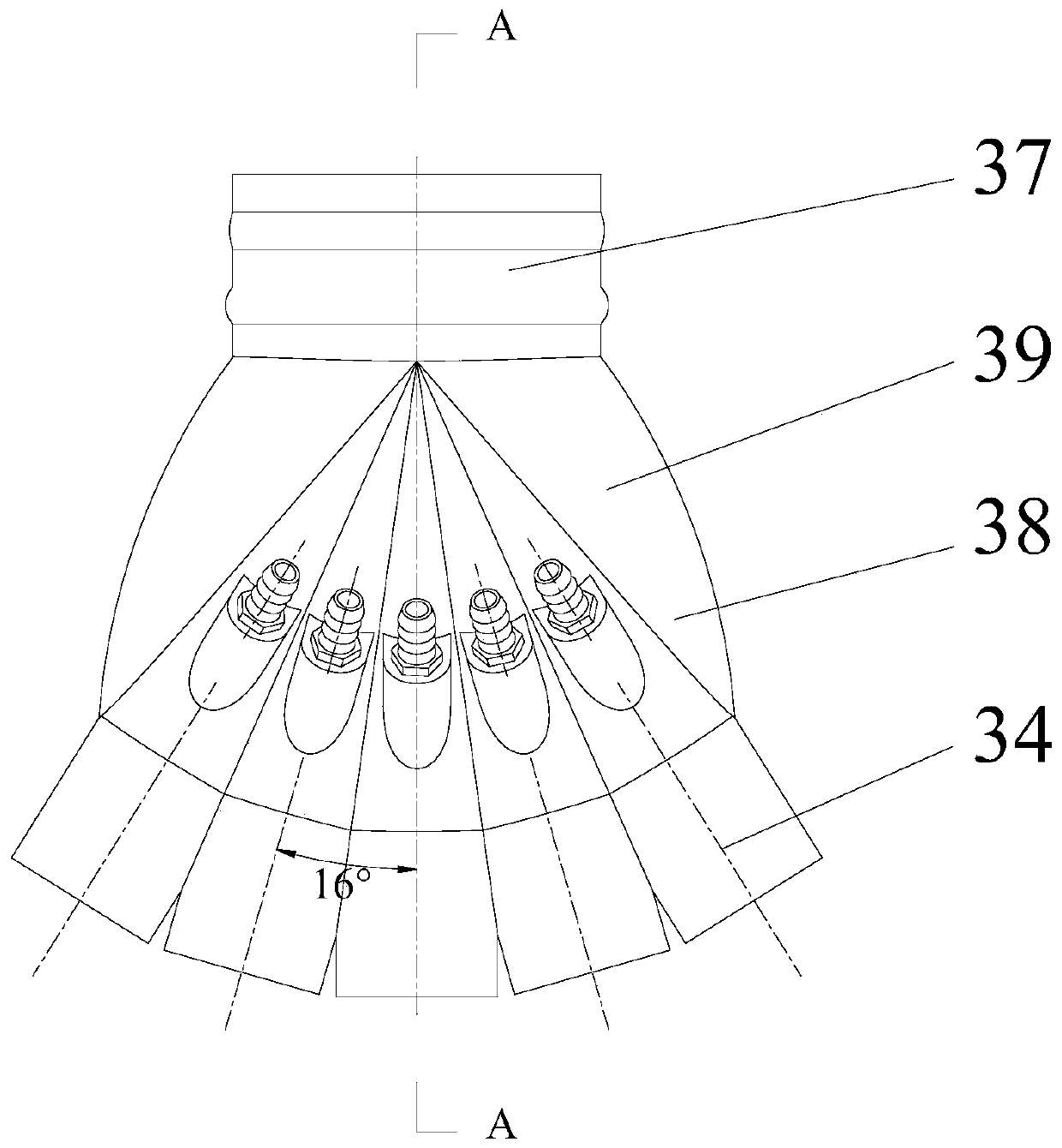

Novel energy-saving nozzle

The invention provides a novel energy-saving nozzle, which comprises a fixing base, a nozzle body, a mixing cavity, a buffer cavity, a nozzle sprayer, a fuel gas supply pipeline, an air supply pipeline, a fuel gas air hole, an impulse ignition mechanism, a spiral pipeline, and air holes; the bottom end of the nozzle body is provided with the fixing base, and the mixing cavity and the buffer cavityare arranged in the nozzle body; the mixing cavity and the buffer cavity are connected through the spiral pipeline, and the other end of the buffer cavity is provided with the nozzle sprayer; the impulse ignition mechanism is arranged on the nozzle sprayer; a coaxial fuel gas supply pipeline is arranged in the mixing cavity, and four sides of the fuel gas supply pipeline are provided with severalair supply pipes distributed a circular form by taking it as the center of a circle; several fuel gas air holes are evenly distributed on the pipe wall of the fuel gas supply pipeline, and several air holes faced to one side of the fuel gas supply pipeline are arranged on the pipe wall of the air supply pipeline. The novel energy-saving nozzle has the beneficial effects of sufficient combustion and energy-saving.

Owner:天津征鑫热能设备制造有限公司

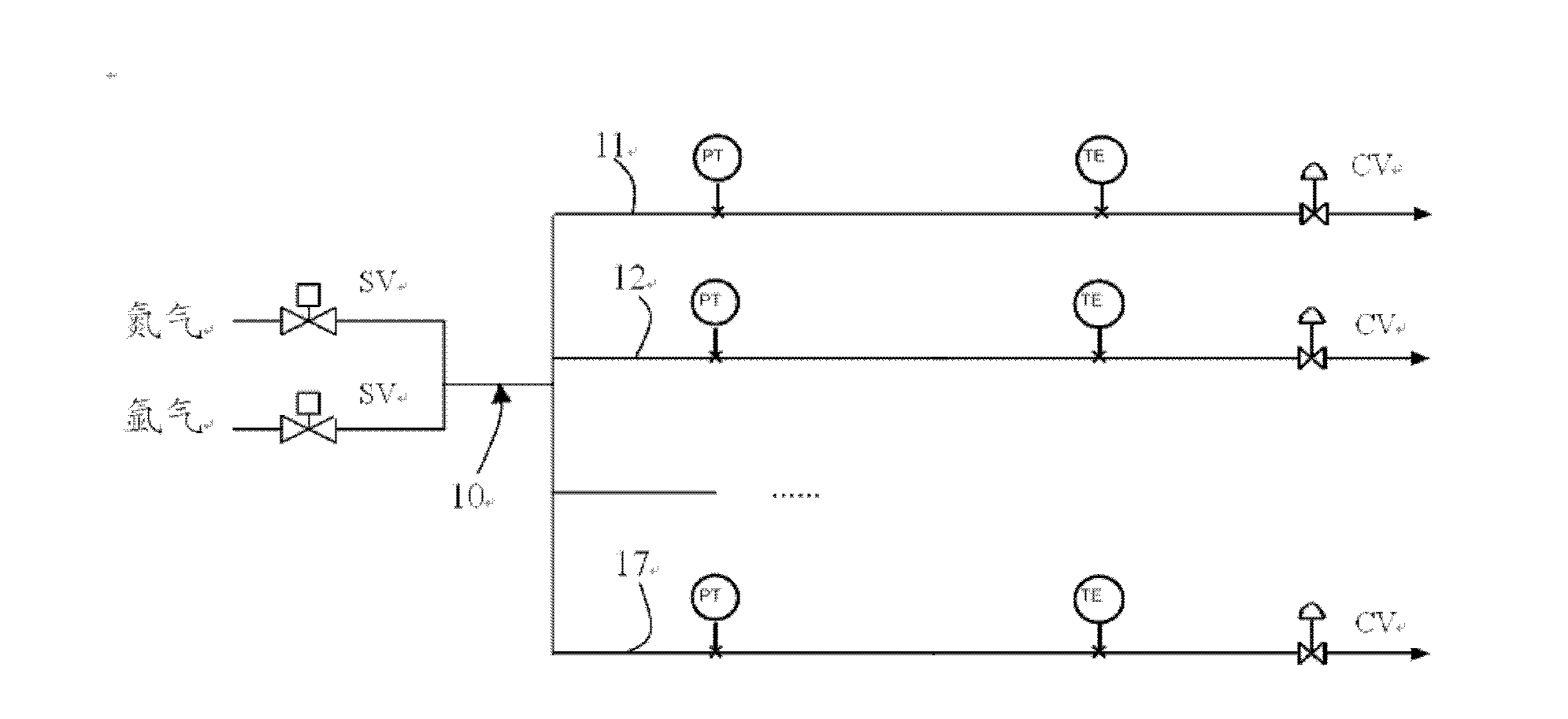

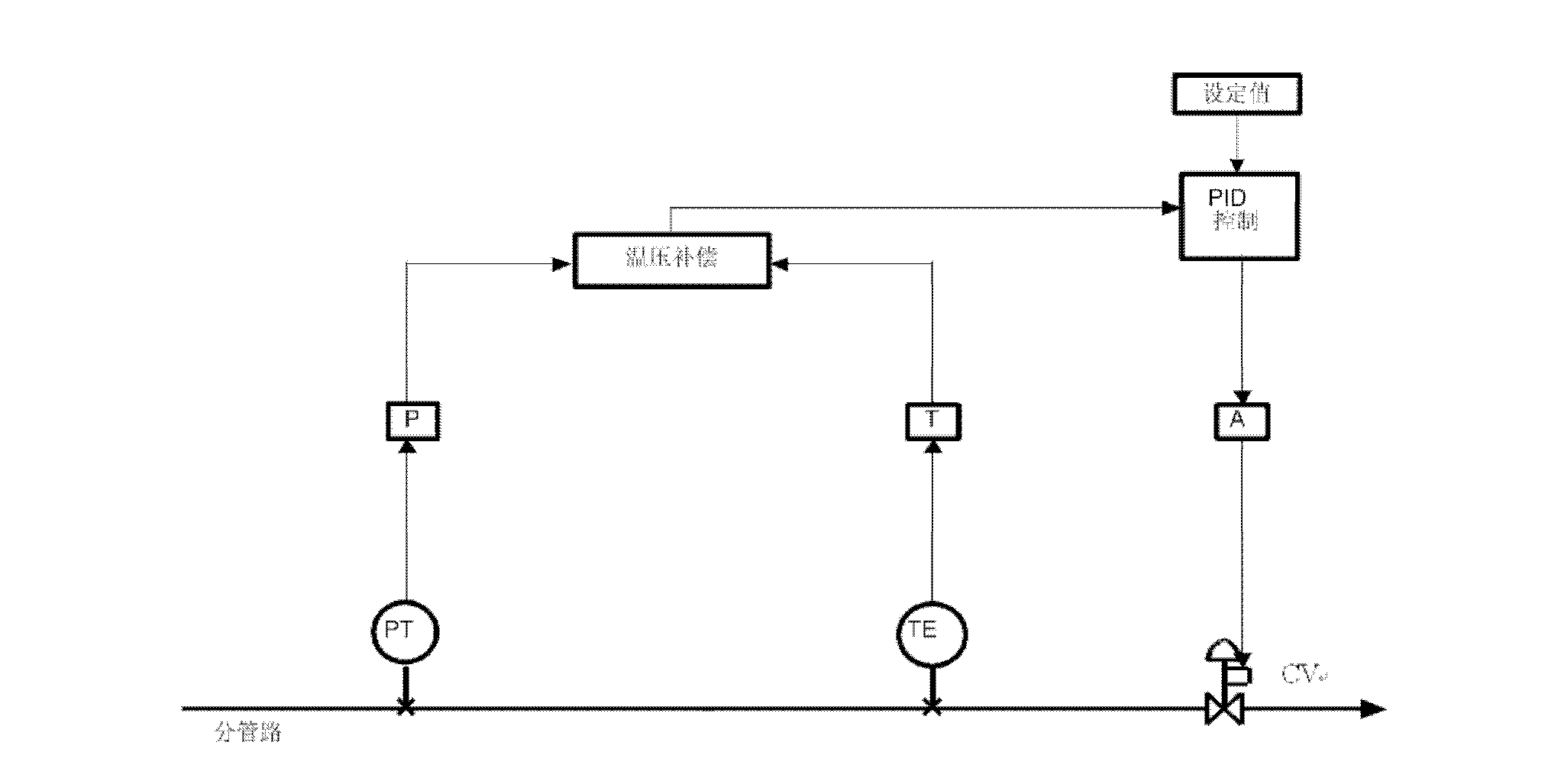

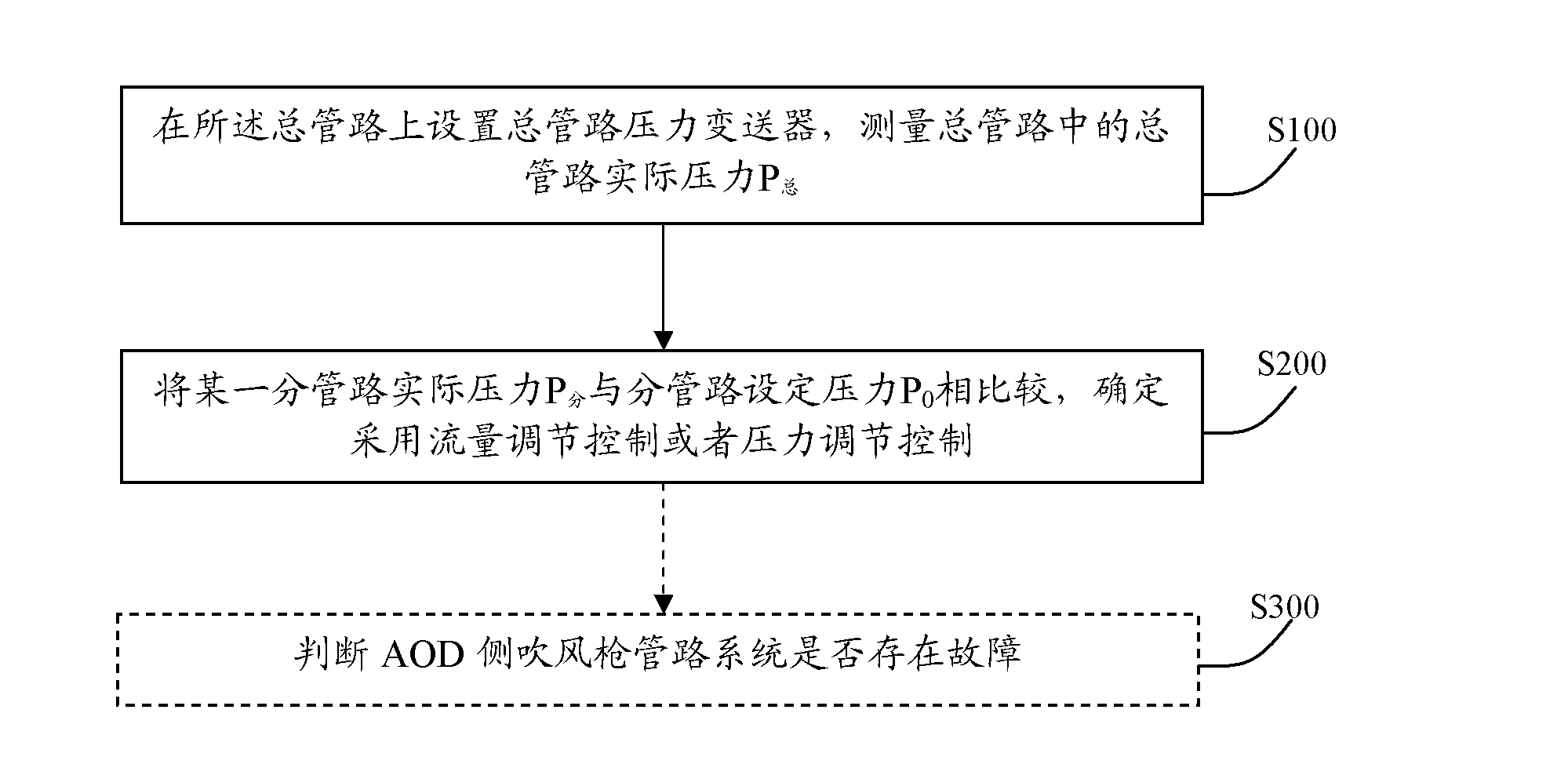

AOD converter side blowing gun pipeline system flow control method

The present invention discloses an AOD converter side blowing gun pipeline system flow control method, which comprises the following steps: 1, arranging a total pipeline pressure transmitter on a total pipeline, and measuring the actual total pipeline pressure P total in the total pipeline; and 2, comparing the actual pressure P branch of one branch pipeline to preset pressure P0 of the of branch pipeline, wherein the condition comprises that: a, flow control regulation is performed if the P branch is less than or equal to 1.2 P0, and b, an opening degree of a flow regulation valve is regulated according to a preset pressure regulation value if the P branch is more than 1.2 P0, and the flow control regulation in the condition a is performed after achieving the preset time. According to the AOD converter side blowing gun pipeline system flow control method, the pressure of the total pipeline is adopted to carry out temperature and pressure compensation on the branch pipeline air flow, and the two control manners such as flow regulation and pressure regulation are adopted, such that the smooth air pipeline is easily achieved, and normal operation of the AOD converter side blowing gun pipeline system can be ensured.

Owner:上海盈德宝气气体有限公司

Air incrementer, fabrication method thereof, and breathing ventilation shoes or pipeline air supply system provided with air incrementer

InactiveCN103225630AGuaranteed to proceed normallyEasy to makeDucting arrangementsJet pumpsExhaust pipeBreathing process

The invention discloses an air incrementer. The tail end of an inlet pipe is connected with the front end of an exhaust pipe; airflow pipe cavities of the inlet pipe and the exhaust pipe are connected to form an airflow channel; a locating cavity is arranged at the tail end of the inlet pipe; a convex connecting air tap is arranged in the locating cavity; a connecting end head matched and mounted with an inner wall face of the locating cavity is arranged at the front end of the exhaust pipe; the airflow pipe cavity of the connecting end head surrounds the periphery of the connecting air tap; an air exciting gap is formed between the airflow pipe cavity of the connecting end head and the connecting air tap; an air inlet end of the air exciting gap receives an airflow outputted by an external compressed air source feeding device; and an air outlet end of the air exciting gap faces toward an airflow of the airflow pipe cavity. In addition, the invention discloses a fabrication method of the air incrementer, and a pair of breathing ventilation shoes or a pipeline air supply system provided with the air incrementer. The air incrementer, the fabrication method thereof, the pair of breathing ventilation shoes or the pipeline air supply system provided with the air incrementer have the advantages of simple structure, low cost, convenience and simplicity in fabrication.

Owner:许景贤

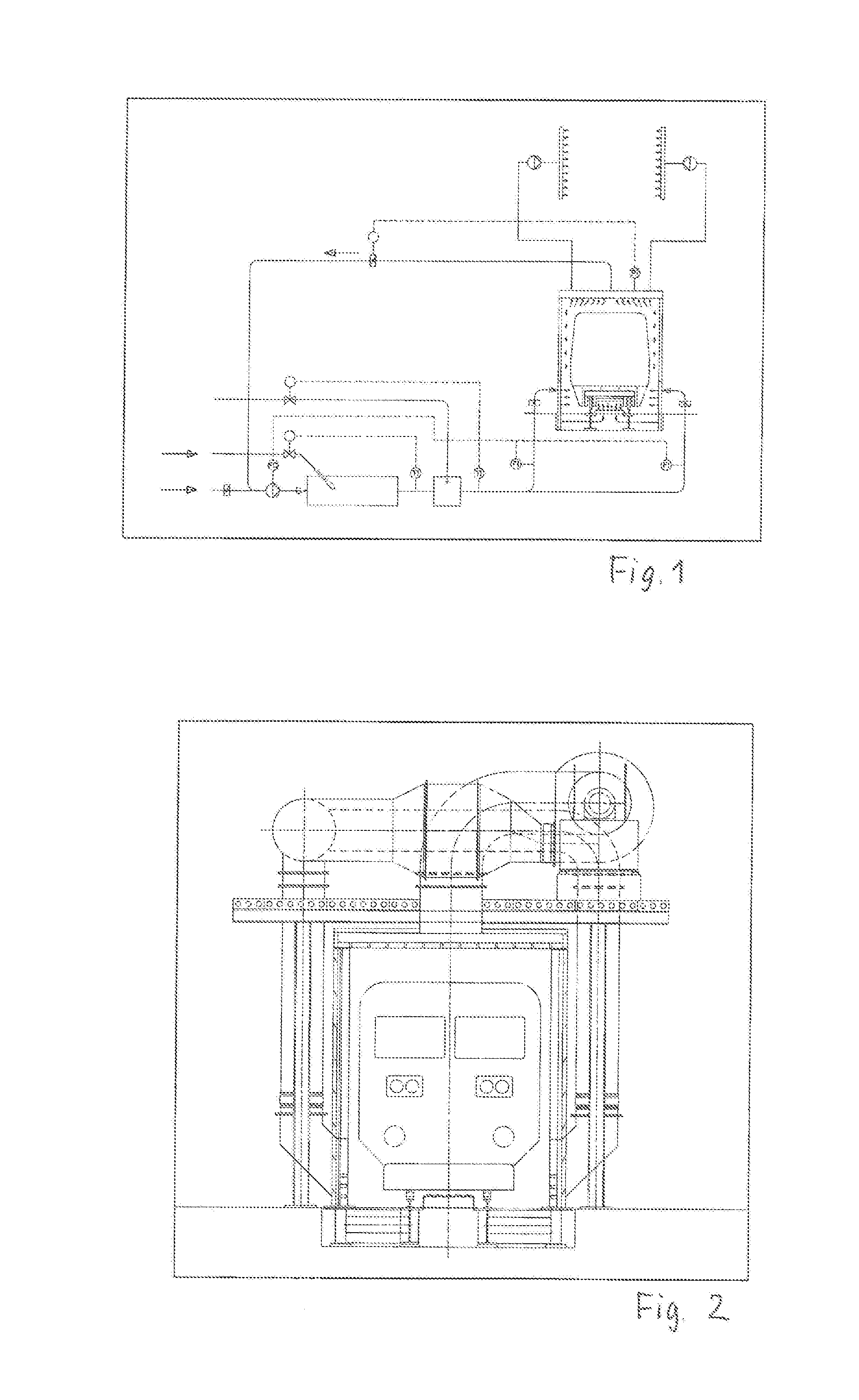

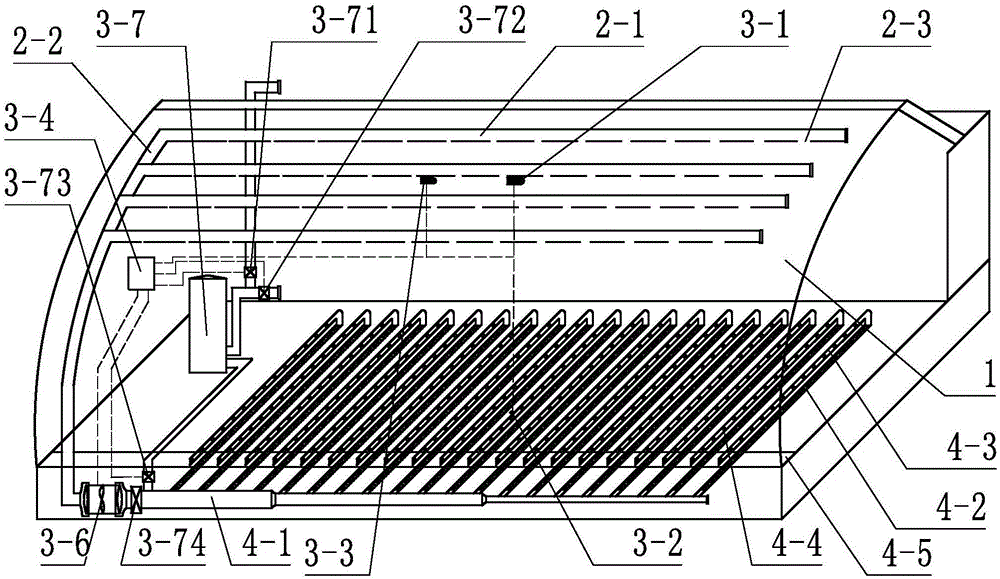

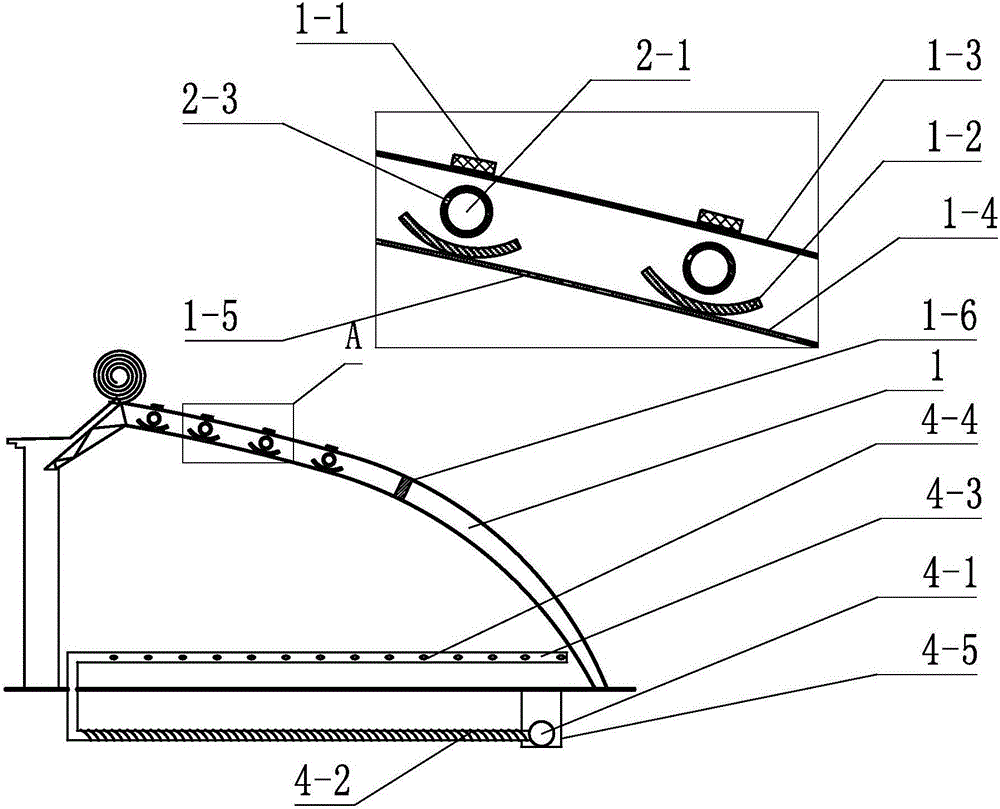

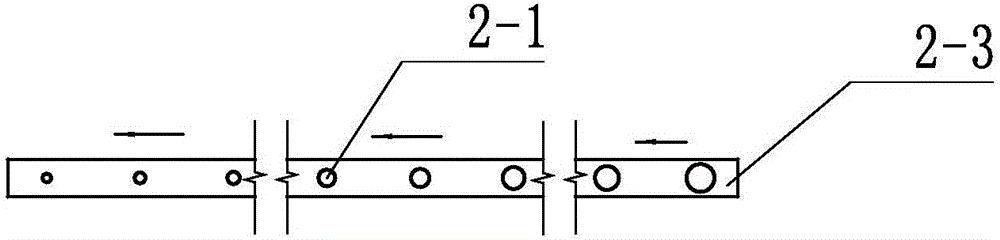

System and method for regulating and controlling comprehensive environment for crop canopy space

PendingCN109699352ASave spaceRealize environmental regulationClimate change adaptationGreenhouse cultivationPipeline.airGreenhouse

The invention discloses a system and method for regulating and controlling comprehensive environment for a crop canopy space, and belongs to the field of environmental factor regulation and control offacility agricultural engineering. The system for regulating and controlling comprehensive environment for the crop canopy space is suitable for being used under a crop cultivation line and is basedon the ground submerged pipeline air supply. The system for regulating and controlling comprehensive environment for the crop canopy space comprises a main air pipe, a branch air pipe, a system air supply fan, a branch air pipe auxiliary booster fan, a heating electric heat source, a carbon dioxide gas source and a channel switching valve; according to the detection data of an environmental factordetection and a regulation module, the operations of the main air pipe, the branch air pipe, the system air supply fan, the branch air pipe auxiliary booster fan, the heating electric heat source, the carbon dioxide gas source and the channel switching valve are controlled; the environment of active airflow, temperature, humidity, gas and the like of greenhouse facilities is regulated and controlled. The method achieves the local spatial regulation and control target of the crop canopy, and has the advantages of strong pertinence, high regulation and control efficiency, low energy consumptionand good economy.

Owner:CHINA AGRI UNIV

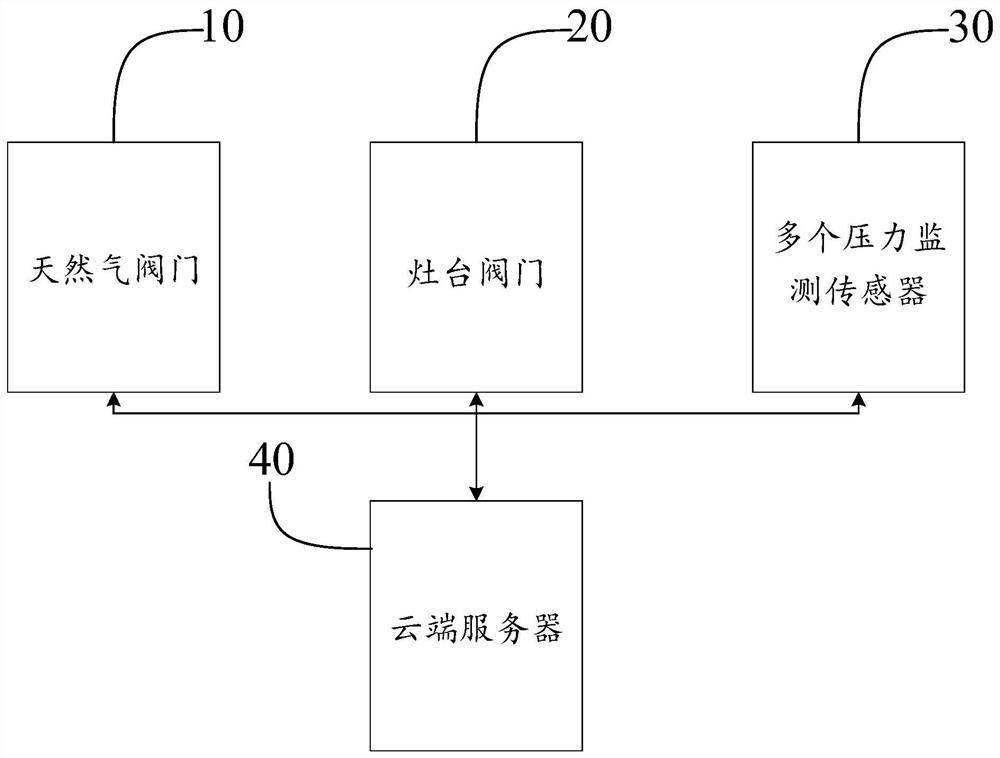

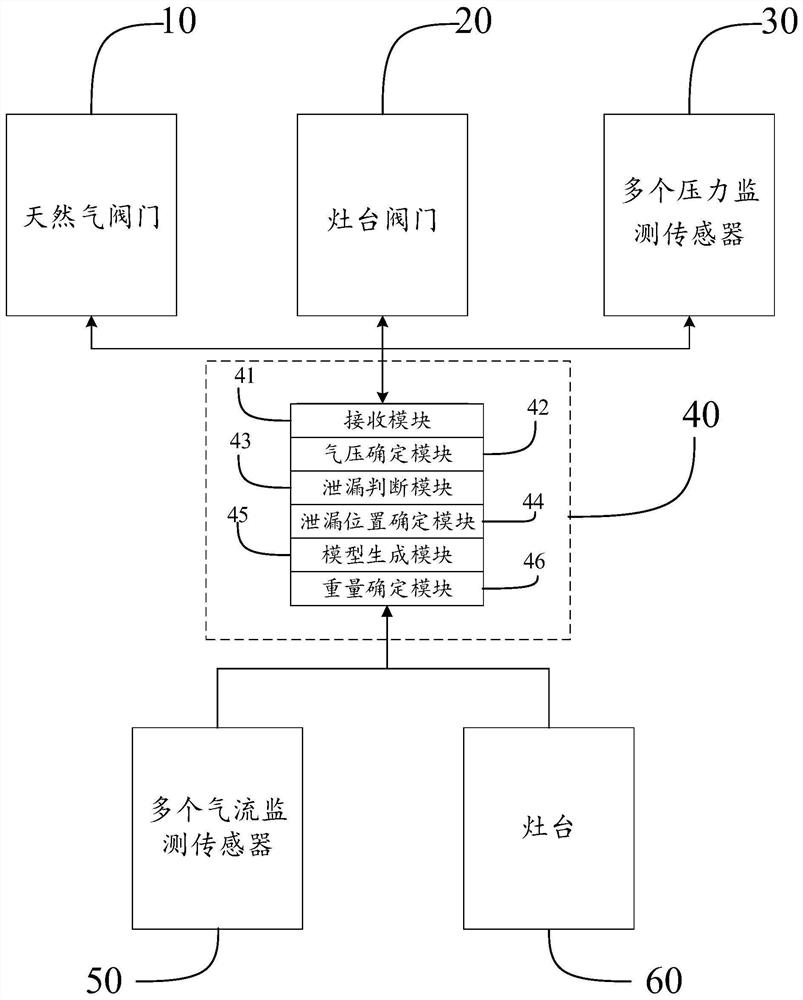

Natural gas leakage monitoring system and method

ActiveCN113418142AImprove securityValve arrangementsMeasurement of fluid loss/gain ratePipeline.airMonitoring system

The invention belongs to the technical field of leakage detection, and discloses a natural gas leakage monitoring system and method. The natural gas leakage monitoring system comprises a natural gas valve used for obtaining the state of the natural gas valve and sending the state of the natural gas valve to a cloud server, a cooking bench valve, a cloud server and a plurality of pressure monitoring sensors; the cooking bench valve is used for acquiring the state of the cooking bench valve and sending the state of the cooking bench valve to the cloud server; the cloud server is used for receiving the natural gas valve state and the cooking bench valve state, determining the current state of the to-be-monitored pipeline according to the natural gas valve state and the cooking bench valve state, and sending a pressure acquisition instruction to the plurality of pressure monitoring sensors when the current state is a closed state; the pressure monitoring sensors are used for acquiring a pipeline air pressure value when receiving the pressure acquisition instruction and sending the pipeline air pressure value to the cloud server; and the cloud server is further used for judging whether natural gas leakage exists in the to-be-monitored pipeline or not according to the pipeline air pressure value, therefore, the leakage detection of the pipeline is realized.

Owner:WUHAN FINEMEMS

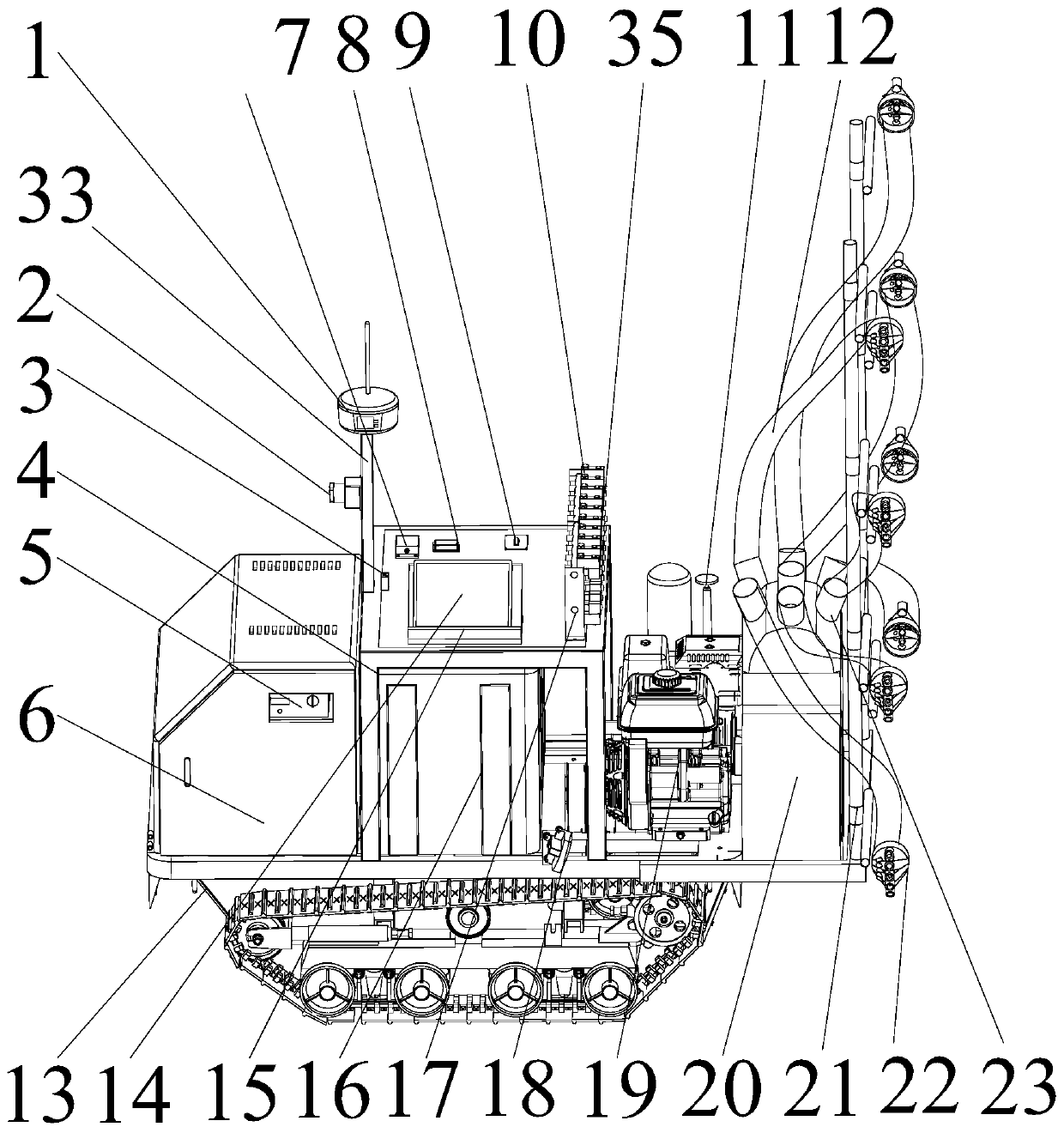

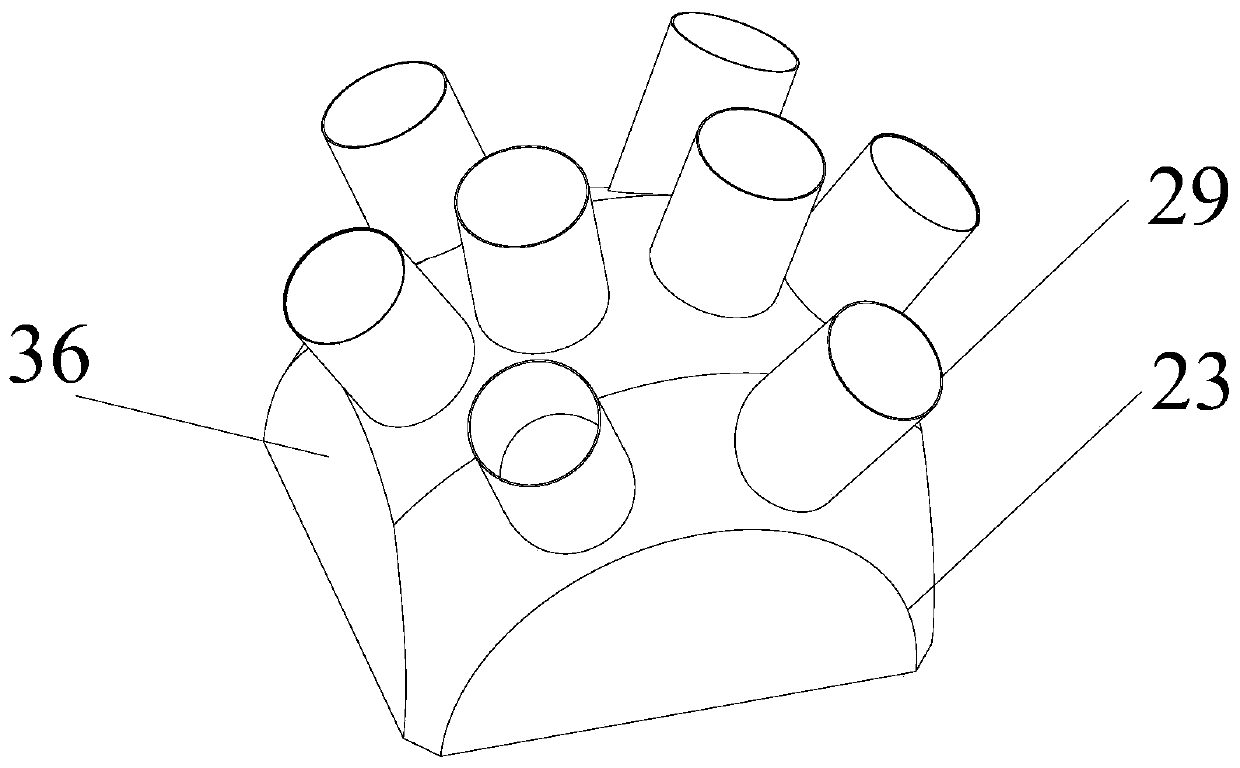

Air-assisted variable-rate spraying machine

The invention relates to a plant protection machine in the field of agricultural and forestry machines, and provides an air-assisted variable-rate spraying machine. The air-assisted variable-rate spraying machine is mainly used for conducting variable-spraying when a pesticide is applied to fruit trees according to the characteristics of the fruit trees. The air-assisted variable-rate spraying machine at least comprises a variable-rate spraying execution module which is composed of an air-assisted system on the rear portion of a rack and a variable-rate spraying system. The air-assisted system comprises an engine in the rack, a centrifugal fan on the rear portion of the rack, a multi-outlet pipeline air-assisted device and air-assisted pipes, wherein the multi-outlet pipeline air-assisted device is communicated with an outlet of the centrifugal fan, the air-assisted pipes are communicated with the multi-outlet pipeline air-assisted device through soft air pipes and provided with a plurality of air-assisted openings. The variable-rate spraying system comprises a pesticide box in the rack, a piston pump driven by the engine, a distributor and sprayers, wherein the distributor is arranged on the rack, communicated with the piston pump through a soft pesticide liquid pipe and provided with a plurality of distribution pipes, the sprayers are arranged in the air-assisted openings respectively, communicated with the distribution pipes through the soft pesticide liquid pipe and electromagnetic valves, and the electromagnetic valves are electrically connected with a single-chip microcontroller.

Owner:NANJING FORESTRY UNIV

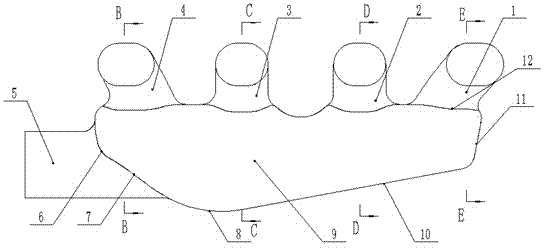

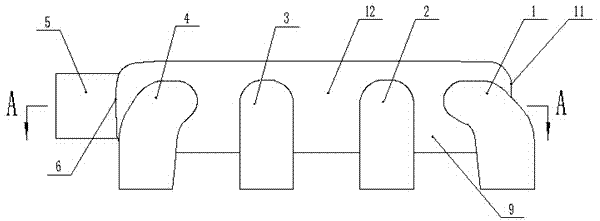

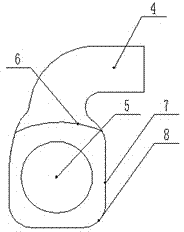

Plastic intake manifold air path for gasoline engine

ActiveCN104279093ASmall footprintLow air resistanceCombustion-air/fuel-air treatmentMachines/enginesPipeline.airSpatial structure

A plastic intake manifold air path for a gasoline engine overcomes the problems that as the existing intake manifold air path is long, the intake efficiency is influenced, the uniform symmetric space structure of a pressure pressurizing cavity is influenced, turbulence is easily caused to the pressure stabilizing cavity, the intake uniformity of four branch pipe air paths is poor, the pressure loss is large, and furthermore, the dynamic property and discharging property of the engine are influenced. The plastic intake manifold air path is characterized in that a pressure stabilizing cavity is in an asymmetric irregular shape; airflow inlets of branch pipeline air paths are directly connected with the upper wall of the pressure pressurizing cavity; the length of the central line of the first branch pipe air path is 78.3mm; the length of the central line of the second branch pipe air path is 73mm; the length of the central line of the third branch pipe air path is 73mm; the length of the central line of the fourth branch pipe air path is 78.4mm; the central lines of the four air paths consist of linear segments and arc segments. The plastic intake manifold air path has the beneficial effects as the air path is shorter, the occupied space of the air path is reduced, the airflow resistance is reduced, the intake uniformity meets the + / -3% demands, the pressure loss is small, and the dynamic property of the engine is favorably improved.

Owner:沈阳航天新光汽车零部件有限公司

Solar greenhouse suitable for facility cherry cultivation

InactiveCN106105887AImprove operational efficiencyPromote growthClimate change adaptationGreenhouse cultivationPipeline.airAutomatic control

The invention discloses a solar greenhouse suitable for facility cherry cultivation. The solar greenhouse comprises shed columns and a light-transmitting layer (1). The solar greenhouse is characterized in that the shed columns and the light-transmitting layer (1) form a solar shed. The light-transmitting layer (1) is provided with a heat collecting device. The solar shed is internally provided with a uniform air inlet device, an automatic control device, and a cooling device. The solar greenhouse solves problems that a system is poor in heat dispersion, non-uniform in pipeline air intake, and low in system operation efficiency, and a heat collection device is added, so sunlight utilization is more sufficient. A hot blast heater temporary warming system is also added, so as to automatically warm soil and air in the greenhouse when extreme weather occurs in facility cherry production, so that a cherry germination period is brought forward, and a flowering phase is brought forward, branch growth amount in an earlier stage is improved, first-class high-quality fruit rate is improved, a fructescence is brought forward, cherries appear on the market in advance, and yield is increased.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Electronic depositing storage wind-cooling freezer for cold-chain distribution

InactiveCN101581525AEffective low temperatureEasy to operateLighting and heating apparatusDomestic refrigeratorsCold chainPipeline.air

The invention provides an electronic depositing wind-cooling freezer for cold-chain distribution, which relates to the technical field of metalwork cabinets. In order to overcome the disadvantage that electronic depositing cabinets in the distribution of clean vegetables and frozen foods are unfavorable for cold-chain distribution and the like, the freezer is characterized in that the electronic depositing wind-cooling freezer for the cold-chain distribution consists of a refrigeration host machine, heat-insulation pipelines for circularly conveying cold air, a pipeline control valve and a pipeline air-blast pump room which are in sequential connection and are connected with the inside of each heat-insulation depositing box grid body; main conveying cold-air pipelines, small branch cold-air pipelines and small branch valves are arranged in the box grid bodies; the heat-insulation pipelines for circularly conveying cold air are in sequential connection and seamlessly pass through the inside of each box grid body; the heat-insulation pipelines for conveying cold air are connected with two small branch cold-air pipelines in each box grid body; the small pipelines are connected with the small valves; magnetic sealing strips are pasted around box doors of the box grids; and two right-angle hangers are hung and arranged on the inner wall of each box grid body. The freezer is used for and adapts to requirements for fast cold-chain large-scale distribution of clean vegetables and frozen foods.

Owner:张春生

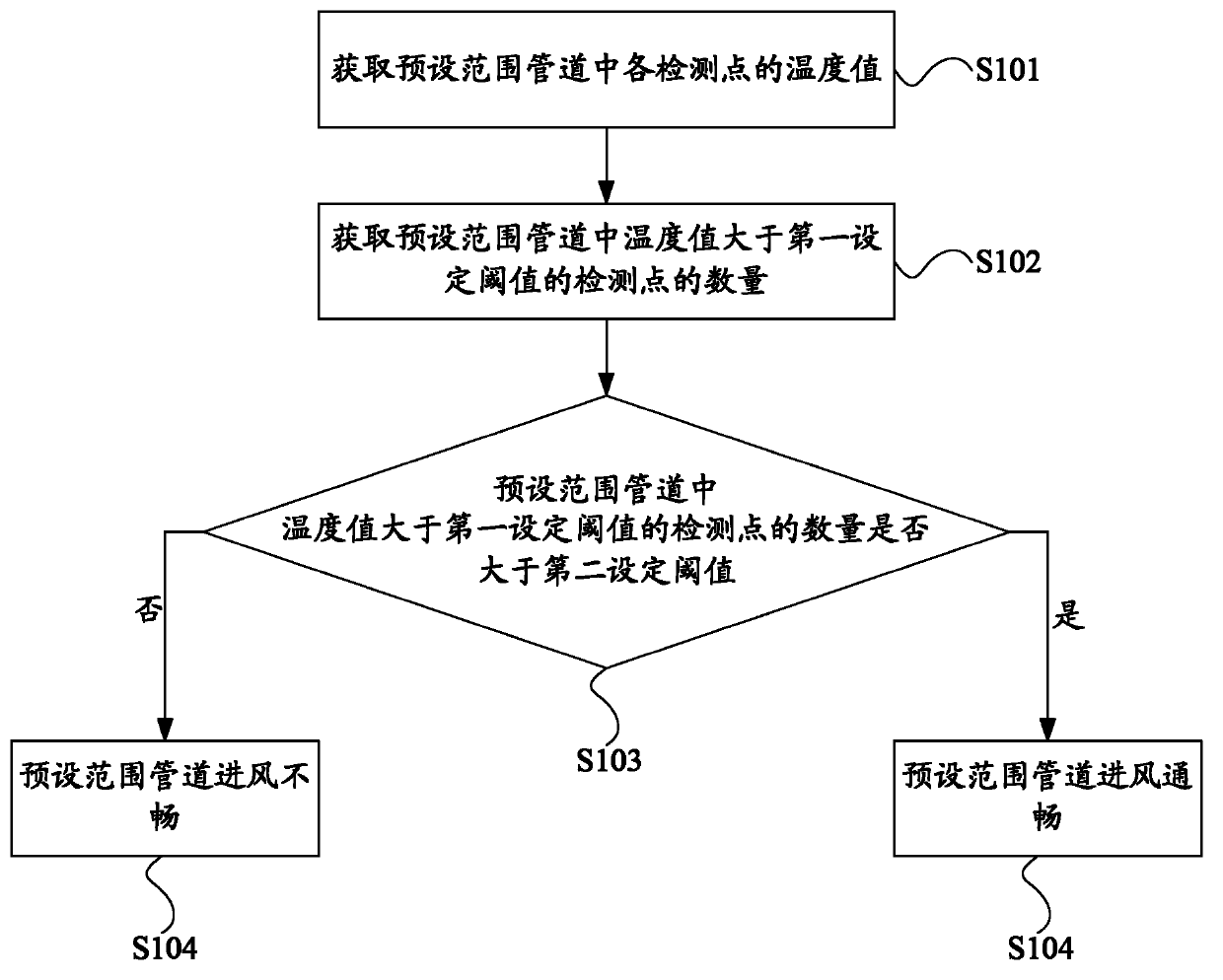

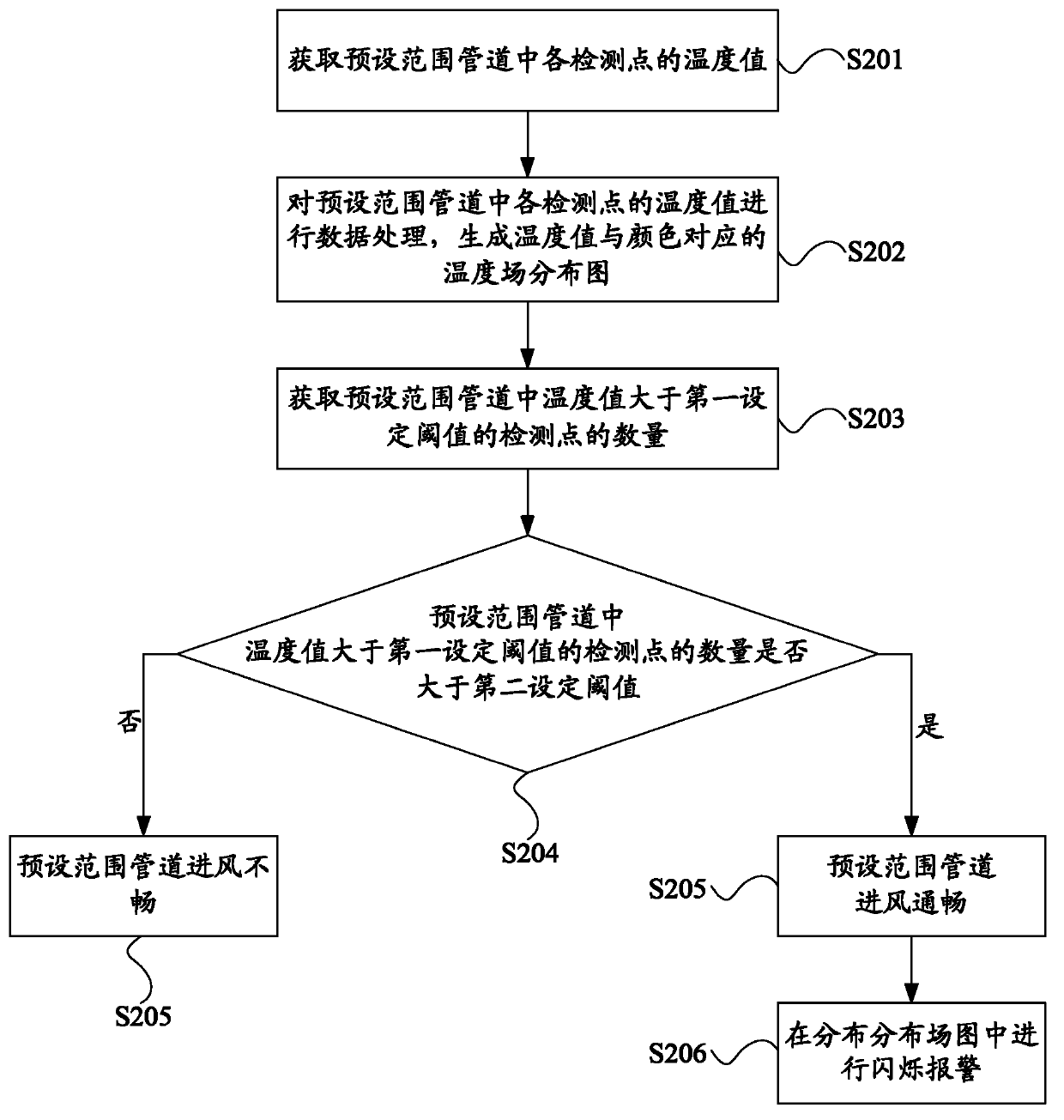

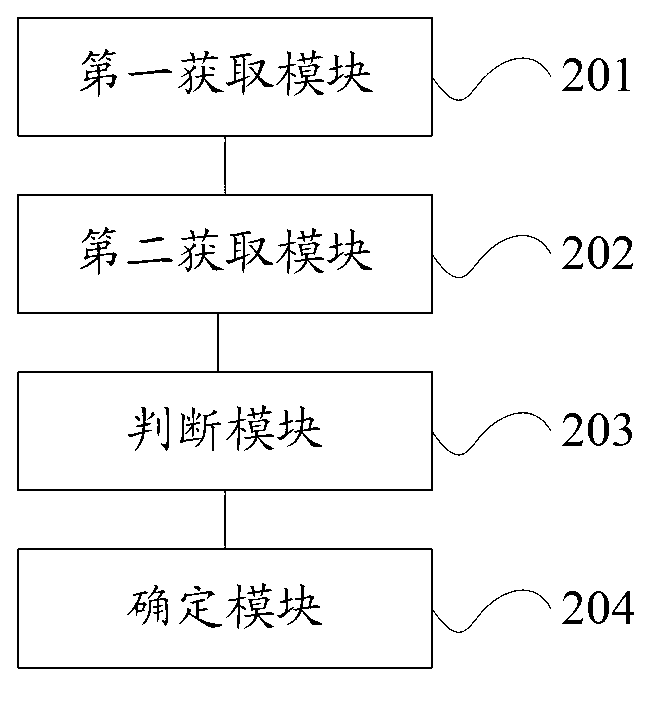

Method and device for detecting draught fan insufficient output fault

ActiveCN103104531AEasy to determineImprove operational efficiencyPump controlNon-positive displacement fluid enginesPipeline.airEngineering

The invention provides a method for detecting a draught fan insufficient output fault and a device for detecting the draught fan insufficient output fault. The method includes the steps: obtaining a temperature value of each detecting point in a pipeline in a preset range; obtaining the number of detecting points with the temperature value in the pipeline in the preset range larger than a first set threshold value; judging whether the number of the obtained detecting points is larger than a second set threshold value, if the number of the obtained detecting points is larger than the second set threshold value, flow of high temperature smoke and gas in the pipeline in the preset range is large, and poor smoothness of pipeline air-in in the preset rang is determined. The characteristics of the temperature of the smoke and the gas in the pipeline are used, according to the obtained temperature values of the detecting points in the pipeline and the number of the detecting points with the temperature values larger than the threshold values, the pipeline with large flow of high temperature smoke and gas is judged, and therefore a pipeline zone which is not smooth in air-in and air-out can be easily determined so as to provide evidences for further improving running efficiency of the draught fan.

Owner:LAIWU IRON & STEEL GRP

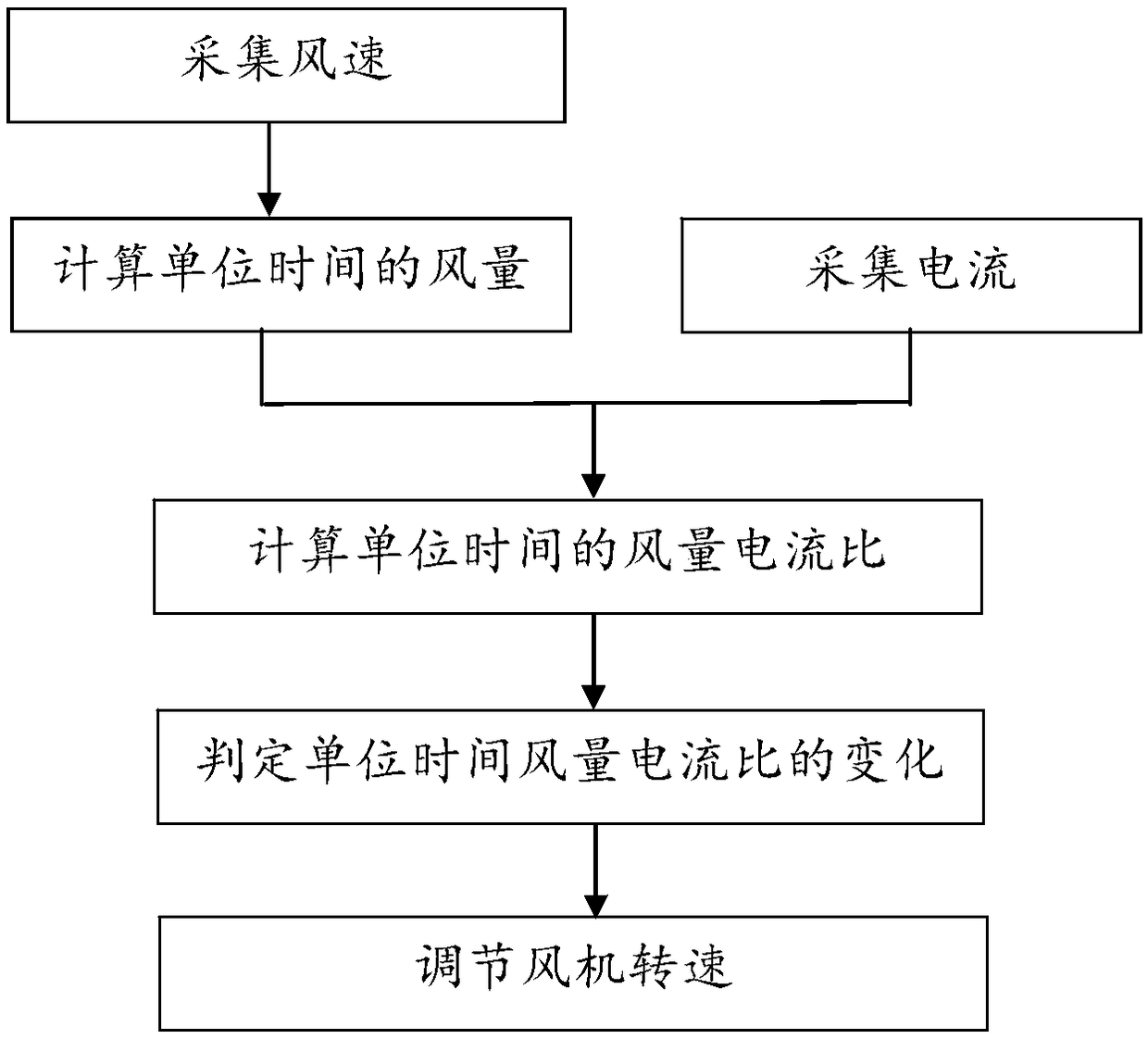

Air speed adaptive control method and device, and combined air conditioner unit

ActiveCN109489215AImprove experienceAccurate speed judgmentMechanical apparatusSpace heating and ventilation safety systemsPipeline.airEngineering

The invention discloses an air speed adaptive control method and device, and a combined air conditioner unit, and relates to the technical field of air conditioners. The problem that in the prior art,the air quantity is adjusted in a mode of changing the opening number of pipeline air valves and / or the starting number of units, and consequently, the air quantity adjusting accuracy is poor is solved. According to the air speed adaptive control method, the rotating speed of a fan is adjusted based on the change of the air quantity at an air outlet. According to the air speed adaptive control method, the air quantity at the air outlet is adjusted by adjusting the rotating speed of the fan, thus the air speed adaptive control method has the advantages that air quantity adjusting is accurate,and constant-air-quantity stable running of the combined air conditioner unit at the different air quantity intervals can be maintained, and the user experience effect is better.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com