Patents

Literature

210results about "Fluid pressure measurement using pistons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

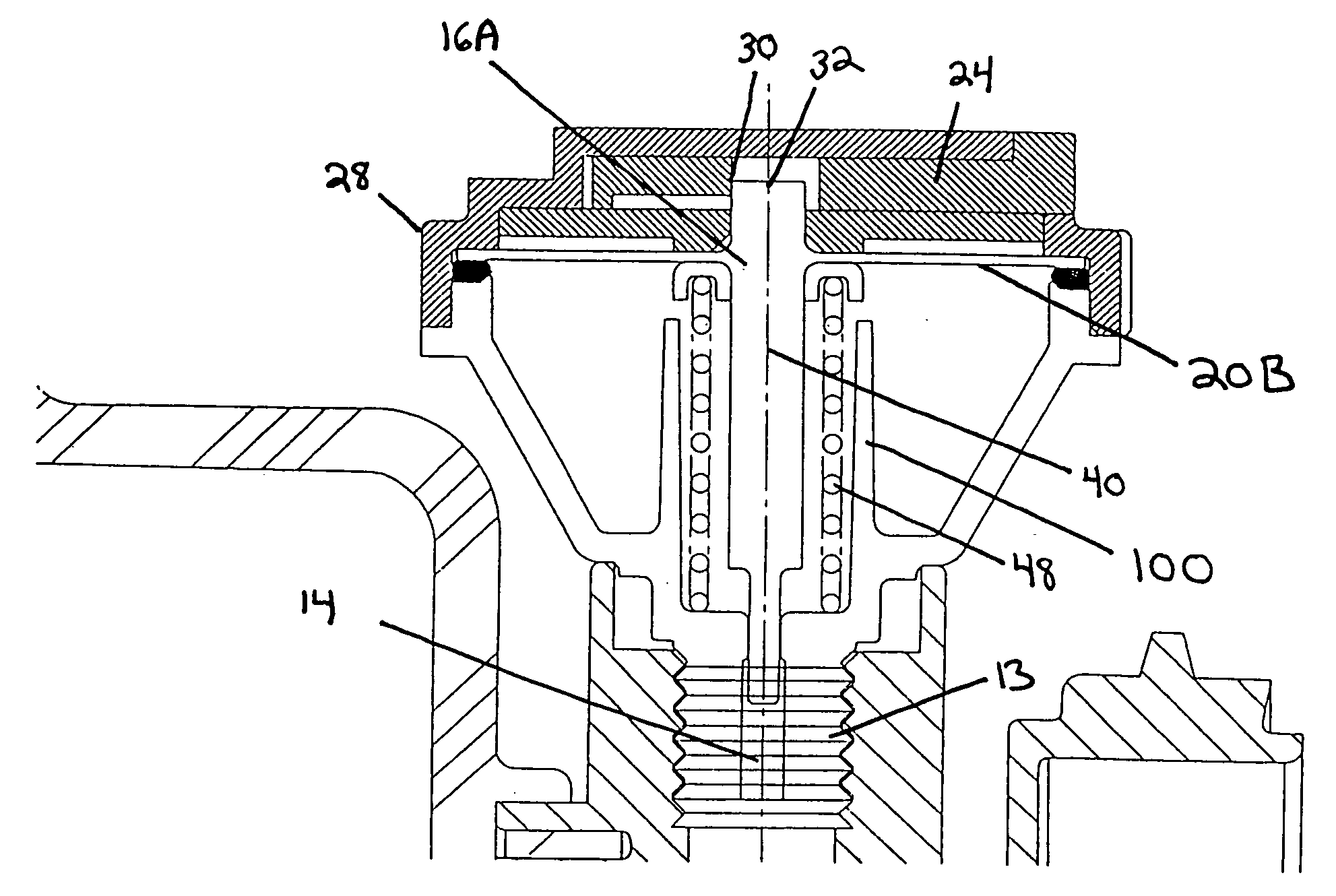

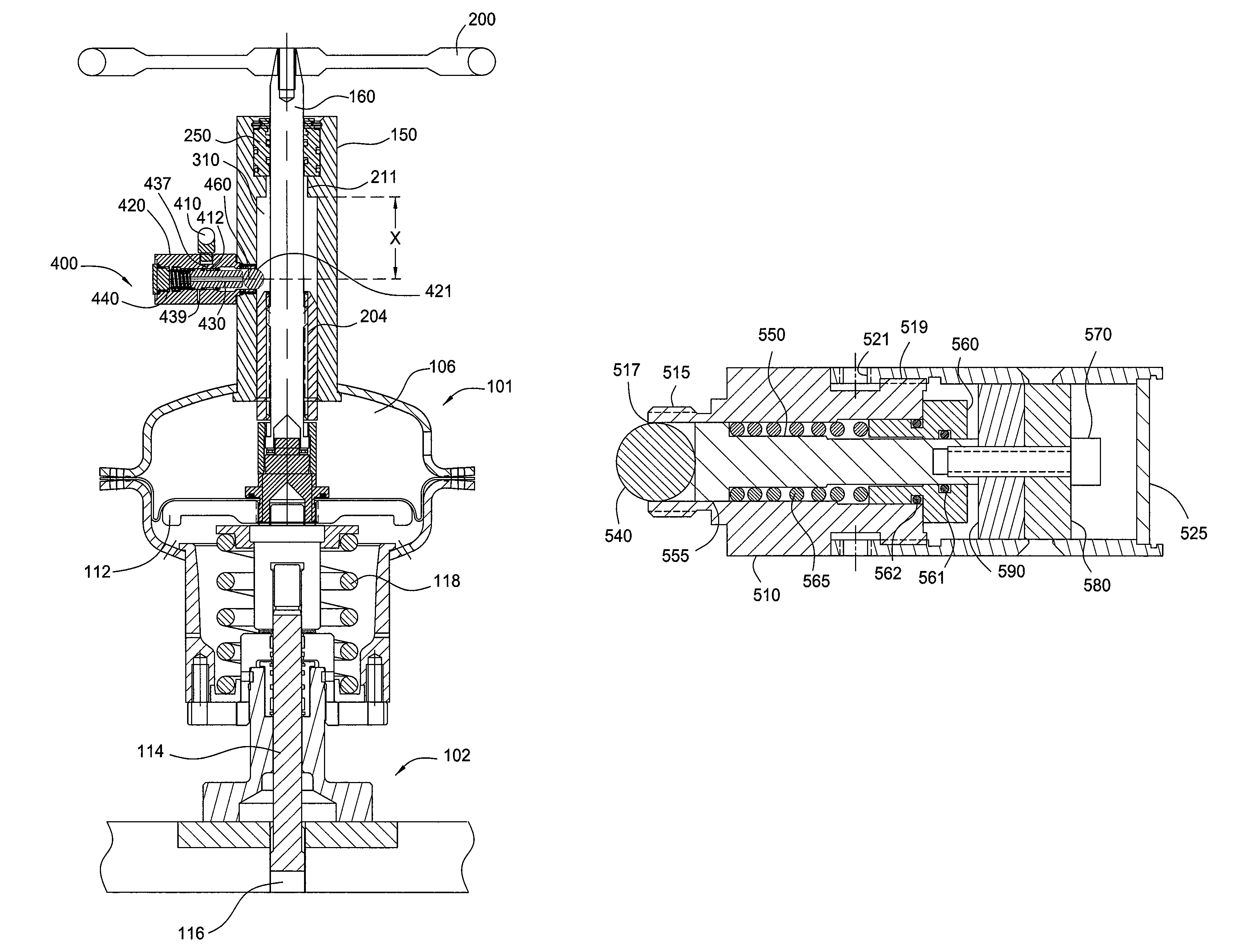

Systems for percutaneous bone and spinal stabilization, fixation and repair

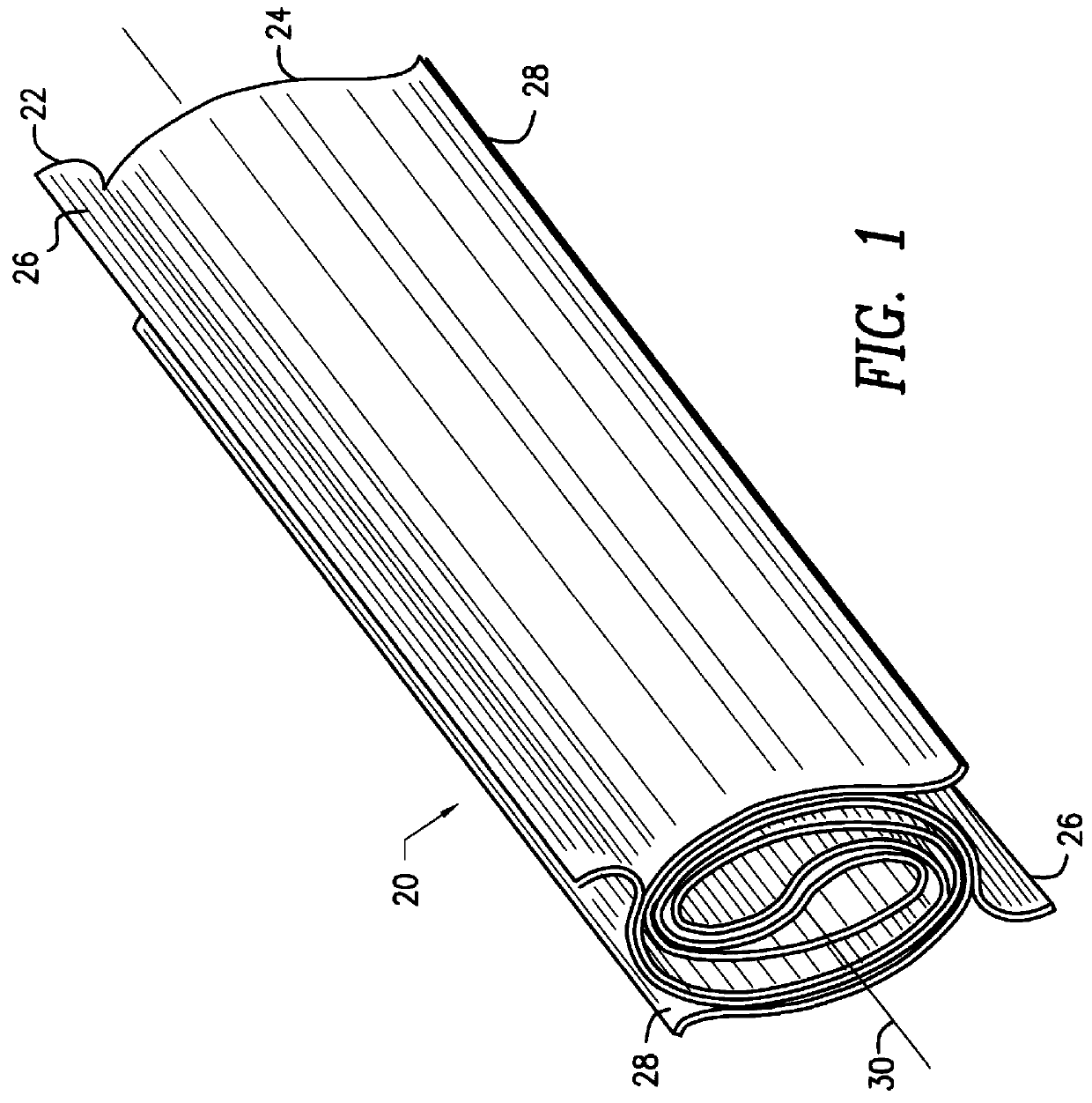

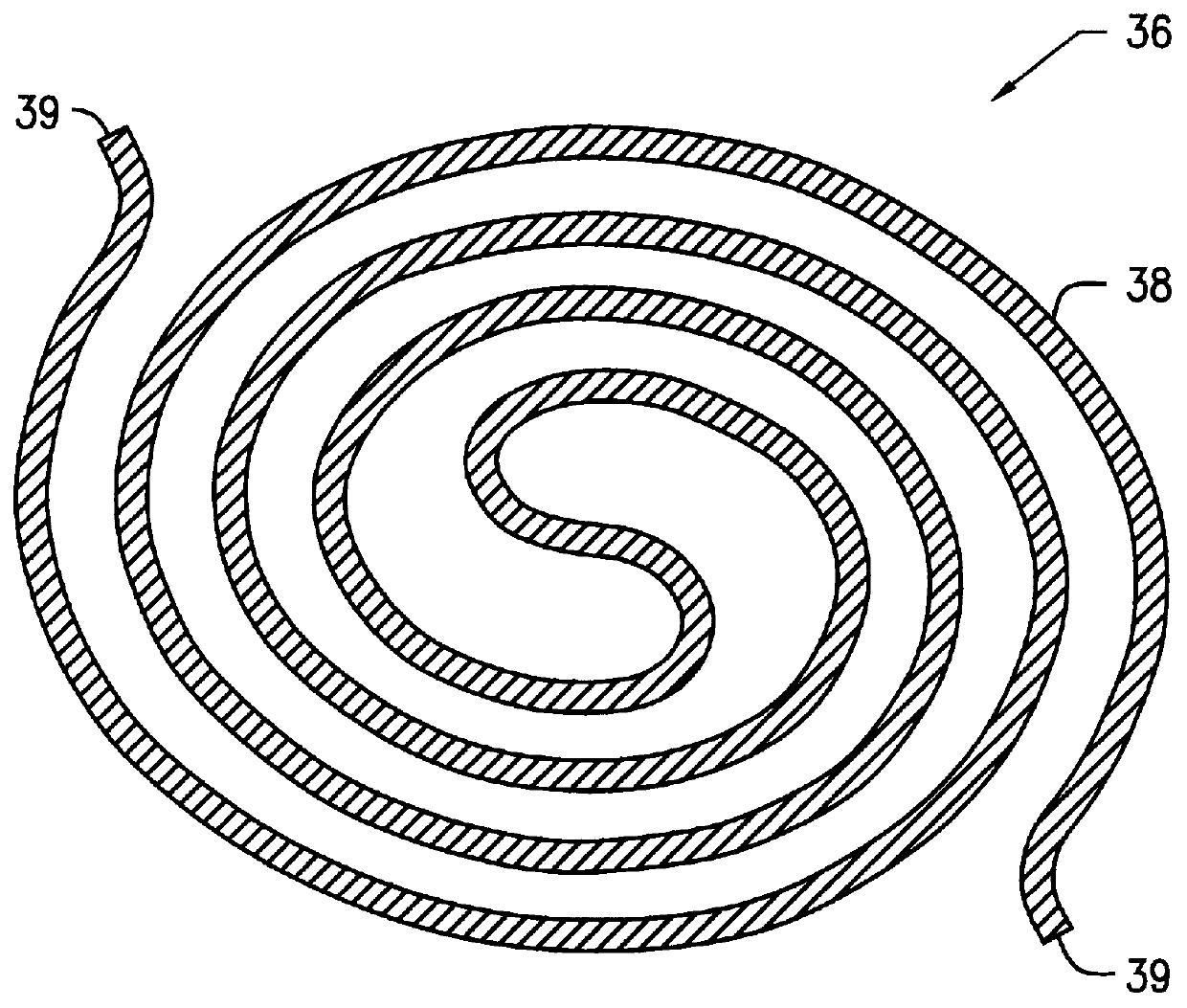

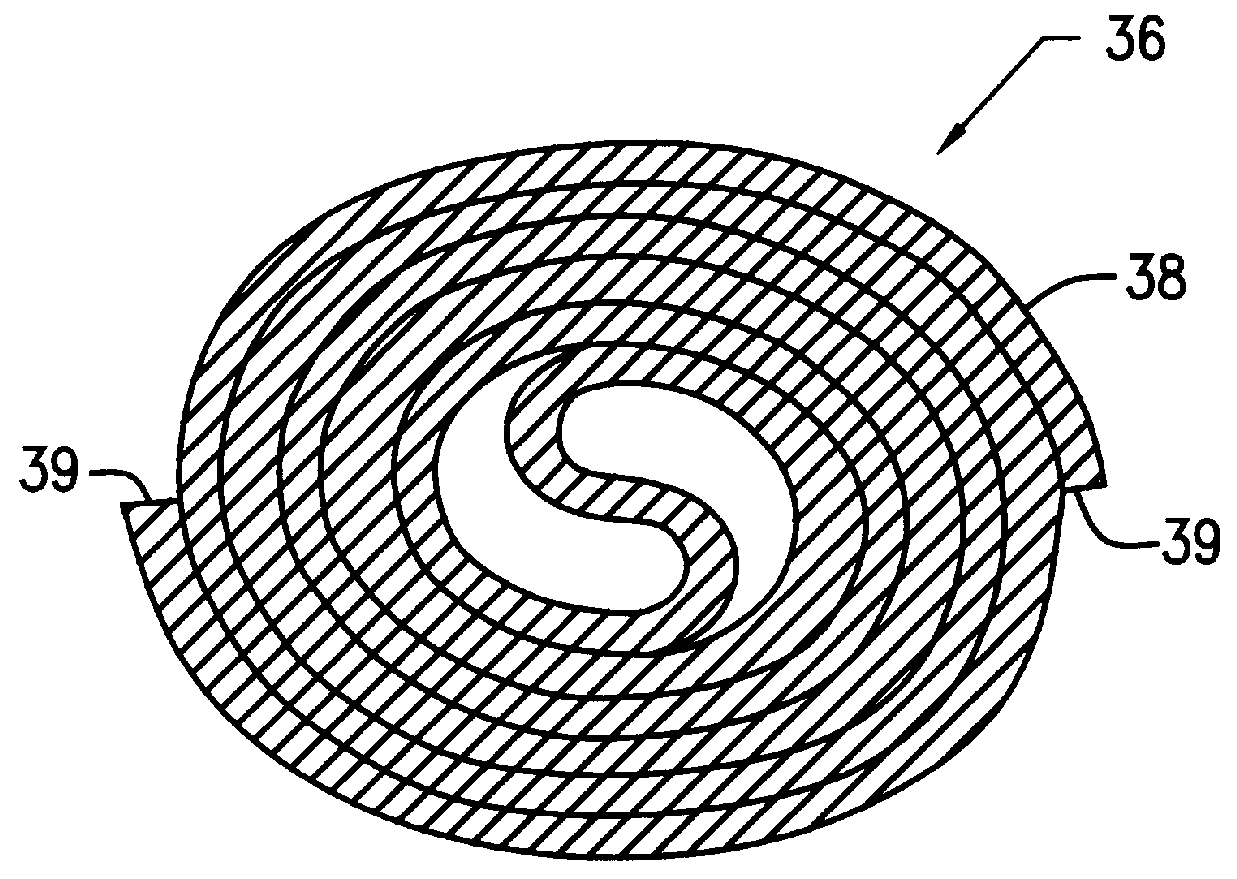

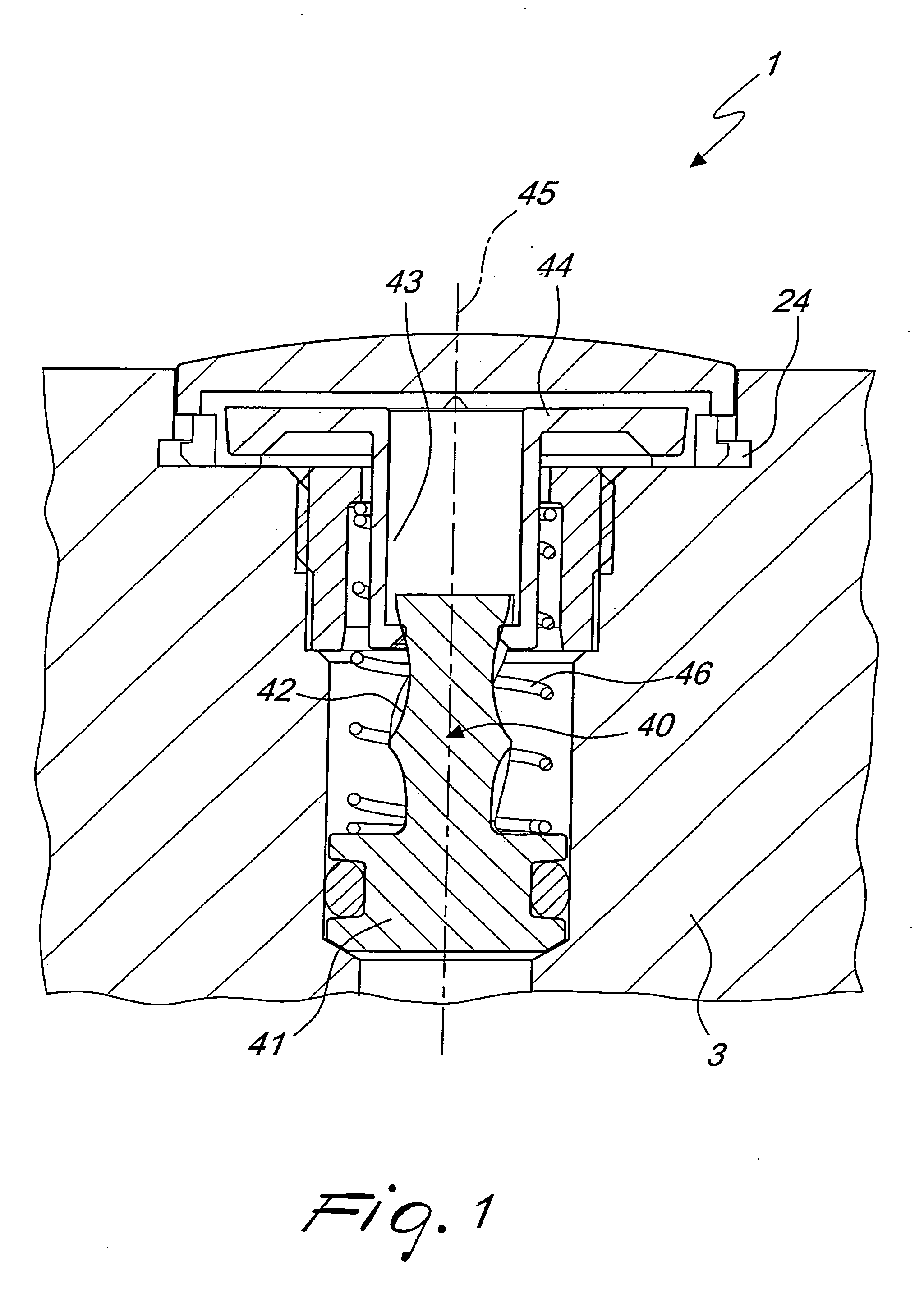

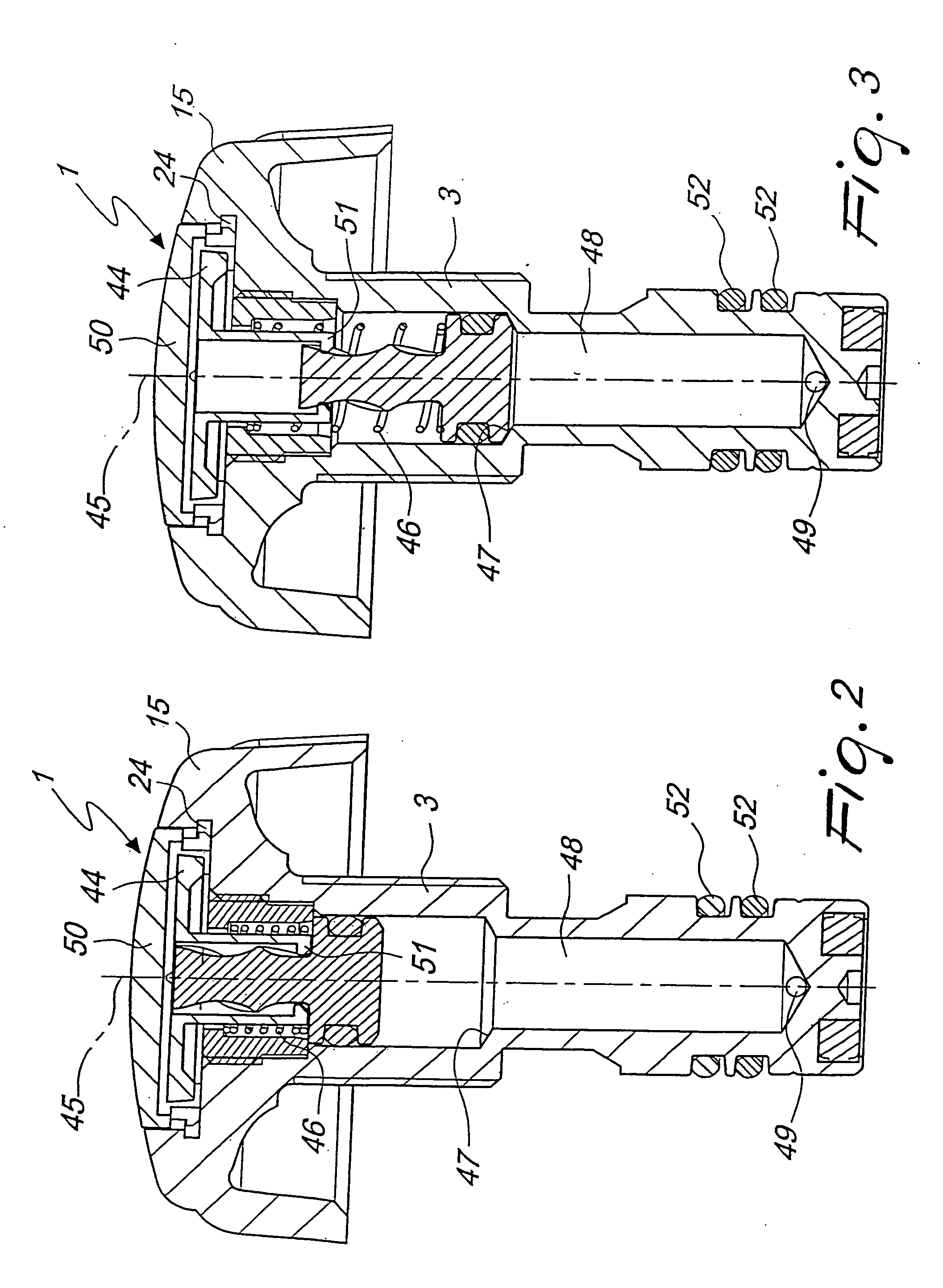

InactiveUS6127597ASize of wire can be enlarged and reducedEnlarging and reducing sizeInternal osteosythesisFluid pressure measurement using pistonsSpinal columnProsthesis

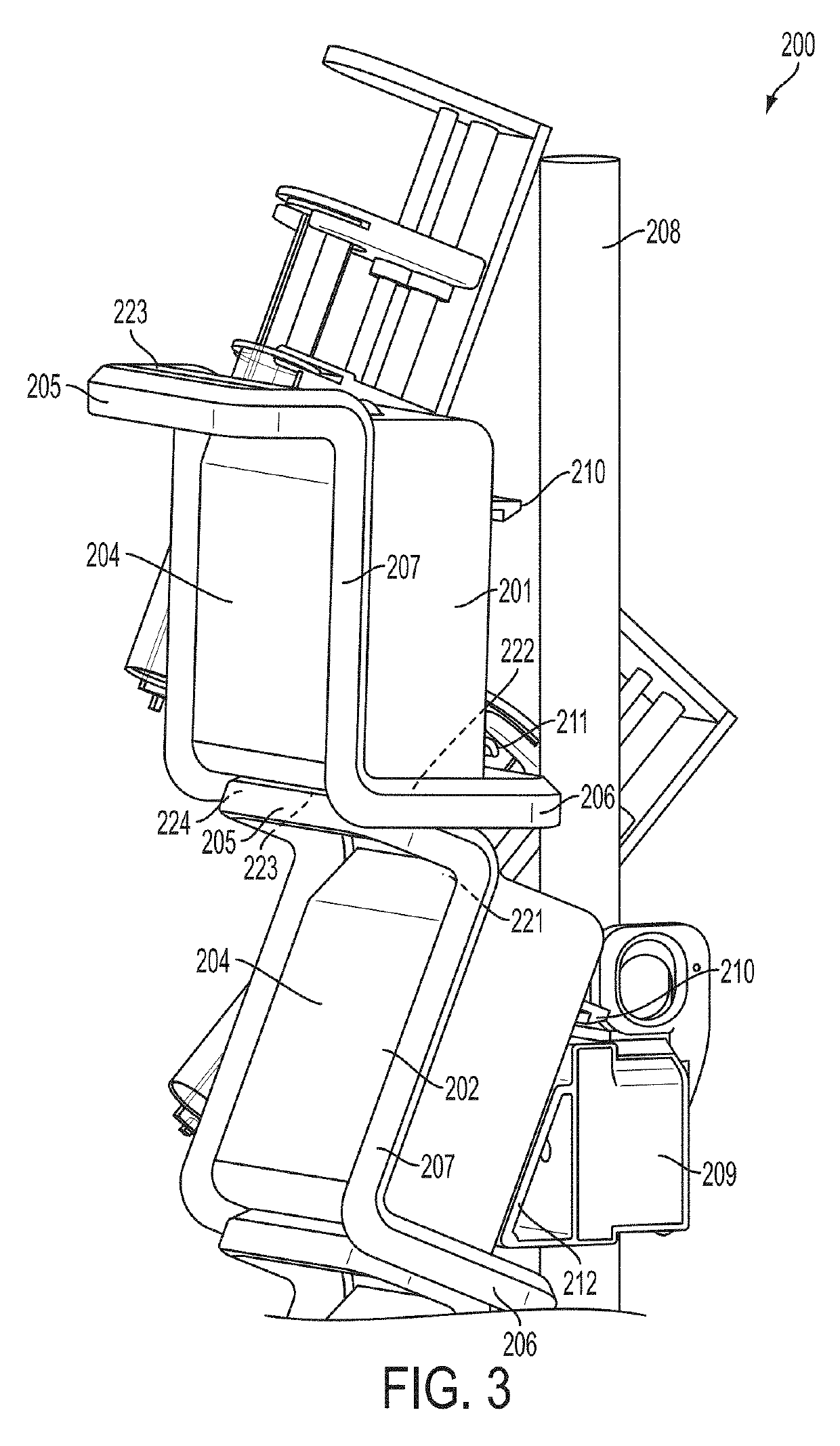

Systems for bone and spinal stabilization, fixation and repair include intramedullar nails, intervertebral cages and prostheses, remotely activatable prostheses, tissue extraction devices, and electrocautery probes. The intramedullar nails, intervertebral cages and prostheses, are designed for expansion from a small diameter for insertion into place to a larger diameter which stabilizes, fixates or repairs the bone, and further can be inserted percutaneously. Remotely activatable prostheses can be activated from an external unit to expand and treat prosthesis loosening. Tissue extraction devices, and electrocautery probes are used to remove tissue from desired areas.

Owner:KYPHON

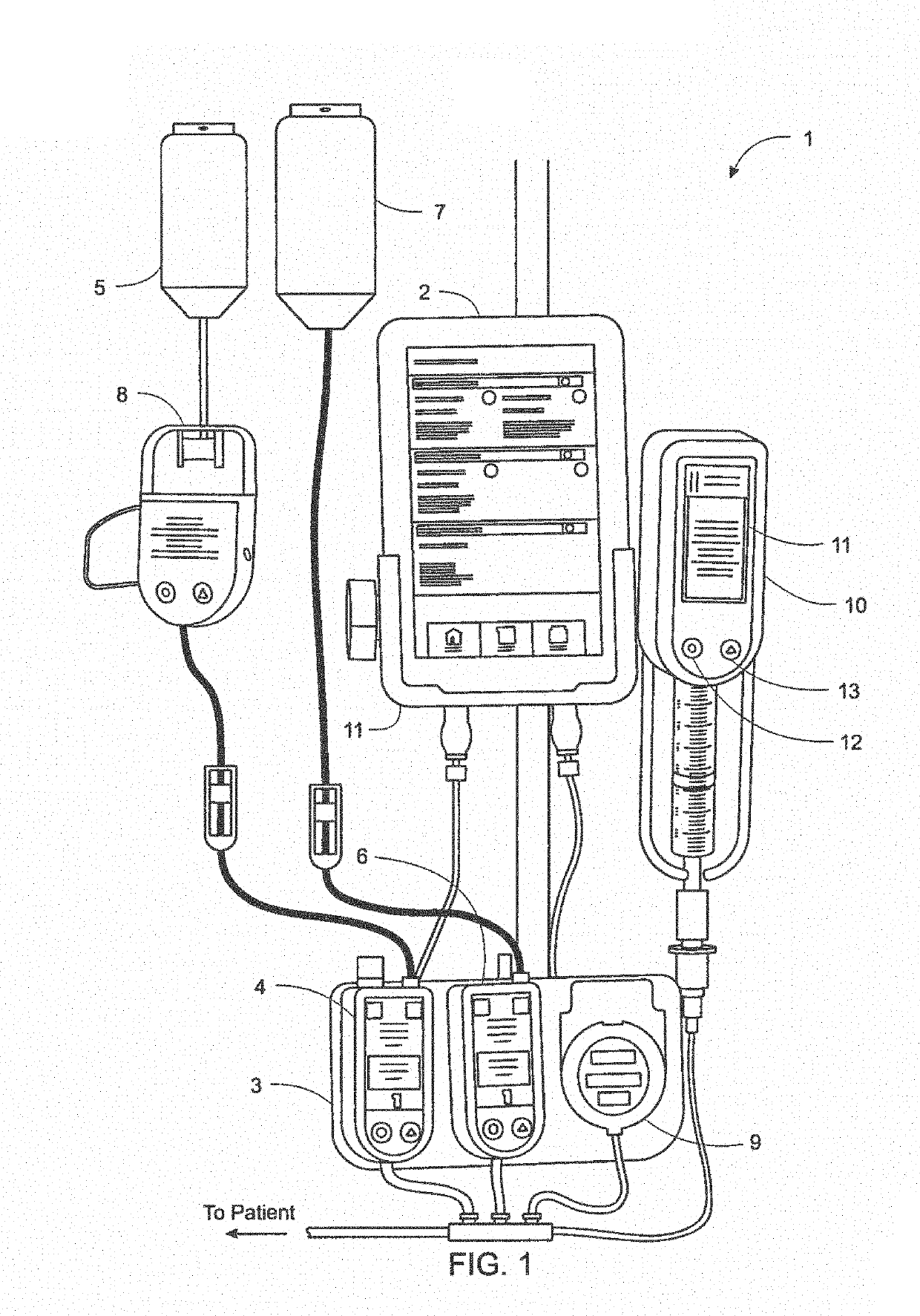

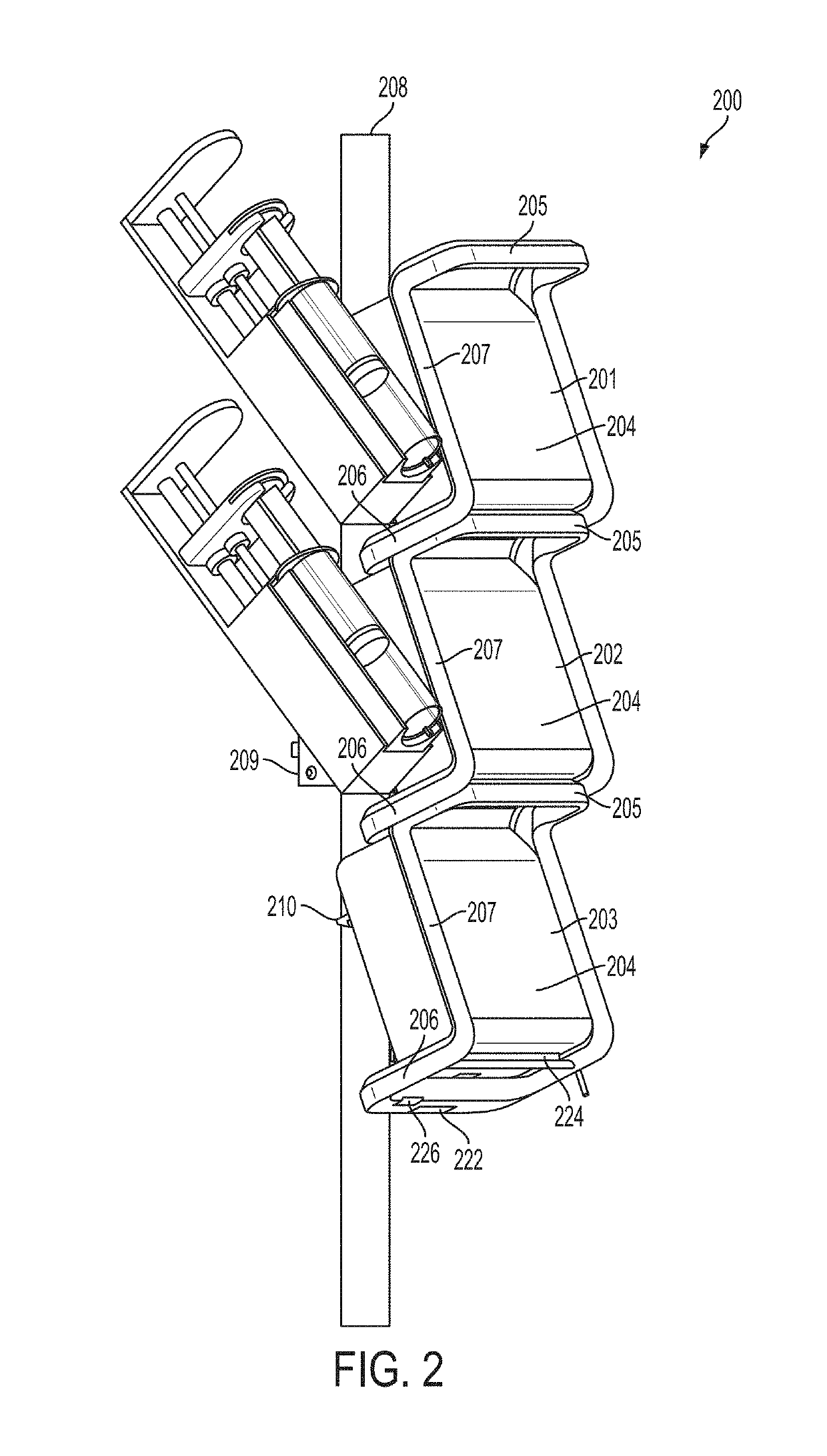

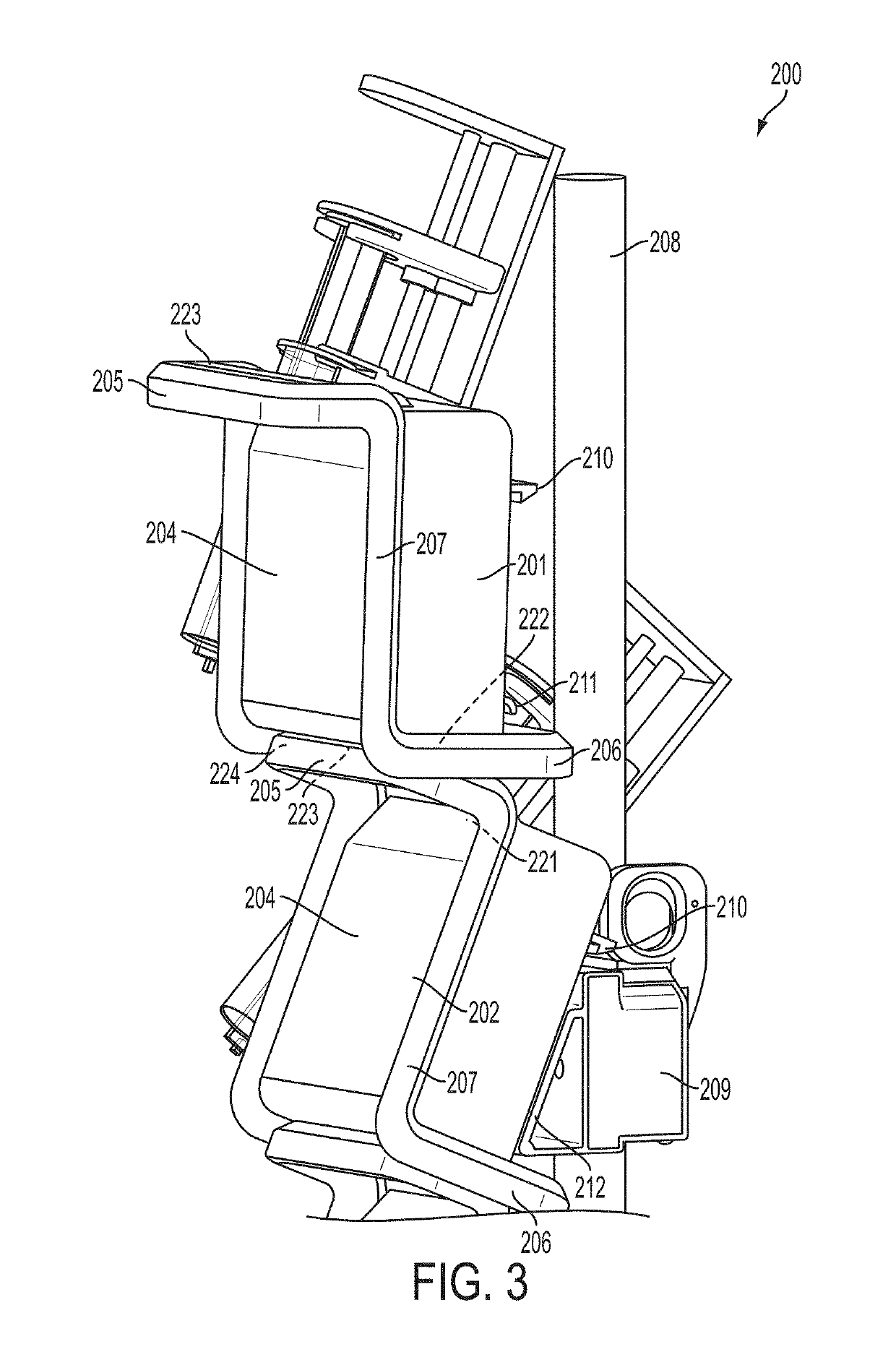

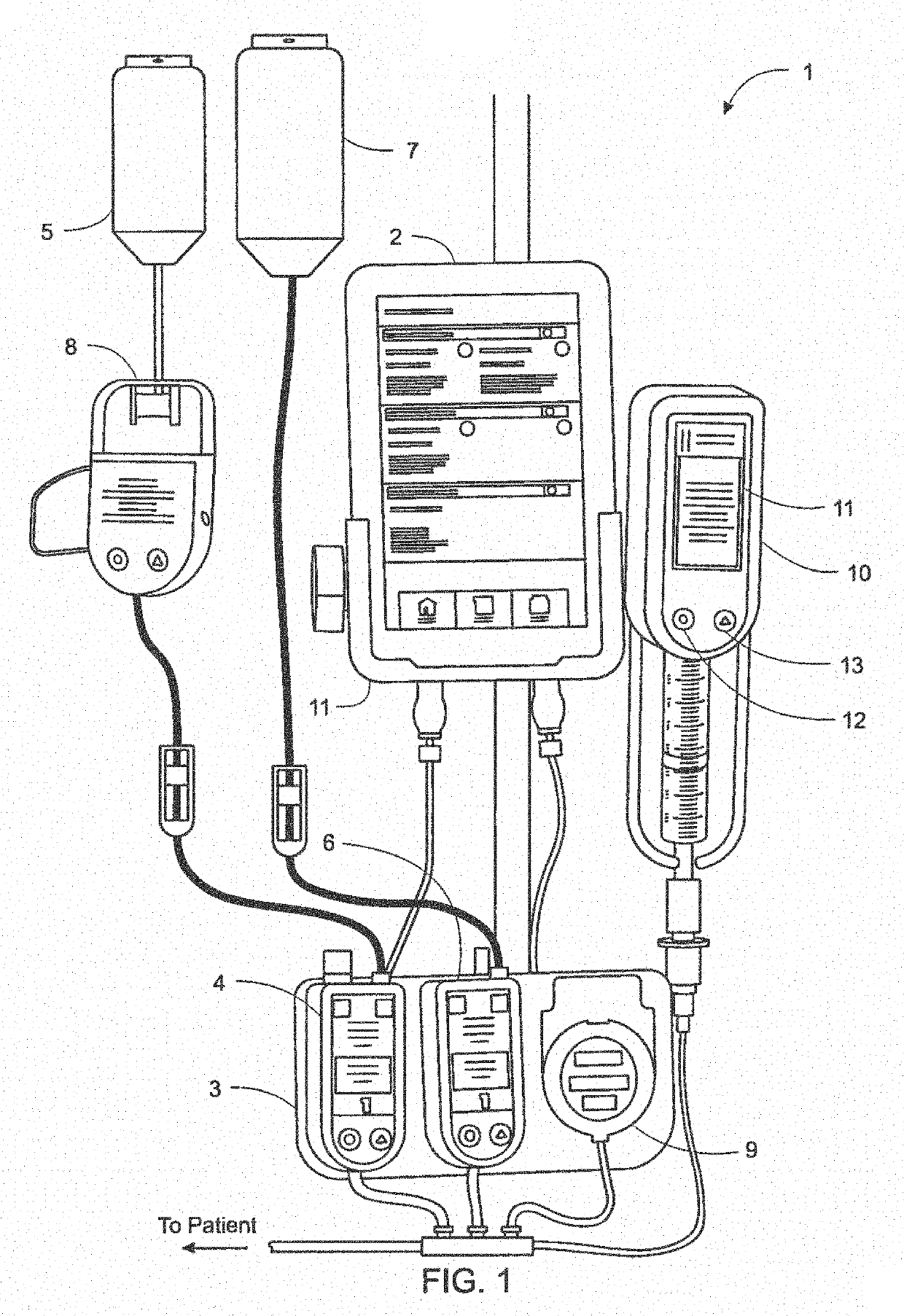

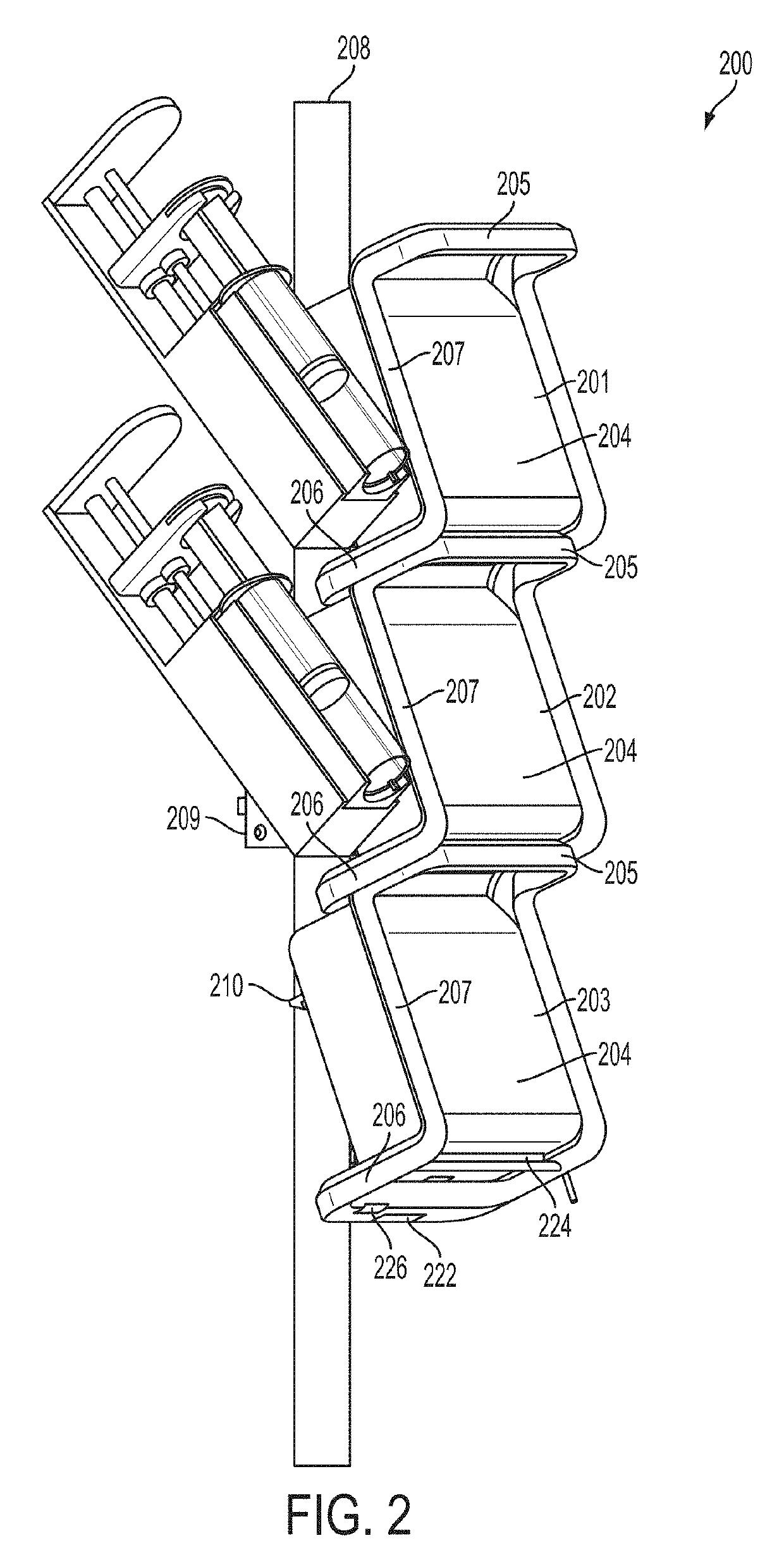

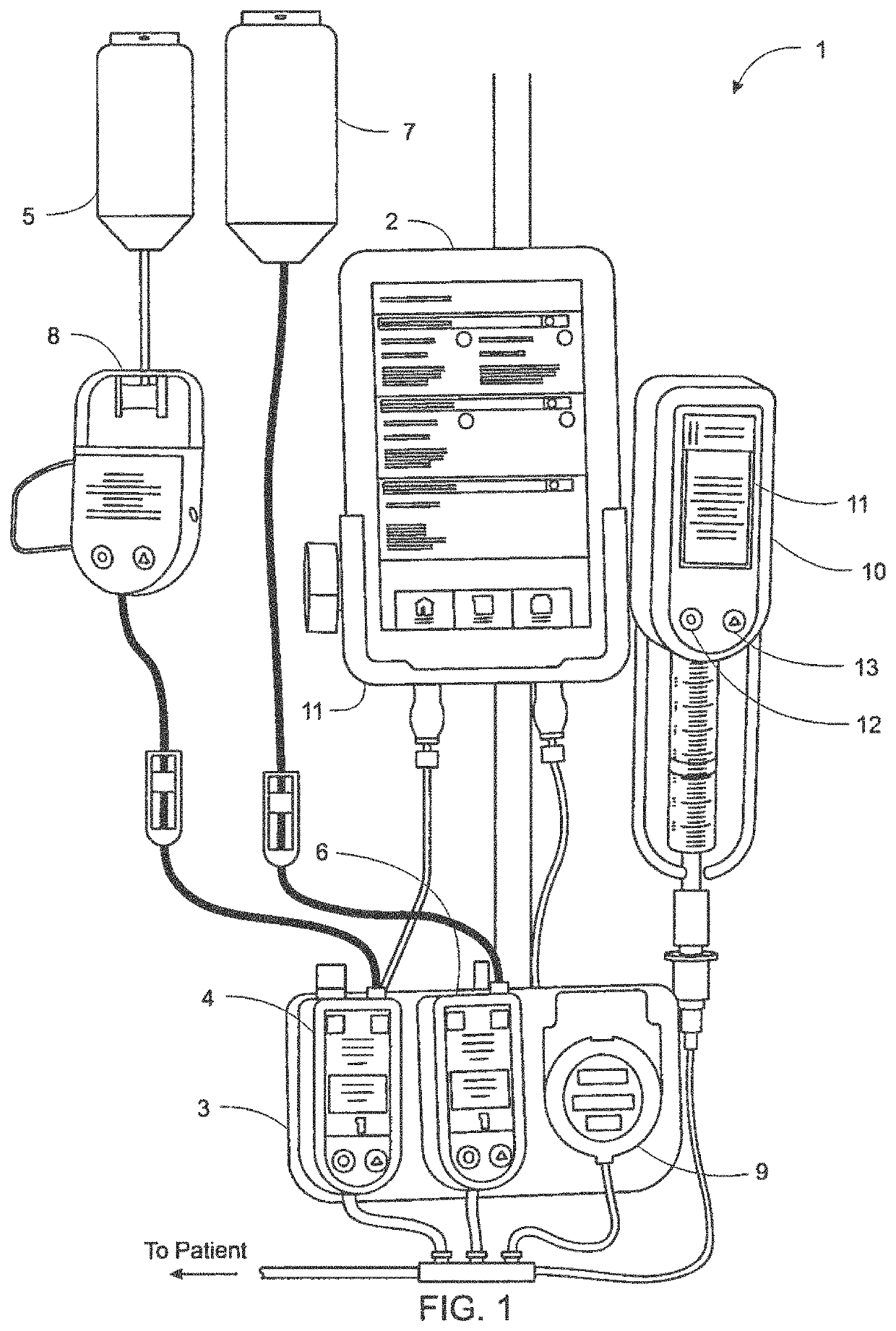

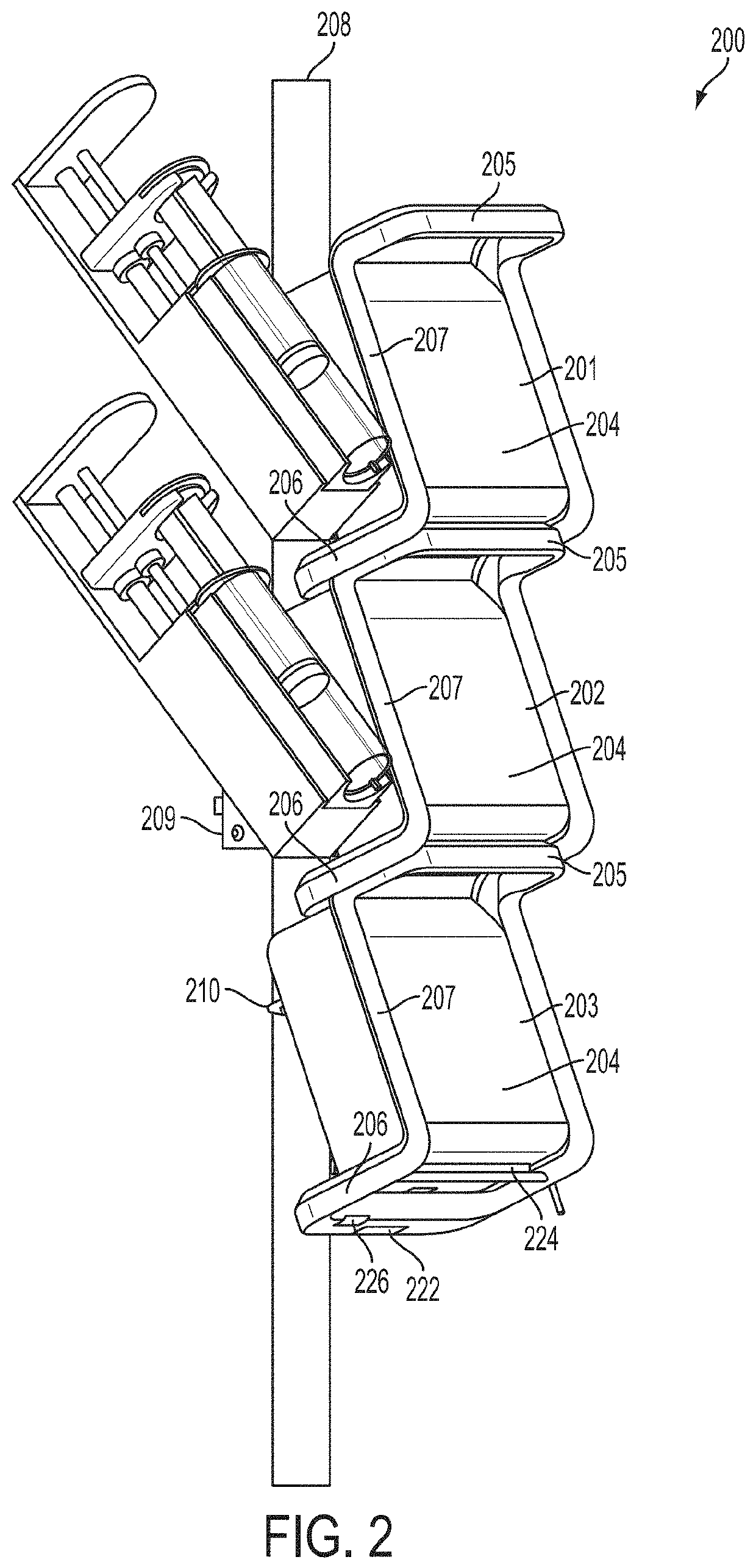

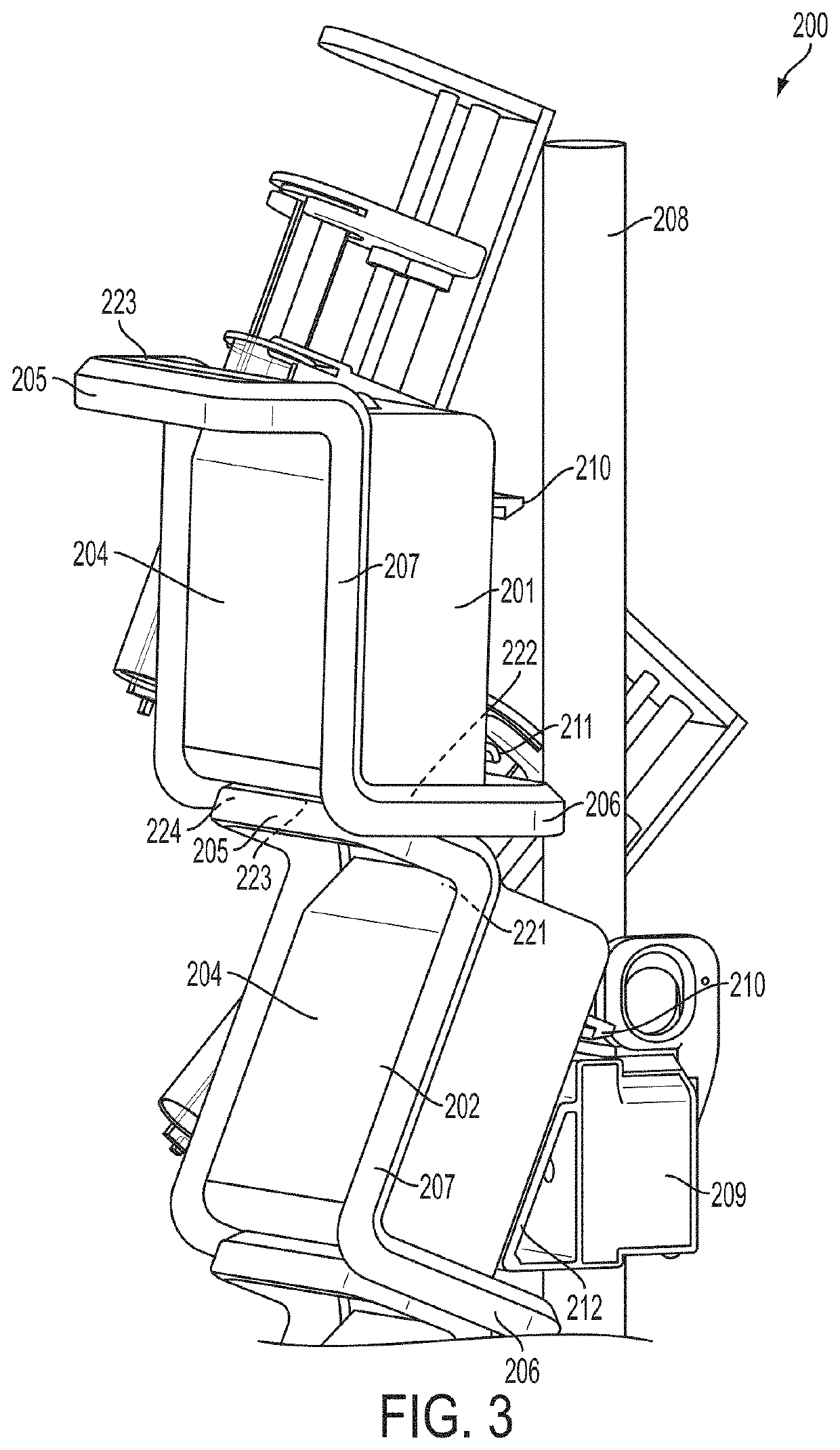

Syringe pump having a pressure sensor assembly

ActiveUS10391241B2Reduce errorsDrug and medicationsFluid pressure measurement by electric/magnetic elementsActuatorBiomedical engineering

A syringe pump is disclosed that includes a body, a syringe seat, a syringe actuator, a memory, and one or more processors. The syringe seat is coupled to the body. The syringe actuator is configured to actuate a syringe secured within the syringe seat. The memory is configured to store a plurality of instructions. The one or more processors, in accordance with the plurality of instructions, is / are configured to: prime the syringe pump in a prime phase; determine if an occlusion exists during the prime phase using a first test; stop the prime phase; initiate fluid delivery into a patient; enter into a start-up phase; determine if an occlusion exists using a second test during the start-up phase; transition from the start-up phase into a steady-state phase; and determine if an occlusion exists during the steady-state phase using a third test.

Owner:DEKA PROD LLP

Syringe Pump Having a Pressure Sensor Assembly

ActiveUS20190328964A1Reduce errorsDrug and medicationsFluid pressure measurement by electric/magnetic elementsEngineeringActuator

A syringe pump is disclosed that includes a body, a syringe seat, a syringe actuator, a memory, and one or more processors. The syringe seat is coupled to the body. The syringe actuator is configured to actuate a syringe secured within the syringe seat. The memory is configured to store a plurality of instructions. The one or more processors, in accordance with the plurality of instructions, is / are configured to: prime the syringe pump in a prime phase; determine if an occlusion exists during the prime phase using a first test; stop the prime phase; initiate fluid delivery into a patient; enter into a start-up phase; determine if an occlusion exists using a second test during the start-up phase; transition from the start-up phase into a steady-state phase; and determine if an occlusion exists during the steady-state phase using a third test.

Owner:DEKA PROD LLP

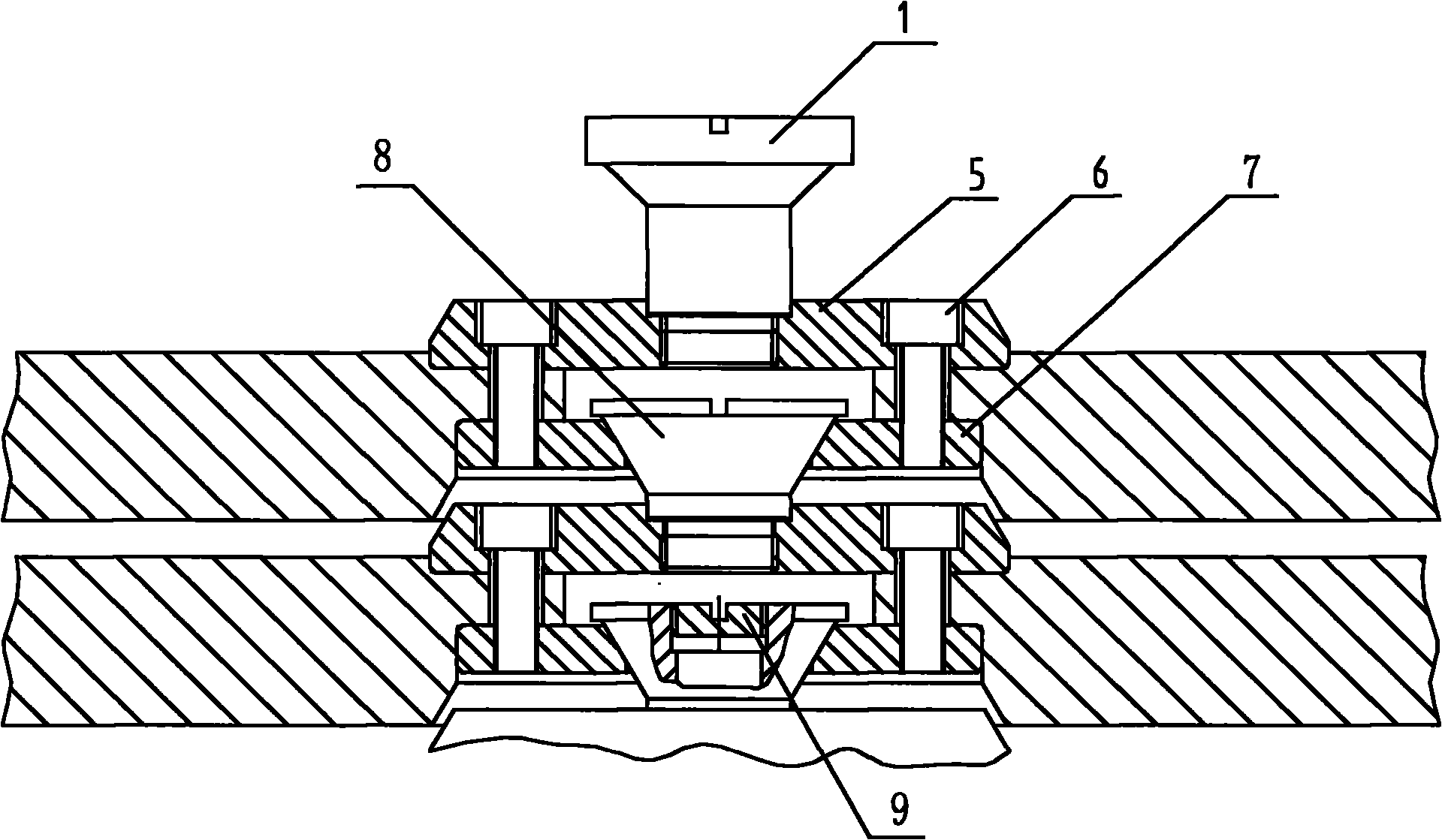

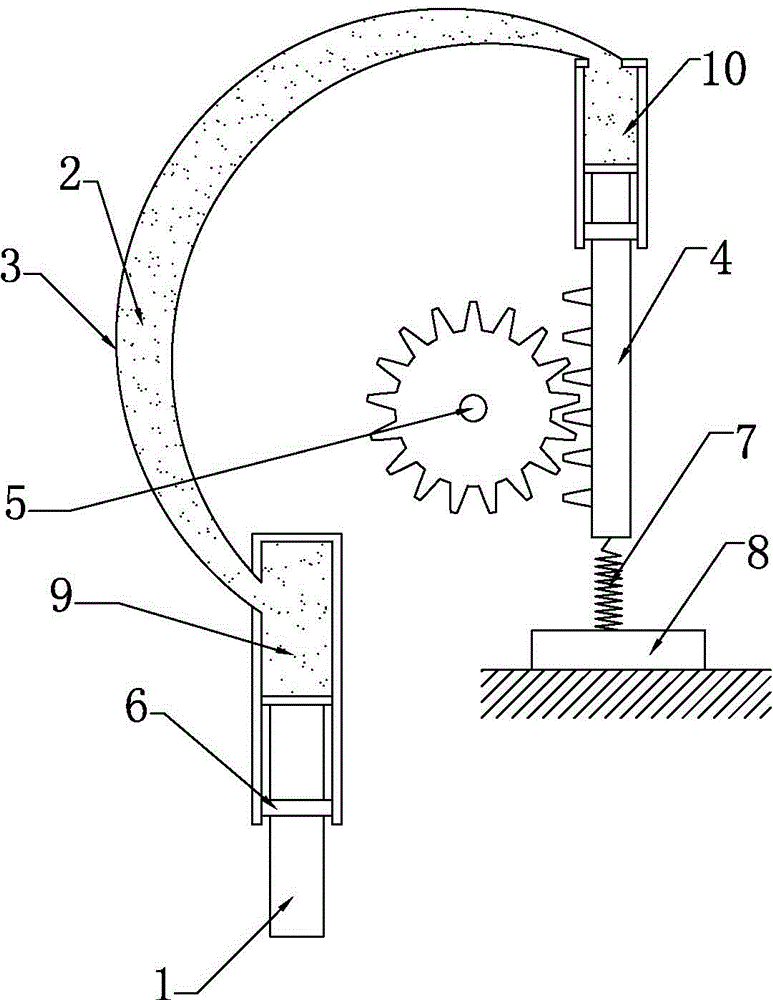

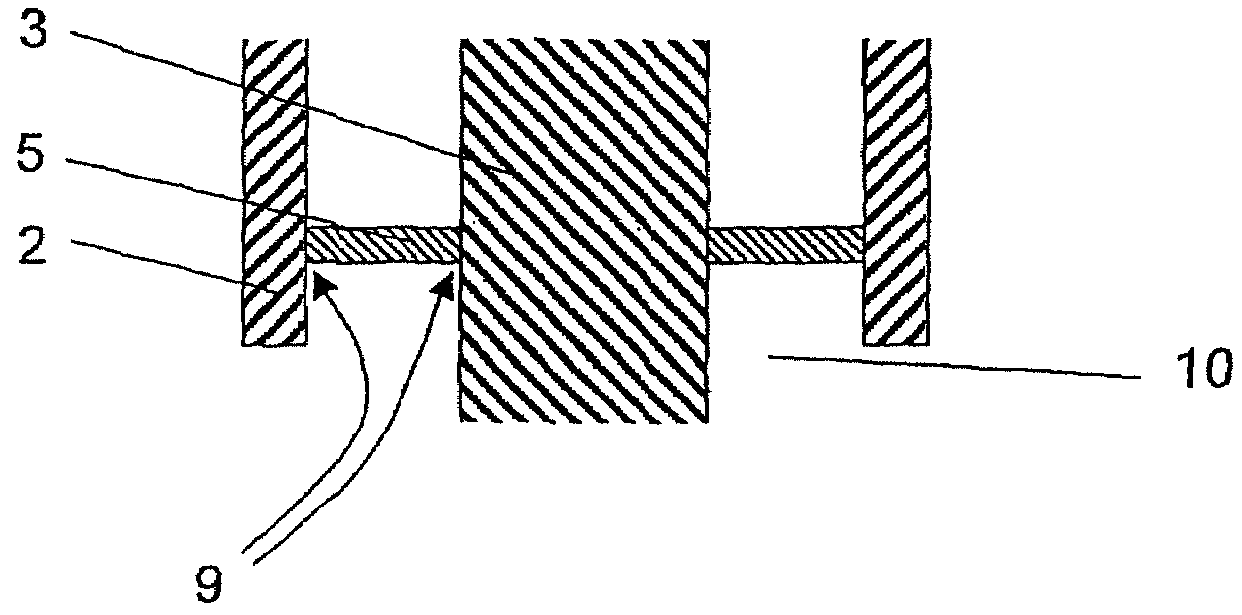

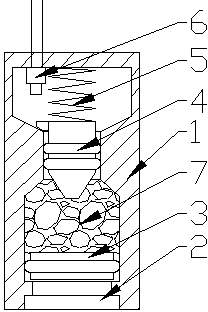

Full-automatic piston type pressure gauge

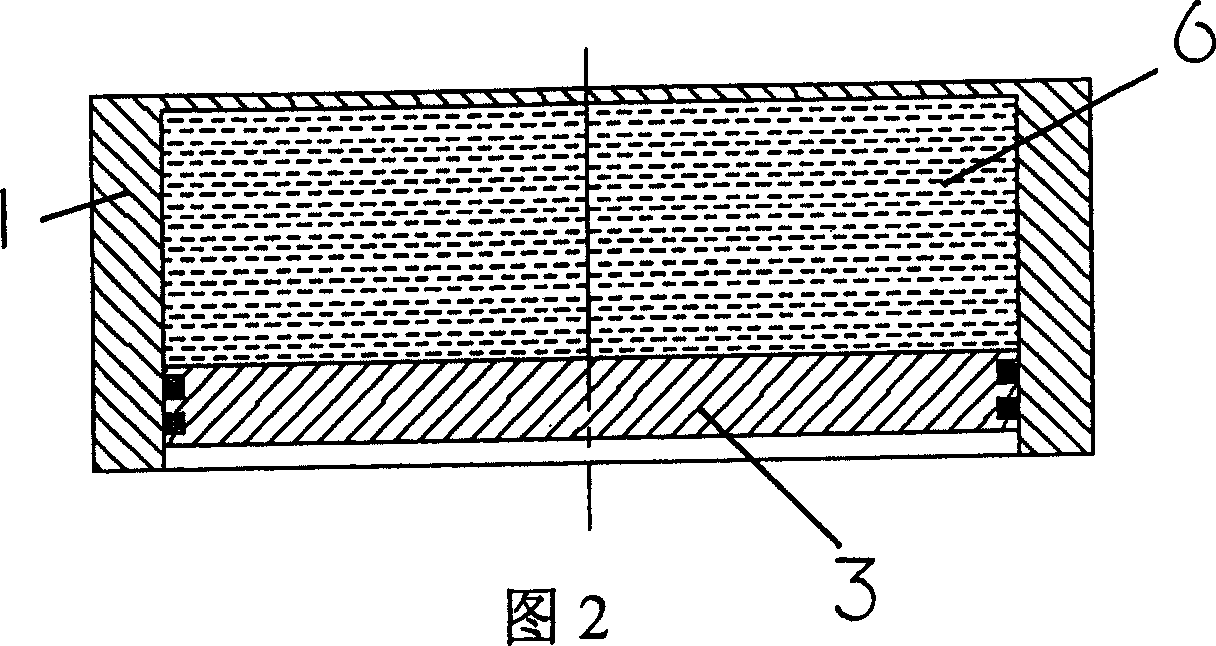

InactiveCN108801533ARealize automatic workHigh precisionFluid pressure measurement using pistonsHanging basketSelection system

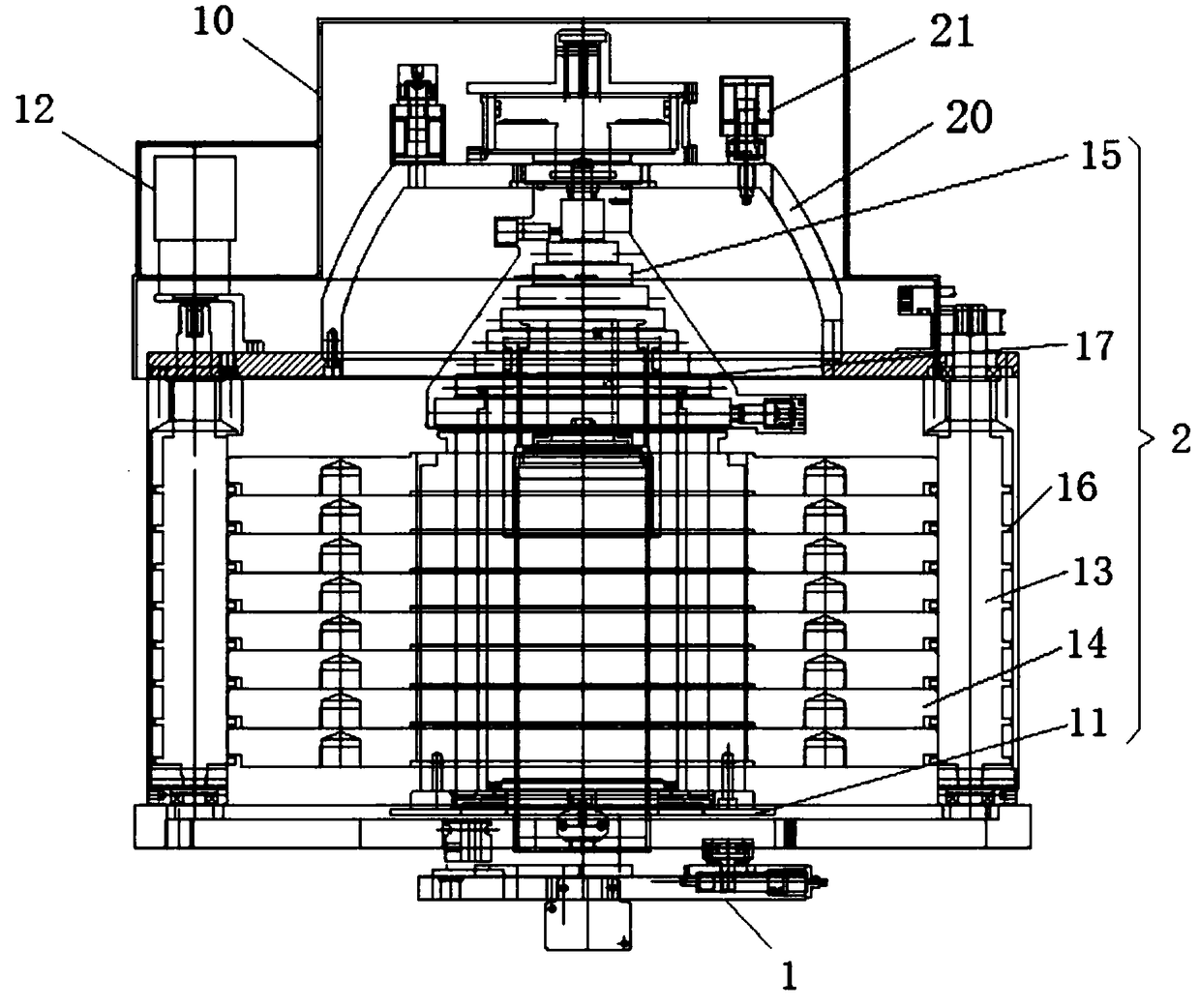

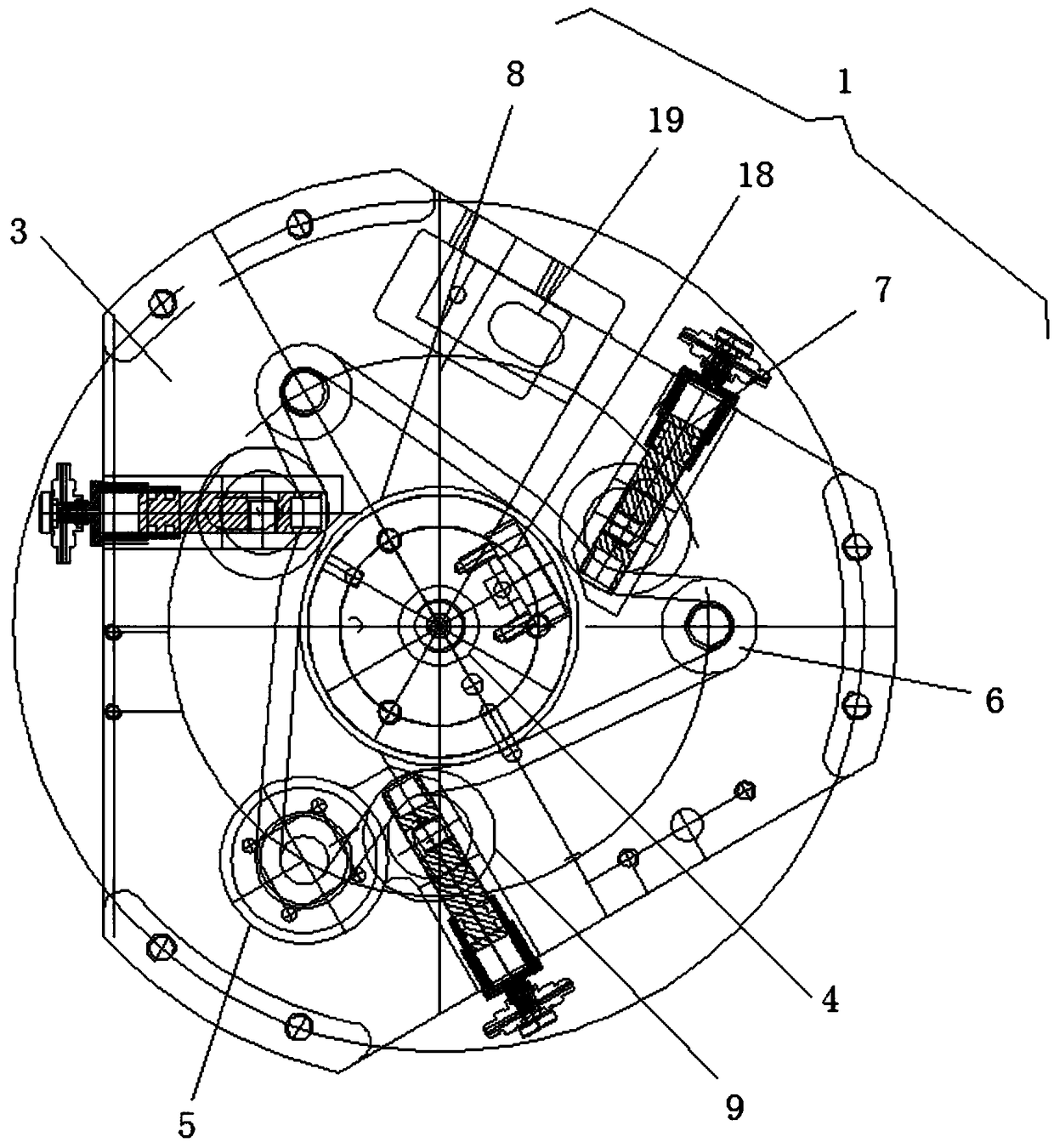

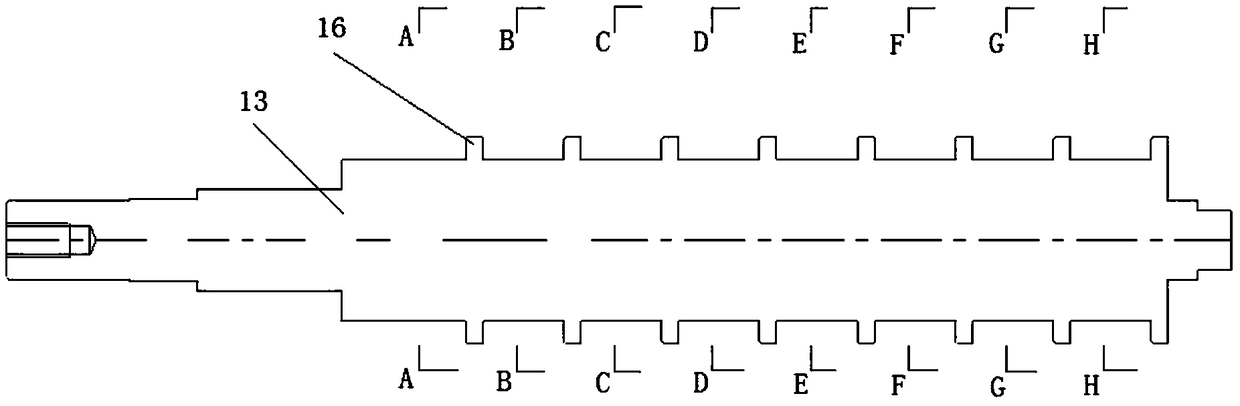

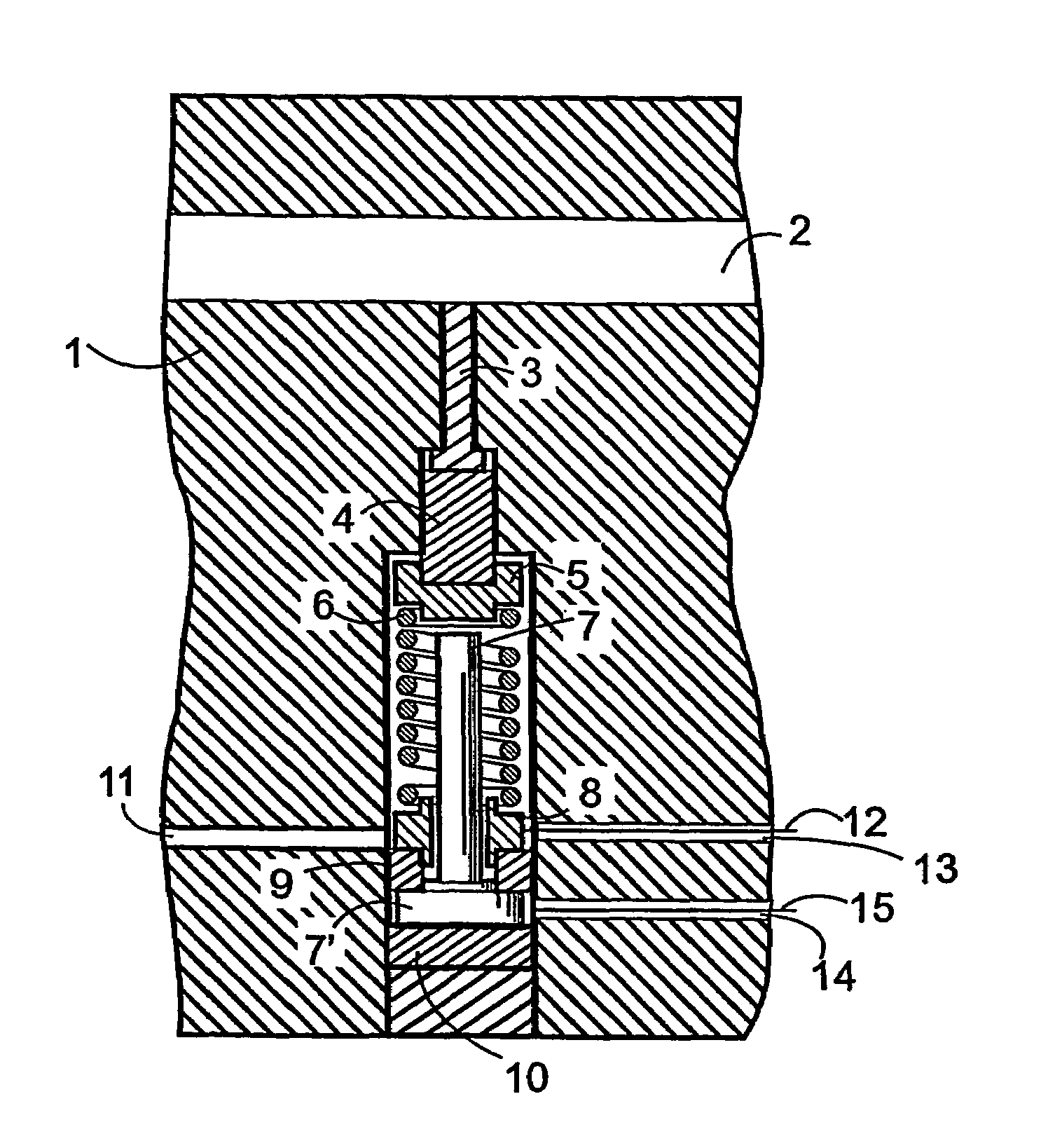

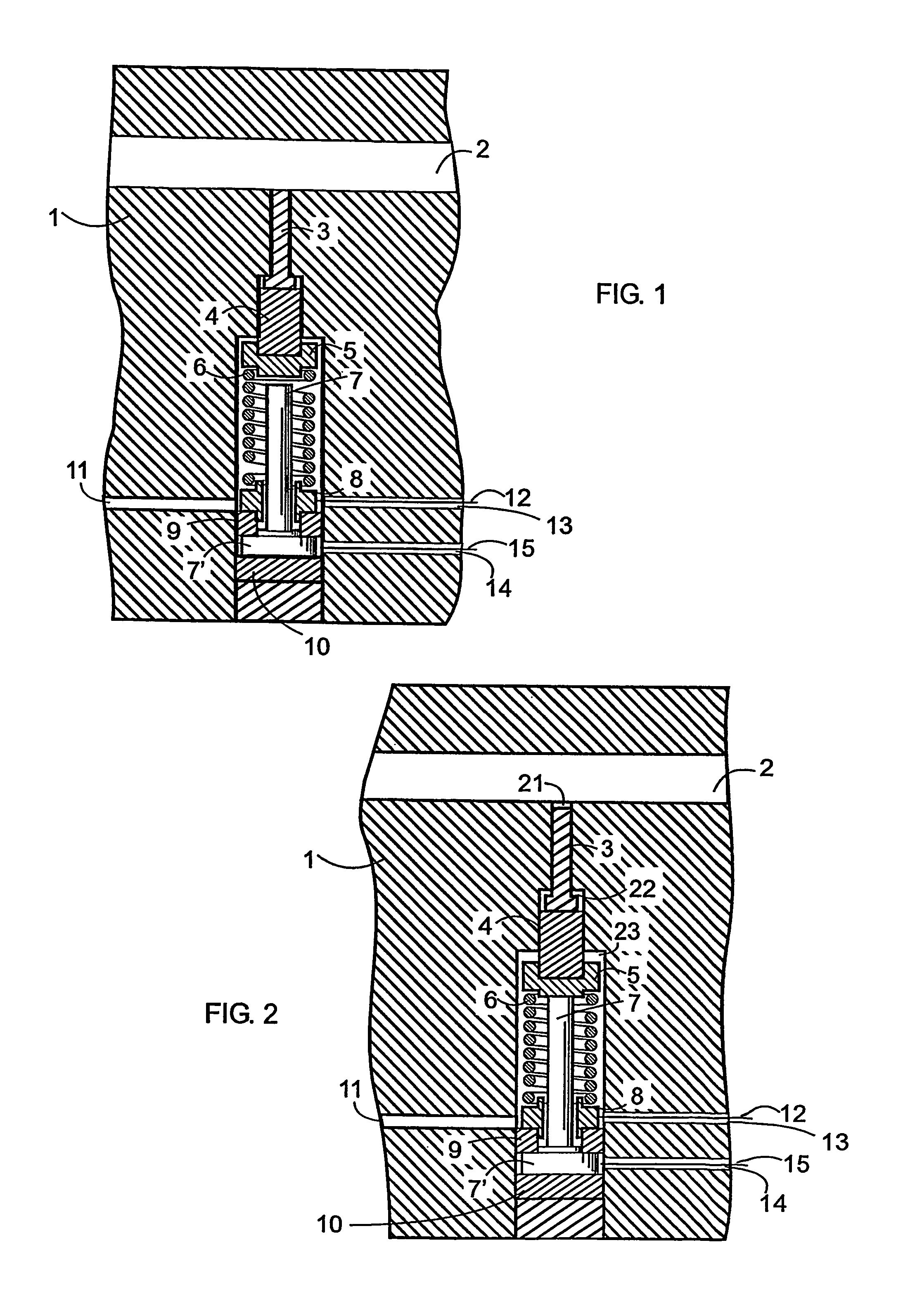

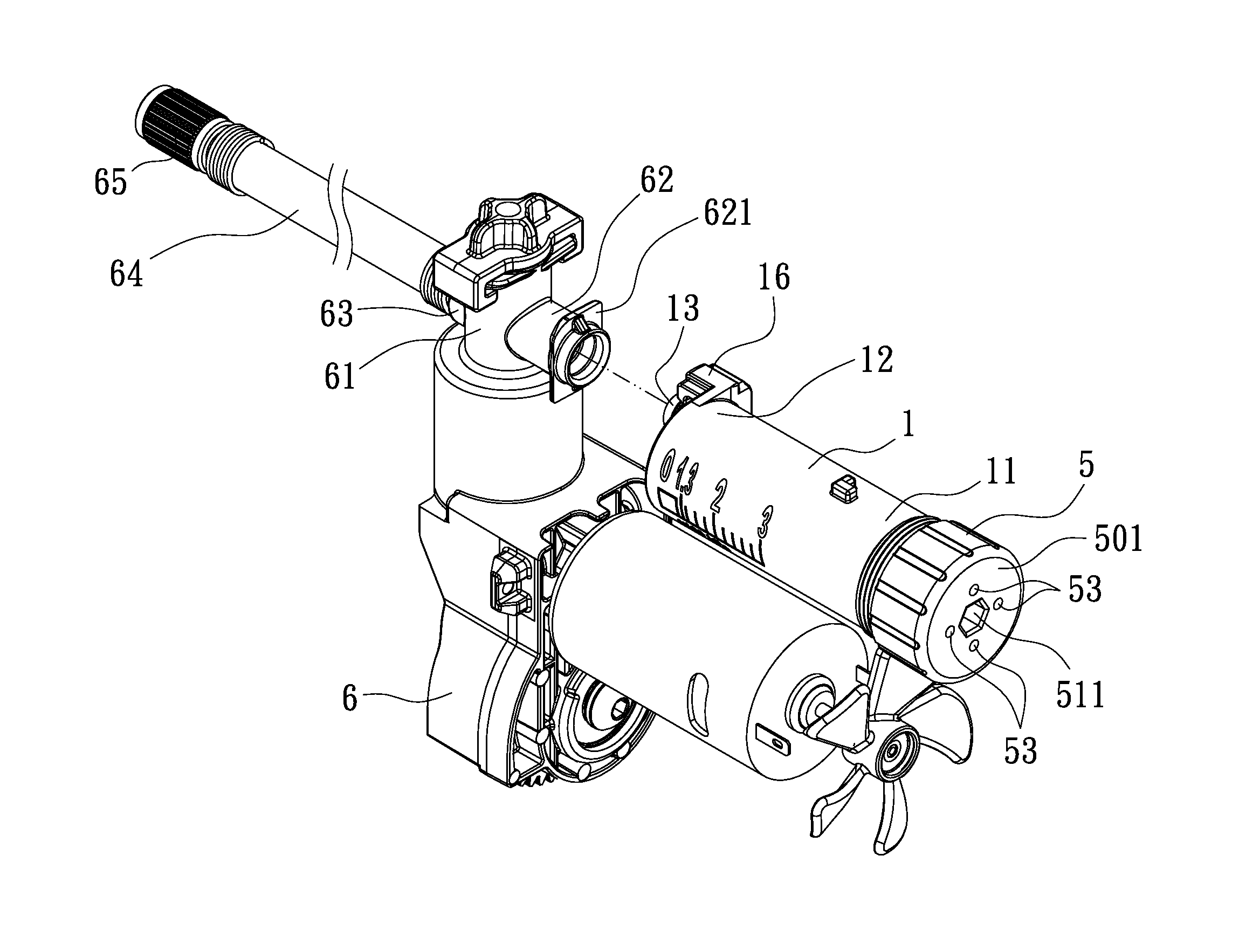

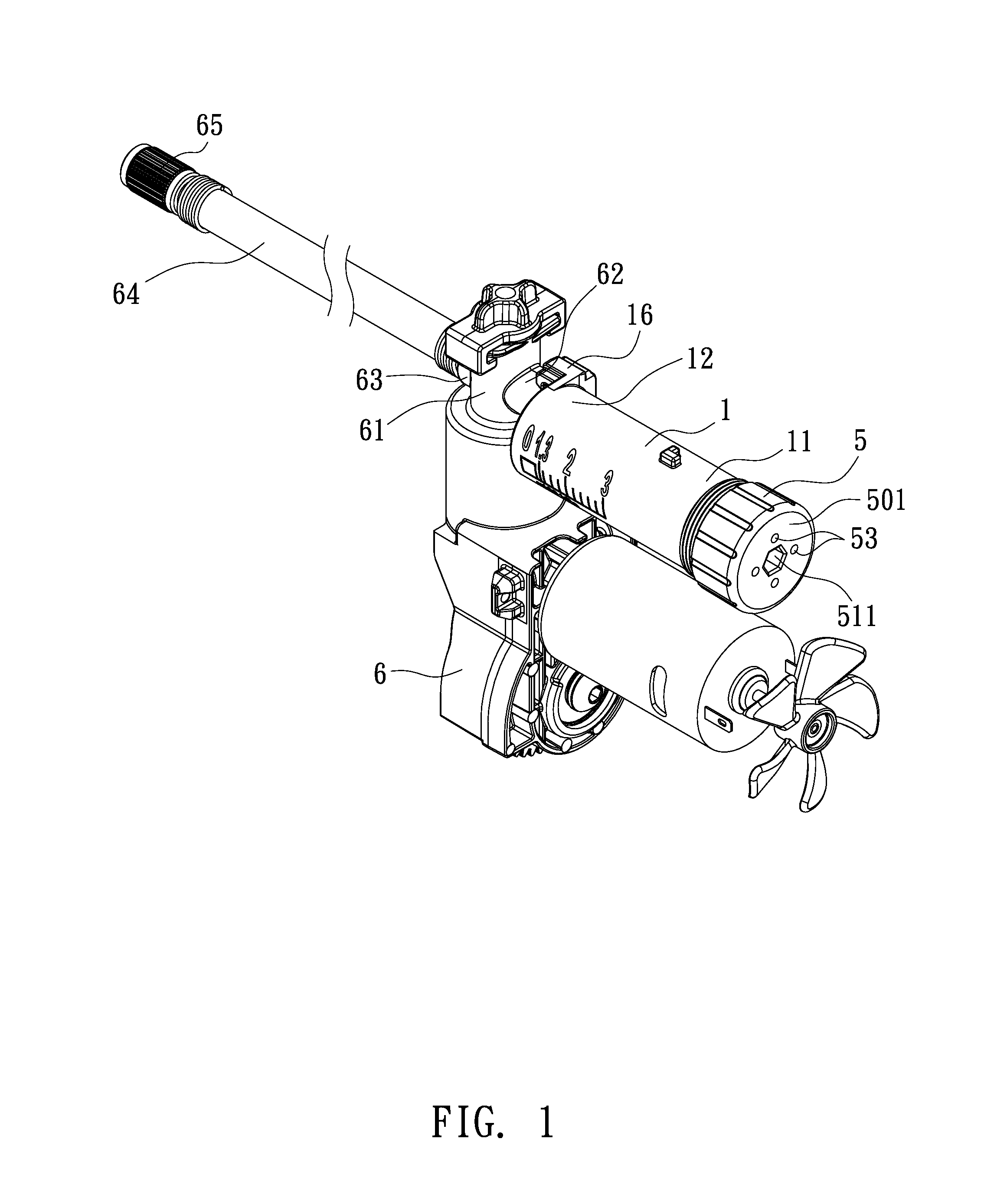

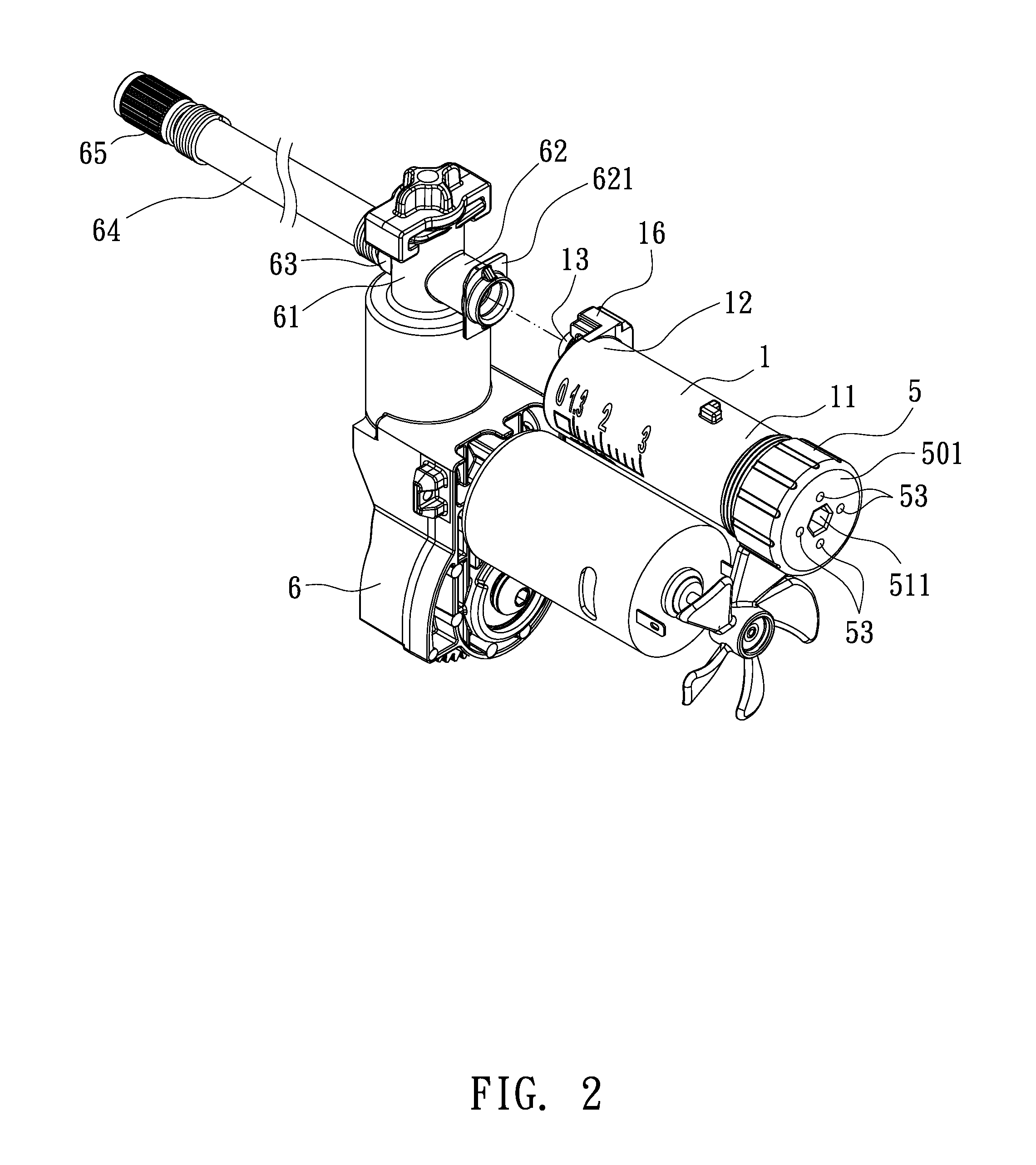

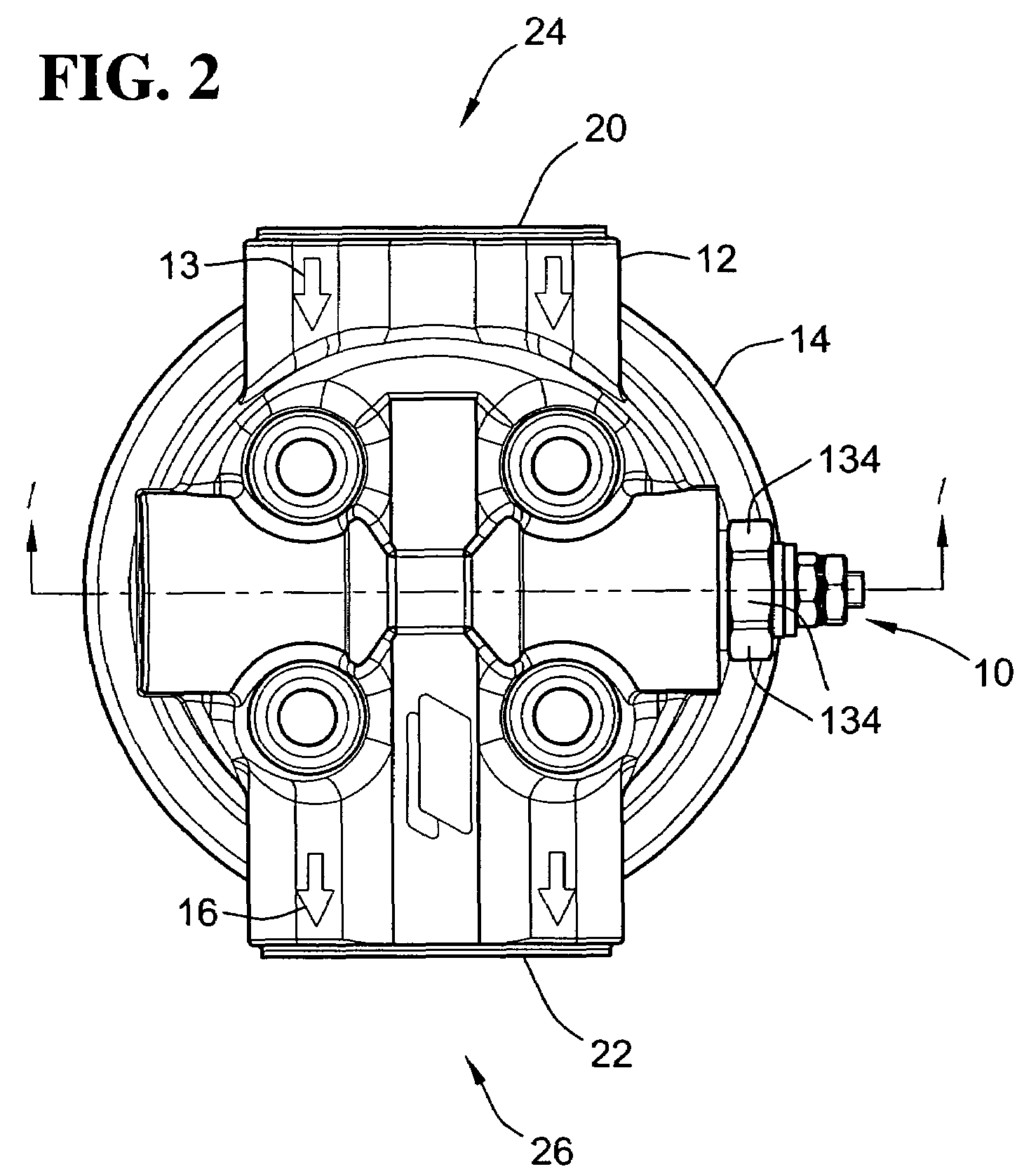

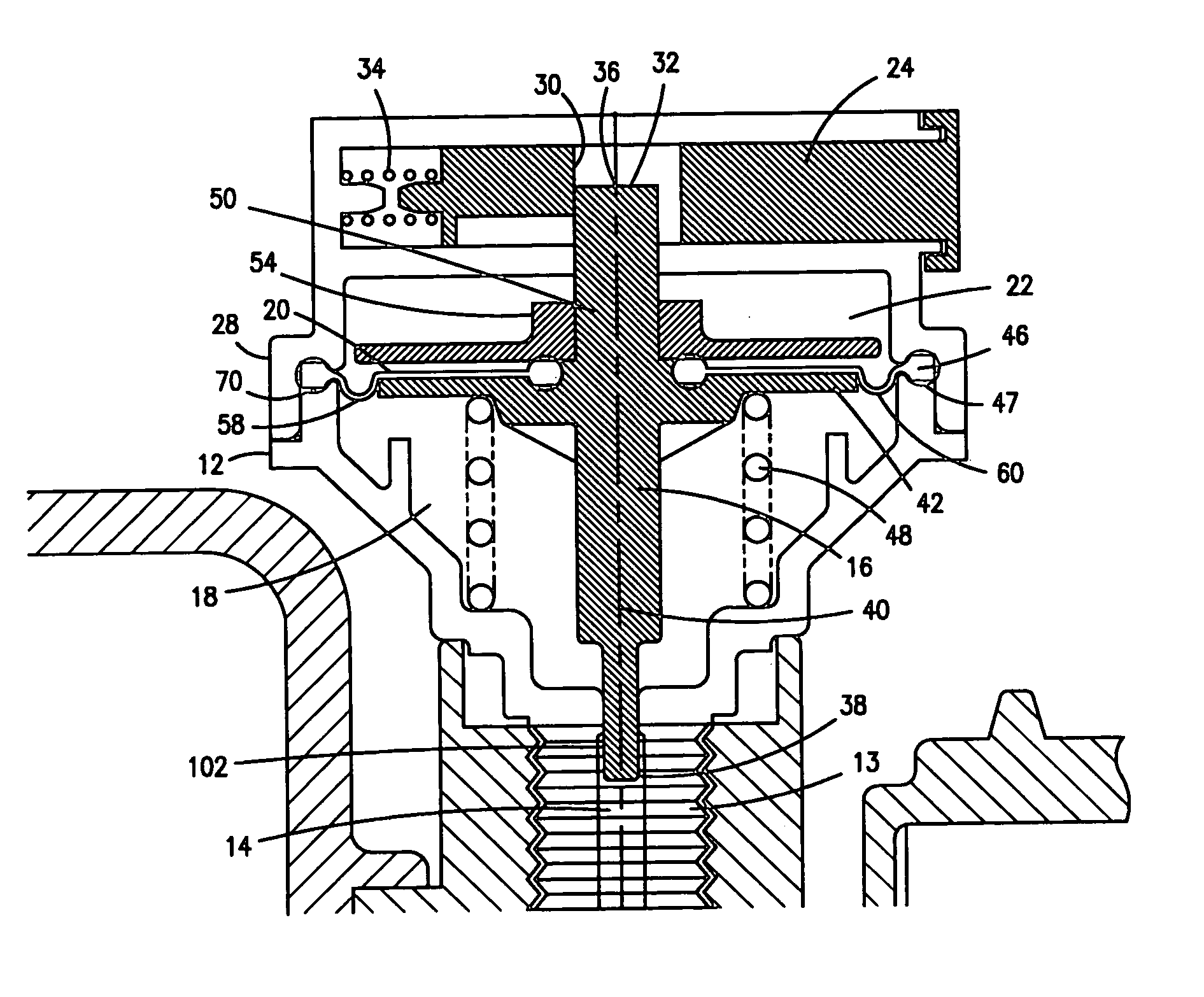

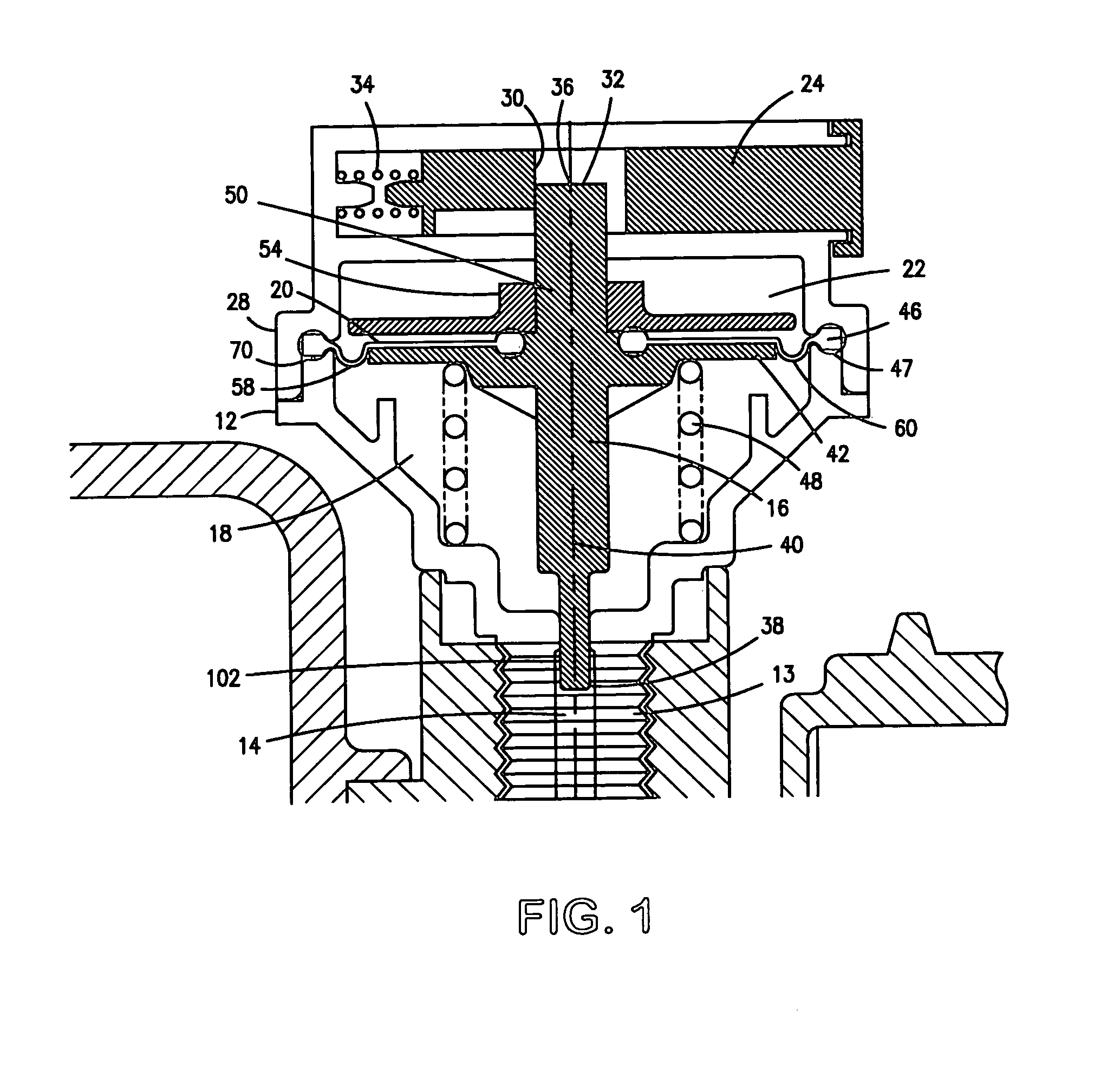

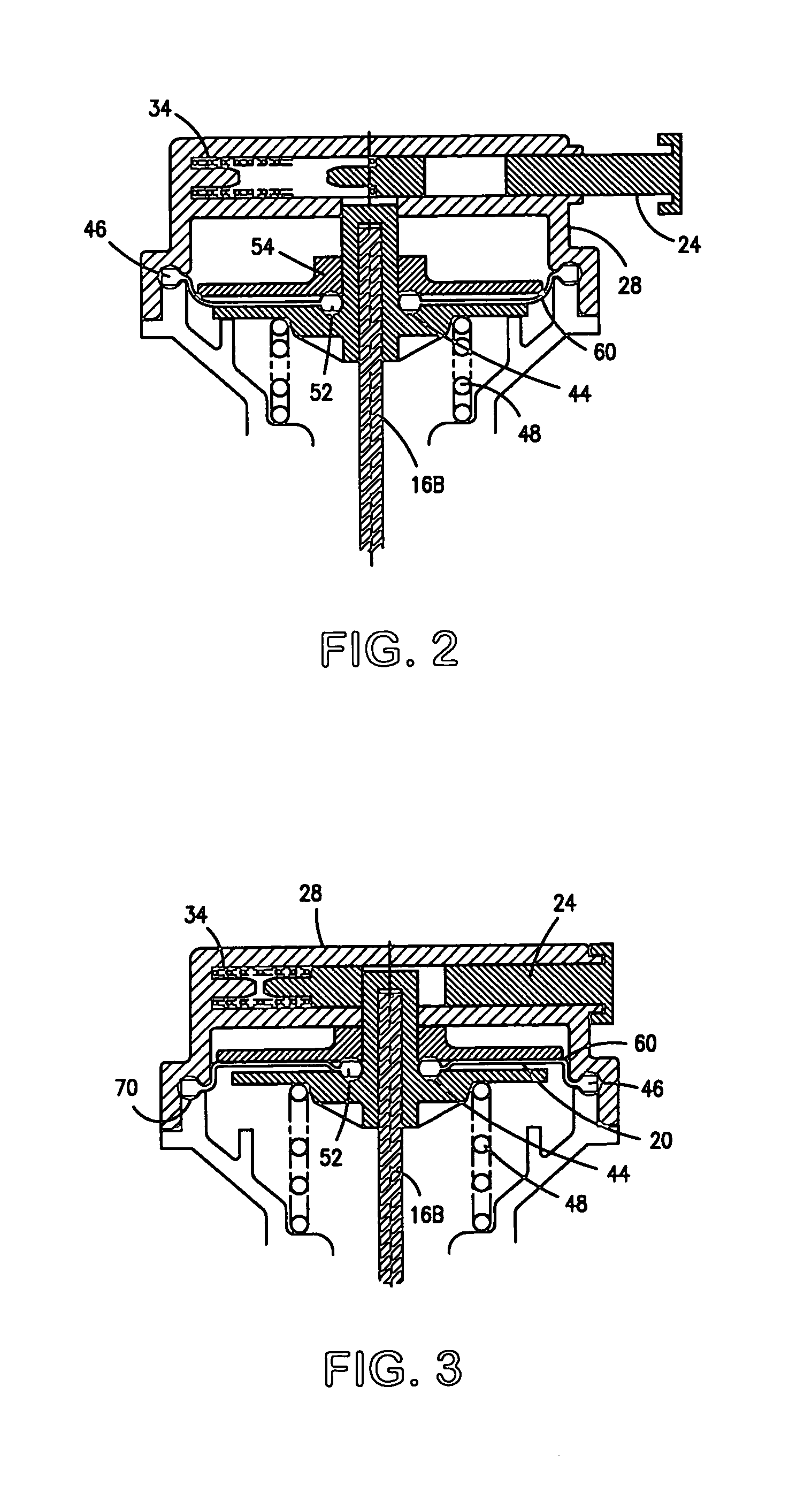

The invention discloses a full-automatic piston type pressure meter which comprises a piston rotating system (1) and a weight selection system (2), wherein the piston rotating system is located on atthe bottom of the weight selection system (2); an upper cover shell (10) is arranged at the top of the weight selection system (2); the piston rotating system (1) comprises a base (3), a central shaft(4), a first stepping motor (5), a belt wheel (6) and a tensioning piston (7), wherein the weight selection system (2) comprises an upper cover shell (10), a hanging basket (11), a second stepping motor (12) and a plurality of guide columns (13). The automatic work of the measuring device is achieved through cooperation of electrical components, the error of manual operation is avoided, and the detection efficiency and accuracy are improved.

Owner:上海敏榆实业有限公司

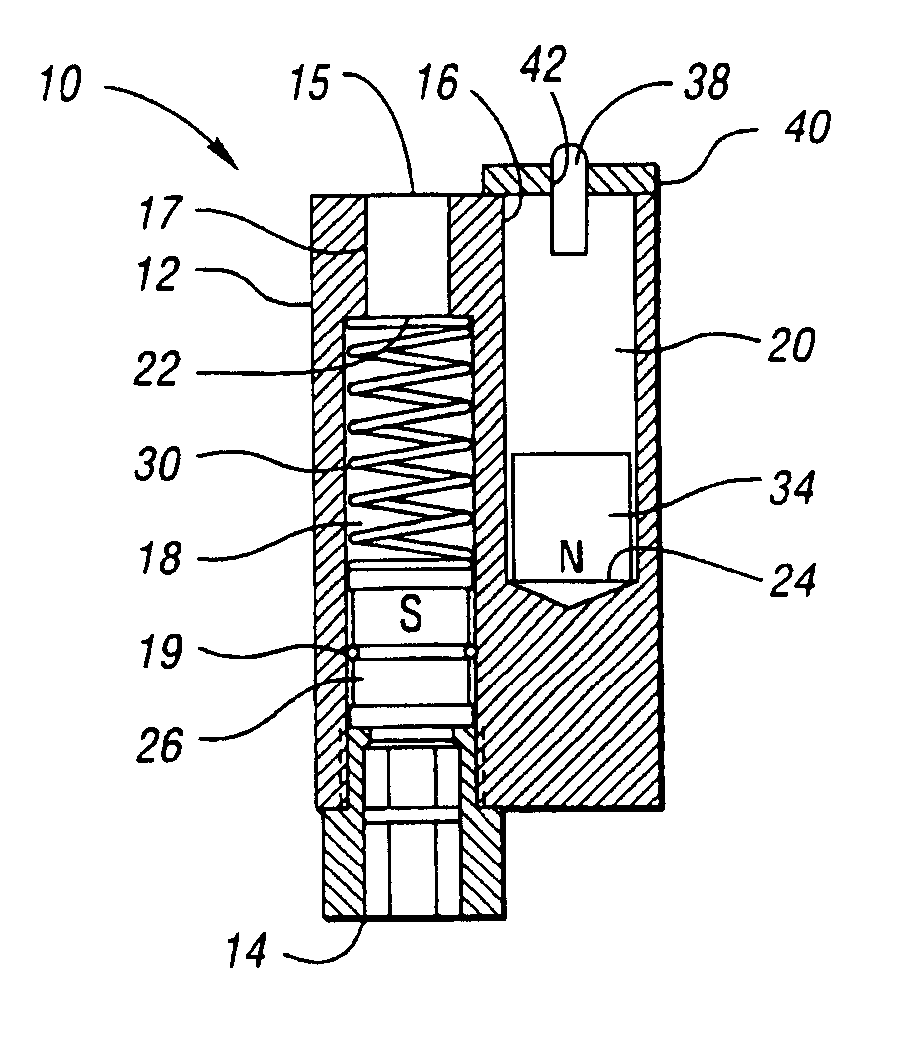

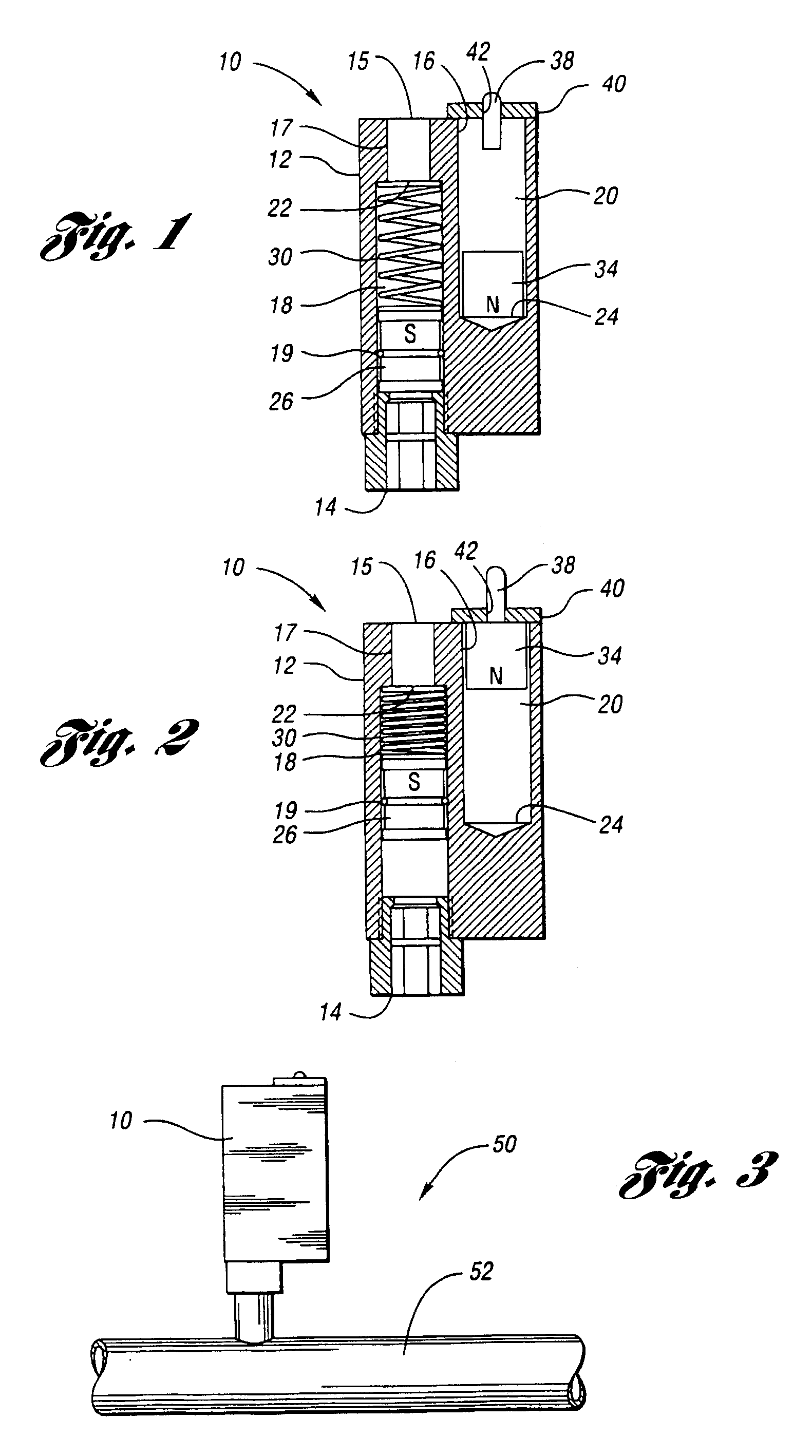

Apparatus for detecting pressure

ActiveUS7360432B2Electrical controlFluid pressure measurement by electric/magnetic elementsCombustionHigh pressure

The present invention relates to apparatuses for detecting fuel pressure in internal combustion engines. The invention especially relates to internal combustion engine applications in which fuel reaches a high pressure. The apparatus according to the invention is a simple switch apparatus. In the apparatus the fuel pressure moves a piston causing a switching operation in the apparatus, which in turn can be detected by means of a separate detector.

Owner:WARTSILA FINLAND OY

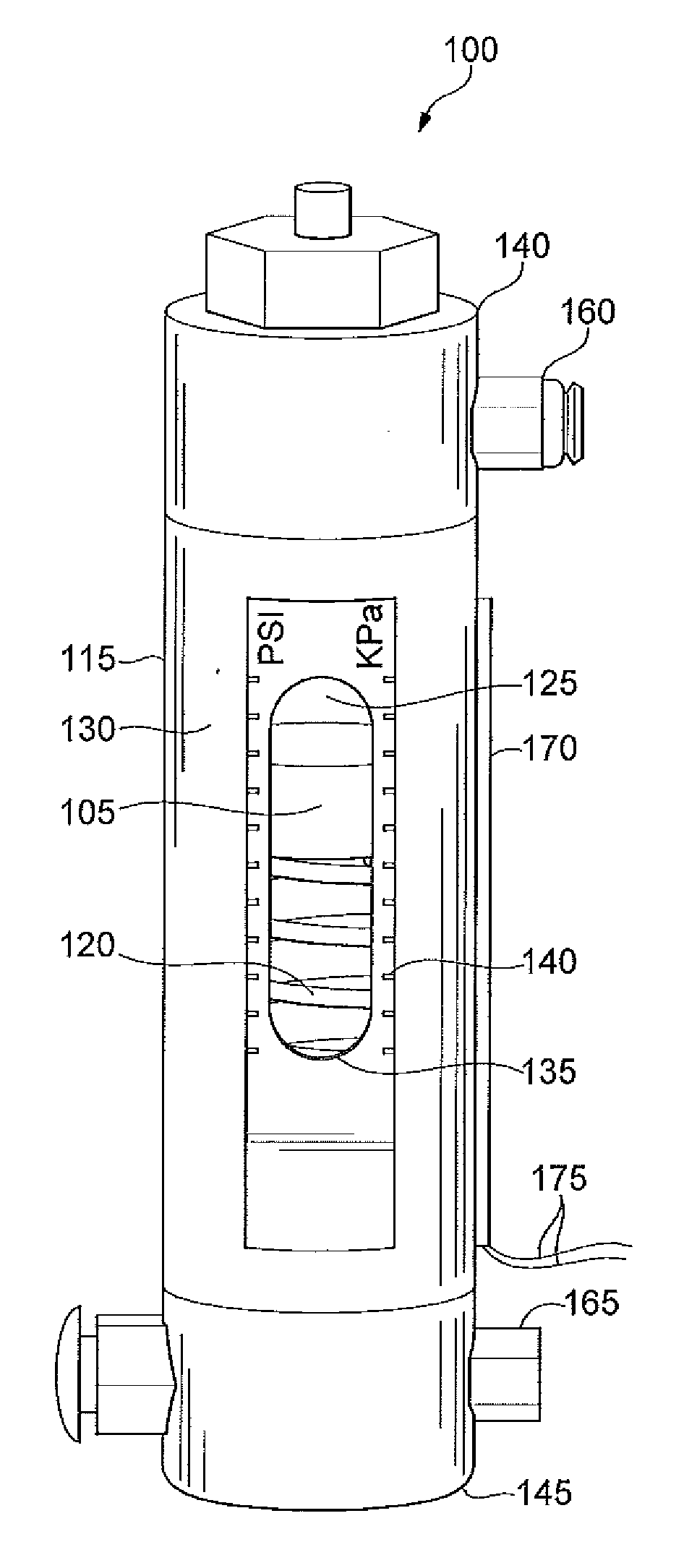

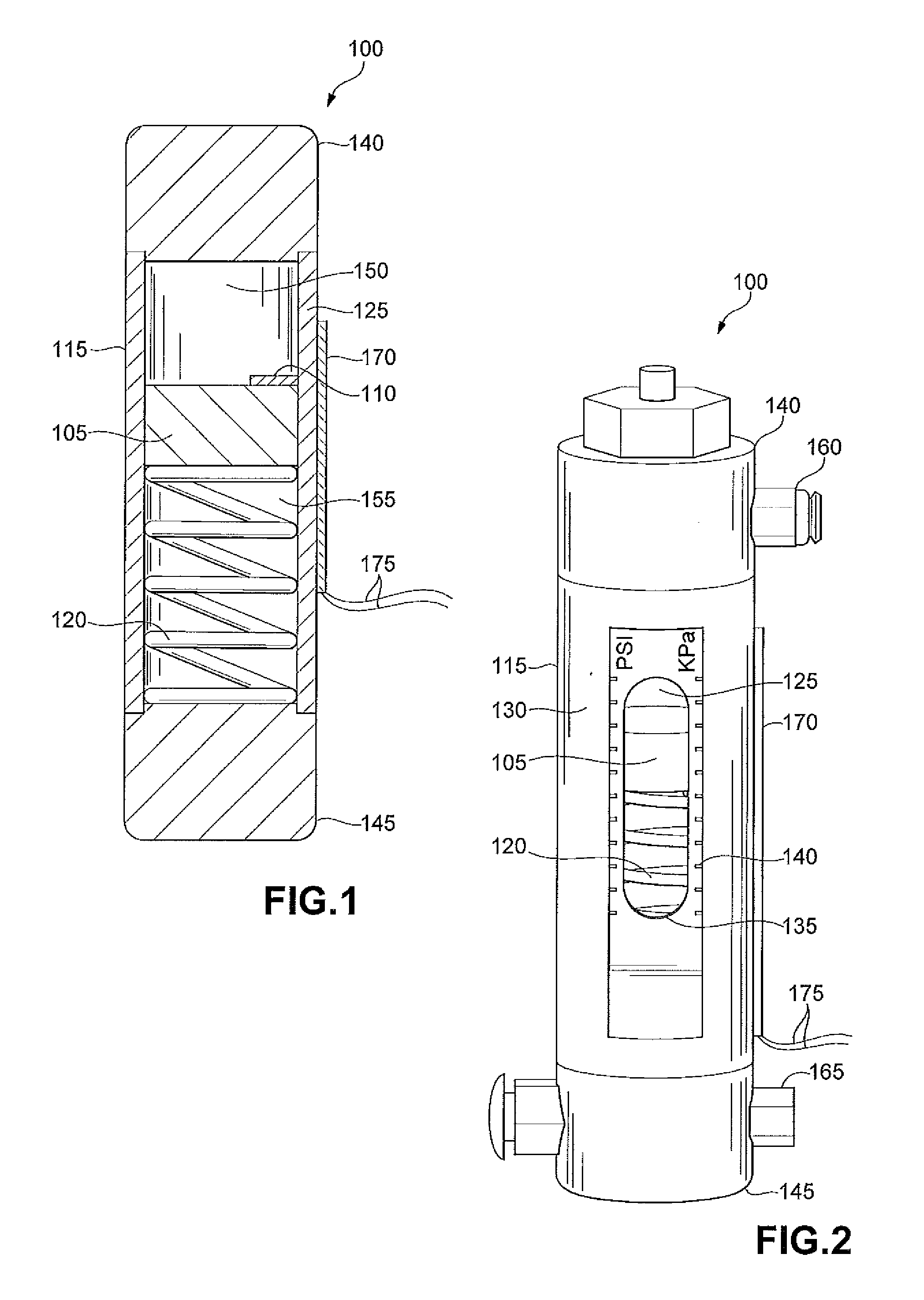

Differential pressure gauge

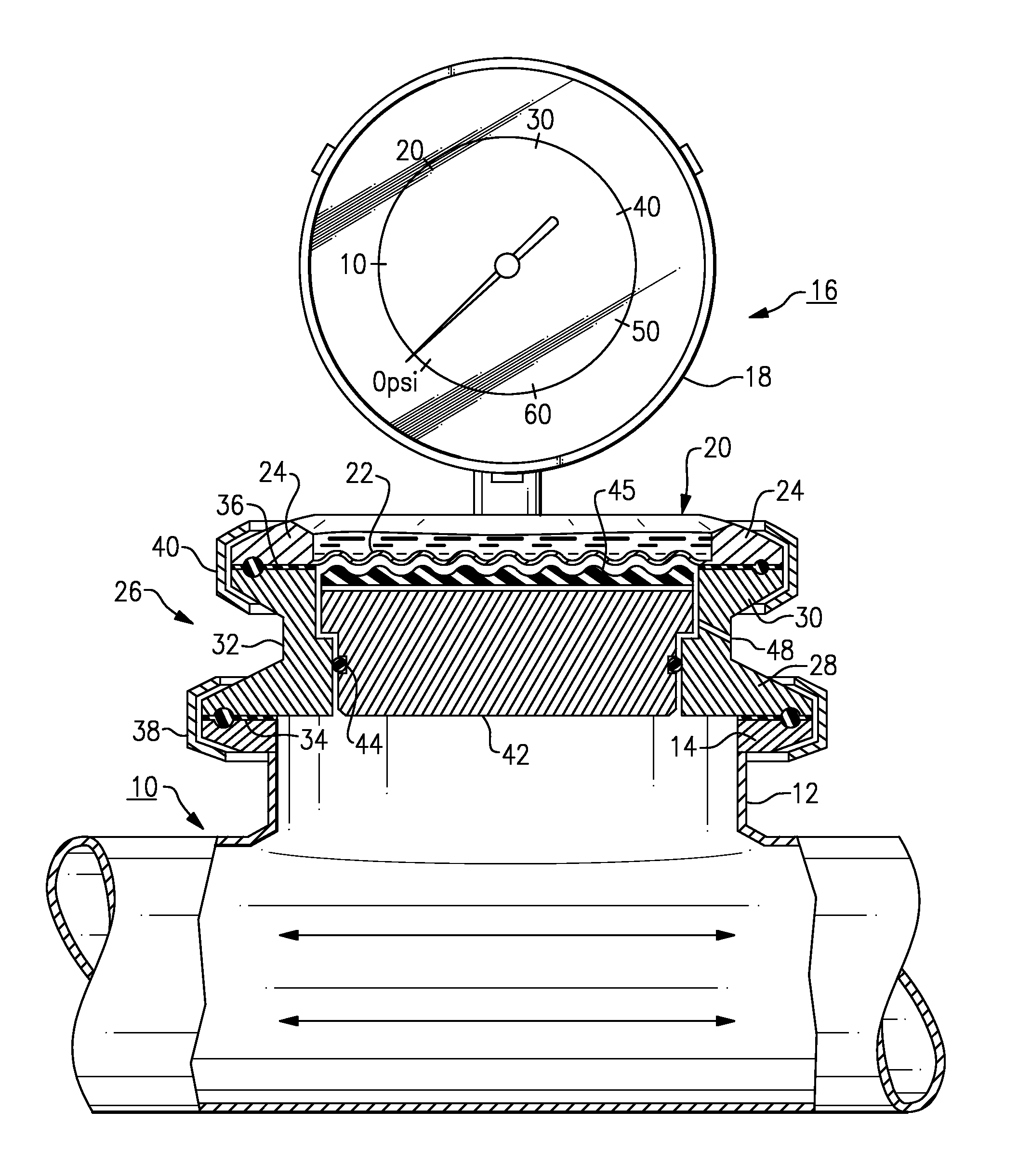

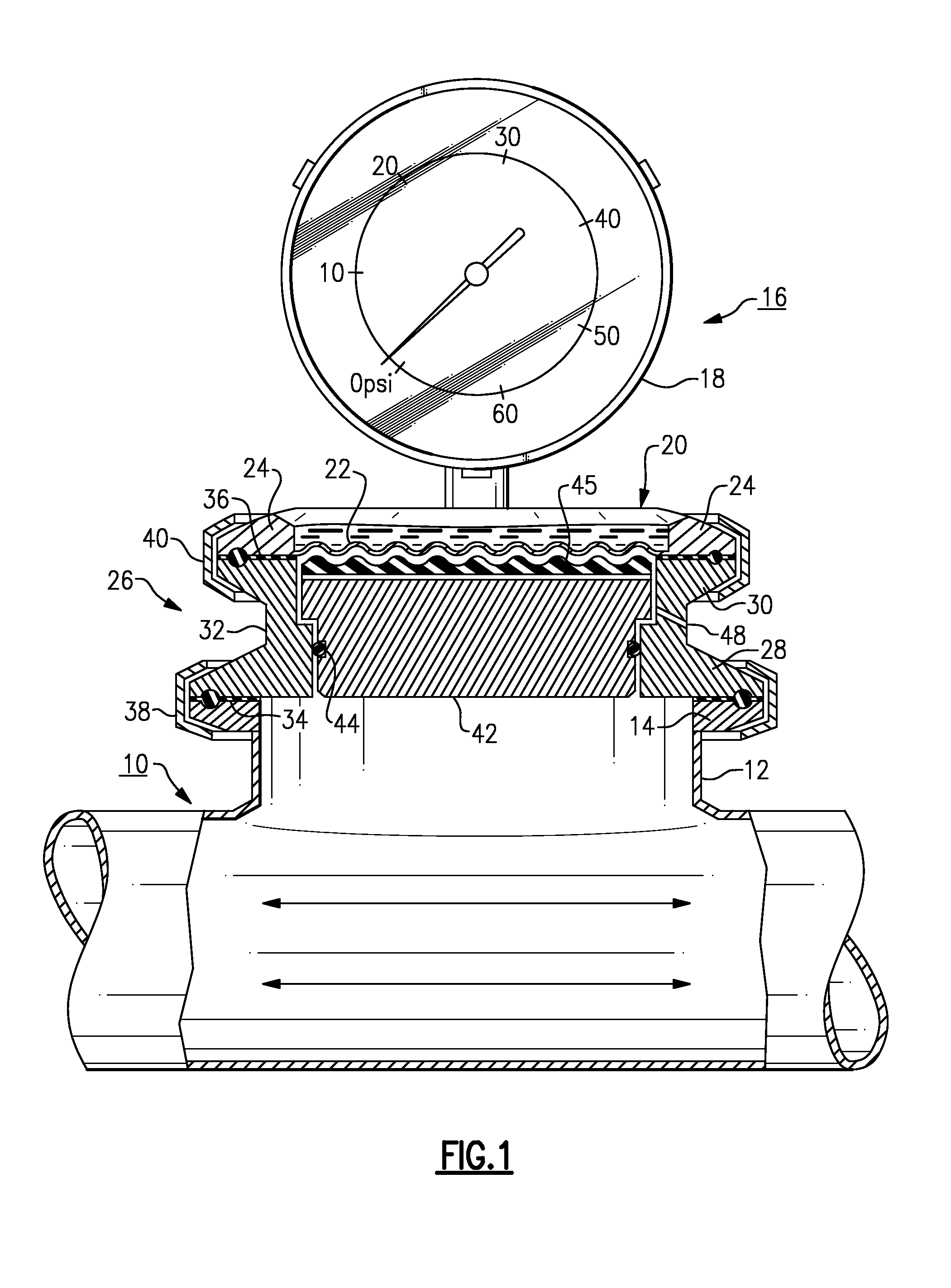

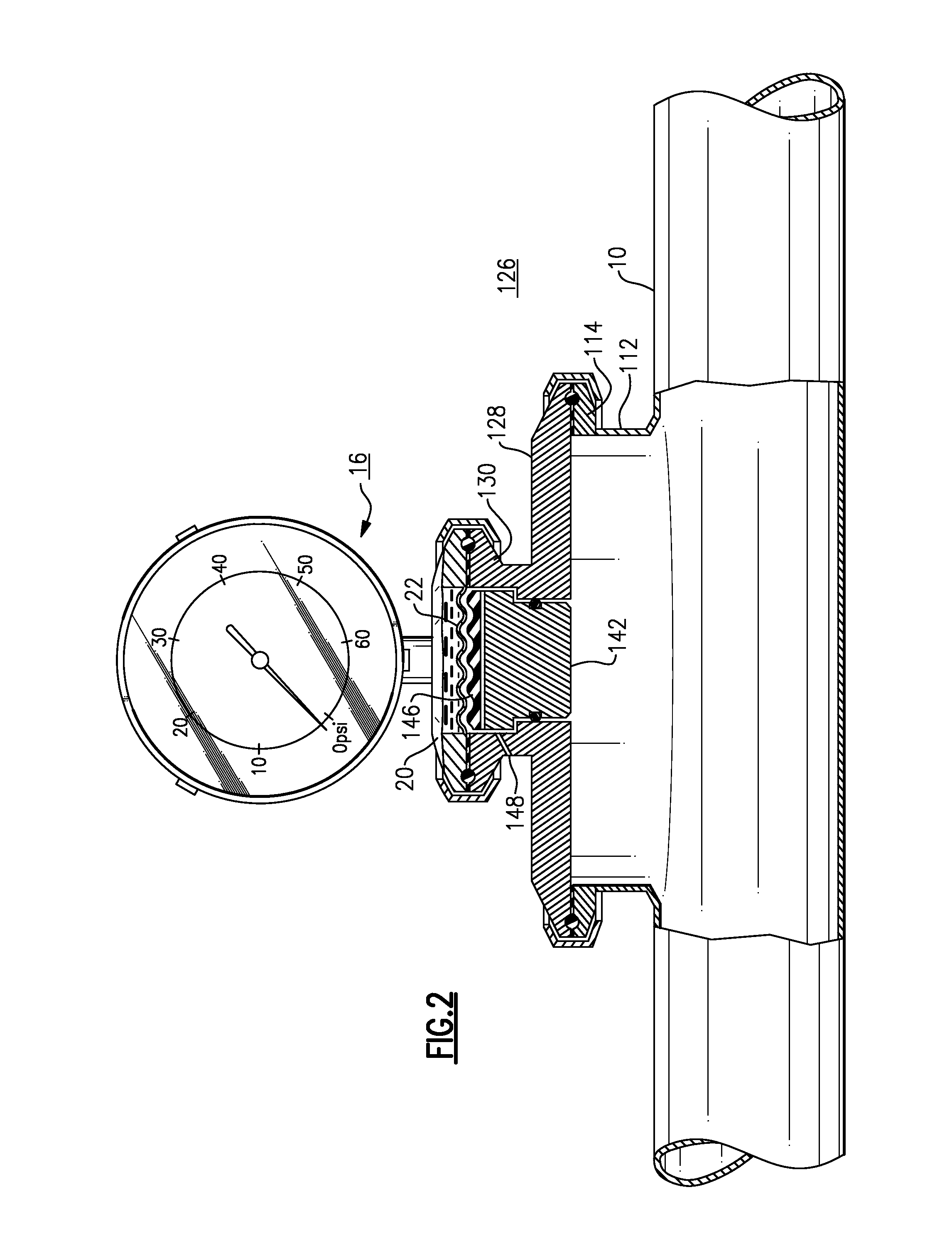

ActiveUS20130291645A1Error minimizationMaximize reliabilityFluid pressure measurement using pistonsPressure difference measurement between multiple valvesEngineeringPressure difference

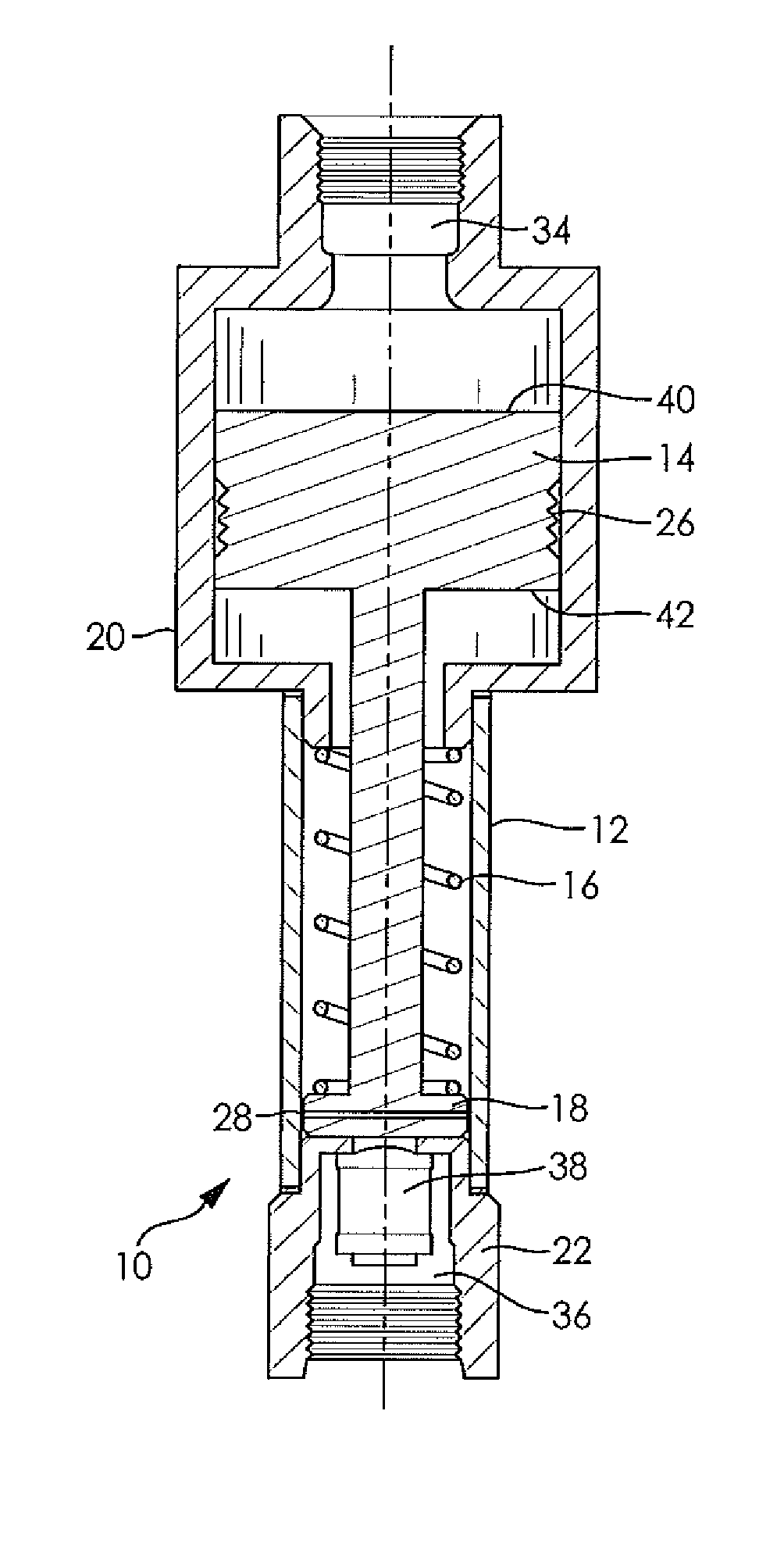

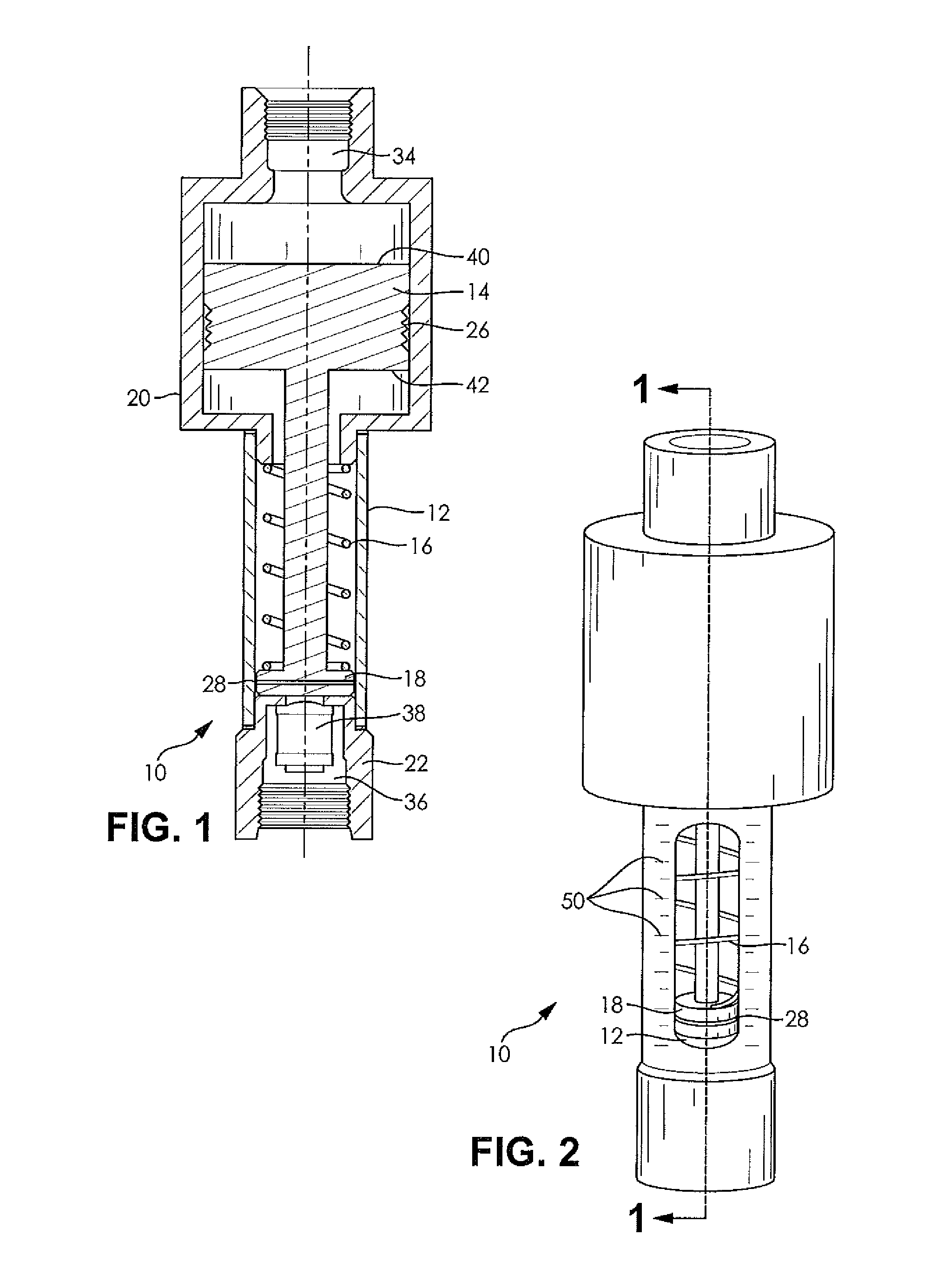

A pressure gauge including a hollow cylinder, a first housing member having a first pressure inlet disposed at a first end of the cylinder, and a second housing member having a second pressure inlet disposed at a second end of the cylinder. The pressure gauge also includes a piston slidably disposed in the first housing member. The piston includes a remote indicator coupled to an end of the piston. At least a portion of the remote indicator extends into the hollow cylinder. A spring is disposed in the cylinder abutting the remote indicator and urges the remote indicator toward the second housing member. An increased pressure difference between the first pressure inlet and the second pressure inlet causes the remote indicator to move away from the second housing member and toward the first housing member, and the remote indicator provides a measure of the pressure difference relative to indicia included on the pressure gauge.

Owner:GAMMON JAMES H

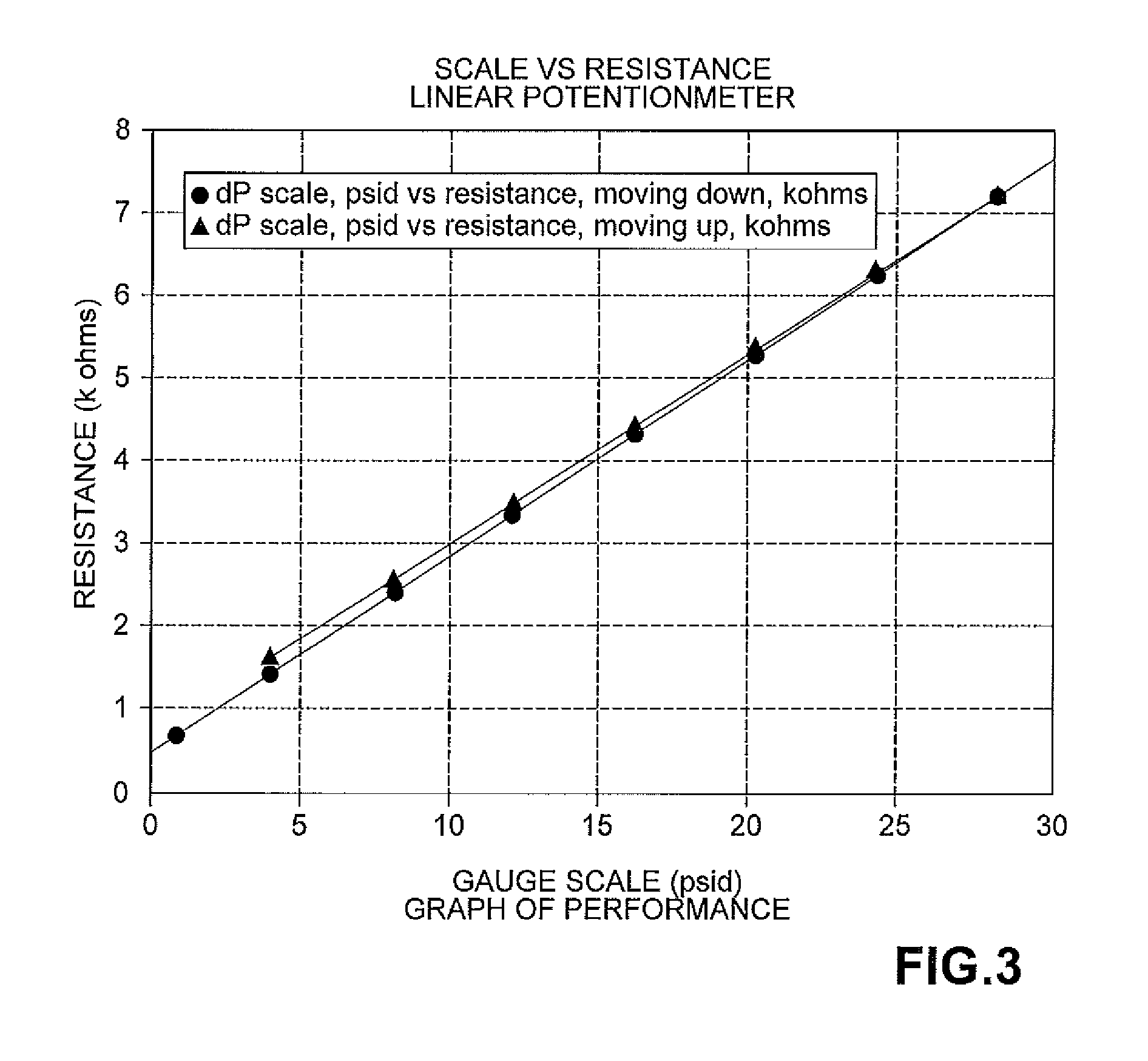

Electronic readout for piston-type differential pressure gauge

InactiveUS20120036937A1Fluid pressure measurement by electric/magnetic elementsFluid pressure measurement using pistonsElectrical resistance and conductanceDifferential pressure

A piston-type differential pressure gauge provides an electronic output for remote monitoring. A linear potentiometer, in communication with a magnetic portion of the piston of the gauge, tracks the location of the piston. Resistance change in the potentiometer can be used by an electronic circuit to provide the electronic output of the differential pressure remotely to a data acquisition system or control electronics.

Owner:PARKER HANNIFIN CORP

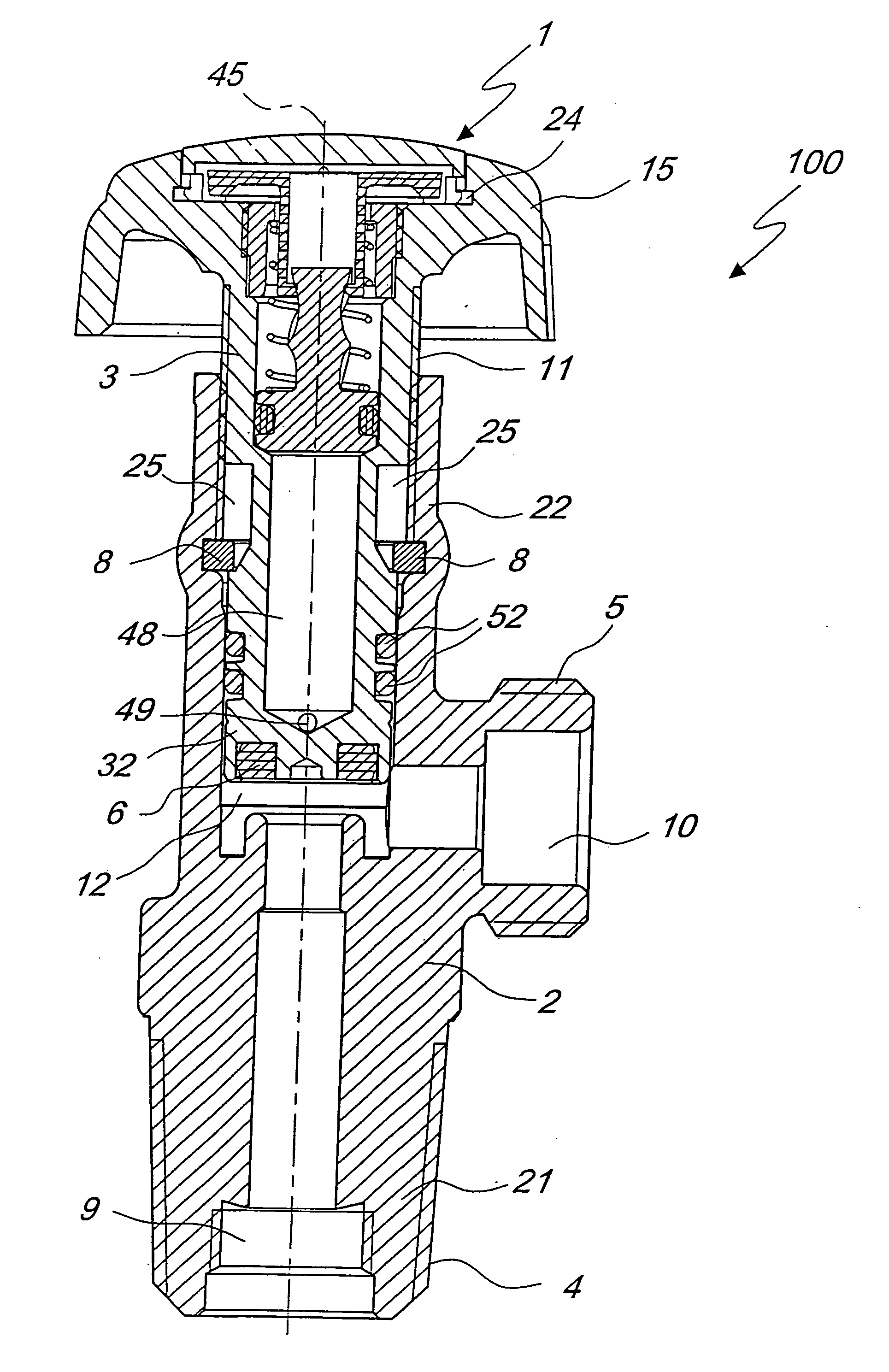

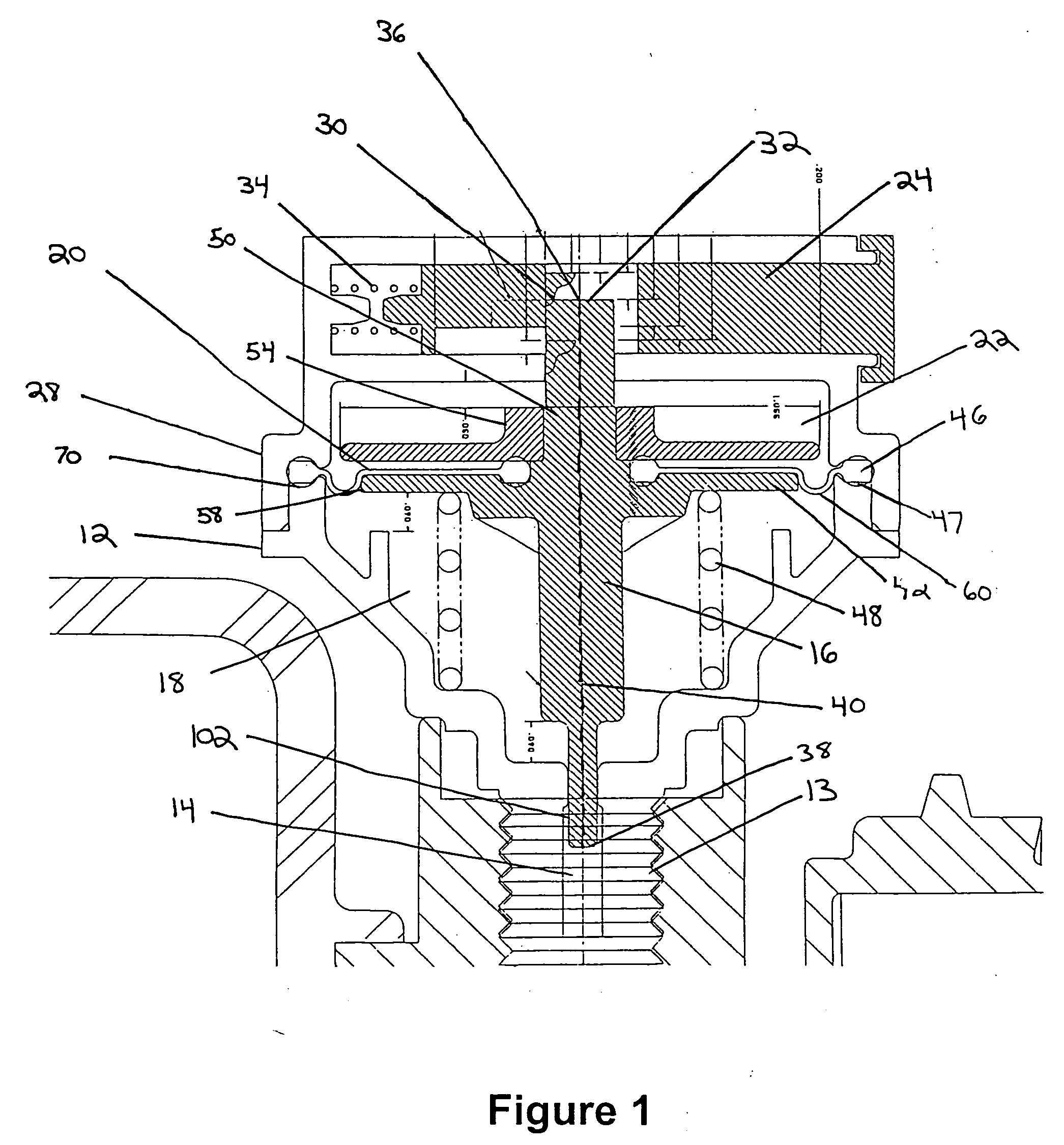

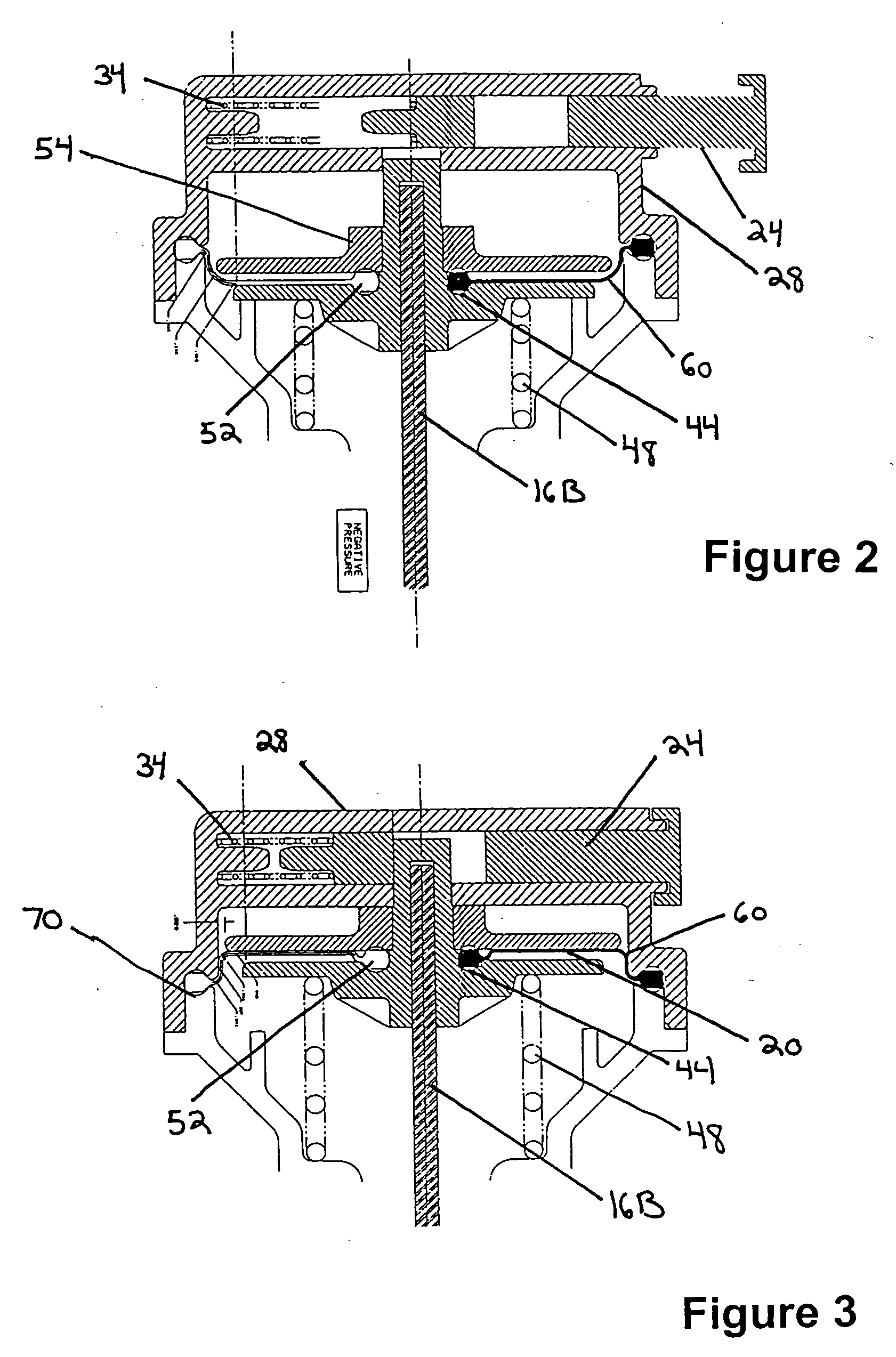

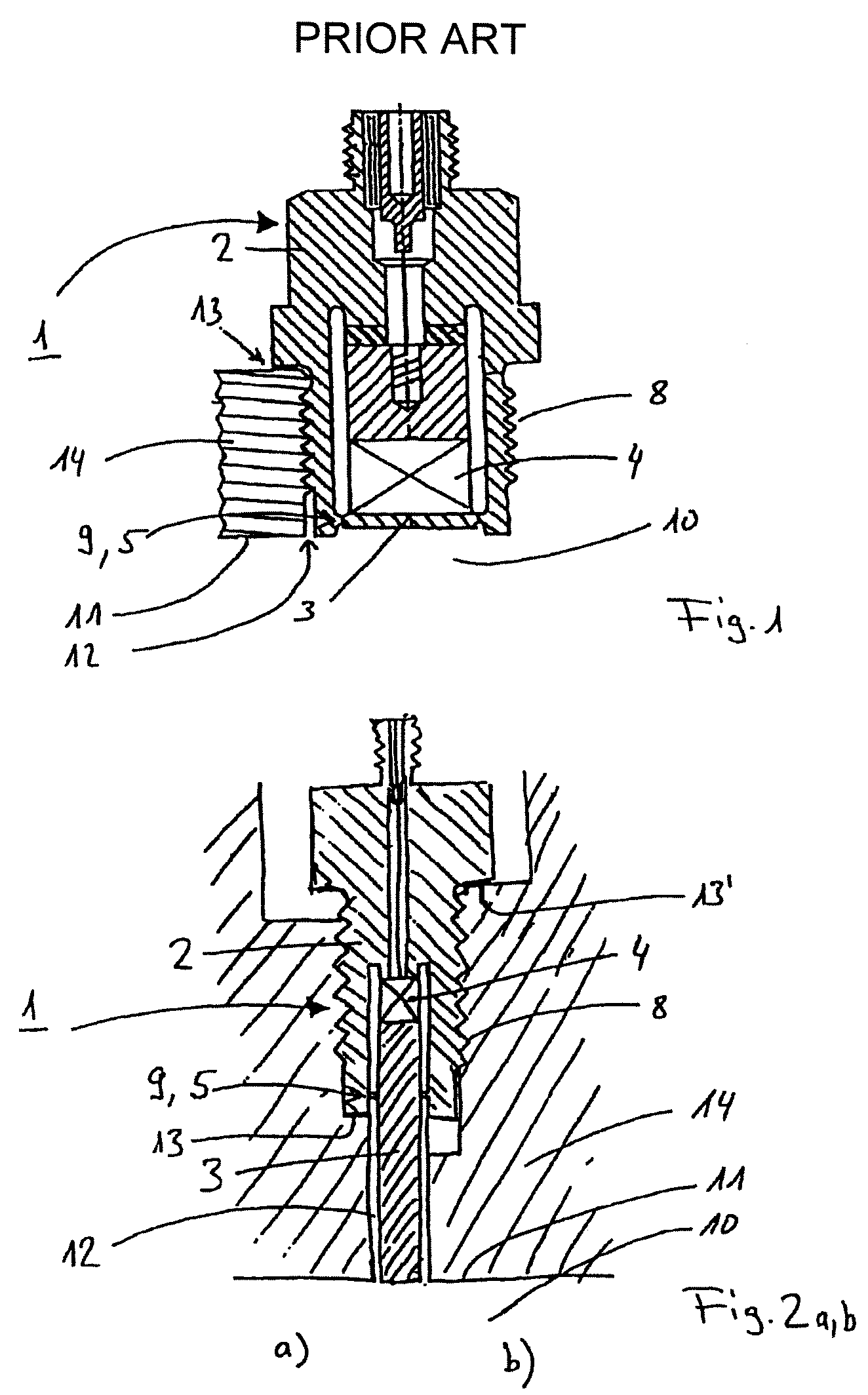

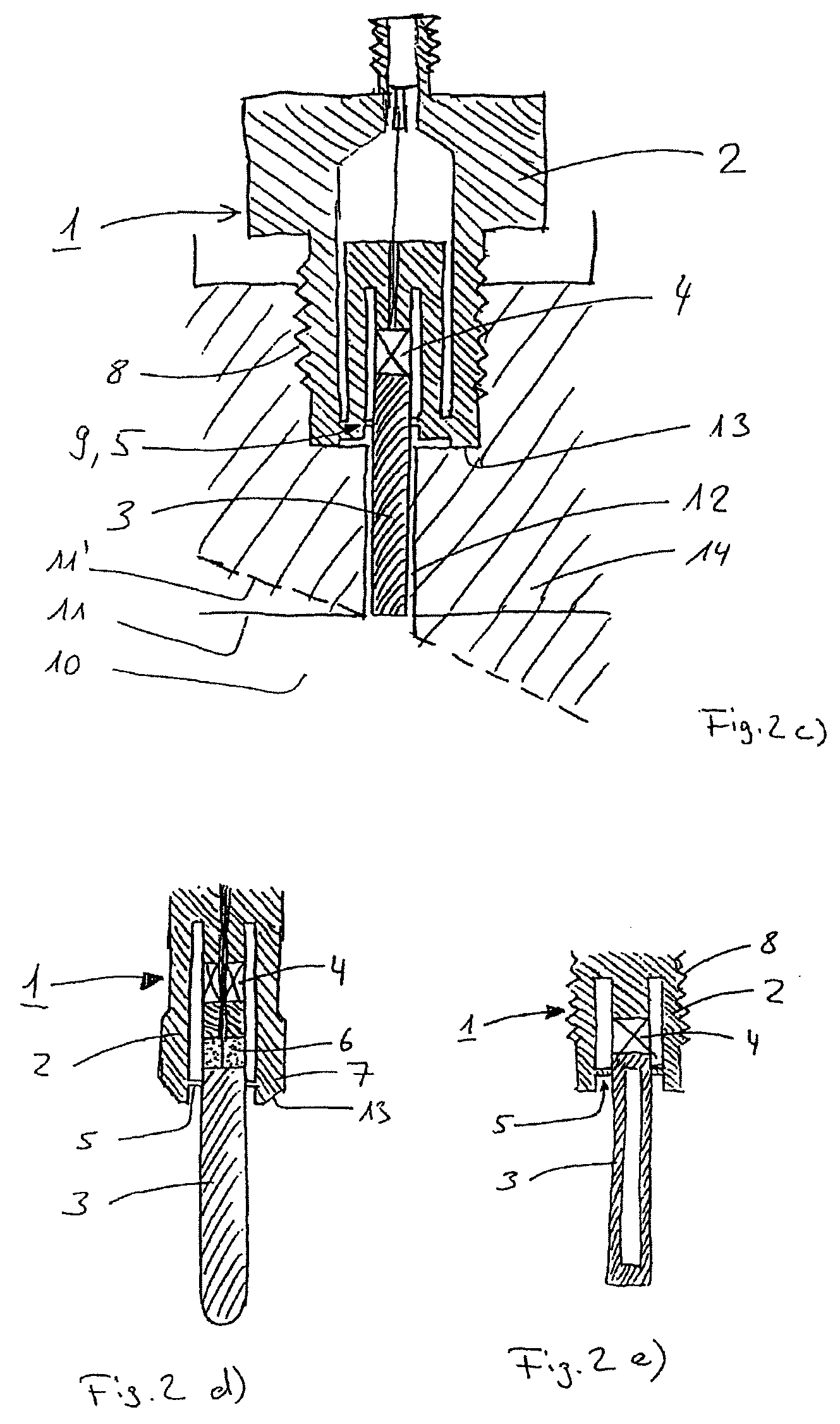

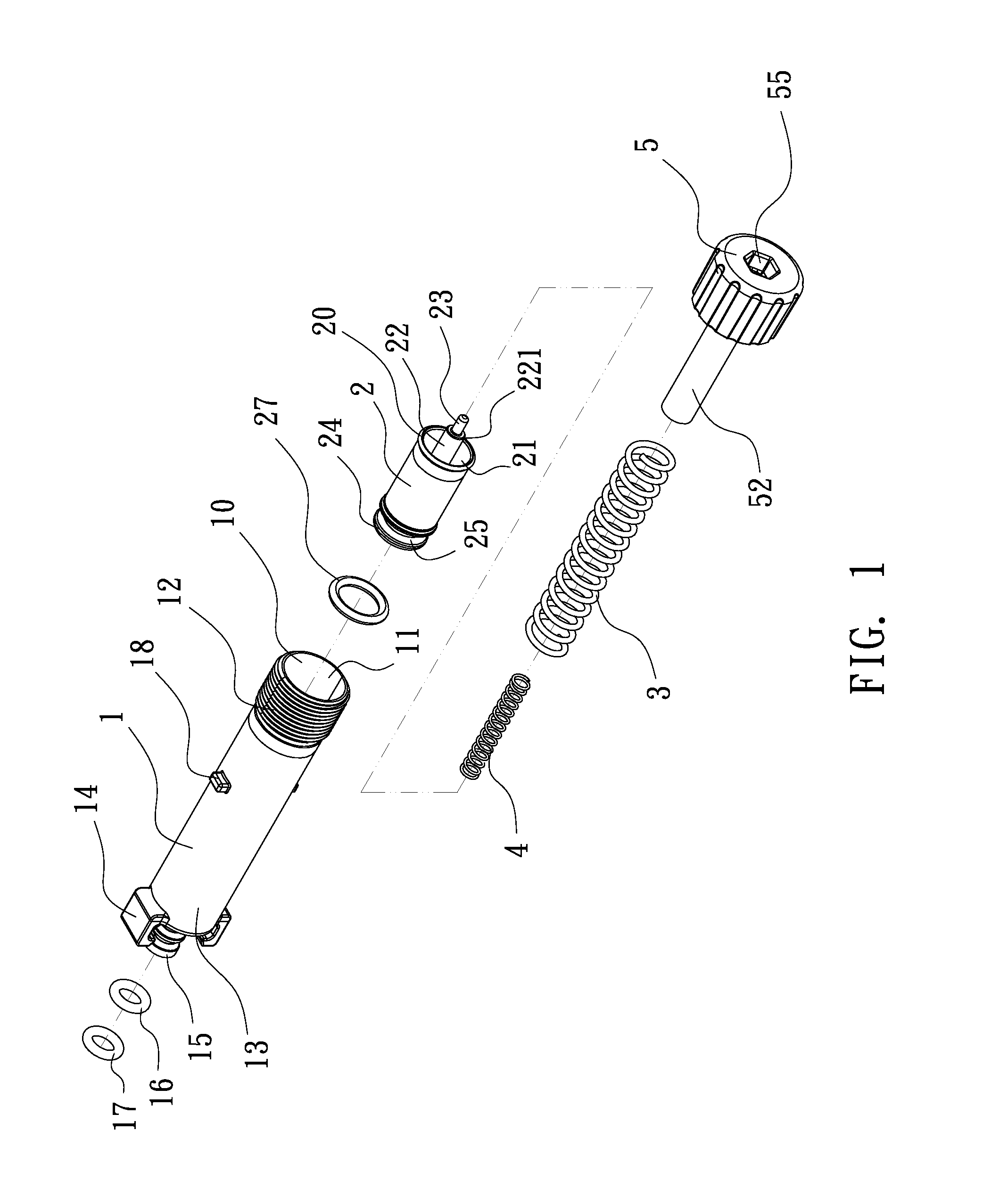

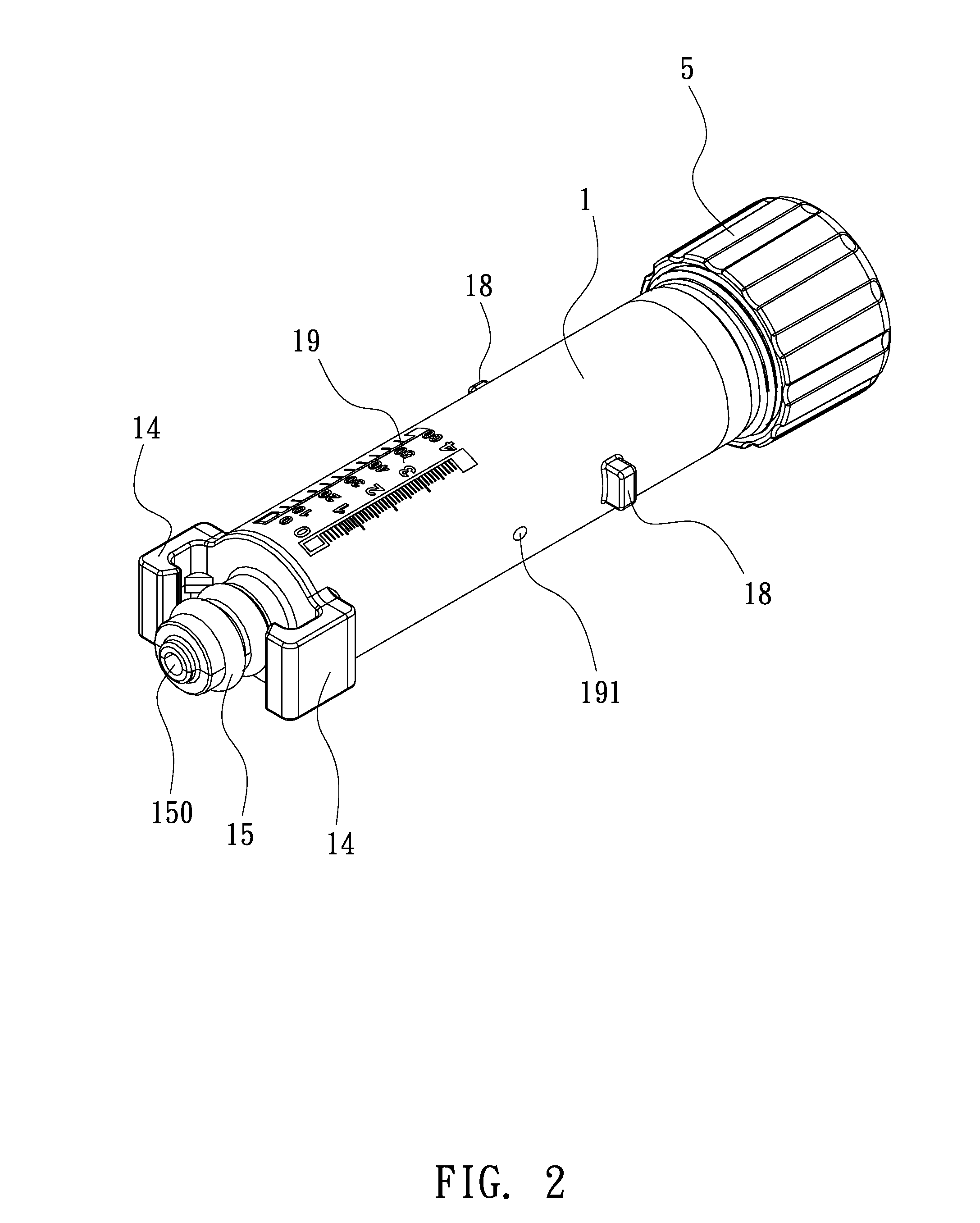

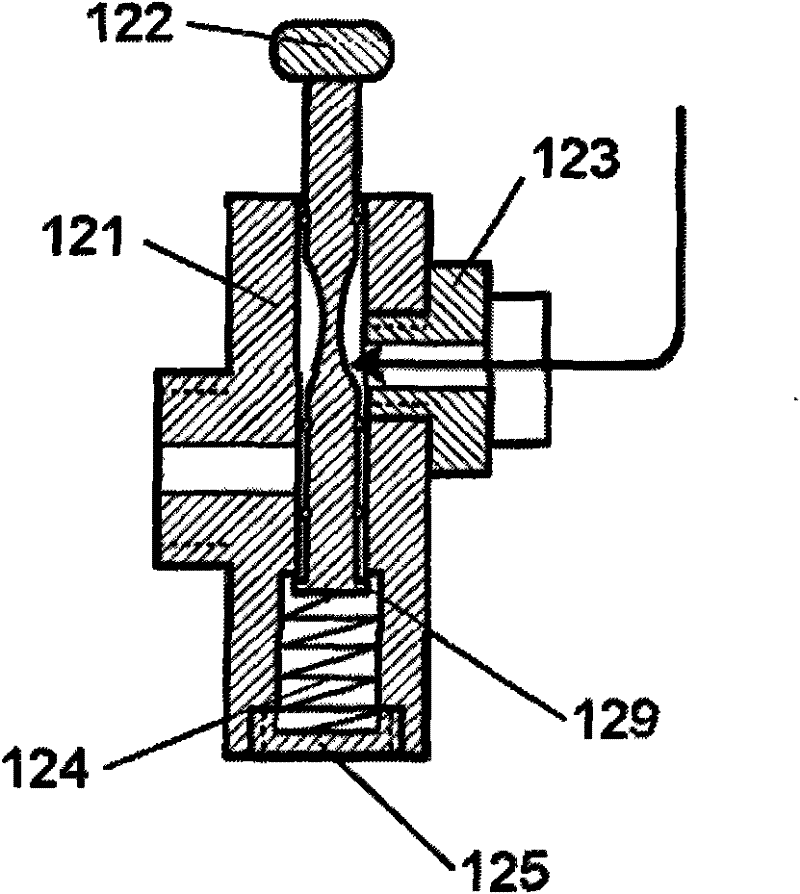

Flow control valve with device for indicating the status of a fluid, particularly for gas containers

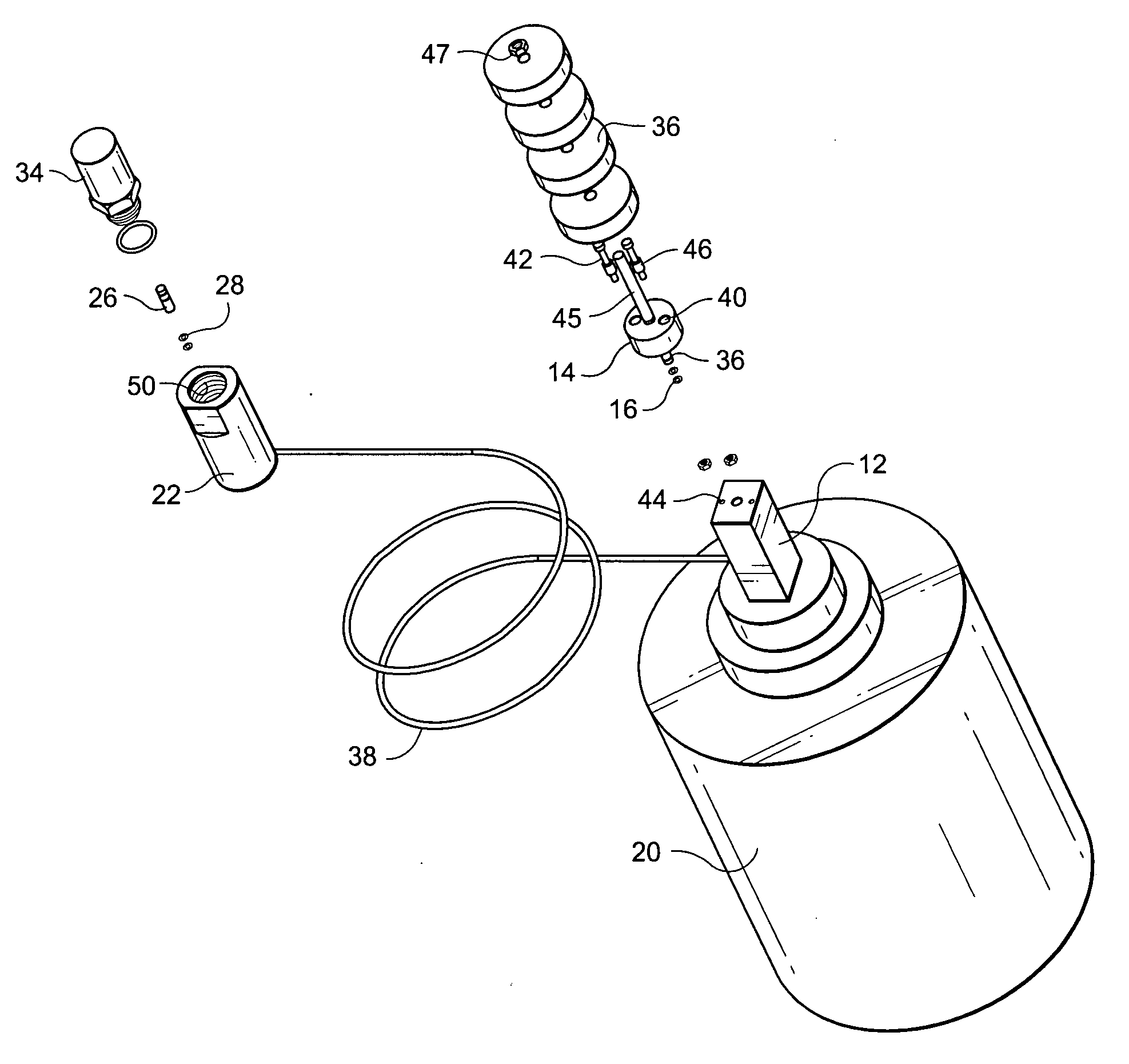

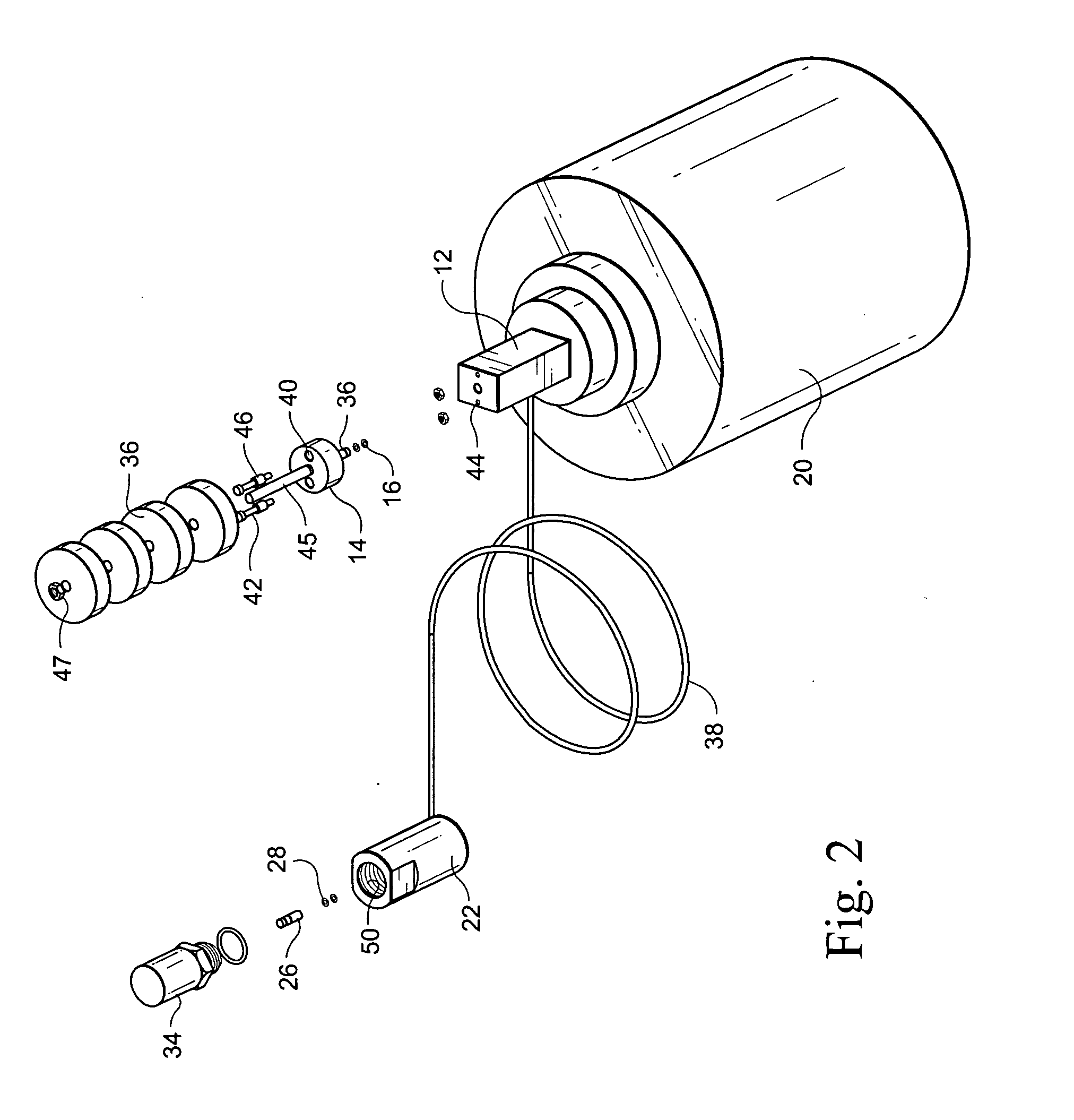

ActiveUS20050229981A1Improve securityImprove practicalityOperating means/releasing devices for valvesMeasurement apparatus componentsCouplingStream flow

A flow control valve with device for indicating the status of a fluid, particularly for gas containers, which includes a body provided with an end on which a threaded shank is provided for hermetic coupling to a gas container, and a handwheel, a gas status indicator device being included within the handwheel, the device including a plunger that is constituted by a head and by a helical stem that is engaged in a cavity of a body that can rotate so that an axial movement of the plunger is matched by a rotation of the rotatable body, which has a visible portion that is marked so as to provide an indication of the status of the plunger, which can move, in contrast with a calibrated spring, between at least one minimum position, in which the head abuts against a shoulder, due to the action of the calibrated spring, and a maximum position, in which the plunger abuts against an end of the rotatable body.

Owner:CAVAGNA GROUP

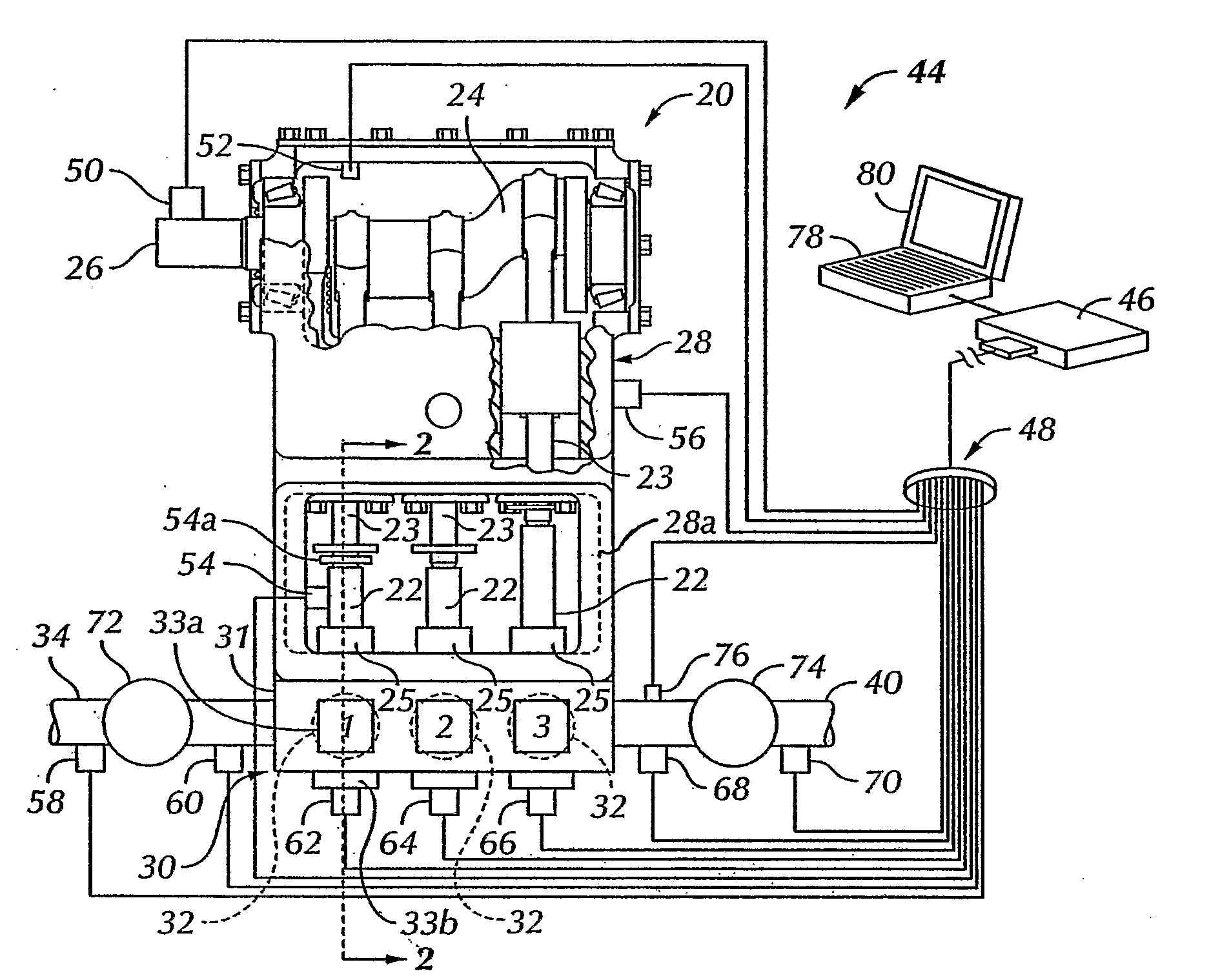

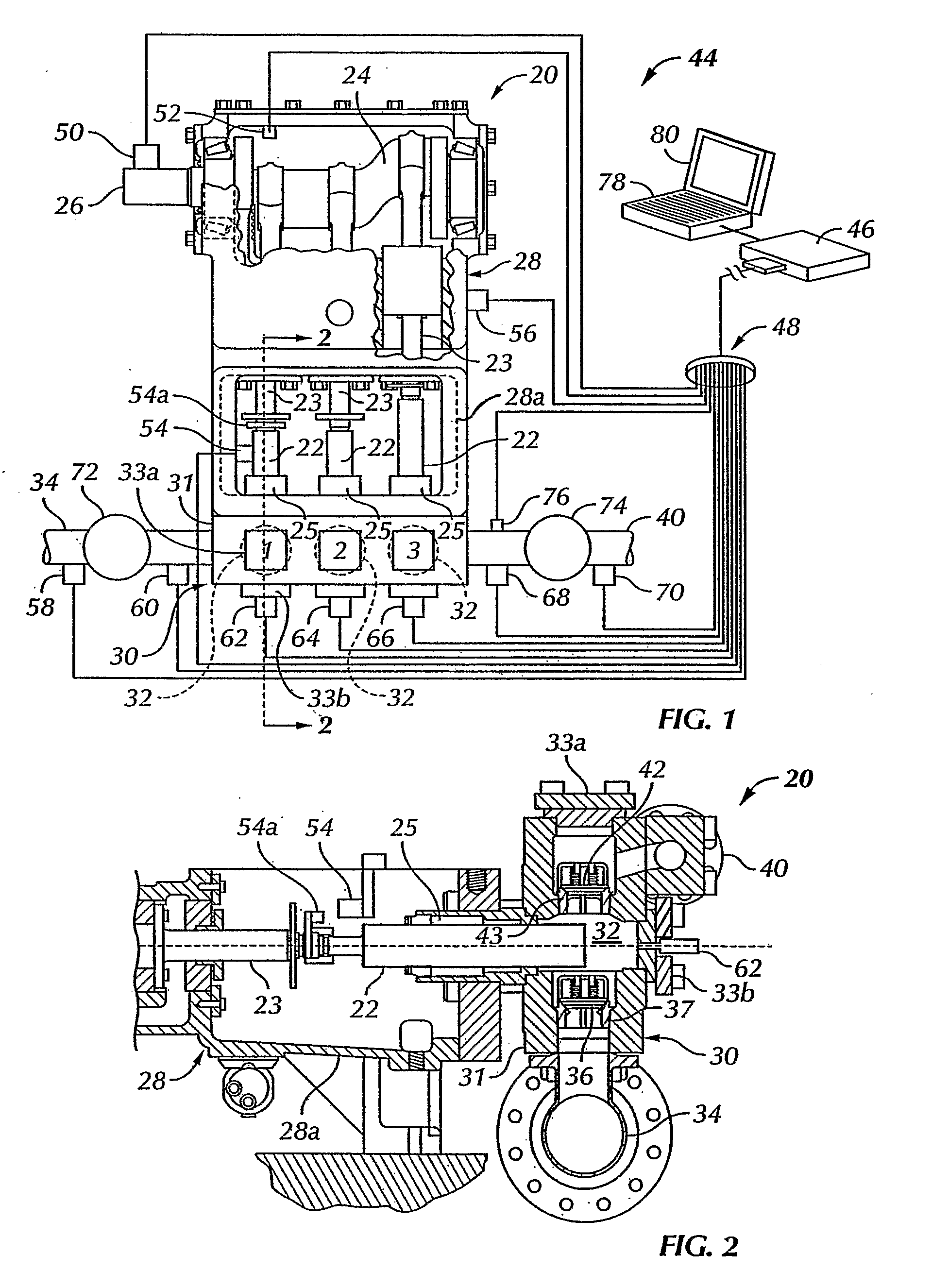

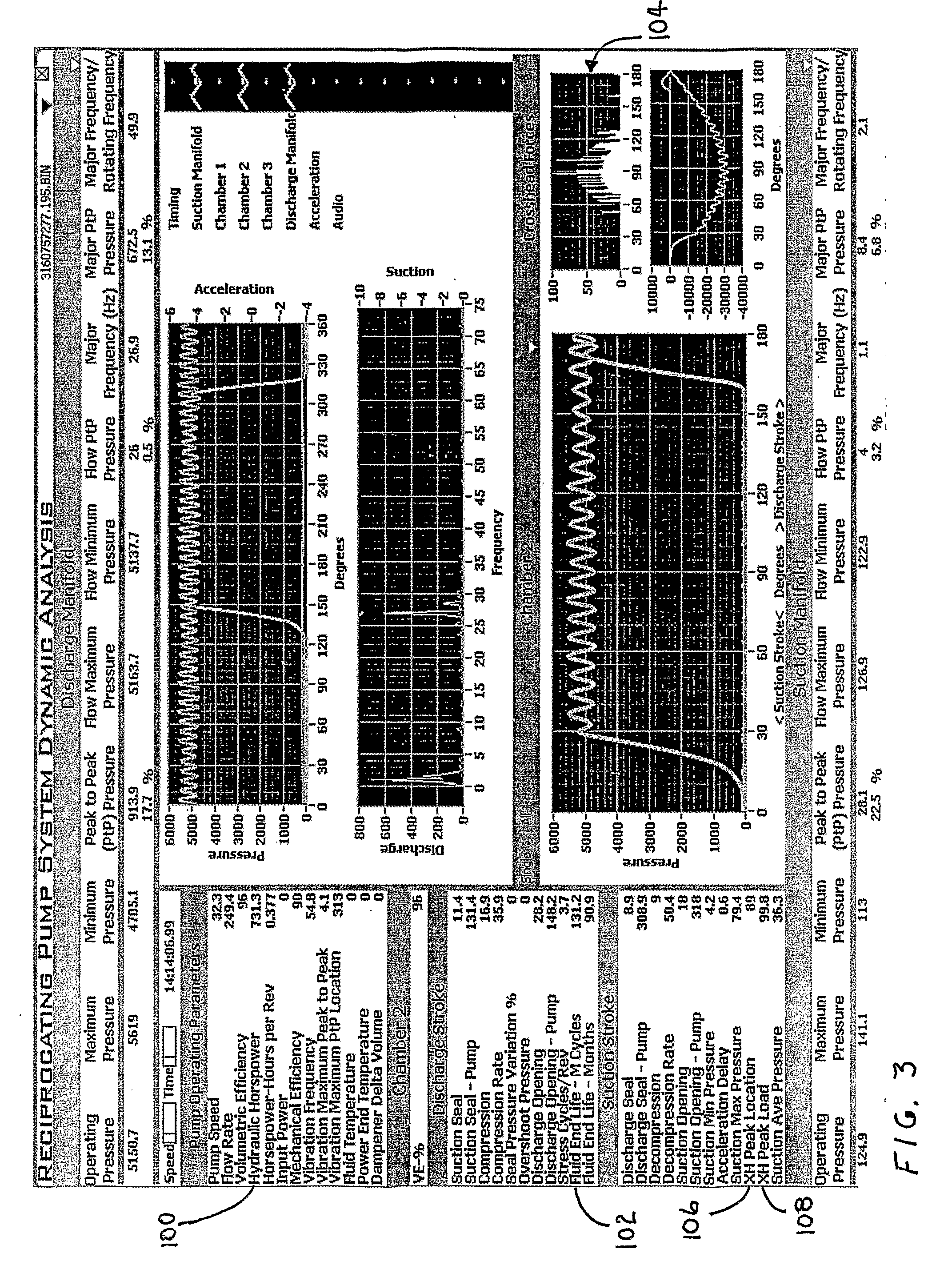

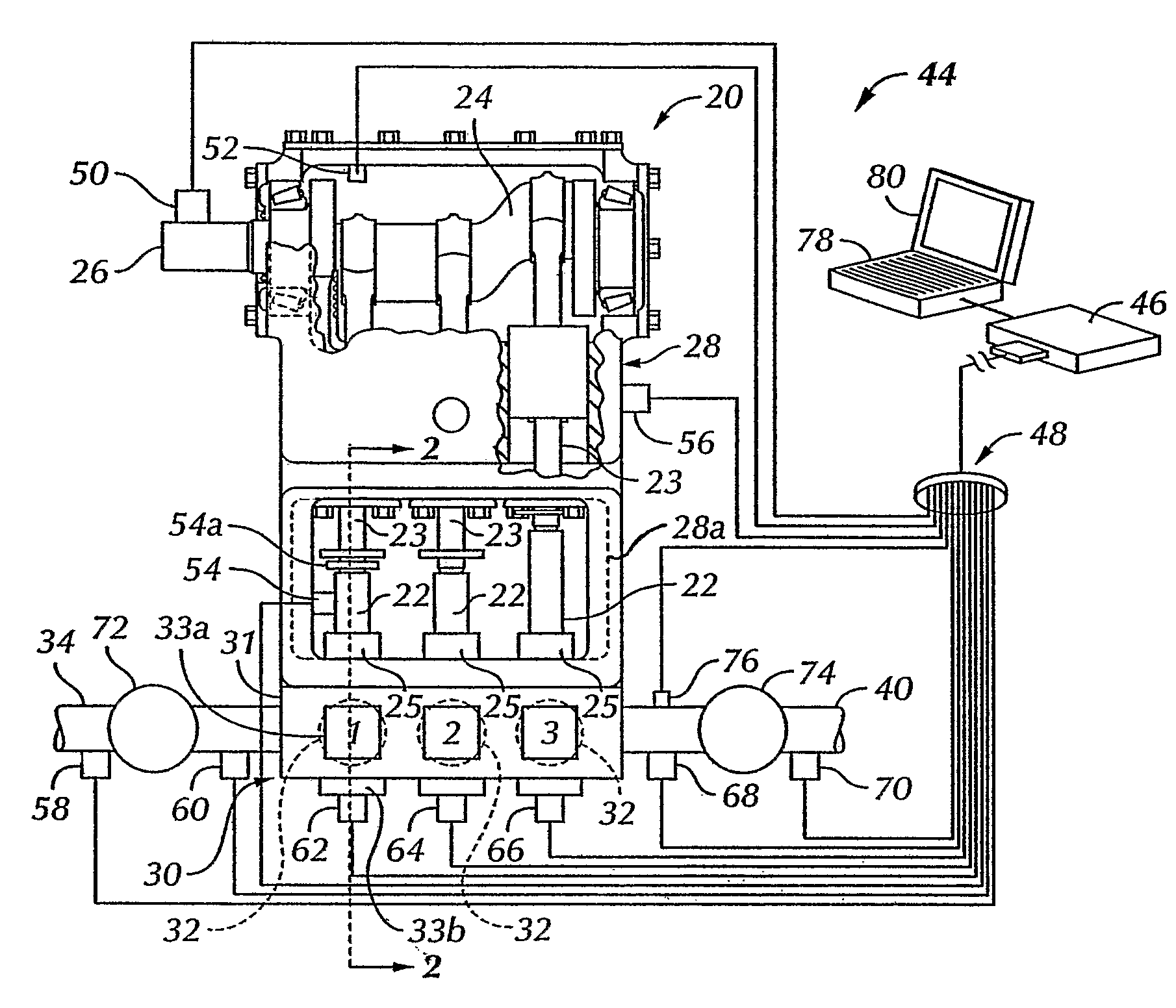

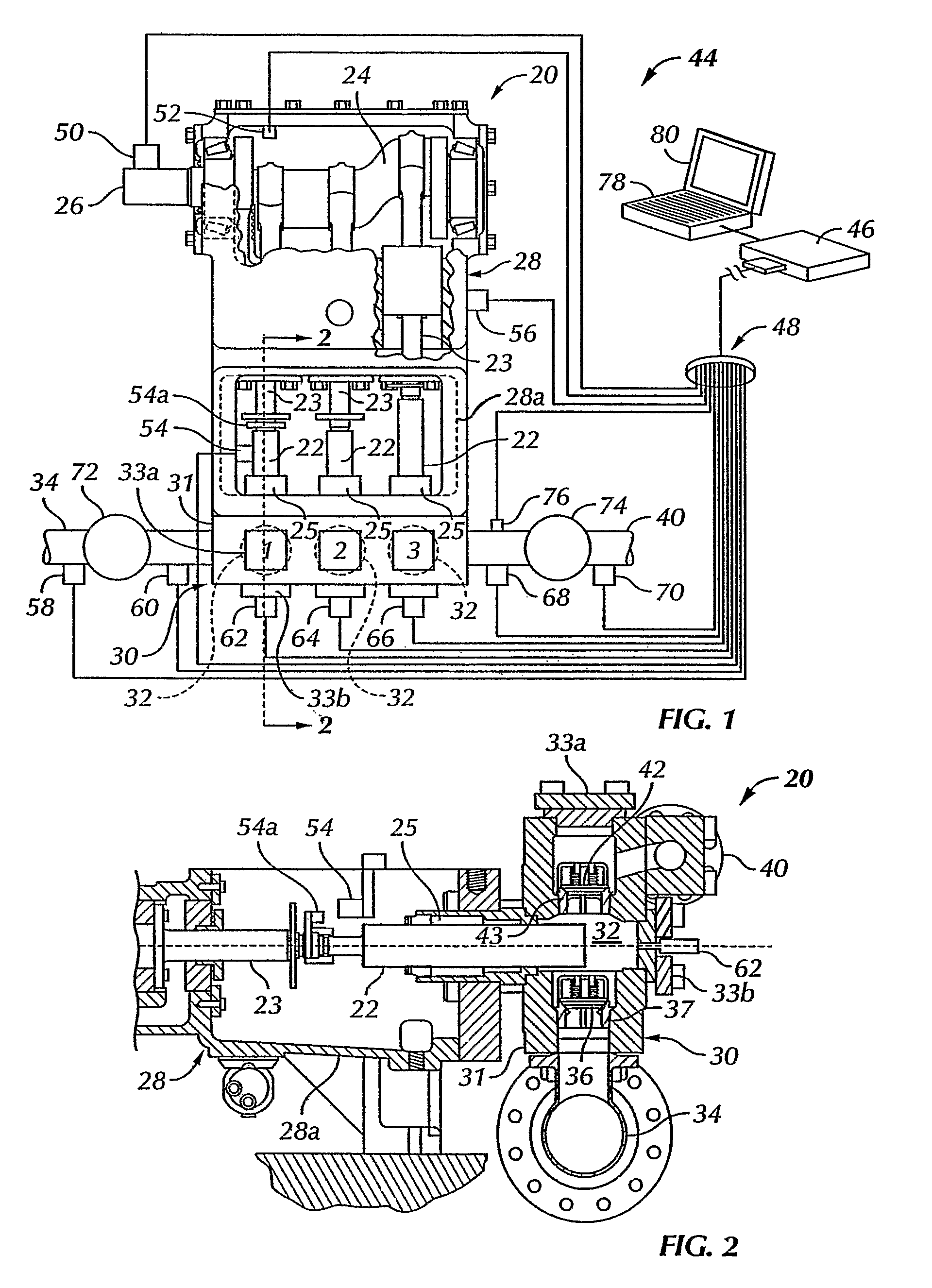

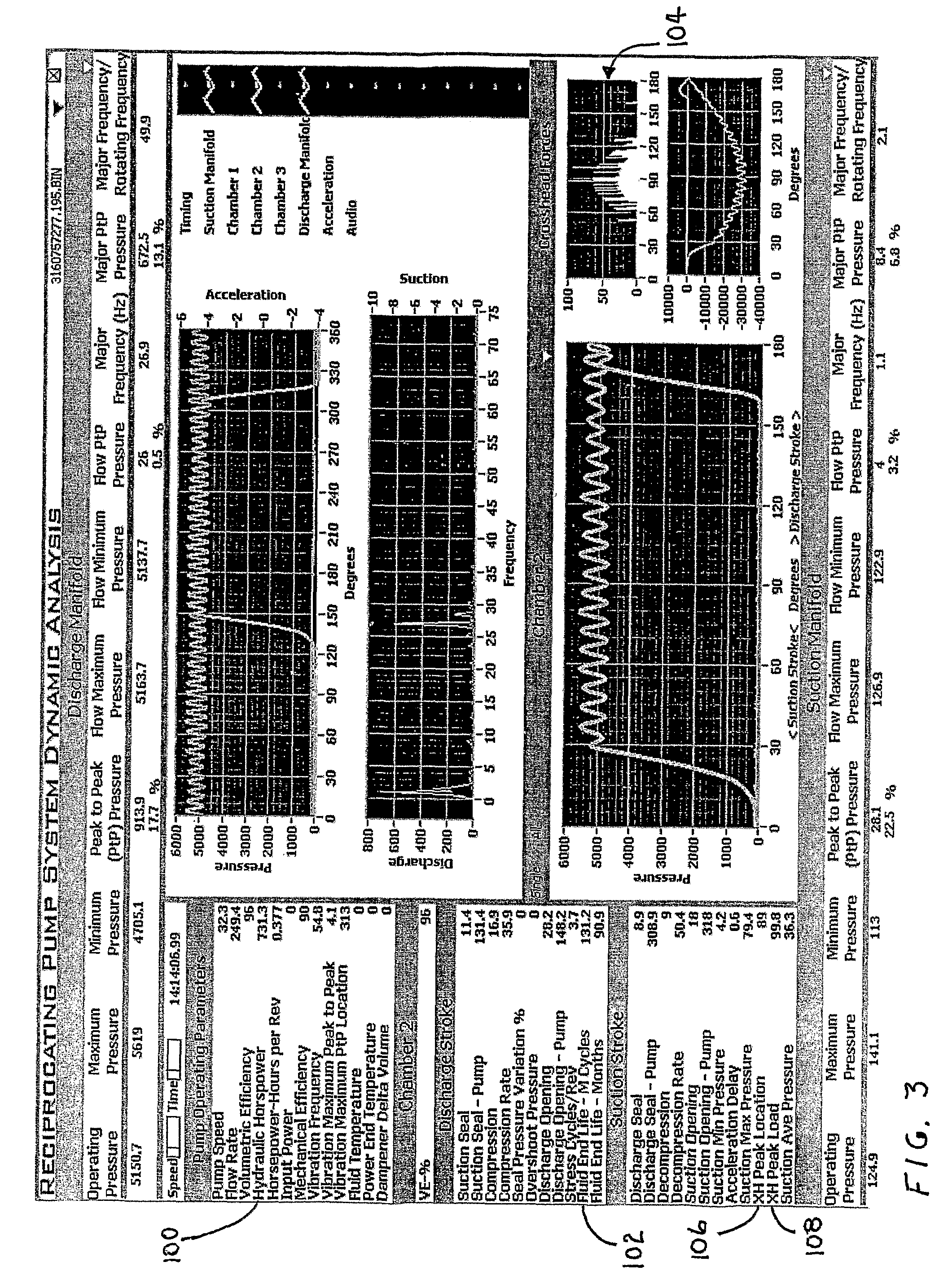

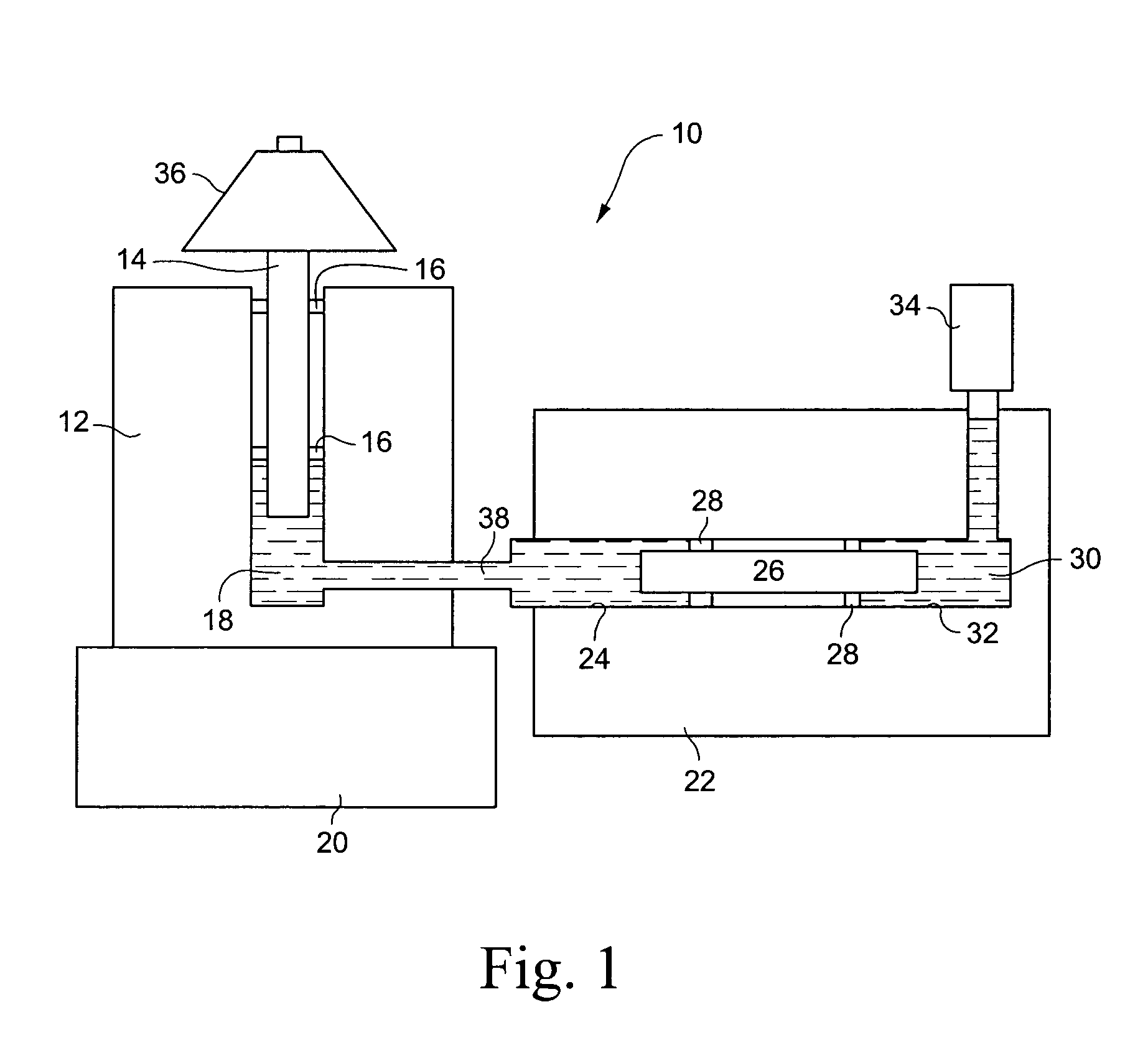

System And Method For Power Pump Performance Monitoring And Analysis

ActiveUS20080196512A1Accurate methodFluid parameterFluid pressure measurement using pistonsEngineeringCrankshaft position sensor

A power pump performance analysis system and methods includes a signal processor connected to certain sensors for sensing pressures and stresses in the cylinder chambers and the inlet and discharge piping of a single or multicylinder pump. Pump speed and pump piston position may be determined by a crankshaft position sensor. Performance analyses for pump work performed, pump cylinder chamber stress, pump fluid end useful cycles to failure, and crosshead loading and shock analysis are provided for estimating pump component life and determining times for component replacement before failure.

Owner:MHWIRTH

System and method for power pump performance monitoring and analysis

ActiveUS7581449B2Accurate methodFluid parameterFluid pressure measurement using pistonsEngineeringCrankshaft position sensor

Owner:MHWIRTH

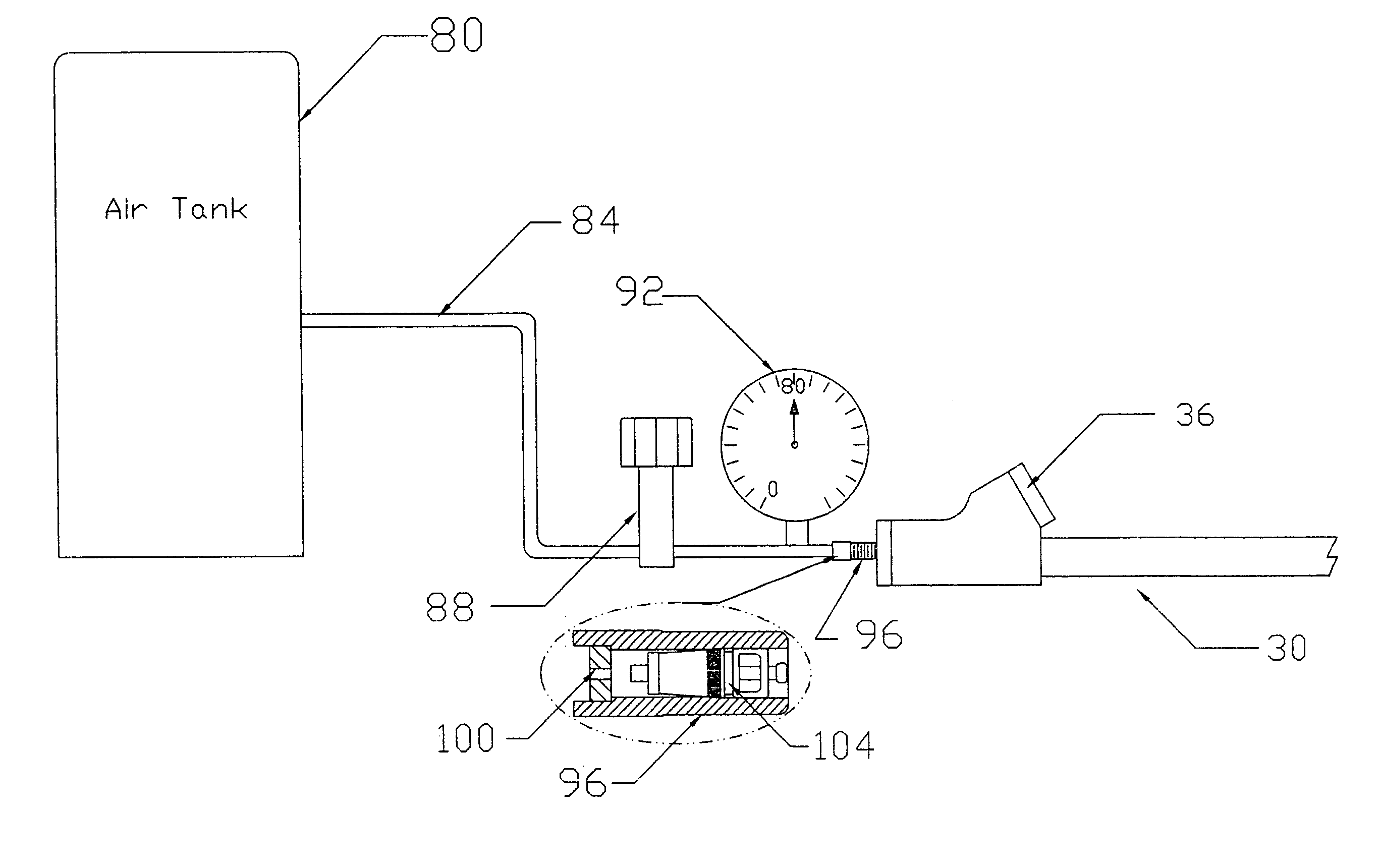

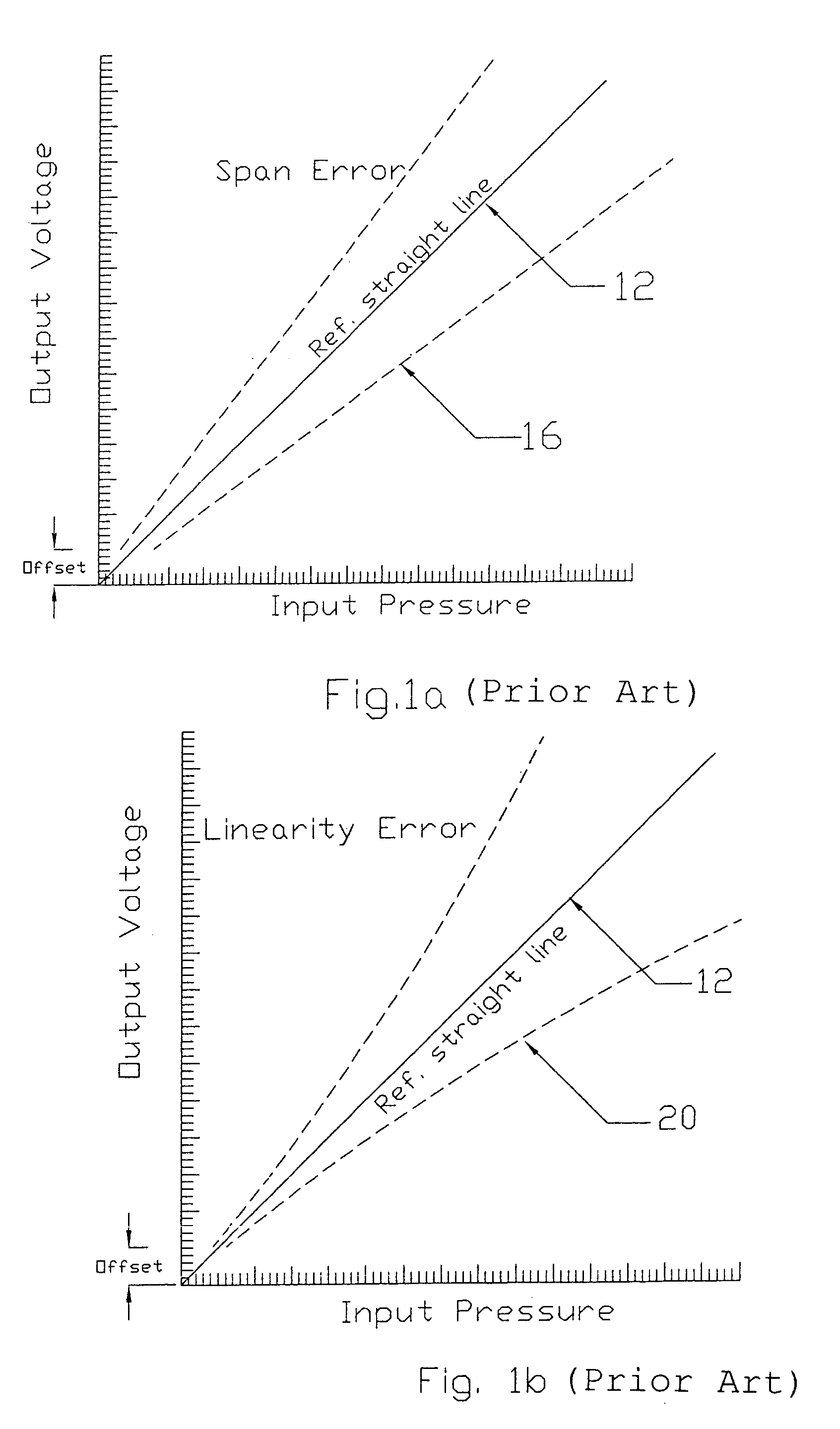

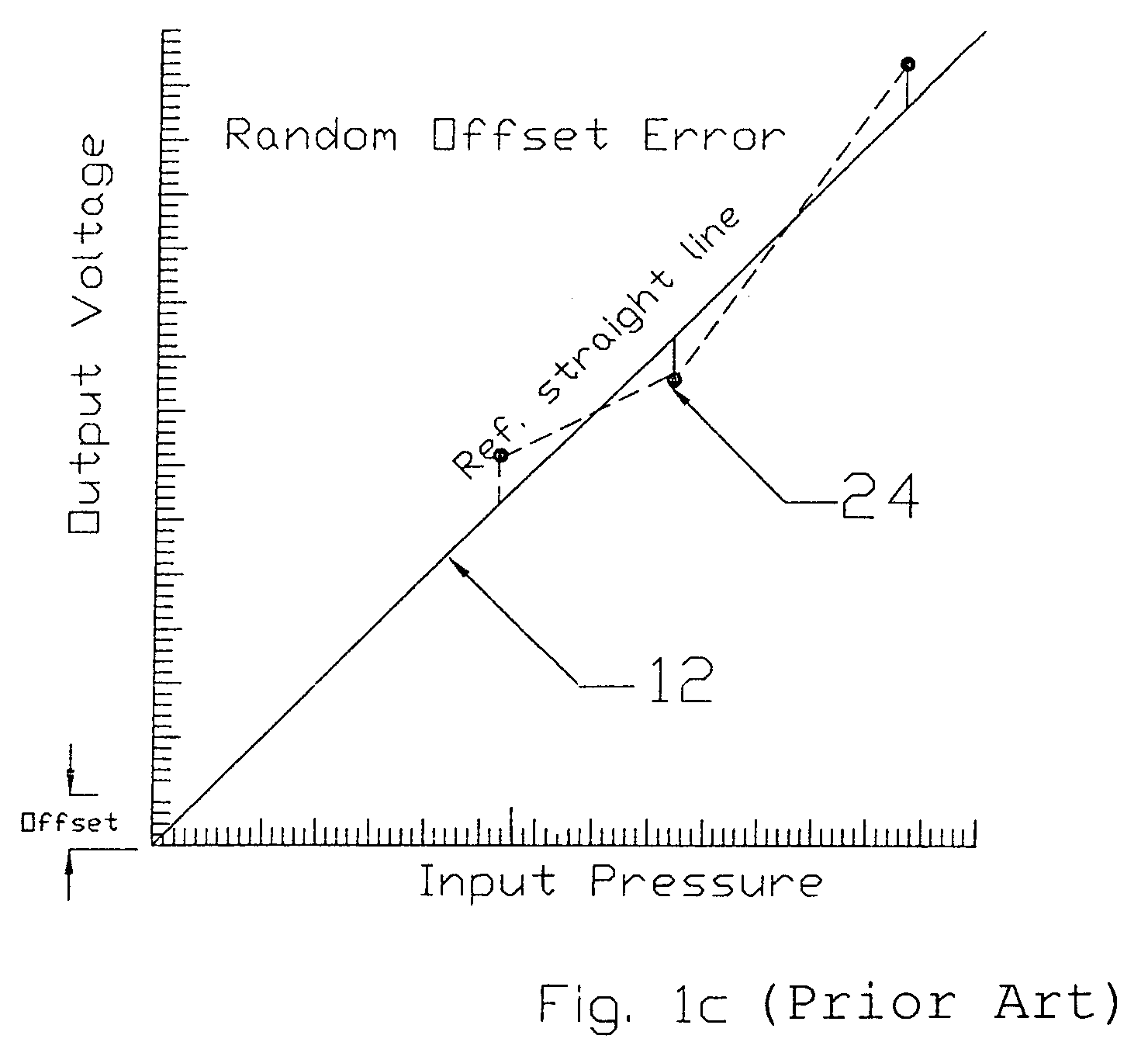

Calibration method for digital air pressure gauge

InactiveUS7086272B2Easy CalibrationImprove accuracyInflated body pressure measurementFluid pressure measurement using ohmic-resistance variationTransducerEngineering

Owner:WU MIN +1

Syringe pump having a pressure sensor assembly

ActiveUS11217340B2Reduce errorsDrug and medicationsFluid pressure measurement by electric/magnetic elementsEngineeringActuator

A syringe pump is disclosed that includes a body, a syringe seat, a syringe actuator, a memory, and one or more processors. The syringe seat is coupled to the body. The syringe actuator is configured to actuate a syringe secured within the syringe seat. The memory is configured to store a plurality of instructions. The one or more processors, in accordance with the plurality of instructions, is / are configured to: prime the syringe pump in a prime phase; determine if an occlusion exists during the prime phase using a first test; stop the prime phase; initiate fluid delivery into a patient; enter into a start-up phase; determine if an occlusion exists using a second test during the start-up phase; transition from the start-up phase into a steady-state phase; and determine if an occlusion exists during the steady-state phase using a third test.

Owner:DEKA PROD LLP

Hydraulic pressure sensor

InactiveUS20050092094A1Avoid YieldEasy to adjustFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringMechanical engineering

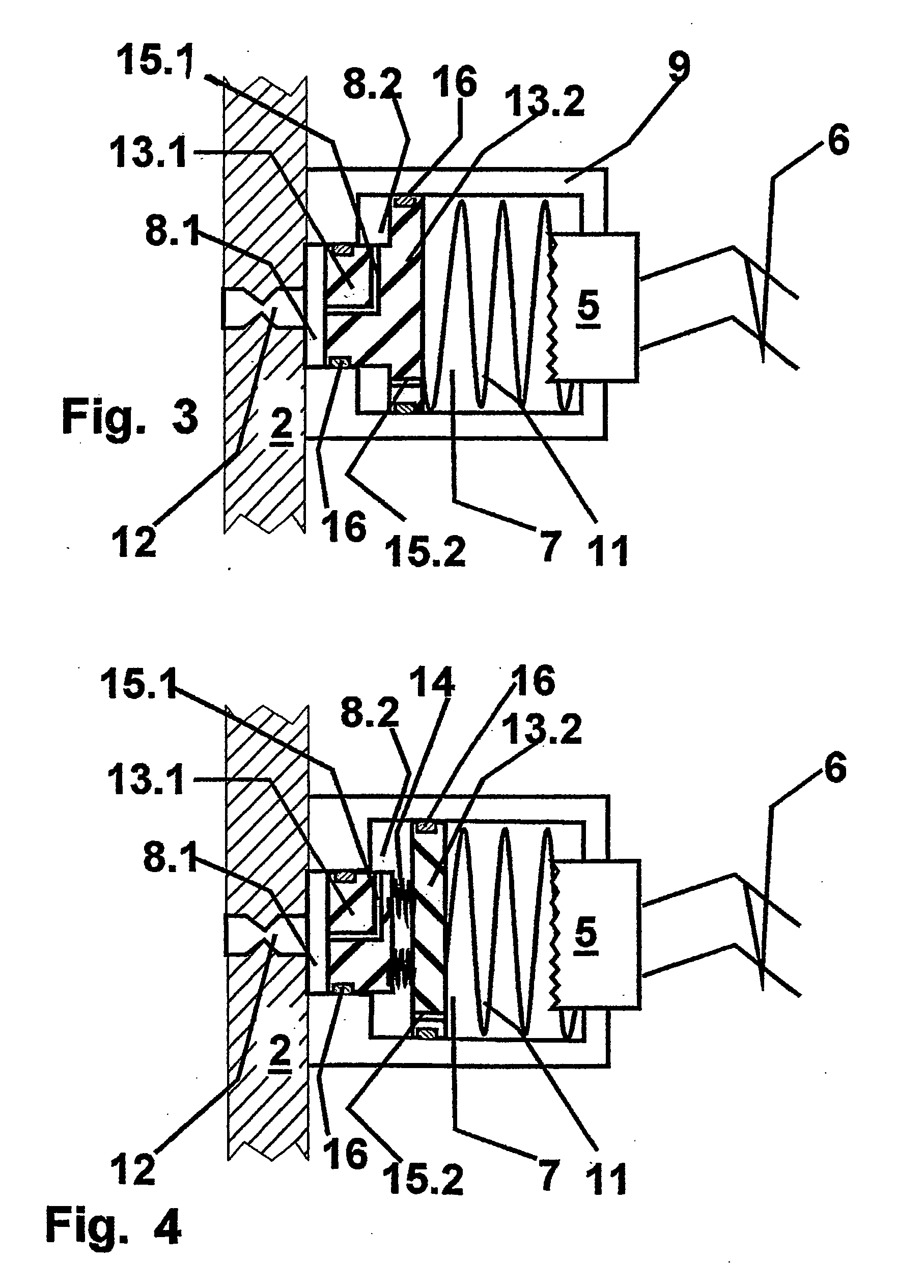

A hydraulic pressure sensor for measuring the pressure in a hydraulic pressure chamber 1. A reservoir housing 9 is connected to the pressure chamber, and the interior of the housing is divided by a slideable partition 13 which defines a reservoir chamber 8 which is connected to the pressure chamber and a sensor chamber 7 which is connected to a sensor element 5. The partition 13 is constructed as a piston and extends for sliding movement along the walls of the reservoir housing while exerting a frictional force. A spring 11 supports the partition relative to the reservoir housing against the pressure in the reservoir chamber 8. The partition 13 may be constructed as a differential piston, and consist of two or more piston sections 13.1, 13.2, 13.3, which extend independently of one another in a sliding and sealing manner, and mutually support one another by an intermediate spring 14.

Owner:TIEFENBACH BERGBAUTECHN

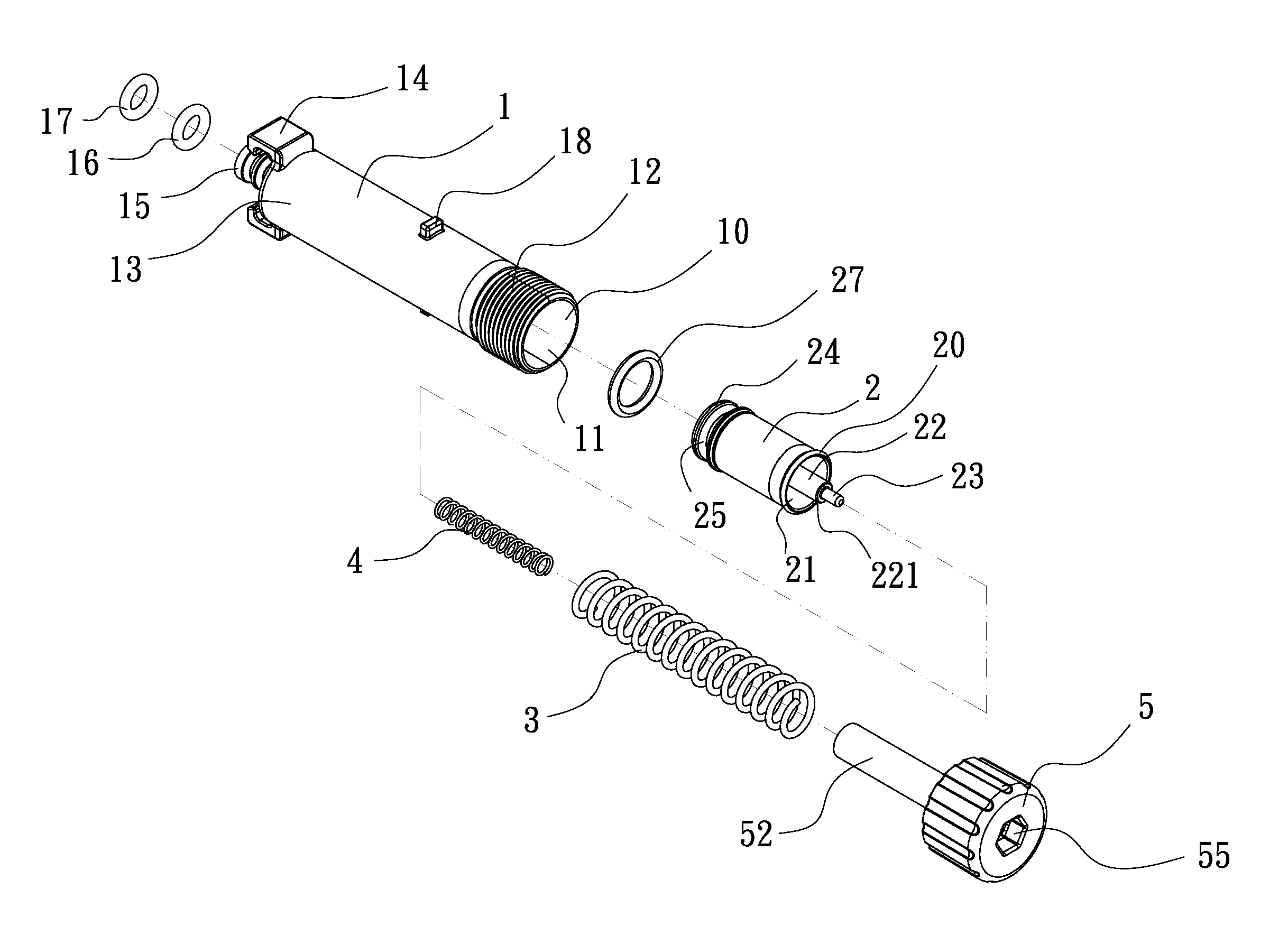

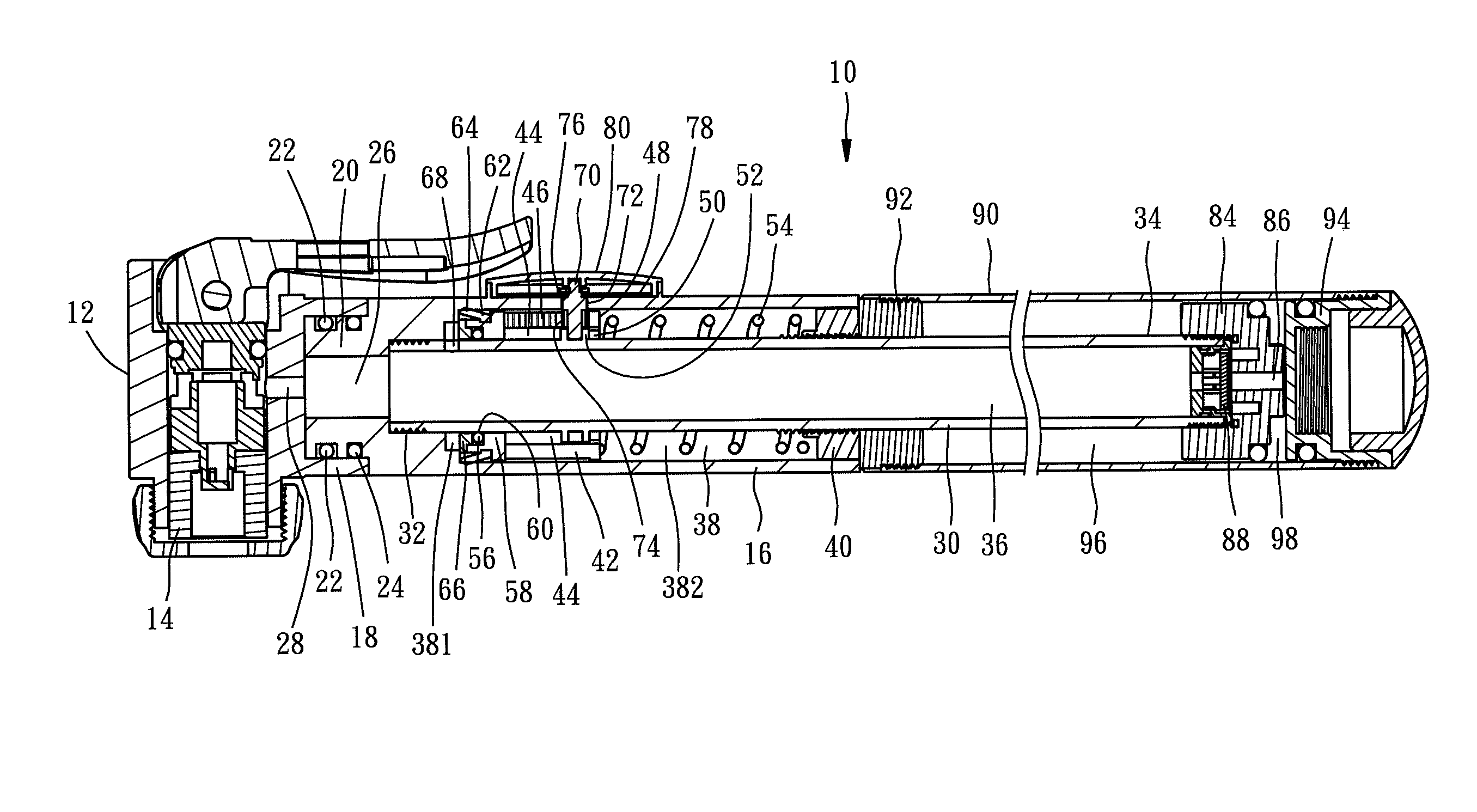

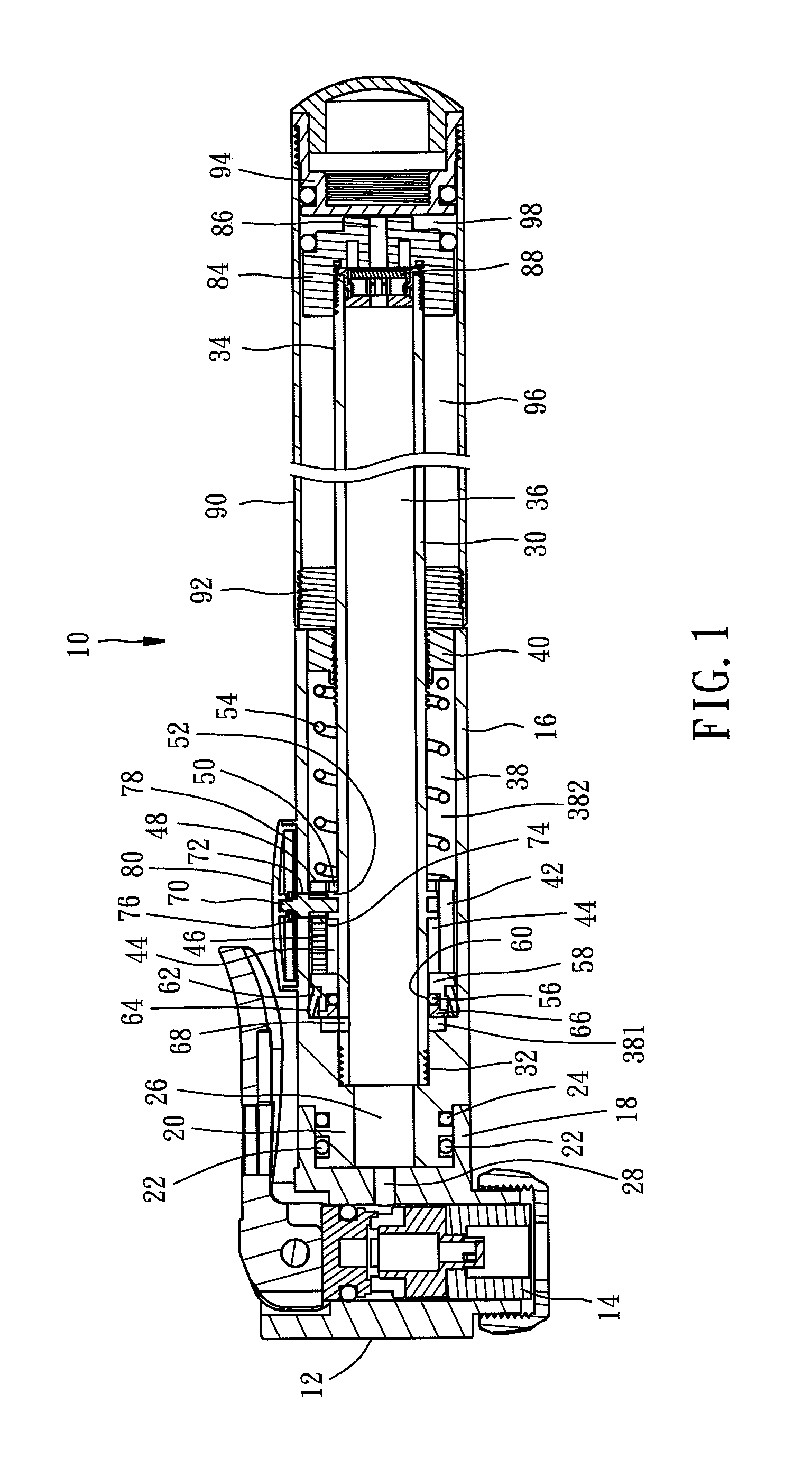

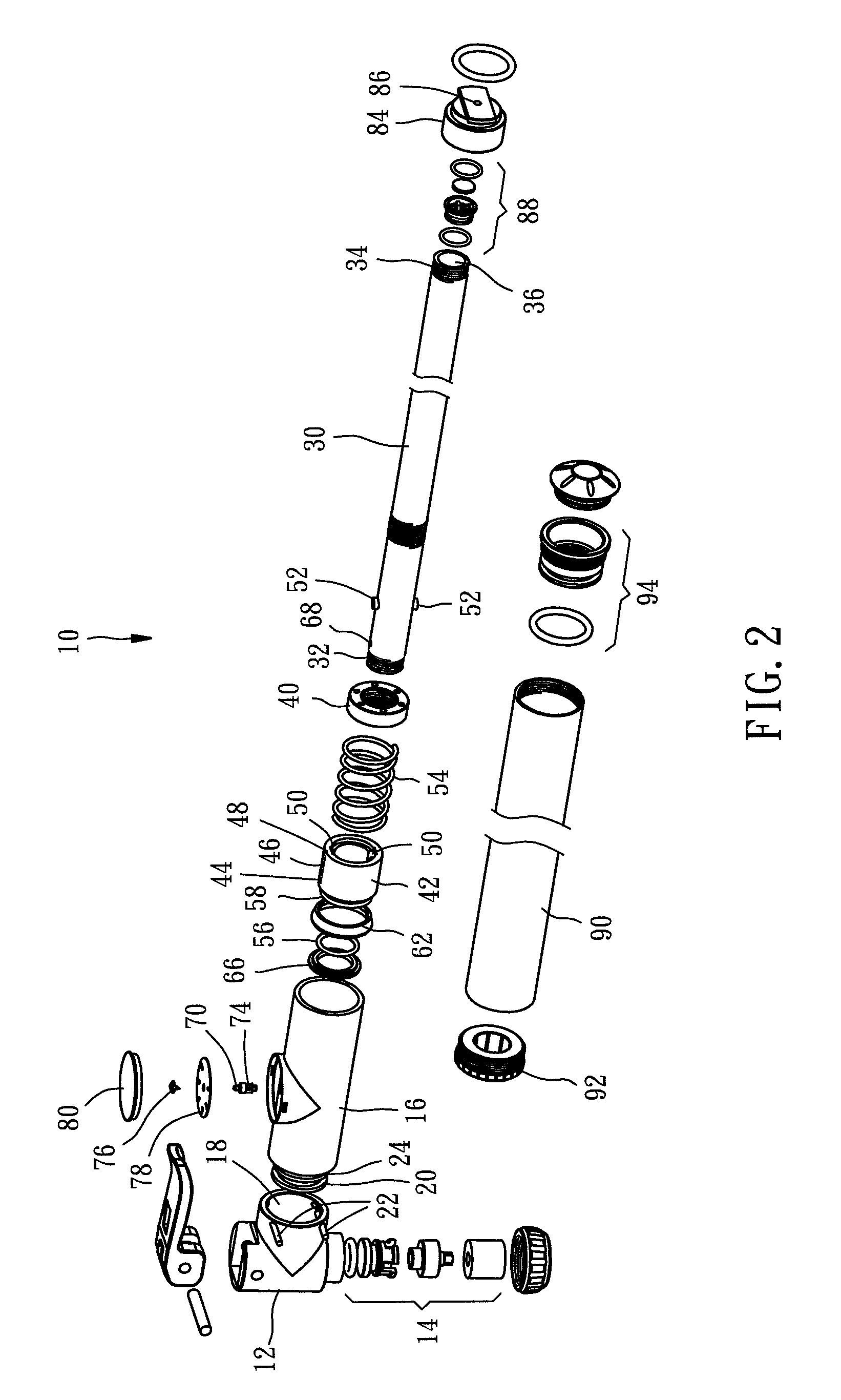

Pen-type pressure indicator for air compressor

ActiveUS20160076534A1Quick connectionProtection from damagePump testingPositive displacement pump componentsLinear compressorGas compressor

A pen-type pressure indicator, which can be detachably connected to an air compressor for measuring the pressure of compressed air produced in the air compressor, includes a transparent tube and a slider. The slider can be moved along a first bore and a second bore of the transparent tube. The motion of the slider in the transparent tube is similar to the motion of a piston in a cylinder. The transparent tube is provided with a tapered annular surface, between the first bore and the second bore. In addition to measuring the pressure of the compressed air delivered to an object, when the pressure of the compressed air exceeds a predetermined pressure, excessive air can be released into the environment, without requiring the air compressor to be installed with a safety valve, so that the object can be protected from damages due to overpressure.

Owner:CHOU

Sanitary diaphragm pressure gauge adapter

InactiveUS7784353B1Easy to installAvoid disadvantagesFluid pressure measurement using pistonsVolume/mass flow by differential pressureEngineeringGuide tube

An adapter fits a diaphragm-type sanitary pressure gauge onto a flanged tubular stub of a sanitary conduit. A cylinder has a lower ring flange that mates with the flange of the tubular stub and an upper flange that mates with the diaphragm mounting foot of the pressure gauge. These are held together with tri-clamps, with suitable sealing glands. The interior of the cylinder is two-tiered, with a larger diameter portion above, a smaller diameter portion below, and an annular shelf or step between. A piston with a larger diameter upper portion and smaller diameter lower portion rides in the cylinder, with a seal ring in the lower portion. A hard rubber pad on the top of the piston contacts the diaphragm of the pressure gauge to transmit fluid pressure from the sanitary conduit to the gauge. A small leak detection hole through the cylinder above the seal ring reveals any leakage.

Owner:FELDMEIER ROBERT H

Pressure sensor in deep-sea and use thereof

InactiveCN1746644ASimple structureEasy to implementFluid pressure measurement using pistonsMultiple fluid pressure valves simultaneous measurementPistonPressure sensor

A pressure transducer used in deep sea is featured as setting piston mechanism for sealed oil cavity of pressure transducer, forming piston mechanism by tube body and piston, forming piston cavity by sealing tube front end with piston and realizing shrink fit between piston and tube body internal wall, enabling piston to move axially in tube when frictional force is overcome by piston, connecting piston cavity through to sealed oil cavity of pressure transducer and filling there full of oil.

Owner:HEFEI UNIV OF TECH

Apparatus and methods for dynamically pressure testing an article

InactiveUS20050183493A1Weather/light/corrosion resistanceFluid pressure measurement using pistonsEngineeringMechanical engineering

The dynamic pressure tester includes a first cylinder and a first piston movable relative to the cylinder. The piston may have one or more weights applied thereto. The cylinder is vibrated by a shaker table and pressure pulses in the fluid are transmitted to a stationary housing and to a second piston in the housing. The opposite side of the piston contacts a corrosive or caustic fluid also in contact with the sensor face of an article being tested. The pressure pulses are transmitted by the second piston and corrosive fluid to the sensor face, enabling dynamic pressure testing in the corrosive fluid.

Owner:GENERAL ELECTRIC CO

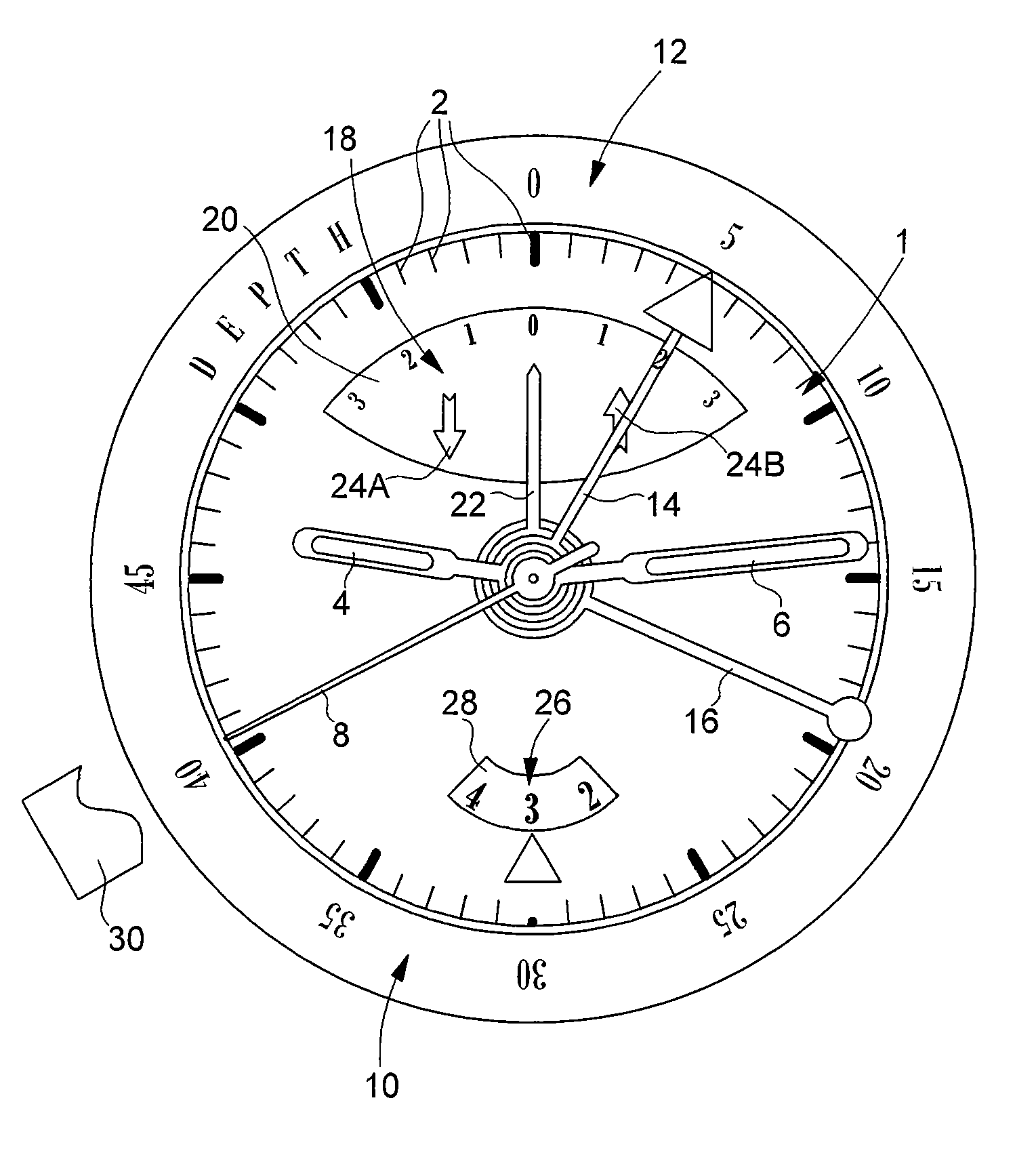

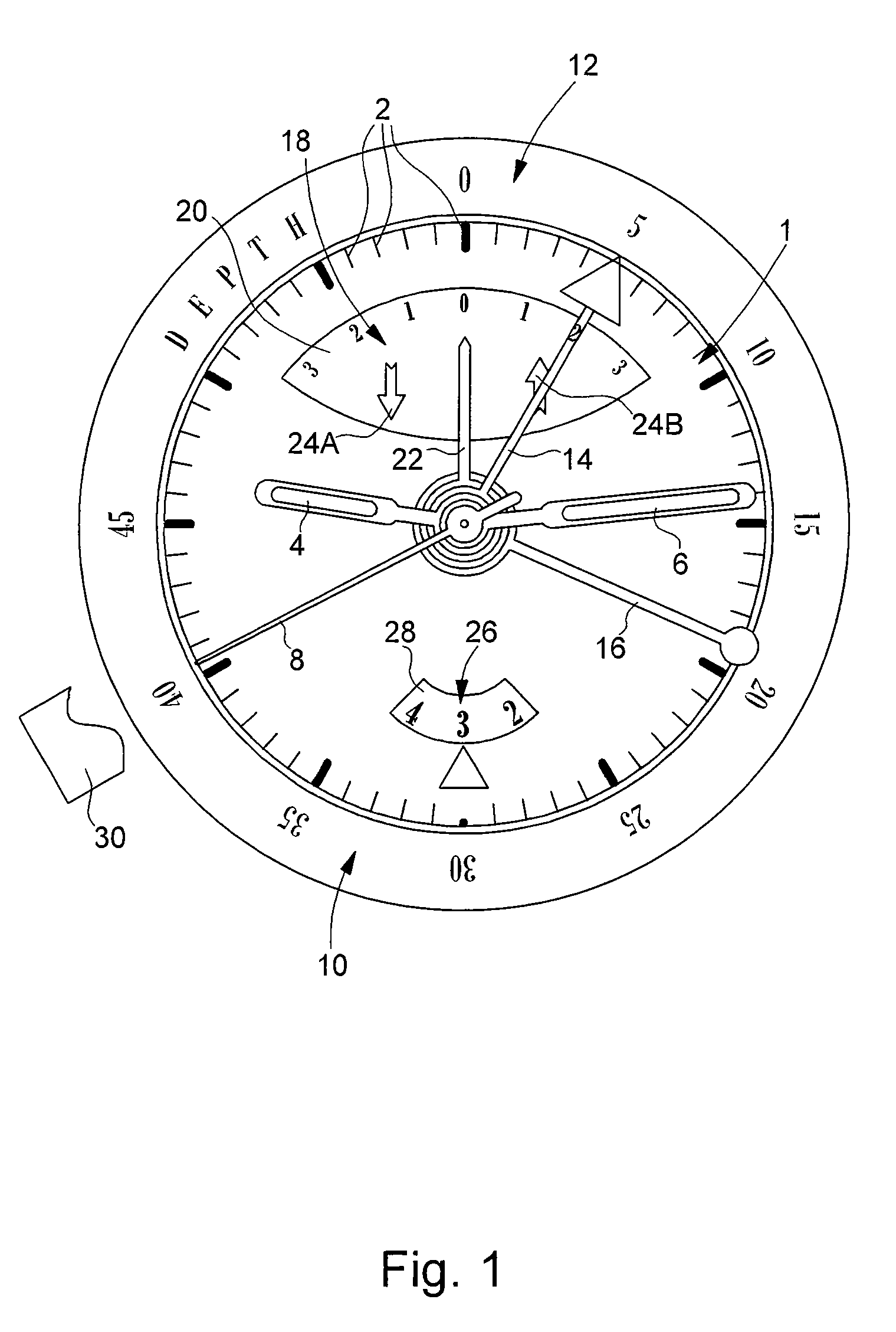

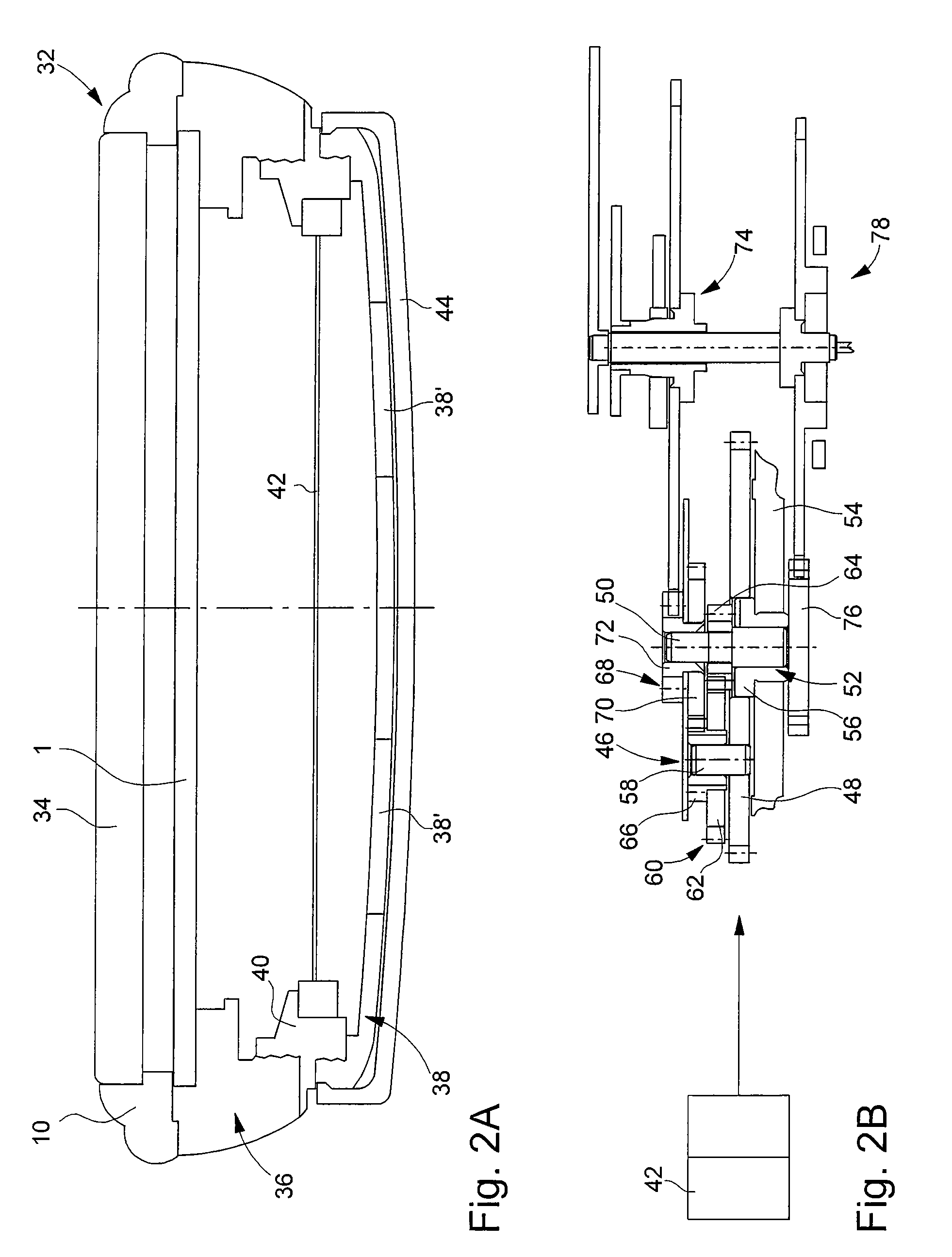

Dive watch

ActiveUS7869308B2Simple and robust differential gear mechanismGuaranteed uptimeVisual indicationMechanical unknown time interval measurementReturn-to-zeroEngineering

The invention concerns a mechanical or electromechanical dive watch including hour (4) and minute (6) hands, a pressure sensor (42), a depth indicator hand (14) and a depth variation indicator hand (22), the depth indicator hand (14) providing a diver with an indication of the instantaneous value of the depth at which he is situated when diving, the depth variation indicator hand (22) being at that moment locked at zero, the depth indicator hand (14) being locked in turn when the diver reaches a required decompression stop and the depth variation indicator hand (22) being released to indicate to the diver any variations in his depth relative to the decompression stop depth, the depth variation indicator hand (22) then being returned to zero and locked while the depth indicator hand (14) is released and again indicates the exact dive depth when the diver resumes his ascent towards the surface.

Owner:BLANCPAIN SA

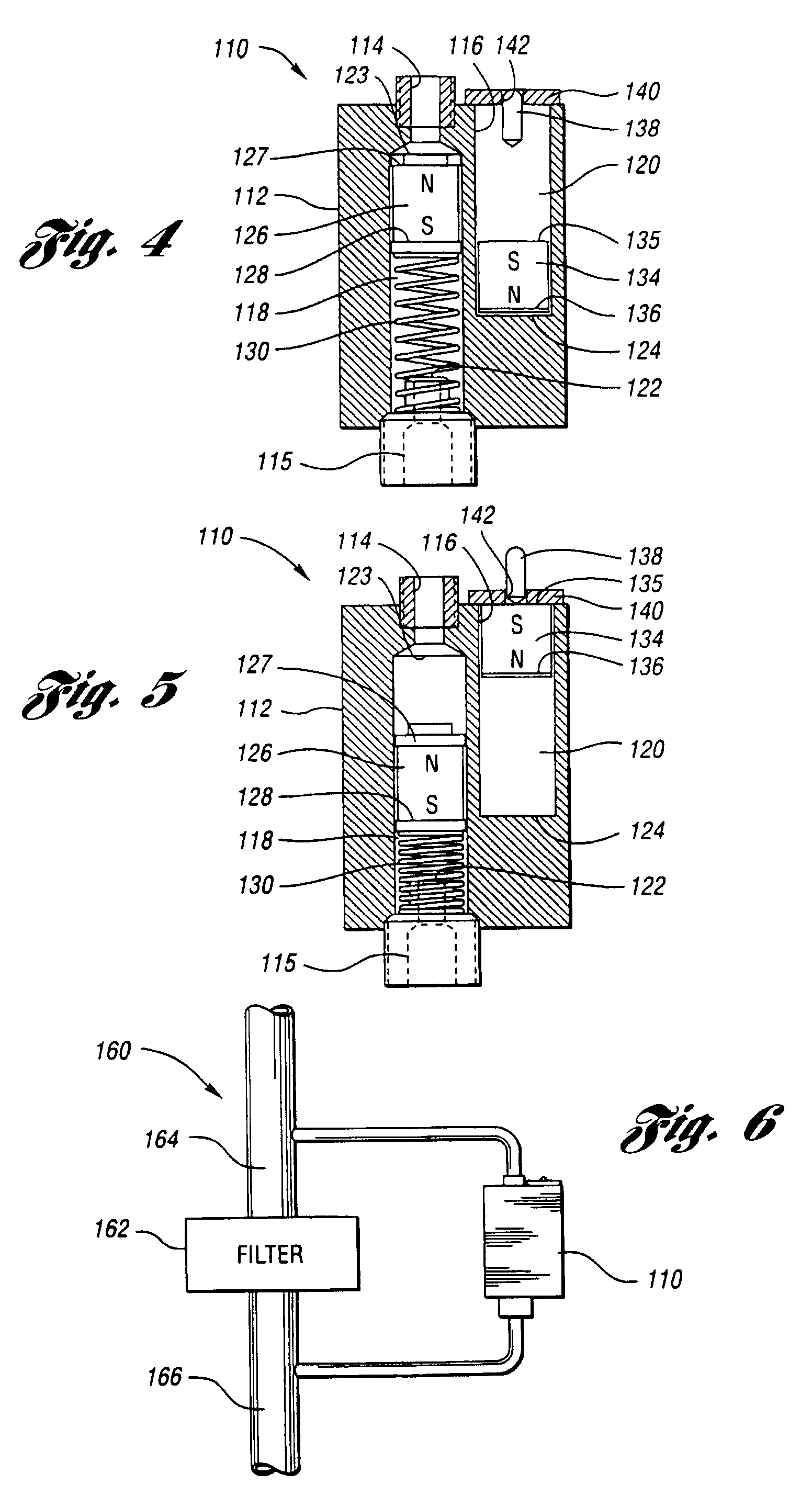

Filter change indicator

InactiveUS20060042392A1Reliable constructionEfficiency tuningSemi-permeable membranesFluid pressure measurement using elastically-deformable gaugesShape changeEngineering

A fluid system pressure indicator is adapted for use in fluid systems having a filter element. The fluid system force indicator includes a housing partitioned to be exposed to the fluid system to provide transmission of a mechanical force between these partitioned environments to indicate the fluid pressure. This exterior shape change is such that it can be identified through tactile means not requiring visual identification.

Owner:STANDYNE INC

Differential pressure indicator and method of manufacture

ActiveUS7308829B1Fluid pressure measurement using pistonsElectric switchesElectricityDifferential pressure

A differential pressure indicator and method of configuring a differential pressure indicator is provided. The differential pressure indicator is configurable to provide open circuit or closed circuit logic and includes a housing, a pressure responsive element, a post, first, second and third electrical contacts and an electrical insulator from an insulative material. The electrical insulator separates the third electrical contact from either the first contact or the second contact to provide a desired type of logic. The differential pressure indicator may use substantially similar components to provide either open circuit or closed circuit logic or the components may be rearranged to provide either open circuit or closed circuit logic.

Owner:BALDWIN FILTERS

Filter change indicator

InactiveUS7137303B2Reliable constructionEfficiency tuningSemi-permeable membranesFluid pressure measurement using pistonsShape changeEngineering

A fluid system pressure indicator is adapted for use in fluid systems having a filter element. The fluid system force indicator includes a housing partitioned to be exposed to the fluid system to provide transmission of a mechanical force between these partitioned environments to indicate the fluid pressure. This exterior shape change is such that it can be identified through tactile means not requiring visual identification.

Owner:STANDYNE INC

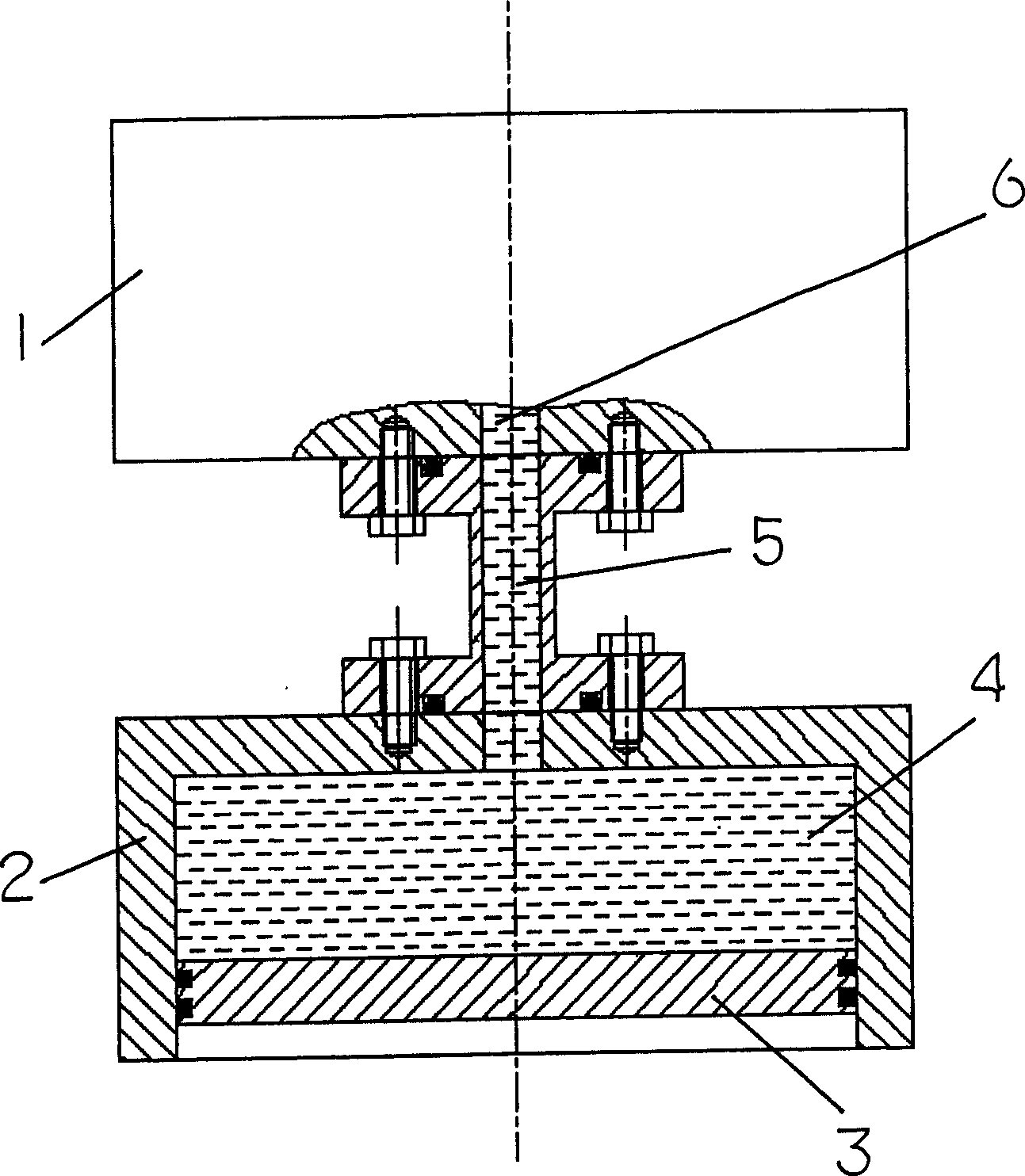

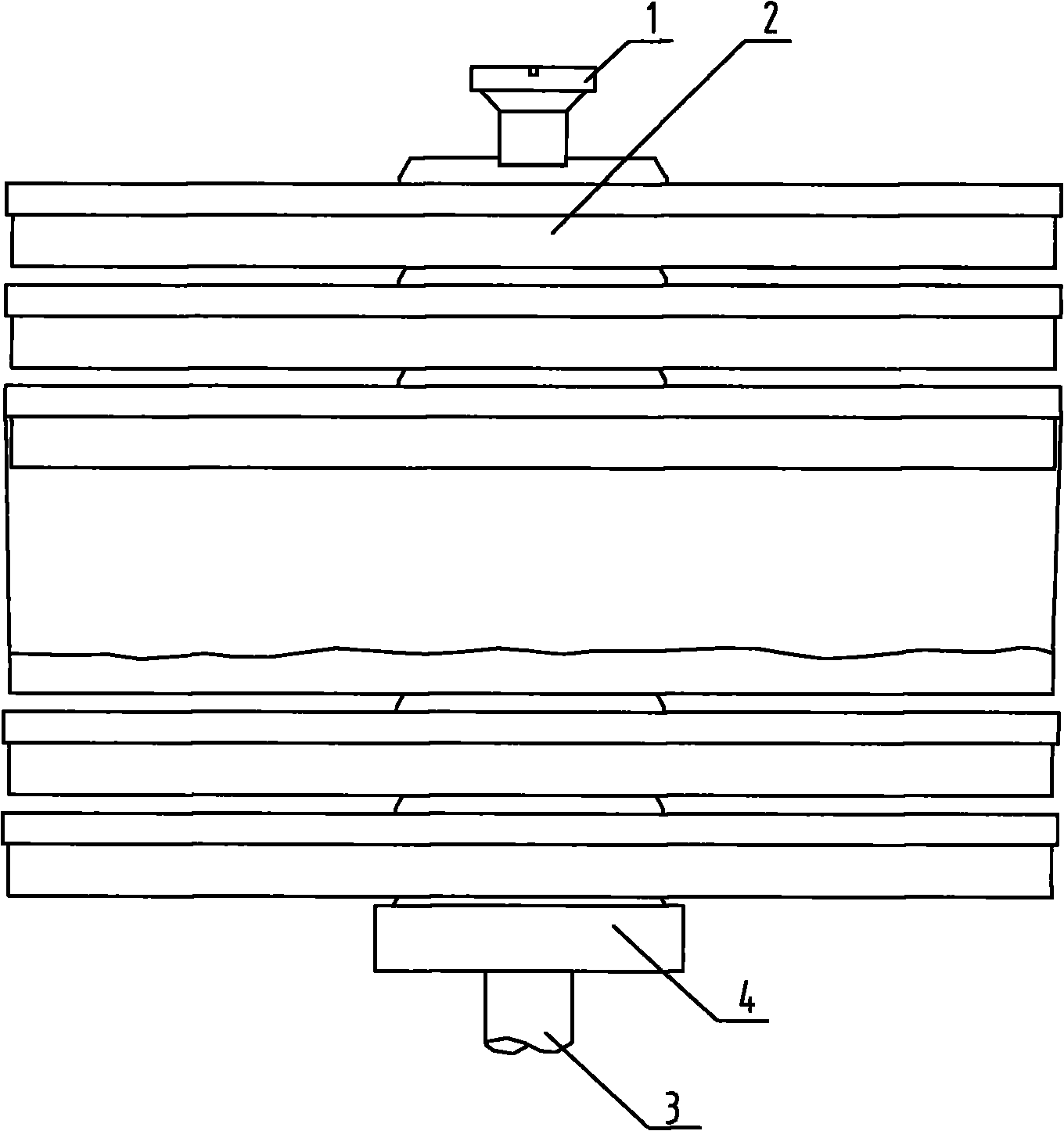

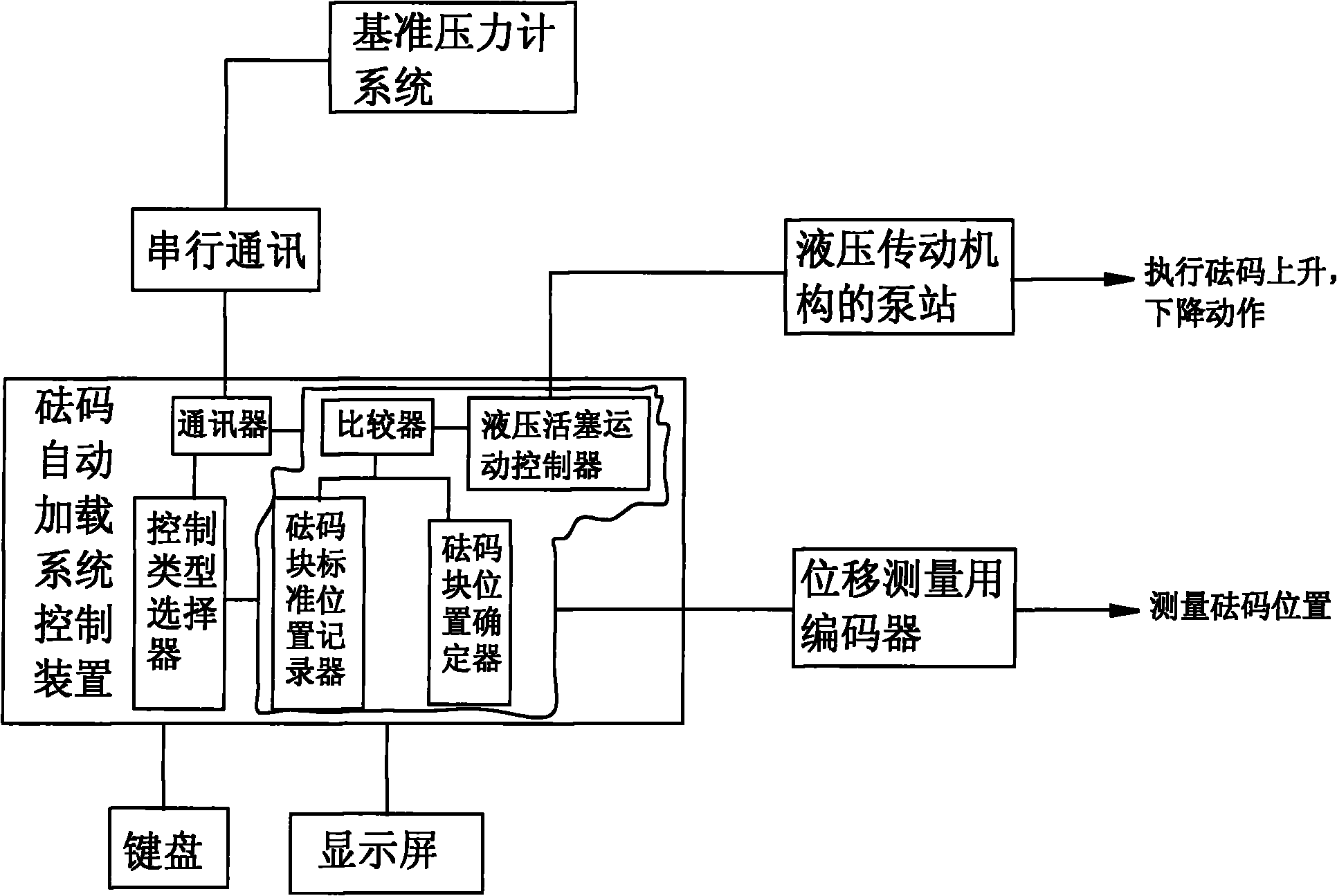

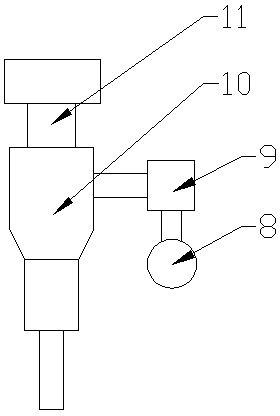

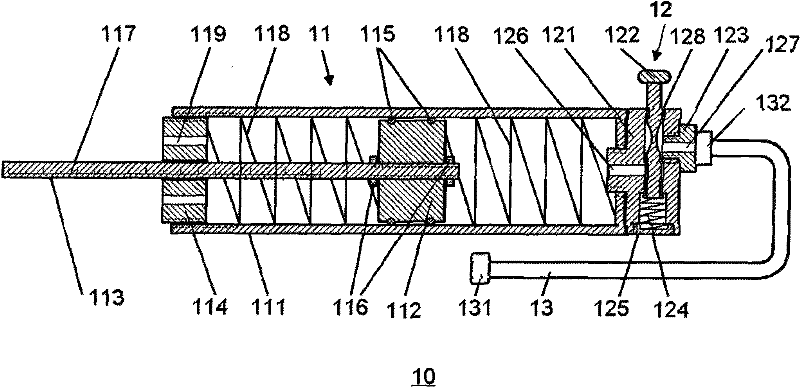

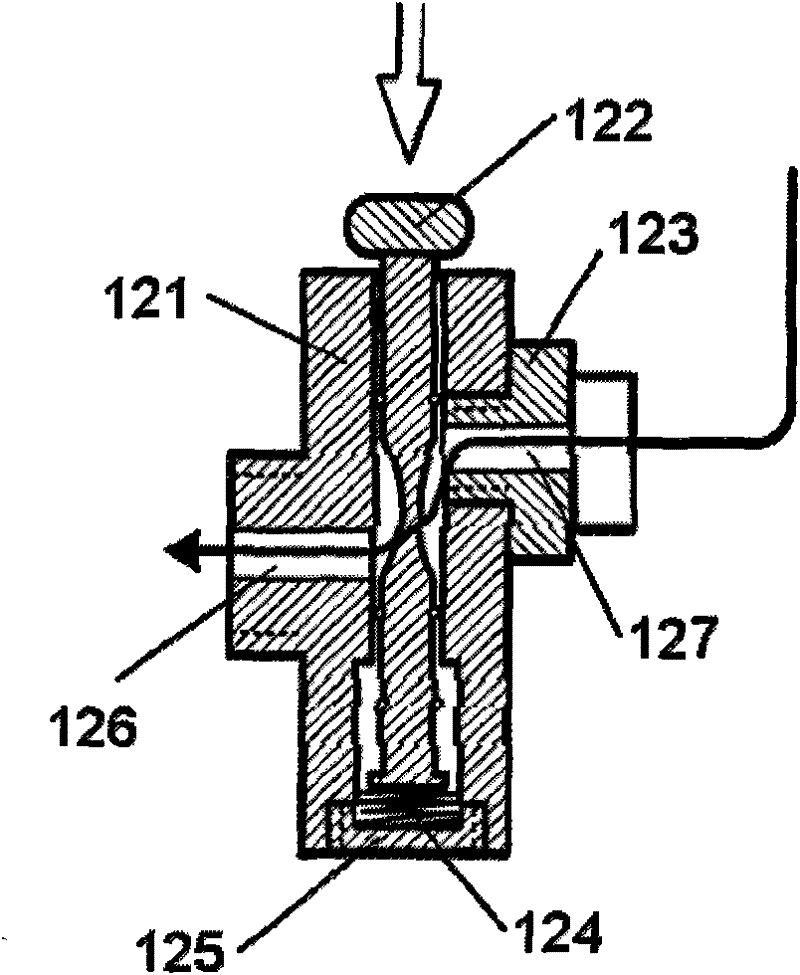

Automatic weight loading system of piston type gauge

InactiveCN101788363AExtended service lifeRealize fully automatic controlFluid pressure measurement using pistonsMicrocontrollerAutomatic control

The invention relates to a piston type gauge, belonging to the technical field of measurement. The automatic weight loading system of the piston type gauge comprises a weight and fluid drive mechanism, a displacement measuring mechanism, a singlechip control device and a computer communication operation system. After the automatic weight loading system of the piston type gauge reforms the existing weight structure, the added displacement measuring device measures the upper and lower displacement of the weight, and displacement amount in practical working condition is compared with a calibrated weight position by the singlechip control technology so as to control the upper and lower displacement of the weight and realize full-automatic control of automatic loading and automatic adjustment; thus, the piston type gauge realizes integral full automation from weight loading to pressure measurement, which simplifies measurement operation, improves accuracy and prolongs the service life of the piston.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

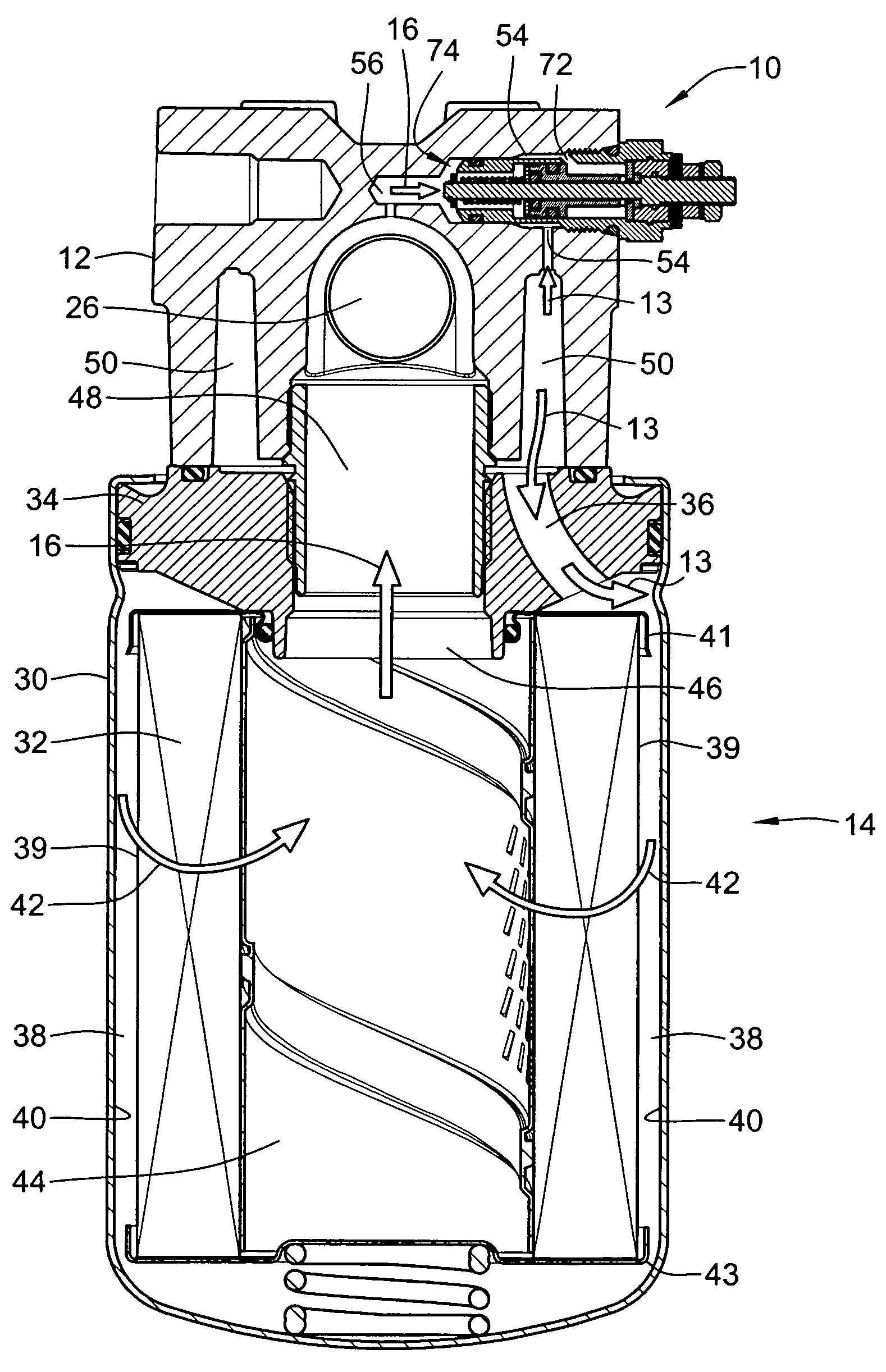

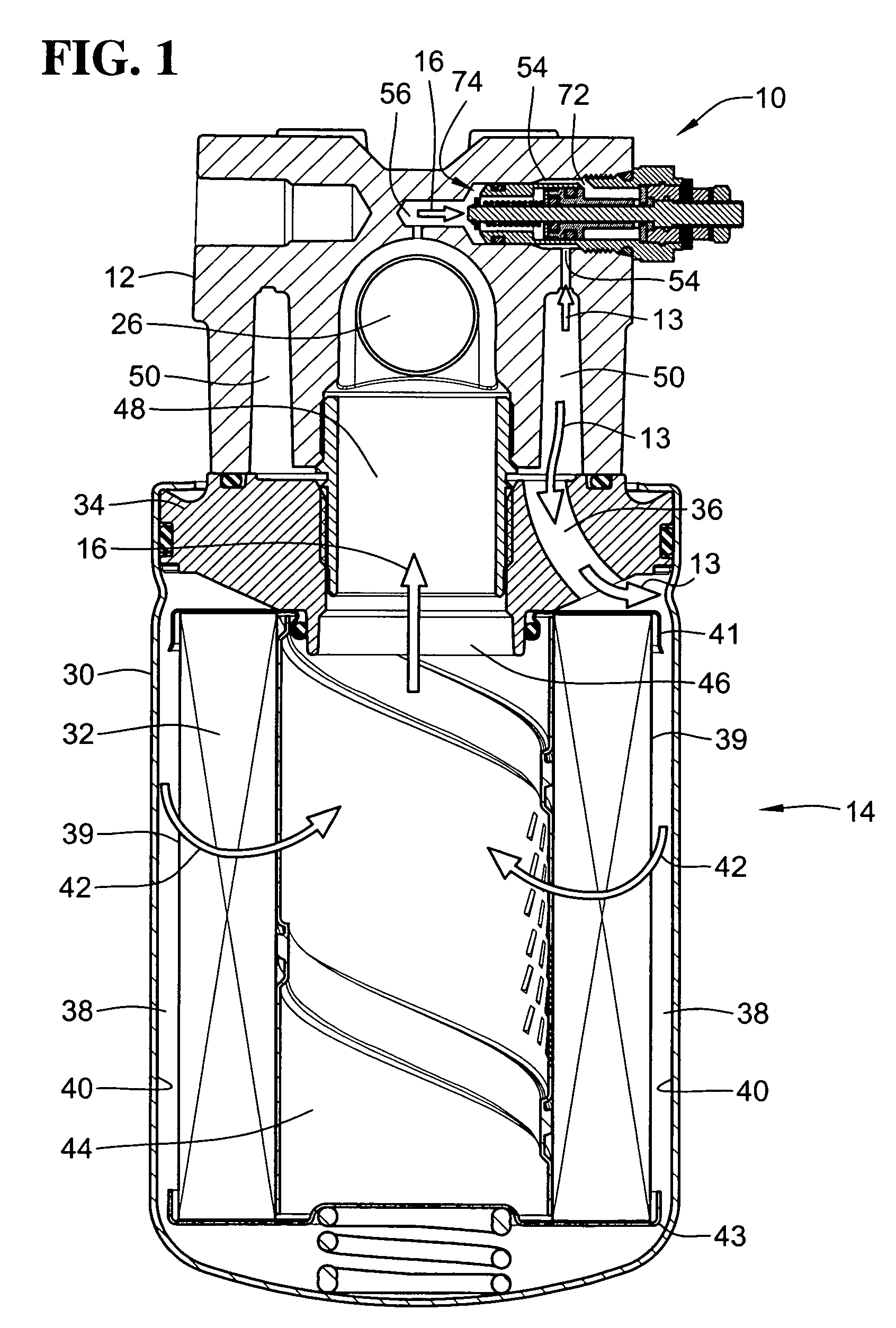

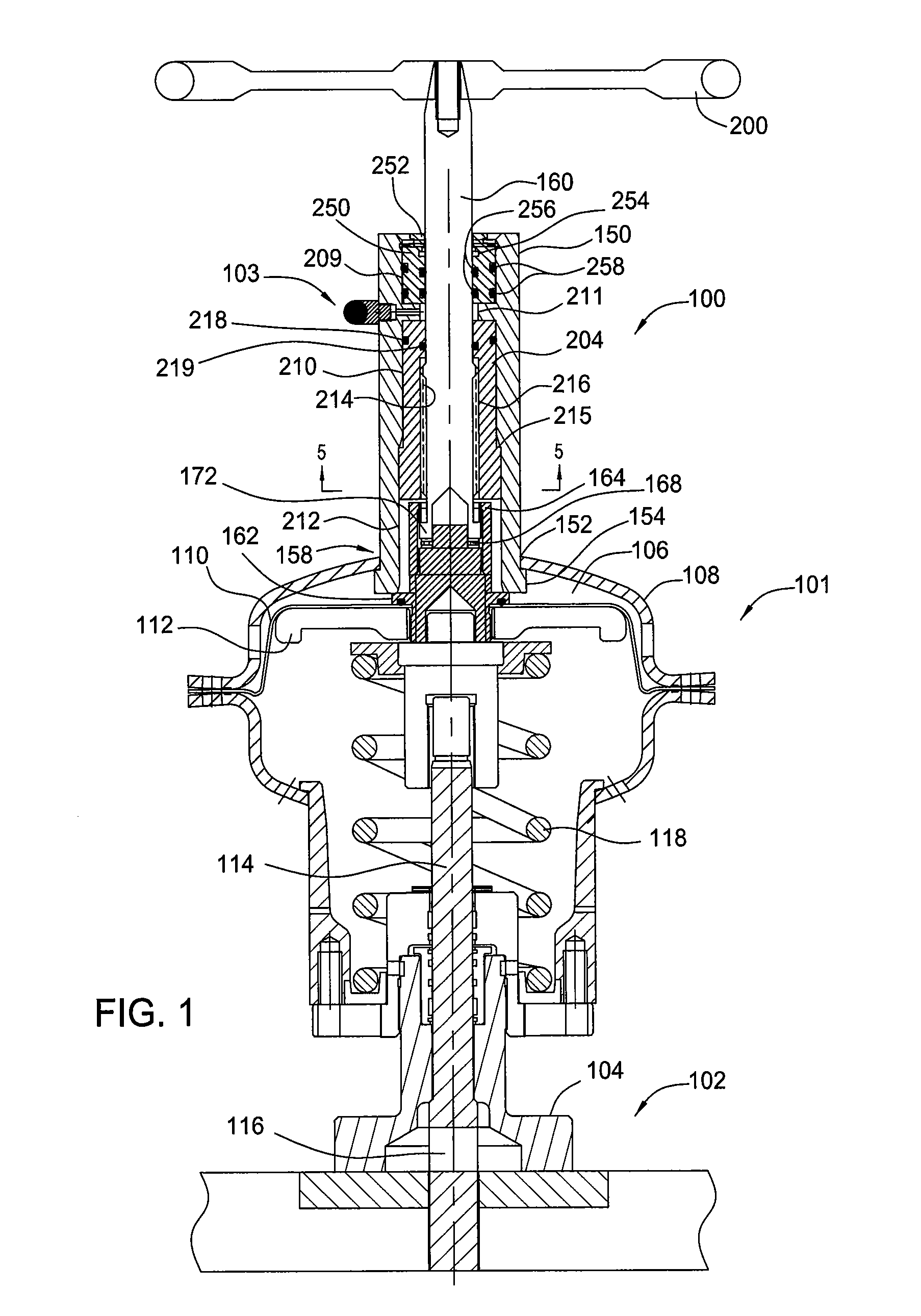

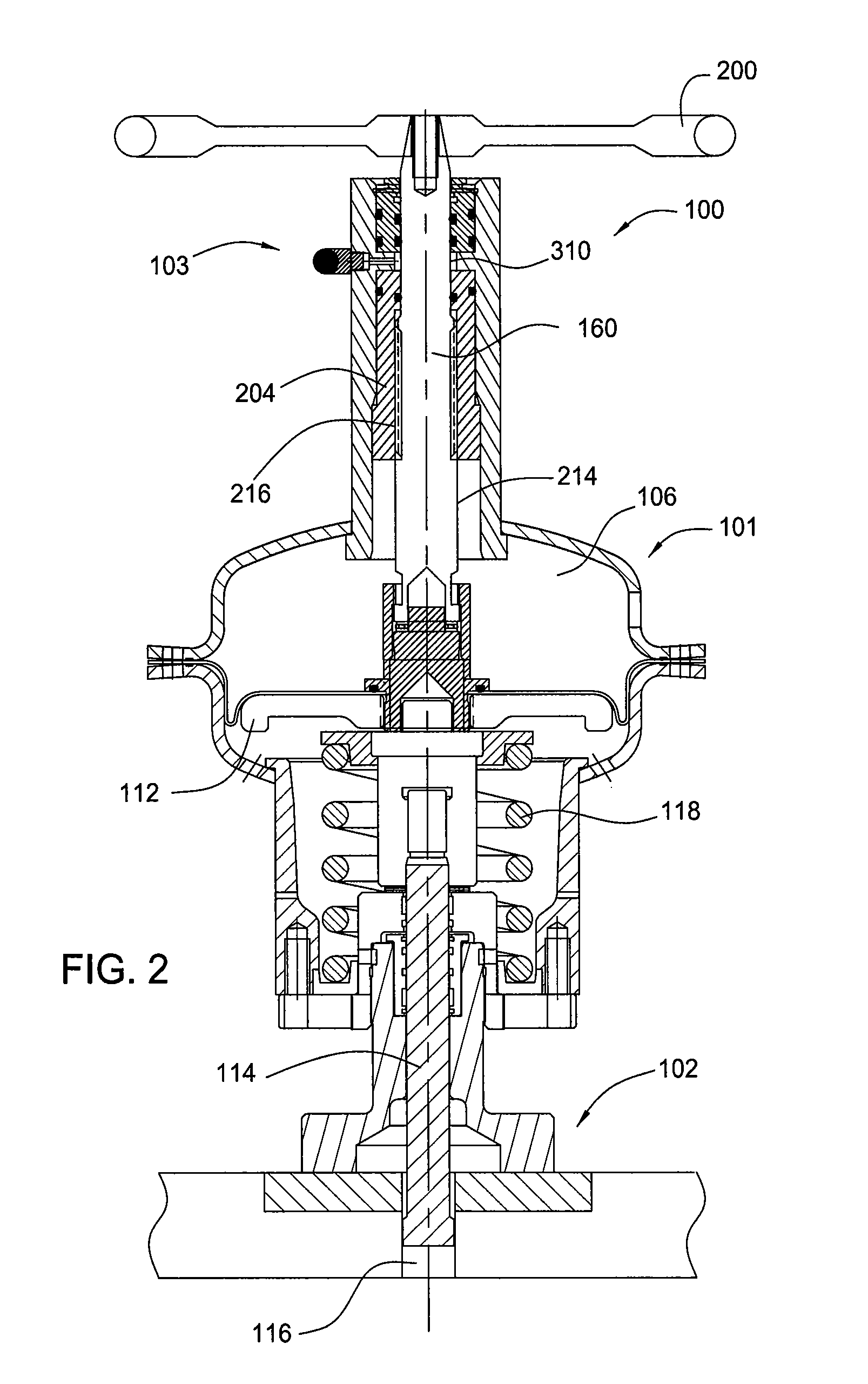

Safety valve and method of use

ActiveUS8851108B2Operating means/releasing devices for valvesFluid pressure measurement using pistonsActuatorSafety valve

Embodiments of a method of operating a safety valve and a safety valve system are provided. The valve system includes a valve, an actuator, a mechanical override, and an indicator. The actuator includes a fail-safe mechanism and the indicator is configured to indicate whether the fail-safe mechanism is operable during use of at least one of the actuator and the mechanical override. In one embodiment, a method of operating the safety valve includes actuating the valve into an open position and sending a signal to indicate that the fail-safe mechanism is operable to move the valve to the closed position, while the valve is in the open position.

Owner:SAFOCO

Hydraulic transmission pressure gauge

InactiveCN105043642AMeasure the pressureShorten production timeFluid pressure measurement using pistonsEngineeringMechanical engineering

The invention discloses a hydraulic transmission pressure gauge. The hydraulic transmission pressure gauge includes a hollow tube; hydraulic oil is arranged in the hollow tube; a piston is connected into a first cavity at one end of the hollow tube in a sliding manner; the piston is communicated with the inlet of the pressure gauge; a rack is connected into a second cavity at the other end of the hollow tube in a sliding manner; one side of the rack, which is far away from the second cavity, is provided with a fixing rod; a spring is connected between the rack and the fixing rod; the rack is engaged with a gear; and the gear is fixedly connected with a pointer. The hydraulic transmission pressure gauge of the invention has the advantages of simple structure and lower production cost.

Owner:CHONGQING BRIGHTY INSTR

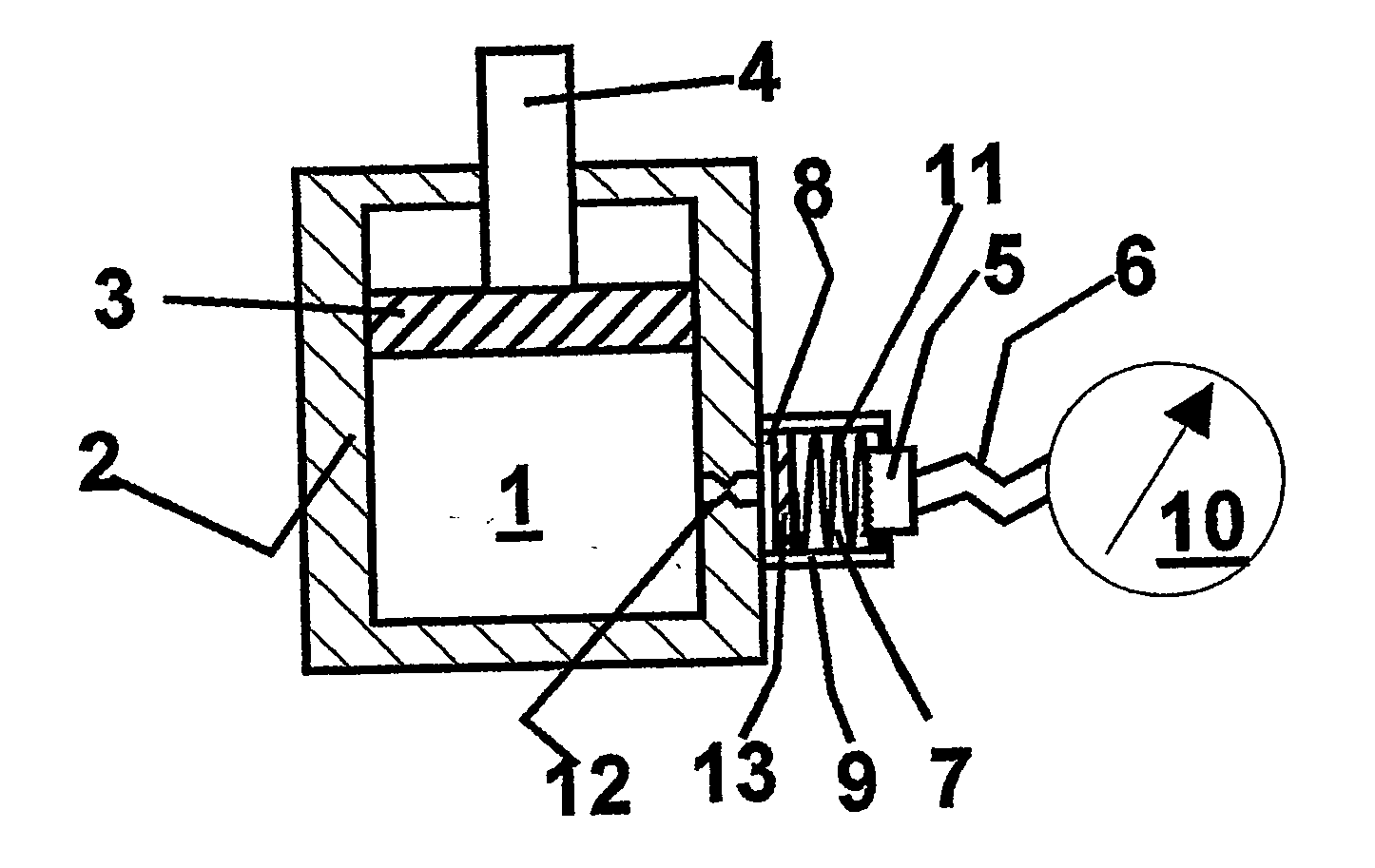

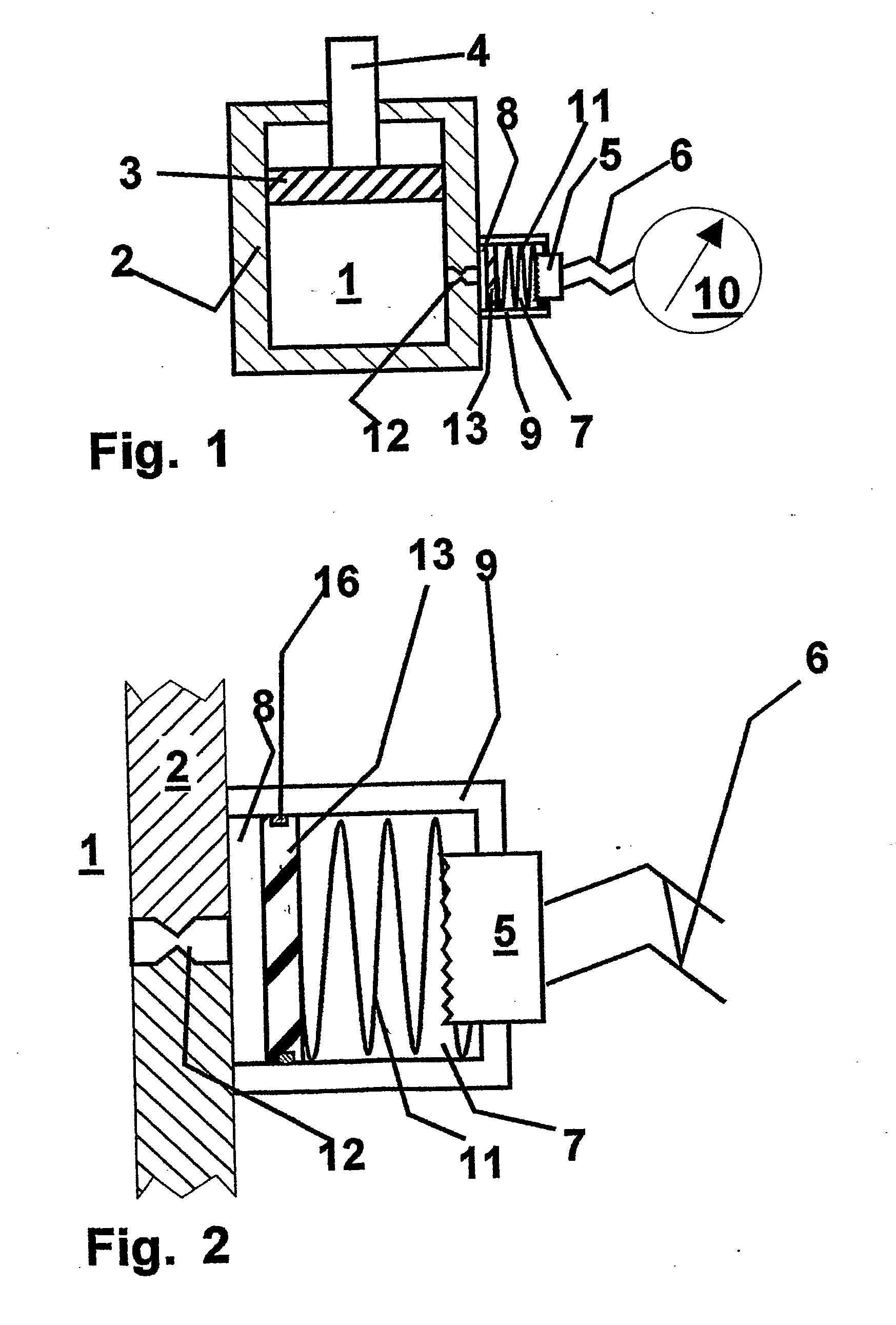

Pressure sensor

InactiveUS7472600B2Fluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsBiomedical engineeringPressure measurement

The invention relates to a pressure sensor (1), comprising a housing (2), a housing element (3) which may be exposed to a pressure chamber (10), mounted on the housing (2) by means of a metallic membrane (5) and a measuring cell (4) which can indirectly measure a pressure acting on the housing element (3) and transmitted to the measuring cell (4) as a force resulting therefrom. According to the invention, said pressure sensor (1) comprises a housing element (3) embodied as a pin and projects out of the housing (2). The advantage of such an arrangement is only a small drilling to a pressure chamber (10) need be provided, in order to carry out a pressure measurement. The pin (3) need only be so long that the front end thereof, in the assembled state, approximately reaches the wall (11) of the pressure chamber (10).

Owner:ROBERT BOSCH GMBH

Nozzle-blocking sensing mechanism for spreading machine

InactiveCN103774530ASimple structureImprove reliabilityFluid pressure measurement using pistonsRoads maintainenceStructural engineeringPiston

The invention discloses a nozzle-blocking sensing mechanism for a spreading machine. The nozzle-blocking sensing mechanism comprises a shell, wherein a blind hole is formed inside the shell; a pipeline connector is formed at an opening of the blind hole; a main piston is arranged in the middle of the blind hole; a spring is arranged at the position, back to the opening of the blind hole, of the main piston; the other end of the spring is fixedly connected with the bottom of the blind hole; a contact switch is also arranged at the bottom of the blind hole. When the pressure of fluid at the pipeline connector is greater than a preset value of the spring, the spring is compressed, the piston contacts the contact switch, and a detection circuit is conducted; the detection circuit comprises a connecting port and a detection end connected with the connecting port; the connecting port is connected with a contact spring; when the contact spring is switched on, the detection circuit is conducted, and the detection end gives a signal prompt.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

Pressure fault device

InactiveUS7059194B1Shorten the timeValve arrangementsFluid pressure measurement using inductance variationDifferential pressureEngineering

The invention involves a pressure fault device for indicating a threshold pressure or a threshold differential pressure. The present invention provides a cost effective way to determine where a pressure problem has occurred. The device includes a housing having at least one inlet aperture and an indicator aperture and having first and second bores in fluid communication respectively with one inlet aperture and the indicator aperture. The device further includes a magnetic piston which is biased in the first bore toward one inlet aperture and moveable a predetermined distance in another direction in the first bore in response to inlet threshold pressure. The device further includes a magnetic responder which is moveable toward the indicator aperture in the second bore in response to movement of the magnetic piston. The device further includes a latching plate in magnetic relationship to the magnetic responder when the piston moves the predetermined distance. An indicator is disposed in the second bore and partially extends through the indicator aperture. At a threshold pressure or differential pressure, the magnetic responder responds to movement of the magnetic piston and latches onto the latching plate, thrusting the indicator partially through the indicator aperture to indicate a threshold has been reached. The configuration of the magnetic piston and the magnetic responder prevents the magnetic responder from being dislodged from the latching plate, even when the threshold is removed and the magnetic piston returns to its initial position. The magnetic responder can be manually reset when the threshold pressure is removed.

Owner:MIDWEST INSTR

Manometer

ActiveUS20140216164A1Accurate measurementEasily read out measured valueFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement using pistonsEngineeringPlunger

A manometer comprises a manometer body with an indicating scale with graduated markings of pressure units and a safety vent, a plunger with a annular groove and a tinted O-ring a cap mount, a primary box spring and an auxiliary box spring. By means of the tinted O-ring and the indicating scale with graduated markings of pressure units, the manometer innovatively functions as indication of air pressure measured. By means of the primary box spring and auxiliary box spring, the manometer precisely measures overall air pressure in combination of coarse air pressure variation responded by the primary box spring and fine air pressure variation responded by the auxiliary box spring. By means of the safety vent disposed on the peripheral of manometer body and the tinted O-ring on the plunger, the manometer provides a safety proactive means for input compressed air.

Owner:CHOU WEN SAN

Pipeline air pressure on-line detector and detection method

ActiveCN102221437AImprove measurement accuracyImprove efficiencyFluid pressure measurement using pistonsPipeline.airEngineering

The invention discloses a pipeline air pressure on-line detector, comprising detection parts, a hand valve and an air inlet pipe. The detection parts comprise a piston housing, a piston and a piston rod, wherein one end of the housing is provided with a chamber cover, one end of the piston rod passes through the chamber cover, the piston rod is provided with a scale and both sides of the piston are respectively provided with a detection spring. The invention also discloses another pipeline air pressure on-line detection method. Under the conditions that the air inlet pipe communicates with the pipeline to be detected and the hand valve is opened, the piston moves under the effect of pipeline air pressure and the piston rod is driven to stretch. The air pressure state value of the pipeline can be detected through the reading of the scale. Therefore, the measuring apparatus has advantages such as high measurement accuracy, on-line detection option, positive and negative air pressure detection option, simple and convenient operation, high efficiency and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Air pump pressure gauge

An air pump pressure gauge includes a casing, an inner tube coaxially affixed to the casing and defining with the casing an accommodation chamber, a movable member movable back and forth in the accommodation chamber, an end cap end cap set between the inner tube and the casing to seal one end of the accommodation space, a spring member stopped between the end cap and the movable member, at least one seal member mounted on the movable member to define a first airtight structure between the outer surface of the inner tube and the at least one seal member and a second airtight structure between the inside wall of the casing and the at least one seal member, an air hole in communication between the axial hole of the inner tube and the accommodation space, a longitudinal sliding slot located on the movable member, a rack extending along one side of the longitudinal sliding slot, a rotating axle inserted through the longitudinal sliding slot and having its inner end pivoted to the inner tube and its outer end extending out of the casing and a middle part thereof mounted with a gear being meshed with the rack, a pointer fixedly connected to the outer end of the rotating axle outside the casing, a graduation scale mounted on the casing below the pointer, and a transparent cover covering the graduation scale and the pointer.

Owner:BETO ENG & MARKEITNG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com