Nozzle-blocking sensing mechanism for spreading machine

A spreader and sensing technology, used in road, piston-type fluid pressure measurement, road repair and other directions, can solve problems such as uneven spreading, affecting project quality, nozzle blockage, etc., to ensure sensitivity, not easy to damage, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be given below in conjunction with the accompanying drawings

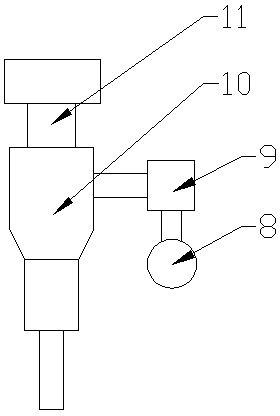

[0016] like figure 2 As shown, this product: the spreader blocking sensor mechanism 9 is installed at the junction of the asphalt spout 10 and the asphalt connecting pipe 11 through a tee;

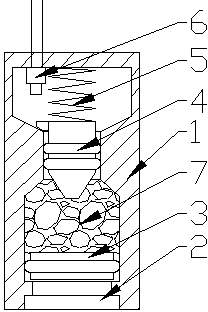

[0017] This product includes a pressure sensor and a detection circuit. The pressure sensor is set at the connection between the asphalt connecting pipe and the asphalt nozzle, and the detection circuit is connected to the pressure sensor;

[0018] The pressure sensor includes a housing 1. A blind hole is arranged inside the housing 1. A pipeline interface 2 is arranged at the opening of the blind hole as shown. A main piston 4 is arranged in the middle of the blind hole, and a main piston 4 is arranged at the opening of the blind hole. Spring 5, the other end of the spring 5 is fixedly connected to the bottom of the blind hole, and a contact switch 6 is also arranged at the bottom of the blind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com