Pipeline air pressure on-line detector and detection method

A detection method and technology of a detector, applied in the direction of piston-type fluid pressure measurement, etc., can solve the problems of increased workload, long time-consuming, wide influence, etc., and achieve the effect of detection operation, high measurement accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

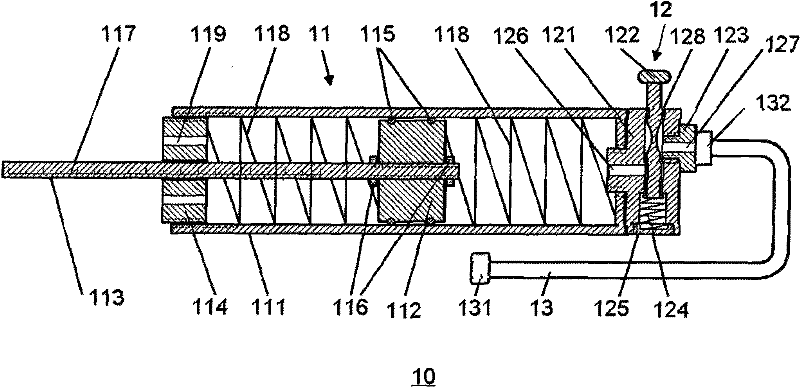

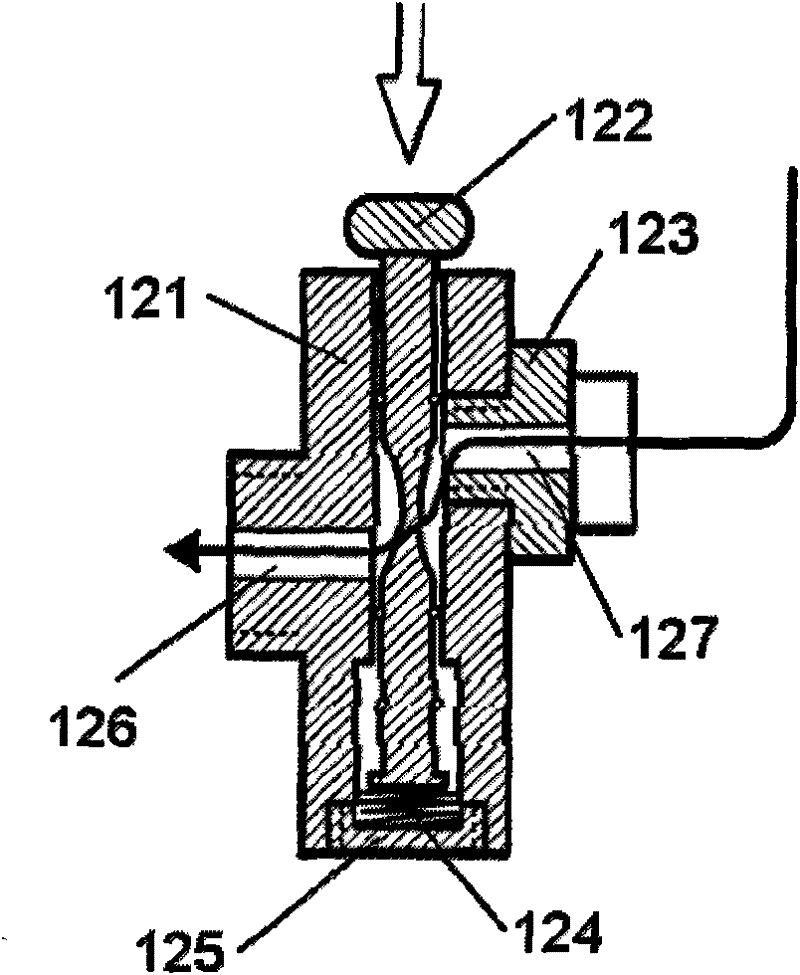

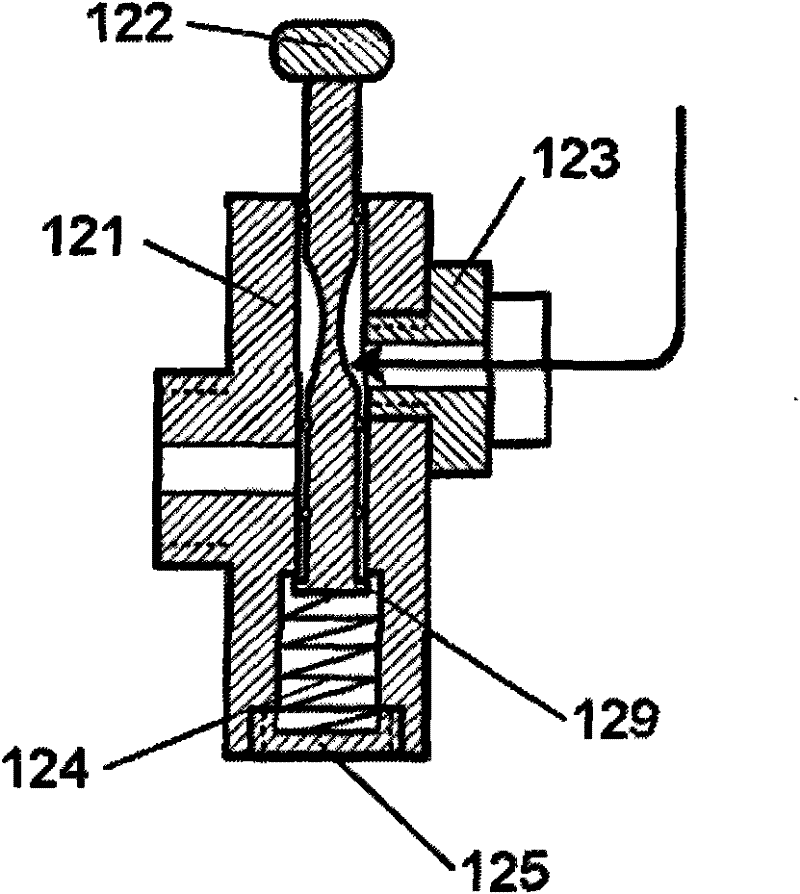

[0040] see figure 1 As shown, the pipeline air pressure online detector 10 of the present invention includes a detection component 11 , a hand valve 12 and an intake pipe 13 . Wherein, the detection part 11 comprises a piston housing 111, a piston 112 and a piston rod 113, a cavity cover 114 is provided at one end of the housing 111, the piston 112 is arranged in the housing 111, and two seals 115 are set on the piston 112, and the housing The body 111 is divided into two left and right chambers. One end of the piston rod 113 passes through the piston 112 and is fixed by a fixing nut 116. The other end passes through the chamber cover 114. The piston rod 113 is provided with a scale 117. A detection spring 118 is provided respectively; a hand valve 12 is arranged at the other end of the piston housing 111 and communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com