Full-automatic piston type pressure gauge

A piston pressure gauge, fully automatic technology, applied in the field of precision instruments, can solve problems such as errors and low work efficiency, achieve the effect of improving accuracy, improving efficiency and accuracy, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

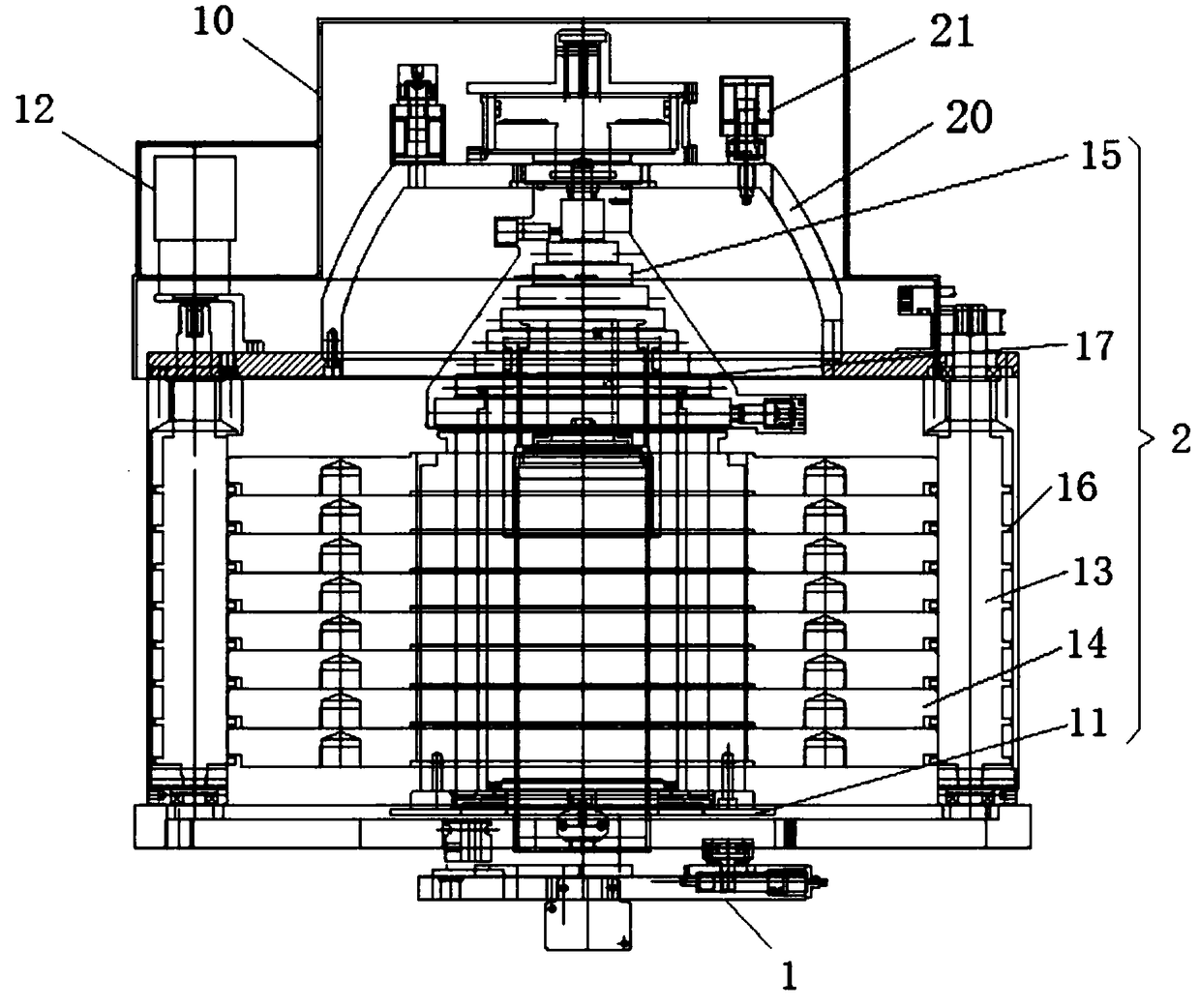

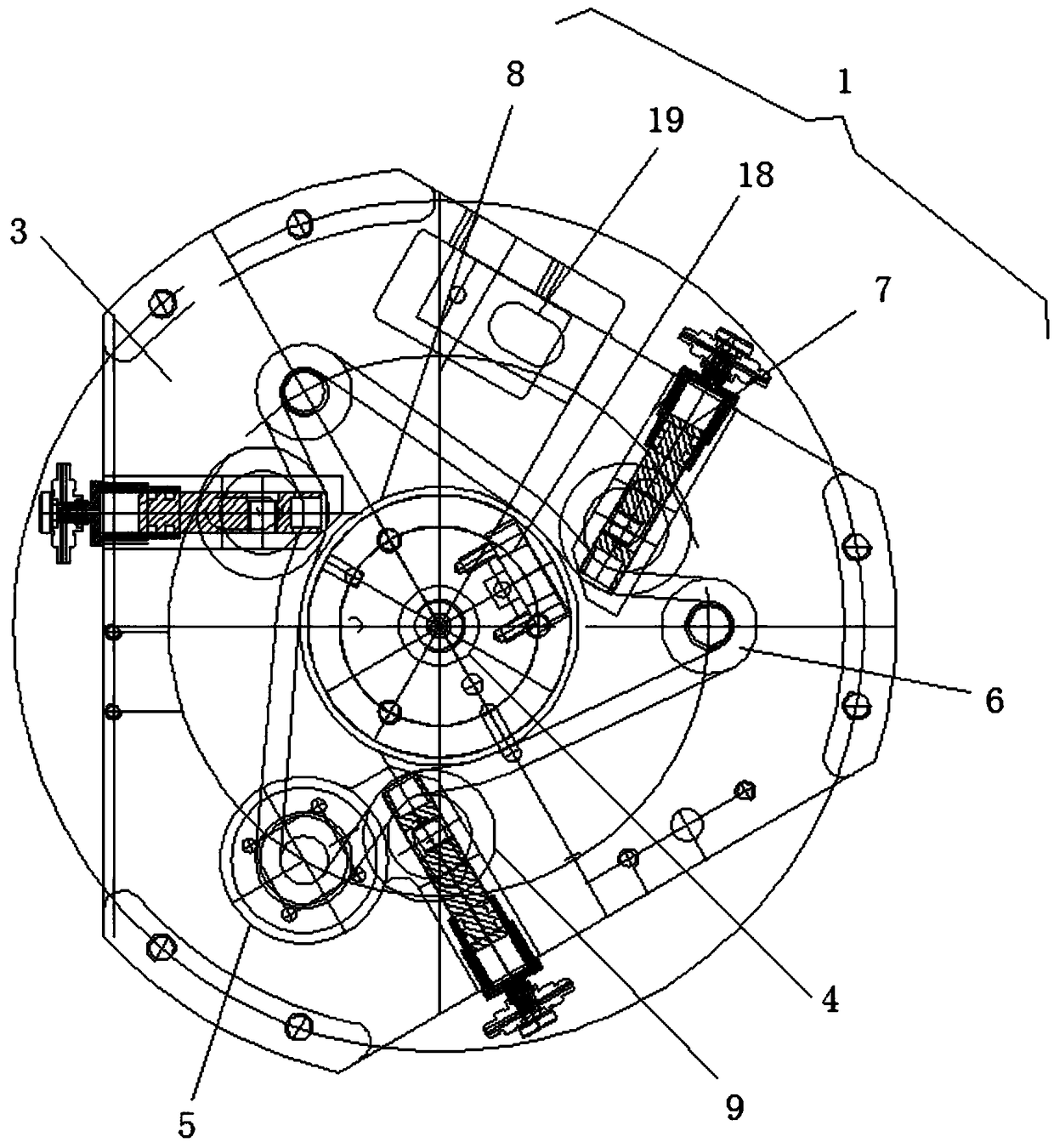

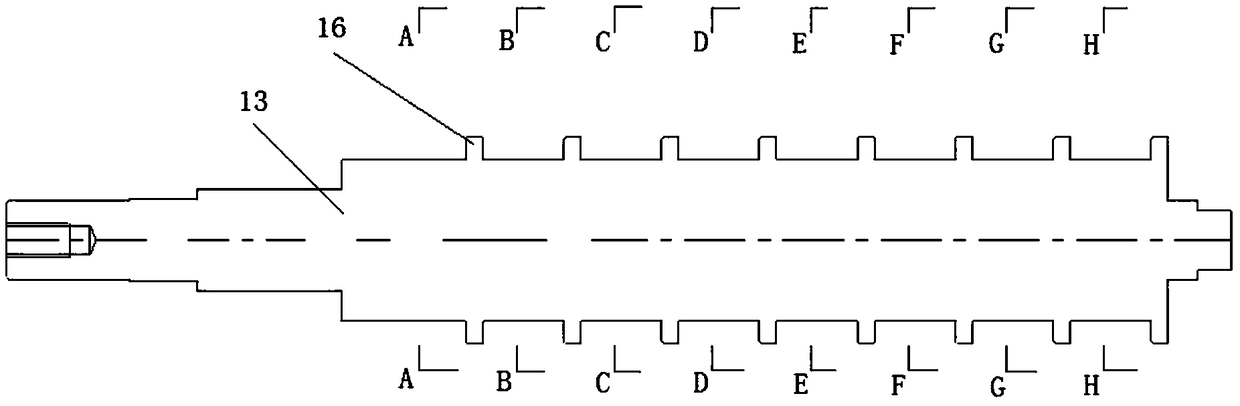

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a fully automatic piston pressure gauge includes a piston rotation system 1 and a weight selection system 2, the piston rotation system 1 is located at the bottom of the weight selection system 2, and the weight selection system 2 The top is provided with an upper casing 10;

[0024] The piston rotation system 1 includes a base 3, a central shaft 4, a first stepper motor 5, a pulley 6 and a tensioning piston 7, a central shaft 4 is provided at the center of the base 3, and on the central shaft 4 A sleeve 8 is provided, and three pulleys 6 are distributed on the outside of the sleeve 8, and the three pulleys 6 are connected to each other by belts, and one of the pulleys 6 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com