Plastic intake manifold air path for gasoline engine

A gasoline engine, intake manifold technology, applied in engine components, machines/engines, combustion air/combustion-air treatment, etc., to increase intake efficiency, reduce airflow resistance, and reduce occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

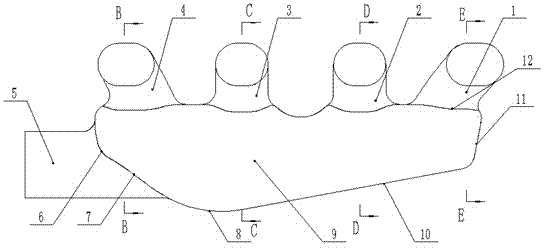

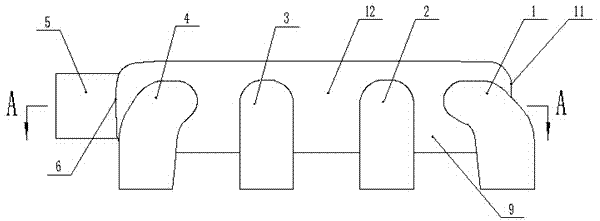

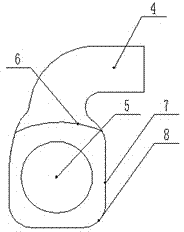

[0062] like Figure 1 to Figure 5 As shown, the present invention includes a first branch pipe airway 1, a second branch pipe airway 2, a third branch pipe airway 3, a fourth branch pipe airway 4, an intake manifold airway 5 and a pressure-stabilizing chamber 9. The air intake uniformity of the air passage is better to ensure the uniformity of the intake air of each cylinder. The pressure stabilization chamber 9 is in an asymmetrical irregular shape. The left lower wall of the cavity 7, the lower wall of the transition arc of the voltage stabilization chamber 8, the right lower wall of the voltage stabilization chamber 10, the right side wall of the voltage stabilization chamber 11 and the upper wall of the voltage stabilization chamber 12 are formed. The angle between the left lower wall 7 of the voltage stabilization chamber and the horizontal plane The angle is 34°~36°, which is relatively steep. The angle between the lower right wall 10 of the pressure regulator chamber an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com