Patents

Literature

153results about How to "Avoid clogging pipes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling acidic vanadium deposit wastewater

ActiveCN102838233AControl calcium ion concentrationAvoid clogging pipesMultistage water/sewage treatmentSulfateWastewater

The invention provides a method for recycling acidic vanadium deposit wastewater. The method comprises the following steps: adjusting the acidic vanadium deposit wastewater to be alkaline by lime milk, then carrying out solid-liquid separation to obtain an alkaline solution and a gypsum residue; adding a decalcifying agent into the alkaline solution for decalcifying, then carrying out solid-liquid separation to obtain a supernatant liquor and a decalcified residue; and adjusting the pH of the supernatant liquor to be 3-7 by sulfuric acid, then returning the supernatant liquor to the leaching step for recycling. Due to the adoption of the method for recycling the acidic vanadium deposit wastewater, concentration of calcium ions in the solution returned to the leaching step can be effectively controlled, calcium sulfate deposit is prevented from being formed, a pipeline and a water outlet are prevented from being blocked due to calcium sulfate scale, and the production equipment is guaranteed to run normally.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

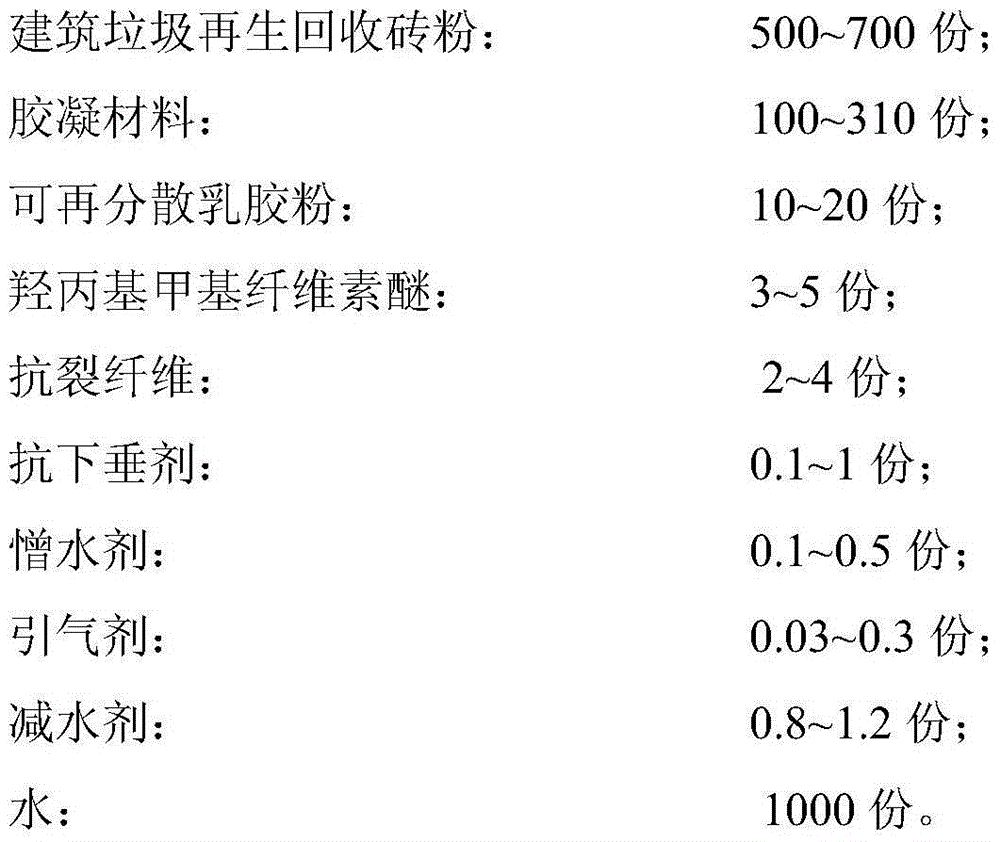

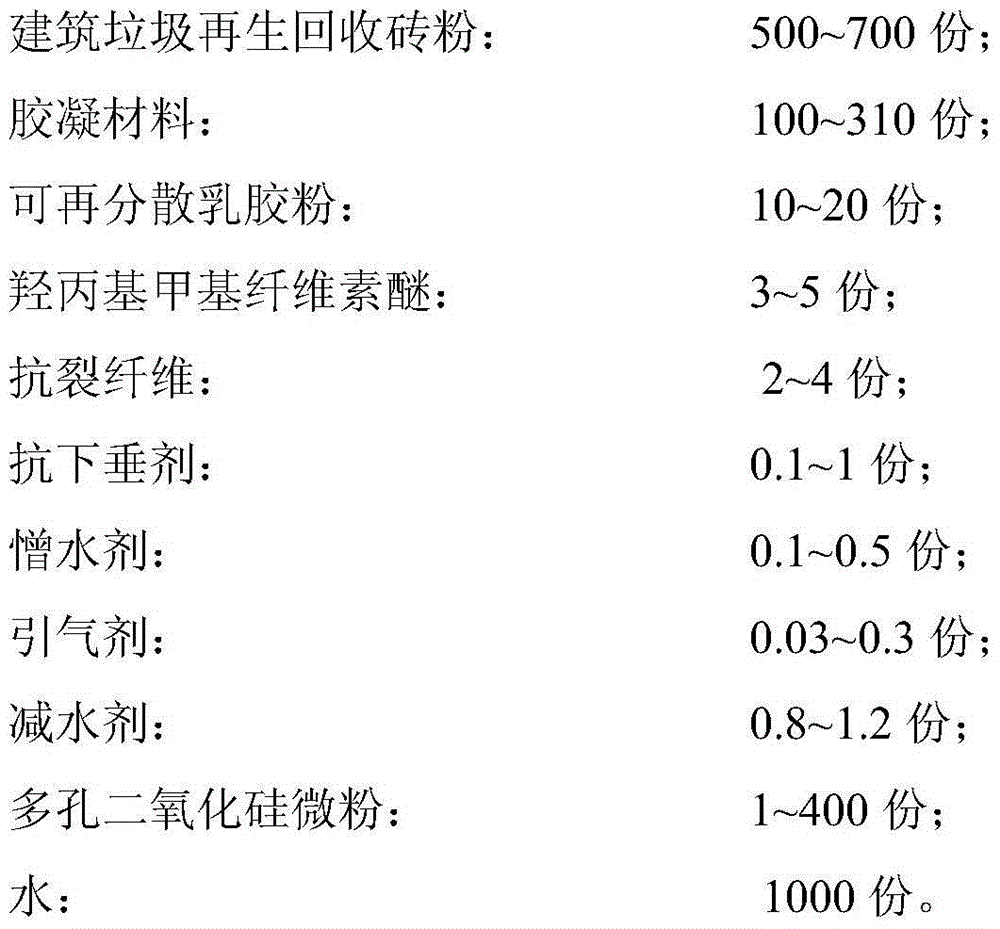

Construction waste reclaimed brick powder-containing spray construction heat insulation mortar

The invention discloses a construction waste reclaimed brick powder-containing spray construction heat insulation mortar. The mortar is prepared from, by weight, 500-700 parts of construction waste reclaimed brick powder, 100-310 parts of a gelling material, 10-20 parts of redispersible powder, 3-5 parts of hydroxypropyl methyl cellulose ether, 2-4 parts of a crack resistant fiber, 0.1-1 part of an anti-sagging agent, 0.1-0.5 parts of a water repellent, 0.03-0.3 parts of an air entraining agent, 0.8-1.2 parts of a water reducer and 1000 parts of water. The mortar has the characteristics of A grade flame retardation, good heat insulation performance, high compression and tensile strength, long life, environmental protection, waste recycling, easy mechanical spraying construction, construction energy consumption reduction, suitableness for internal and external wall heat insulation construction, simplicity, feasibility and low cost.

Owner:TONGJI UNIV

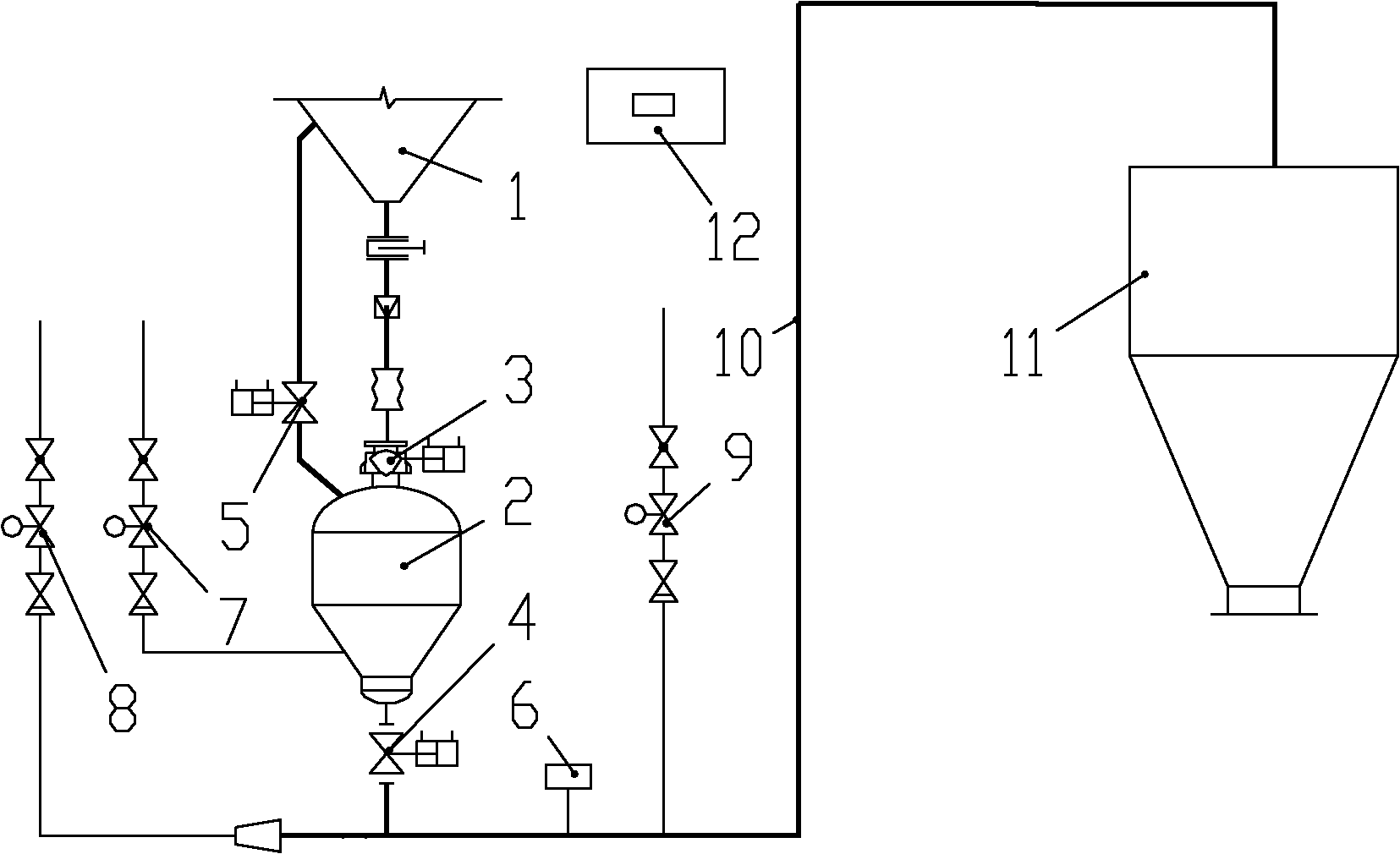

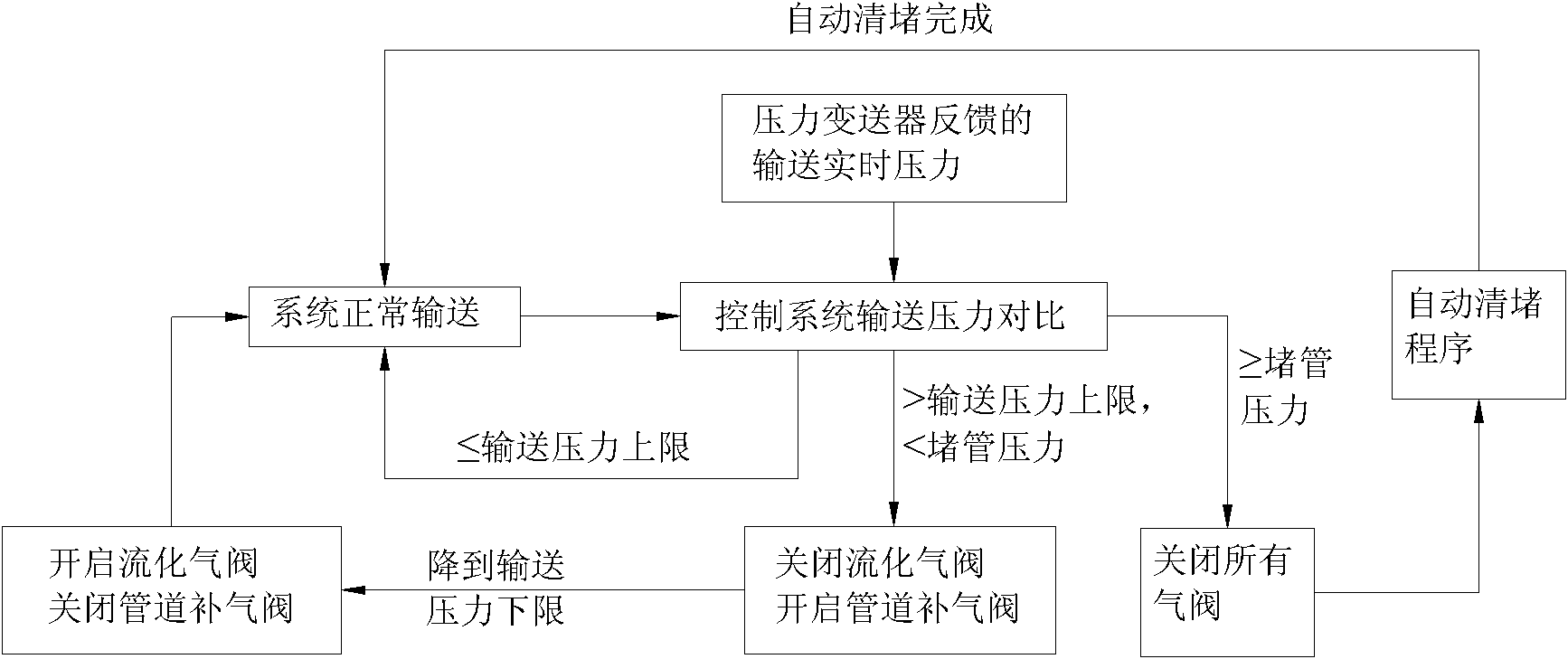

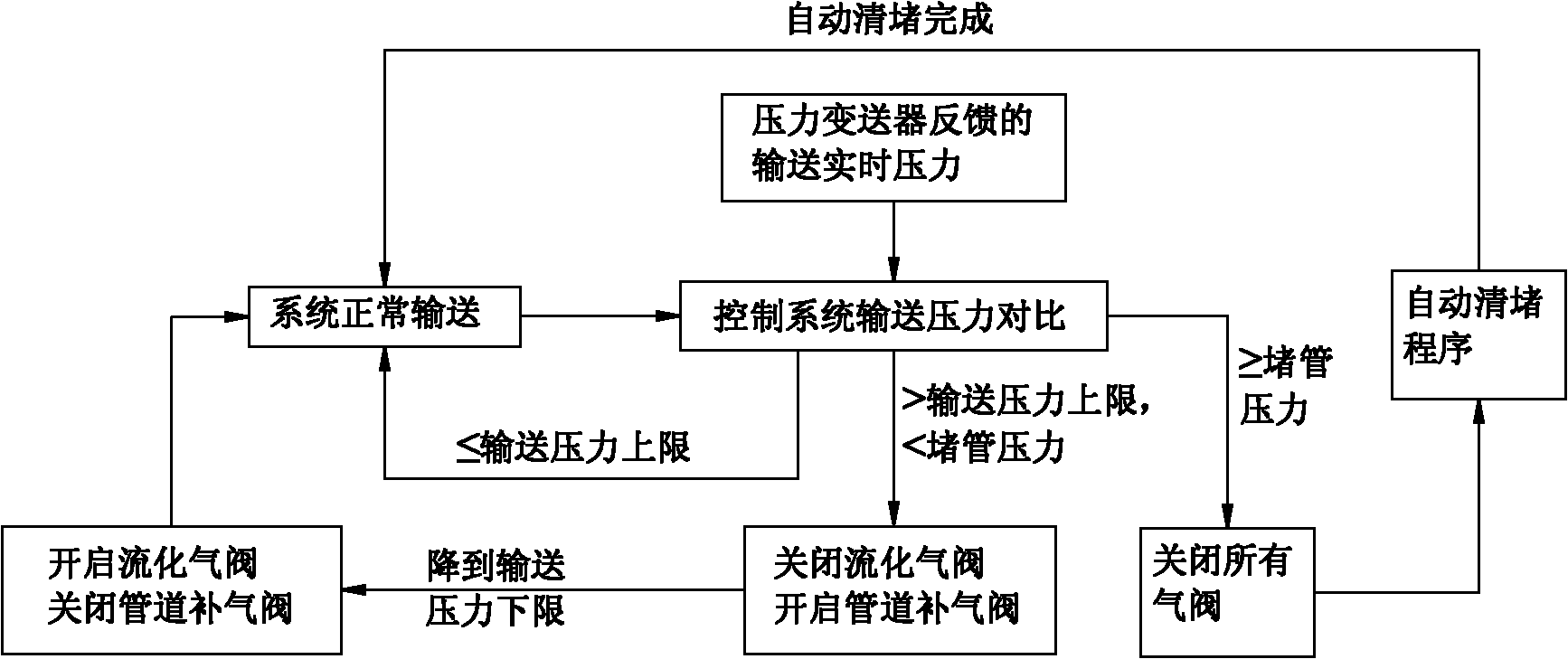

Conveying control method for pneumatic conveying system

The invention provides a conveying control method for a pneumatic conveying system. The conveying control method comprises the following steps of: 1) opening a fluidifying air valve, closing a pipeline air supply valve, comparing conveying real-time pressure with a conveying pressure upper limit, and normally conveying when the conveying real-time pressure is less than or equal to the conveying pressure upper limit, transferring to step 2) when the conveying real-time pressure is more than the conveying pressure upper limit and less than a blockage pressure set value, and transferring to step3) when the conveying real-time pressure is more than or equal to the blockage pressure set value; 2) closing the fluidifying air valve, opening the pipeline air supply valve, and transferring to thestep 1) when the conveying real-time pressure is reduced to a conveying pressure lower limit; and 3) closing all the air valves, transferring to an automatic blockage clearing program, and transferring to the step 1) after the blockage clearing is completed. In the conveying control method, the logic judgment is added on a control system, corresponding air valves are controlled to be opened and closed according to judgment results, the blockage phenomenon is effectively avoided, the time for blockage clearing of the system is shortened, the abrasion and the energy consumption of the system are reduced, and the reliability of the pneumatic conveying system is improved.

Owner:FUJIAN LONGKING

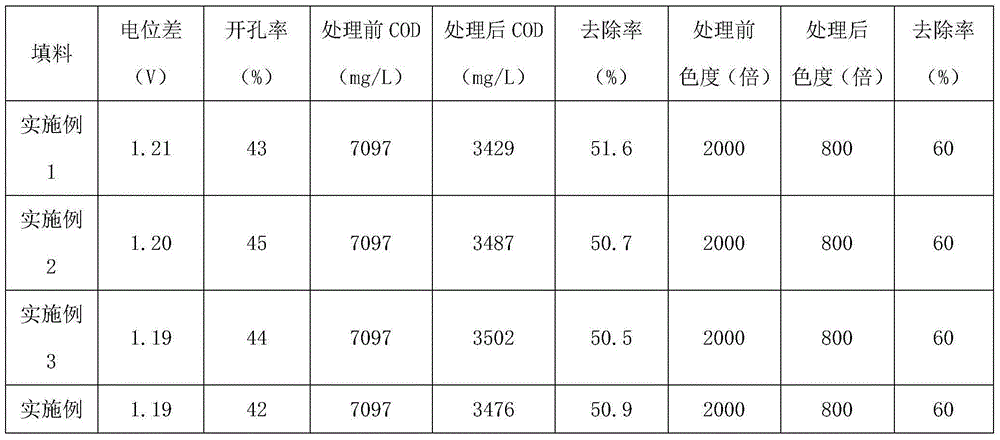

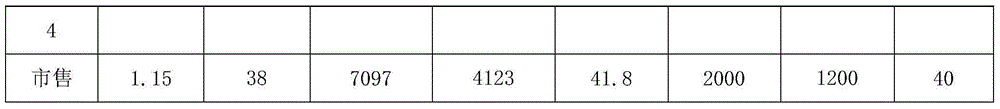

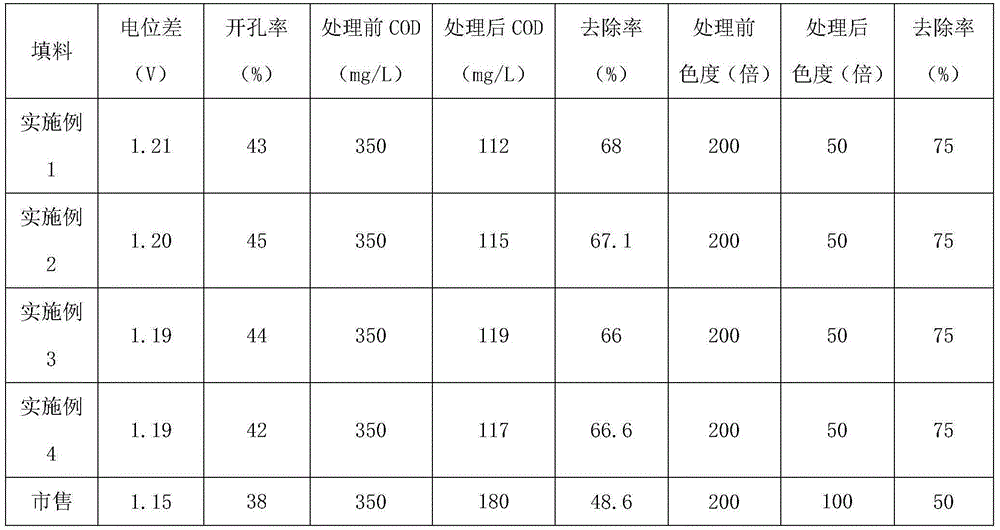

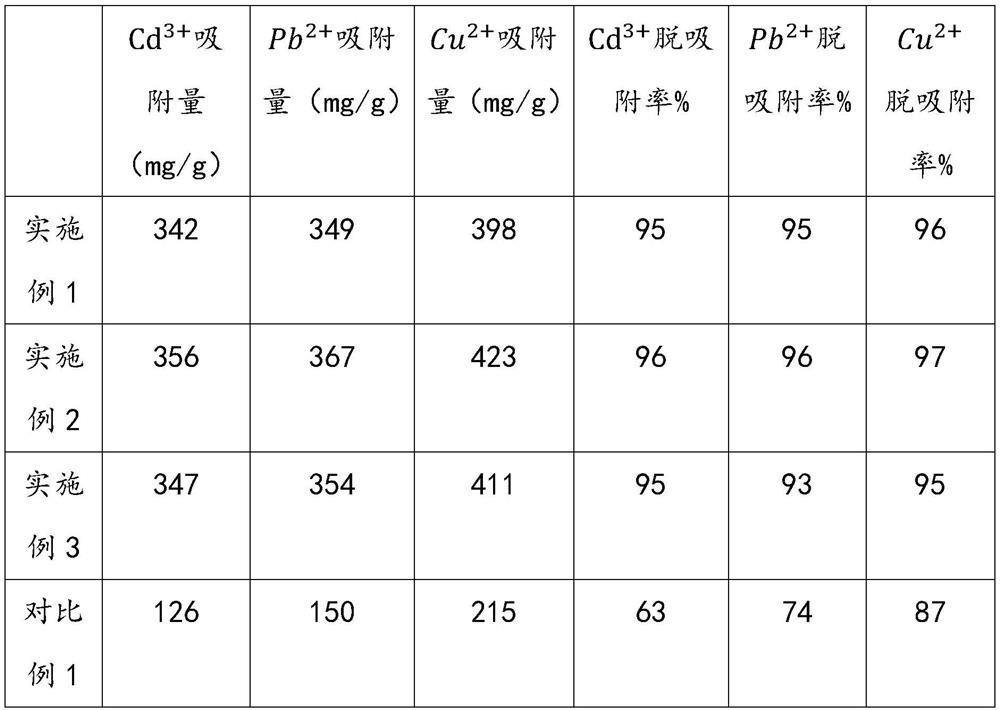

Composite micro-electrolysis filler as well as preparation method and application thereof

ActiveCN105110427ASolve easy hardeningSolving Passivation ProblemsWater/sewage treatmentElectrolysisIron powder

The invention discloses composite micro-electrolysis filler as well as a preparation method and application thereof, and belongs to the field of wastewater treatment. The micro-electrolysis filler is prepared from the raw materials such as iron powder, charcoal active powder, a dispersing agent, a binding agent, a catalyst and the like. By applying the micro-electrolysis filler into the wastewater treatment, the problem that traditional micro-electrolysis filler is likely to harden and passivate can be solved, the biodegradability of wastewater can be obviously improved, and the wastewater processing efficiency is improved.

Owner:东营国安化工有限公司

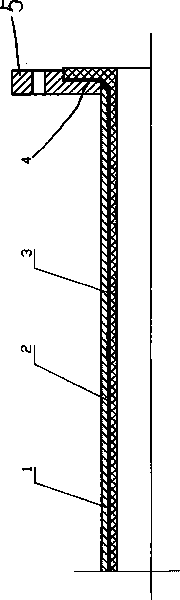

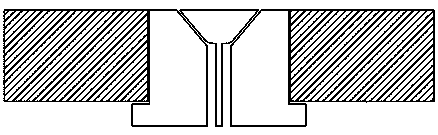

Mine wear-resistant composite metal plastic pipe, special preparation equipment thereof and preparation method thereof

InactiveCN101725774AImprove pressure bearing capacityLight weightLayered productsRigid pipesPolymer scienceWear resistant

The invention belongs to the technical field of pipes and discloses a mine wear-resistant composite metal plastic pipe, special preparation equipment thereof and a preparation method thereof. The mine wear-resistant composite metal plastic pipe has the main technical characteristics that: the wear-resistant composite metal plastic pipe comprises an outer wall steel pipe, wherein a high molecular weight polyethylene lining layer is arranged in the outer wall steel pipe; a maleic anhydride graft copolymerization modification low molecular weight polyethylene intermediate bonding layer used for bonding the high molecular weight polyethylene lining layer and the outer wall steel pipe into a whole is arranged between the high molecular weight polyethylene lining layer and the outer wall steel pipe; the end part of the outer wall steel pipe is provided with a flange plate with a trough; and the end part of the high molecular weight polyethylene lining layer is flanged and clamped into the trough. The mine wear-resistant composite metal plastic pipe uses the outer wall steel pipe as a pressure-bearing body with high pressure-bearing capability, uses the high molecular weight polyethylene lining layer as a wear-resistant and anti-corrosive layer to convey media such as slurry, paste, corrosive fluids and the like with different particle diameters, and uses the maleic anhydride graft copolymerization modification low molecular weight polyethylene intermediate bonding layer to composite the three layers of materials into a whole with the same expansion and shrinkage coefficients on the inner layer and the outer layer to overcome the defect that the pipe is blocked caused by plastic pipe end face deformation and steel-plastic delamination in the process of use.

Owner:河北金菱管业股份有限公司

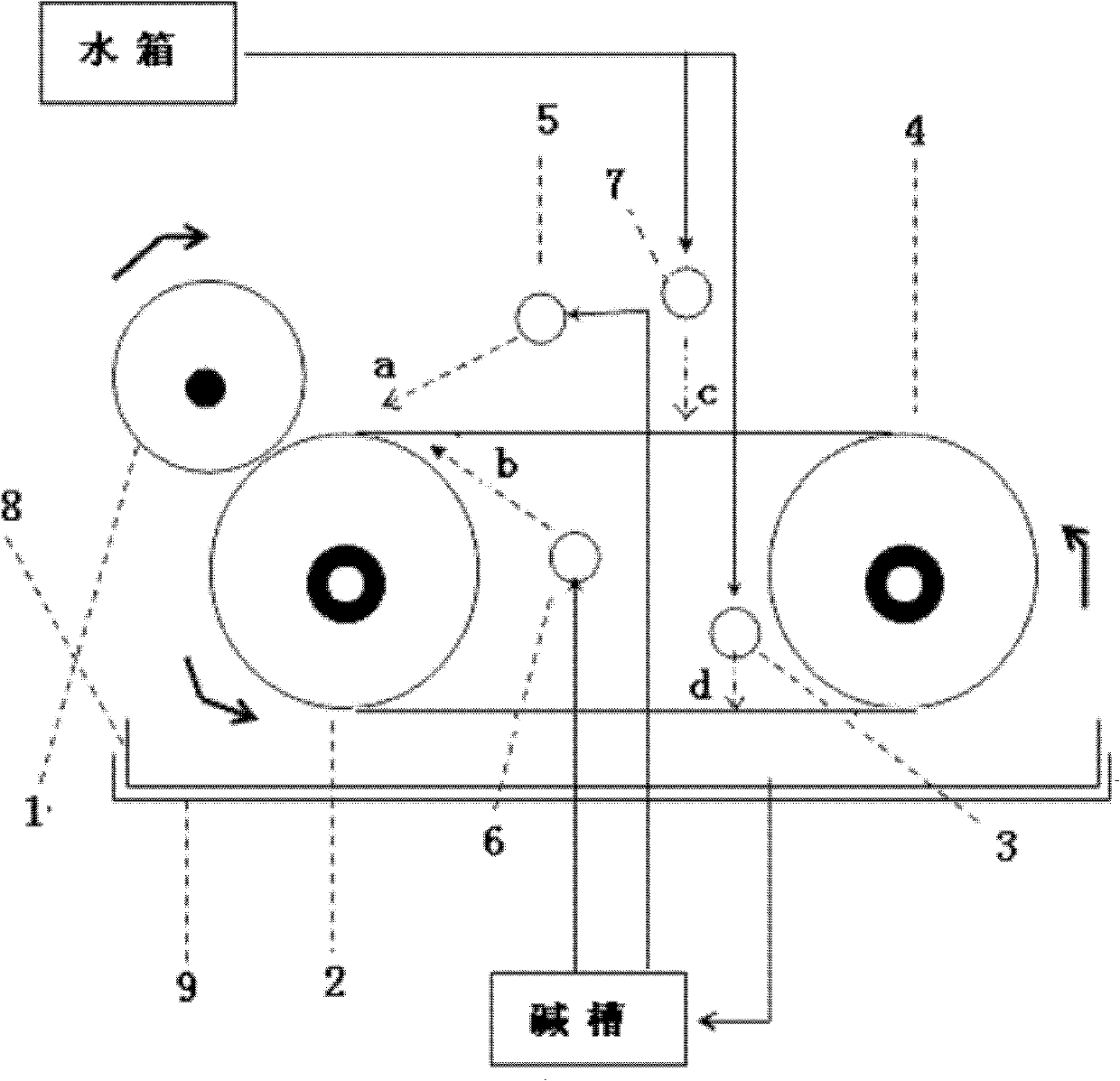

Cotton sliver mercerizing process and mercerizing device utilizing same

InactiveCN102704225AImprove spinning efficiencyHigh glossMercerising of yarns/threads/filamentsMercerising of sliversComposite materialPolymer chemistry

Disclosed are a cotton sliver mercerizing process and a mercerizing device utilizing the same, which belong to the technical field of textile technology. The cotton sliver mercerizing process includes: a, cotton sliver pretreatment step including dewing cotton slivers and dewatering the same or squeezing water out of the same to form wet cotton slivers with certain liquid content; b, a cotton sliver reeling step including reeling the wet cotton slivers on a reeling machine and fixing the cotton slivers by lay bands; c, a covering step including wrapping the reeled cotton slivers with the wrapping cloth integrally; and d, a mercerizing step realized by concentrated spraying and instant squeezing. The sliver cottons are mercerized effectively by dewing to reinforce and by means of concentrated spraying and instant squeezing, and alkali content of the cotton slivers is controlled all the time, so that the cotton slivers cannot be dissolved due to excessive swelling, and the difficult problem of failure in mercerizing the cotton slivers without twist is solved. In addition, the mercerized cotton slivers are bright, smooth and fluffy, and dye color yield is increased by 20%-30%.

Owner:WUXI NON SIZING TECH

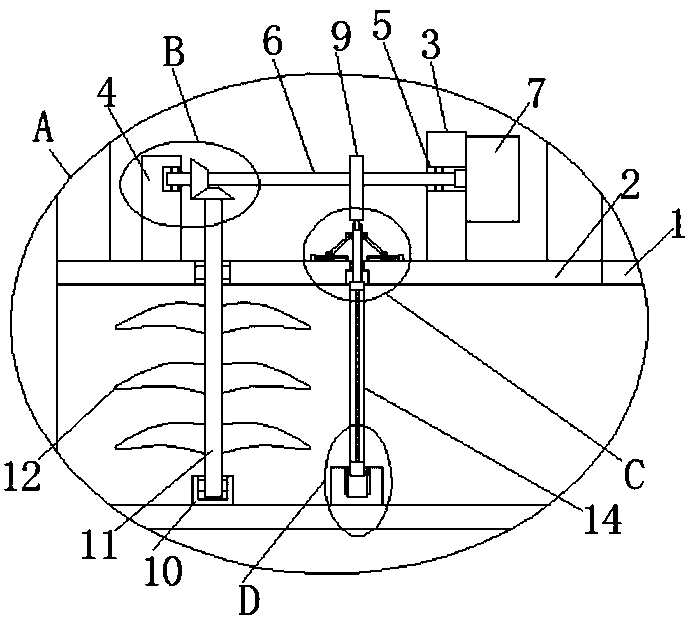

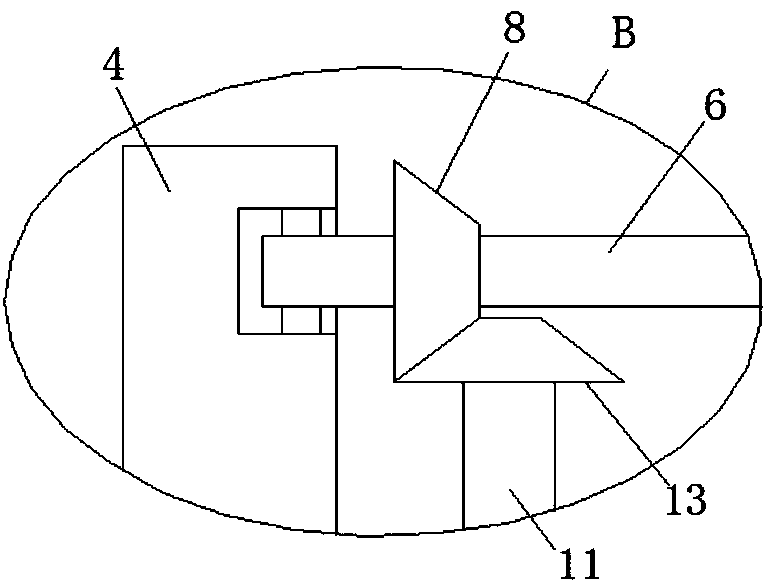

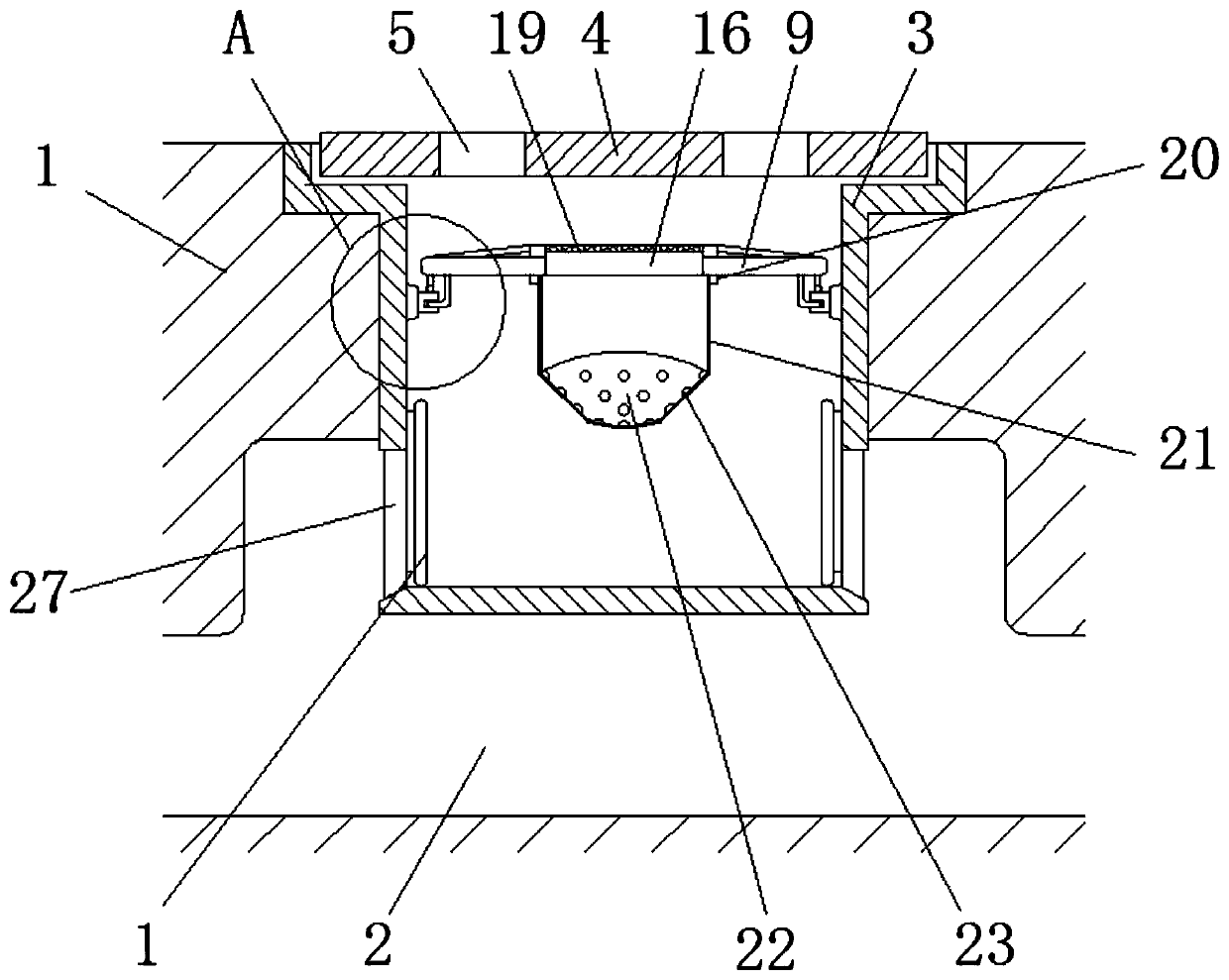

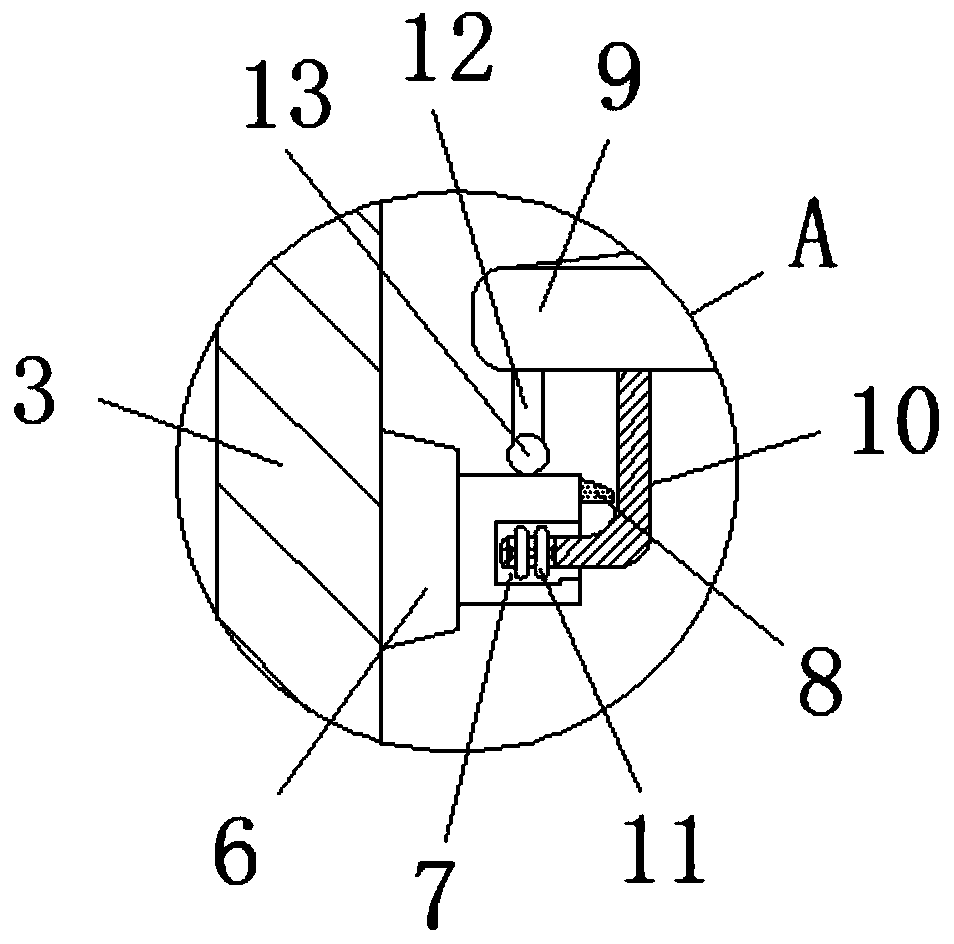

Sewage draining device for achieving pipeline blocked avoidance

InactiveCN108105105AAvoid clogging pipesSimple structureSpecific fluid pumpsPump componentsCentrifugal pumpEngineering

The invention discloses a sewage draining device for achieving pipeline blocked avoidance. The sewage draining device comprises a centrifugal pump, a filter pipe is fixedly mounted on a water inlet pipe of the centrifugal pump, a first fixing seat is fixedly mounted at the top of the filter pipe, a second fixing pipe fixedly mounted at the top of the filter pipe is arranged on the side, away fromthe centrifugal pump, of the first fixing seat, a first through hole is formed in the side, close to the second fixing seat, of the first fixing seat, a first rotary shaft is rotatably mounted in thefirst through hole, one end of the first rotary shaft extends out of the first through hole, and rotatably mounted on the second fixing seat, a motor is fixedly mounted on the side, away from the second fixing seat, of the first fixing seat, and an output shaft of the motor extends into the first through hole, and fixedly connected with the first rotary shaft. The sewage draining device is simplein structure and high in practicality, not only can large impurities in sewage be prevented from entering a sewage draining pipeline, the sewage draining pipeline is prevented from being blocked, butalso the large impurities in the sewage can be crushed, and thus normal flowing of the sewage is facilitated.

Owner:南安市溪美辉宇电脑维修部

Formula of pumping light aggregate concrete

The invention provides a formula of pumping light aggregate concrete. In the formula, the pumping light aggregate concrete comprises cement, coal ash, rubber materials, sand, ceramsite, additive and water, wherein the cement is of P.042.5 level cement and has the 28-day tensile strength of 49.6MPa, the weight percentage of the coal ash is 60-80%, the fineness of the coal ash is 6.3%, the ignition loss is 3.6%, and the water demand ratio achieves 92%; and the weight ratio of the water and the rubber material is 0.44. Compared with the prior art, the formula of pumping light aggregate concrete solves the problem of pumping the light aggregate concrete, prevents pipe blocking, improves the concrete workability by regulating the proportion of raw materials of coal ash and the like, improves the concrete cohesiveness, solves the technical problem of pumping difficulty, and improves the construction efficiency.

Owner:HEBEI ZHONGCHENG NEW BUILDING MATERIALS

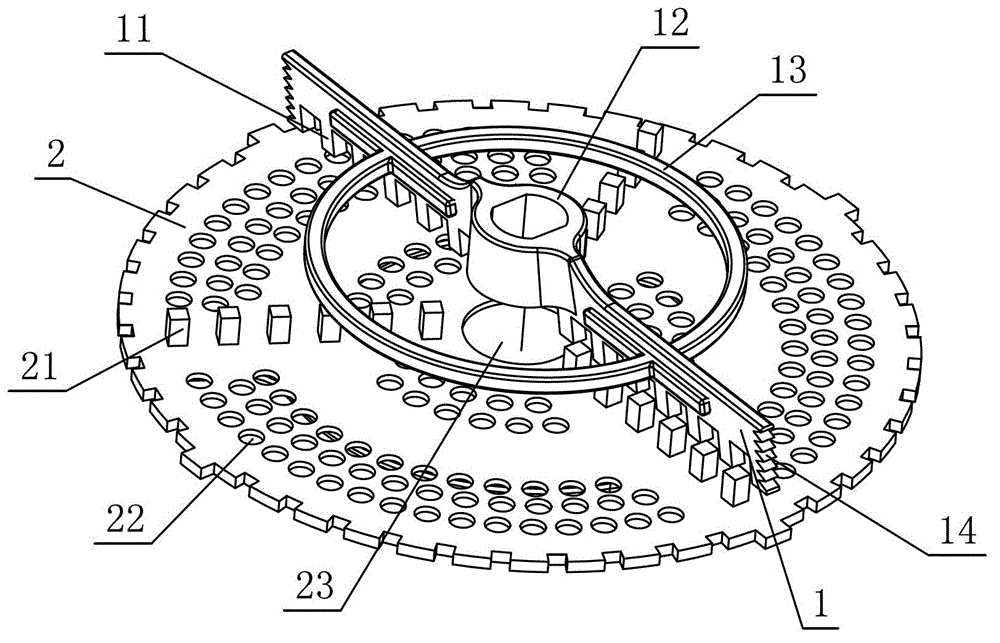

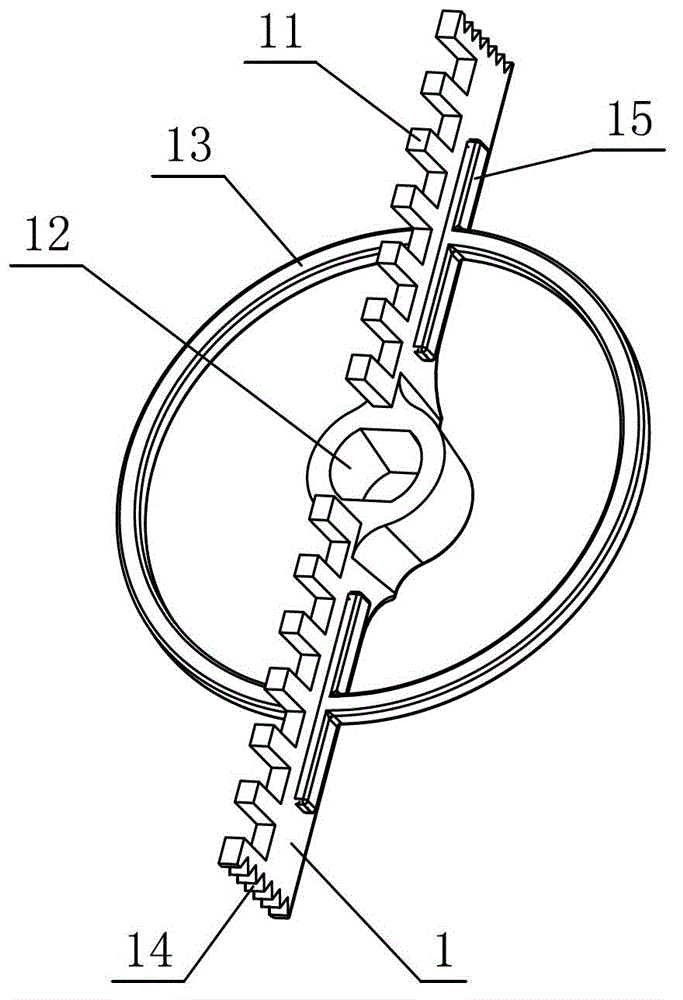

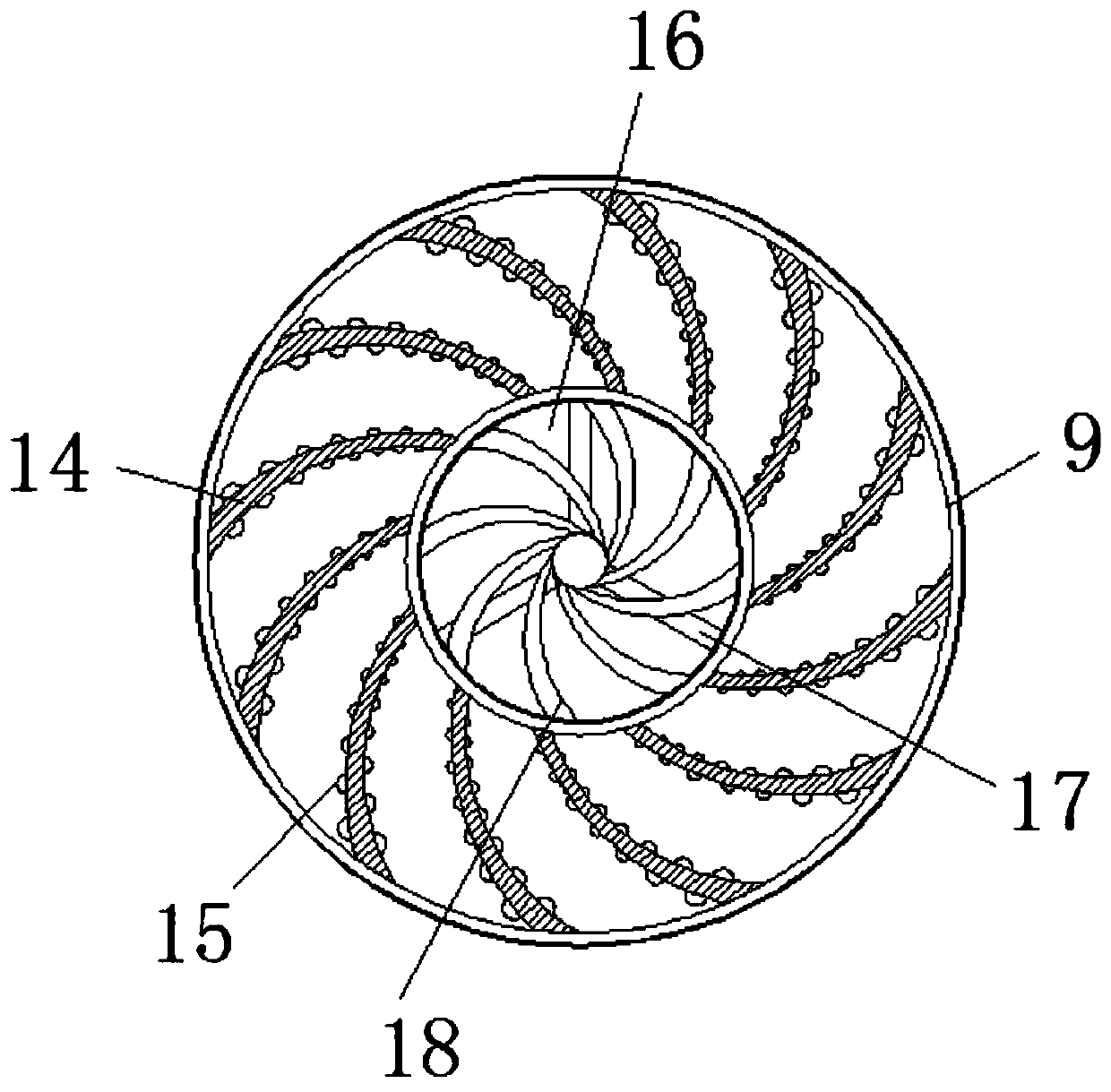

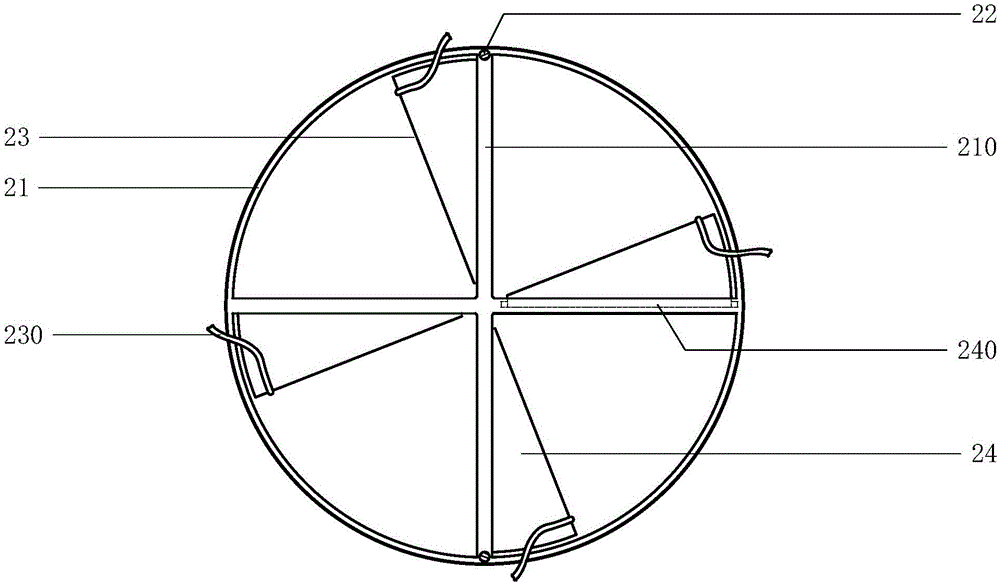

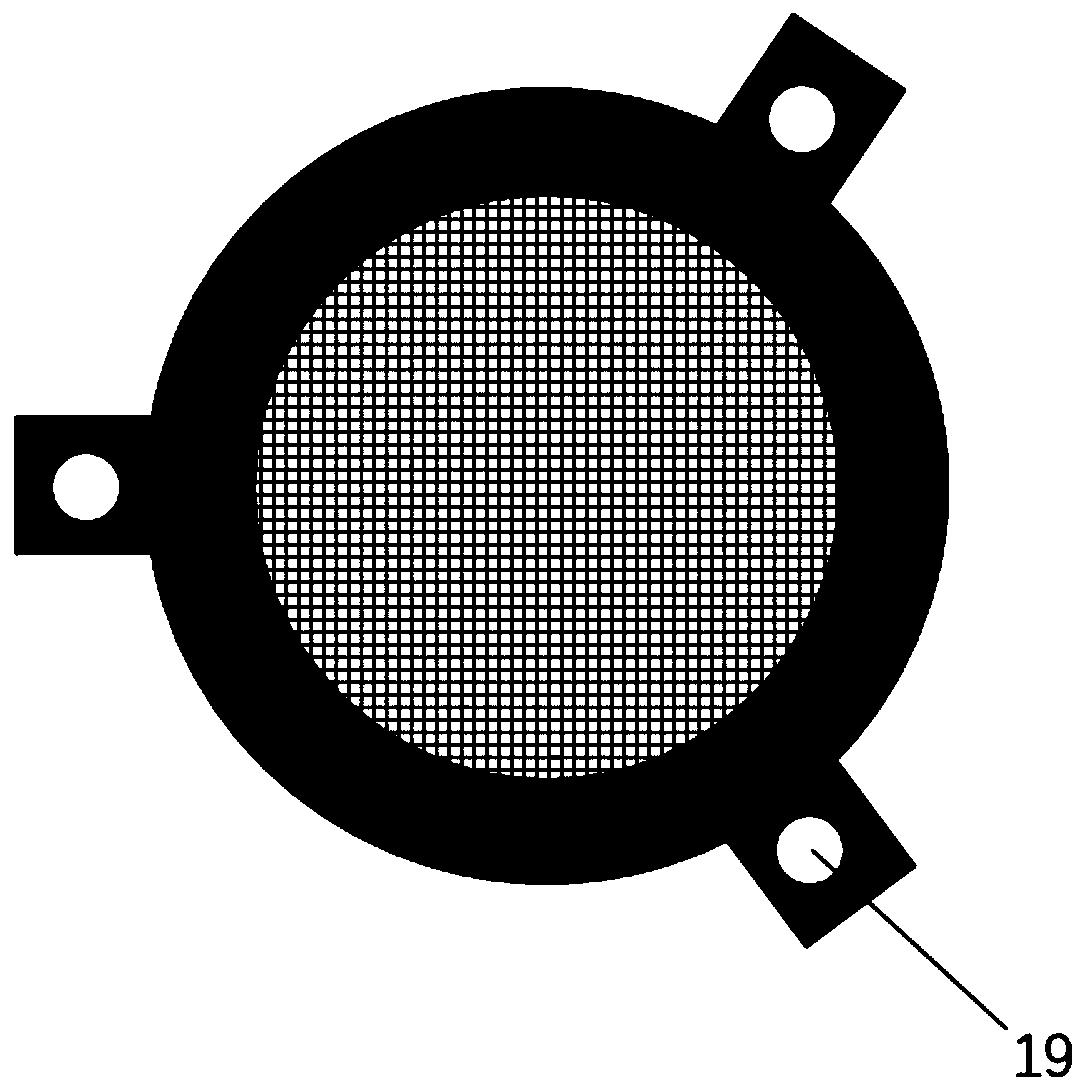

360-degree combing assembly of waste processor

The invention relates to a 360-degree combing assembly of a waste processor. The 360-degree combing assembly comprises a filtering chassis and a stirring paddle, wherein the filtering chassis is fixedly arranged in the waste processor; the stirring paddle is rotatably arranged above the filtering chassis; a plurality of filtering holes are formed in the surface of the filtering chassis; lower comb teeth are arranged on the top surface of the filtering chassis in the radial direction; upper comb teeth are arranged on the bottom surface of the stirring paddle; and the upper comb teeth and the lower comb teeth are staggered. According to the waste processor, through the stagger cooperation of the lower comb teeth of the filtering chassis and the upper comb teeth of the stirring paddle, when the stirring paddle rotates, the upper comb teeth pass through the tooth spaces of the lower comb teeth and can shear, so that relatively large food waste which can not pass through the tooth spaces can be cut off by the shearing force so as to be broken via repeating for a plurality of times, so that the waste treatment is relatively environment-friendly and a pipeline is prevented form being blocked.

Owner:张建明

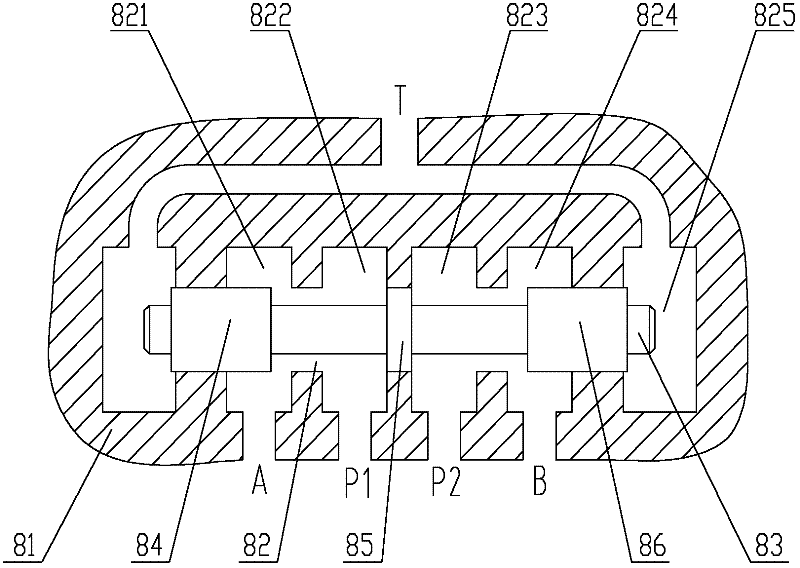

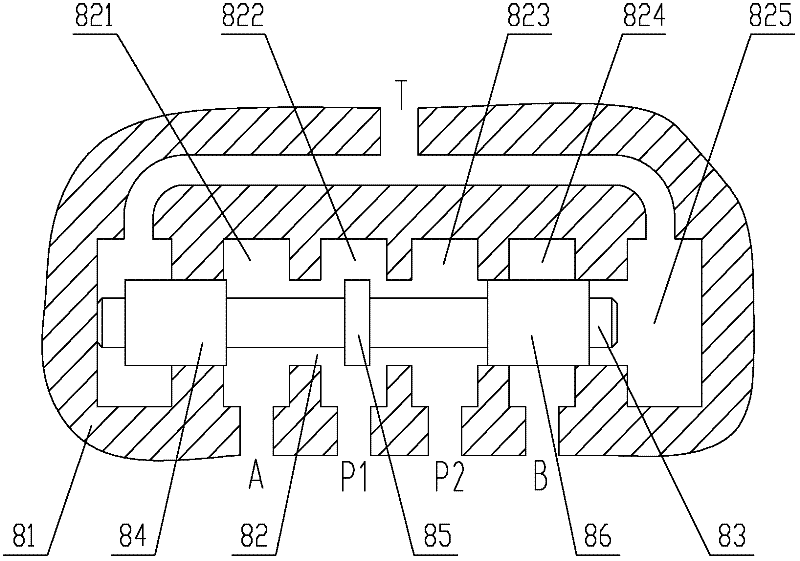

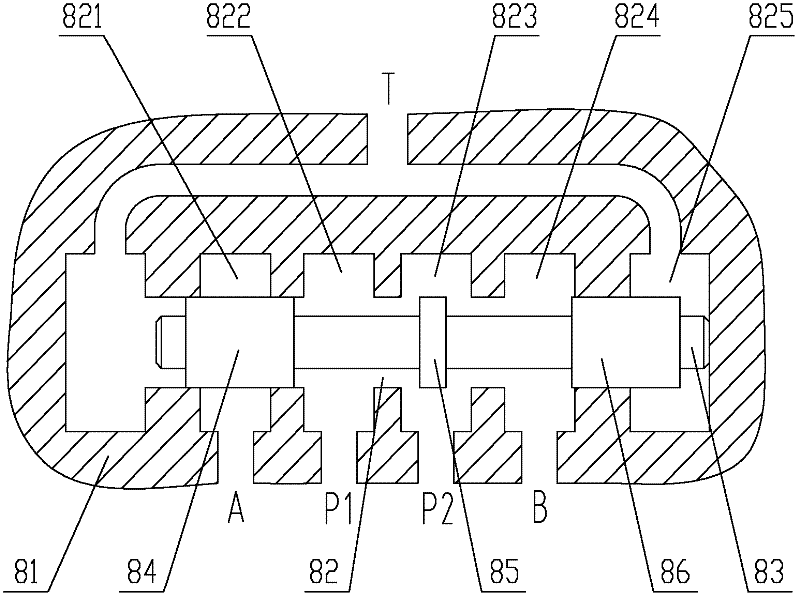

Hydraulic valve, hydraulic system and concrete pumping equipment

InactiveCN102400968AIncrease displacementRealize emergency clothServomotor componentsServomotorsConcrete pumpHydraulic brake

The invention relates to the technical field of engineering machinery and discloses a hydraulic valve, a hydraulic system and concrete pumping equipment, wherein the hydraulic valve comprises a valve body, a valve rod and a driving part, wherein the valve body is provided with a valve cavity; the valve rod is arranged in the valve cavity; the driving part drives the valve rod to move in the valve cavity; the valve cavity is provided with a first oil inlet, a second oil inlet, a first oil outlet and a second oil outlet; under a first working state, the first oil inlet is communicated with the first oil outlet; the second oil inlet is communicated with the second oil outlet; under a second working state, the first oil inlet and the second oil inlet are respectively communicated with the first oil outlet, and the second oil outlet is closed; and under a third working state, the first oil inlet and the second oil inlet are respectively communicated with the second oil outlet, and the first oil outlet is closed. The embodiment of the invention provides the hydraulic system applying the hydraulic valve, so that the function of mutual oil filling or emergent oil supplying are achieved between the hydraulic system for pumping and a hydraulic system of an arm frame, and the occurrence of the phenomenon that the progress of the engineering is influenced or pipes are blocked is effectively avoided.

Owner:SANY AUTOMOBILE MFG CO LTD

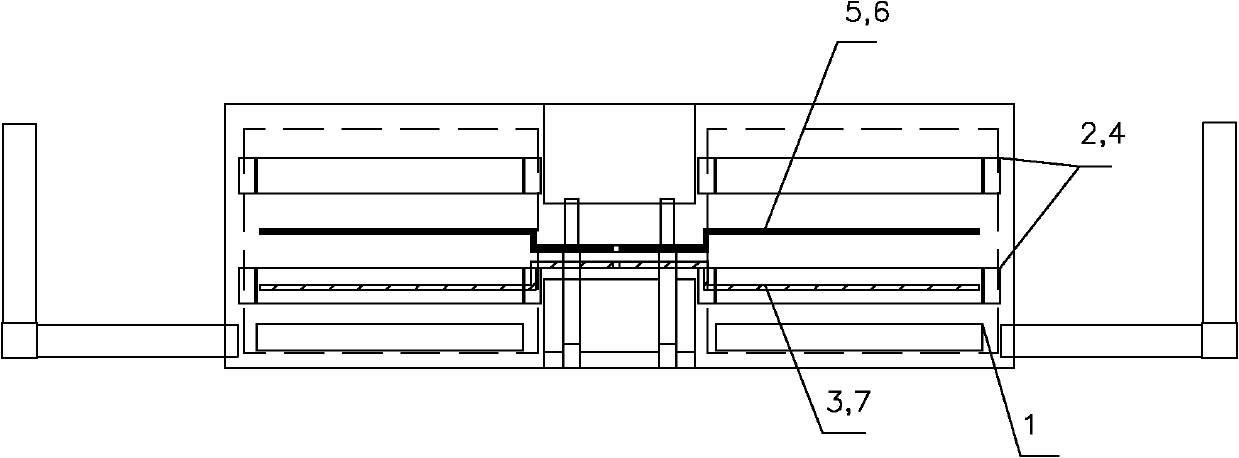

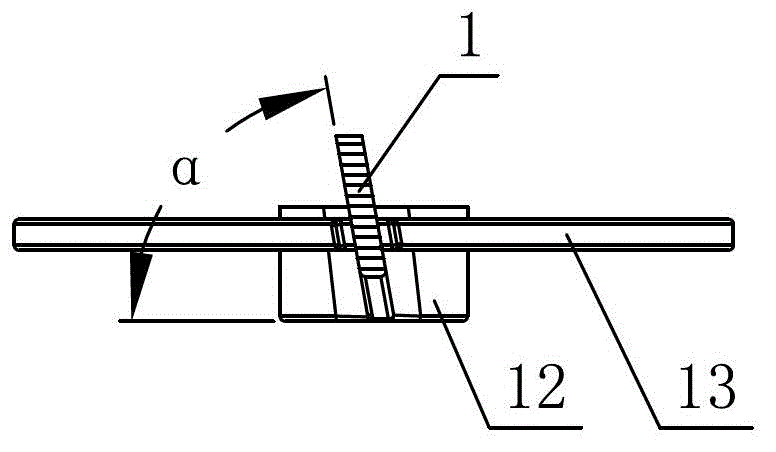

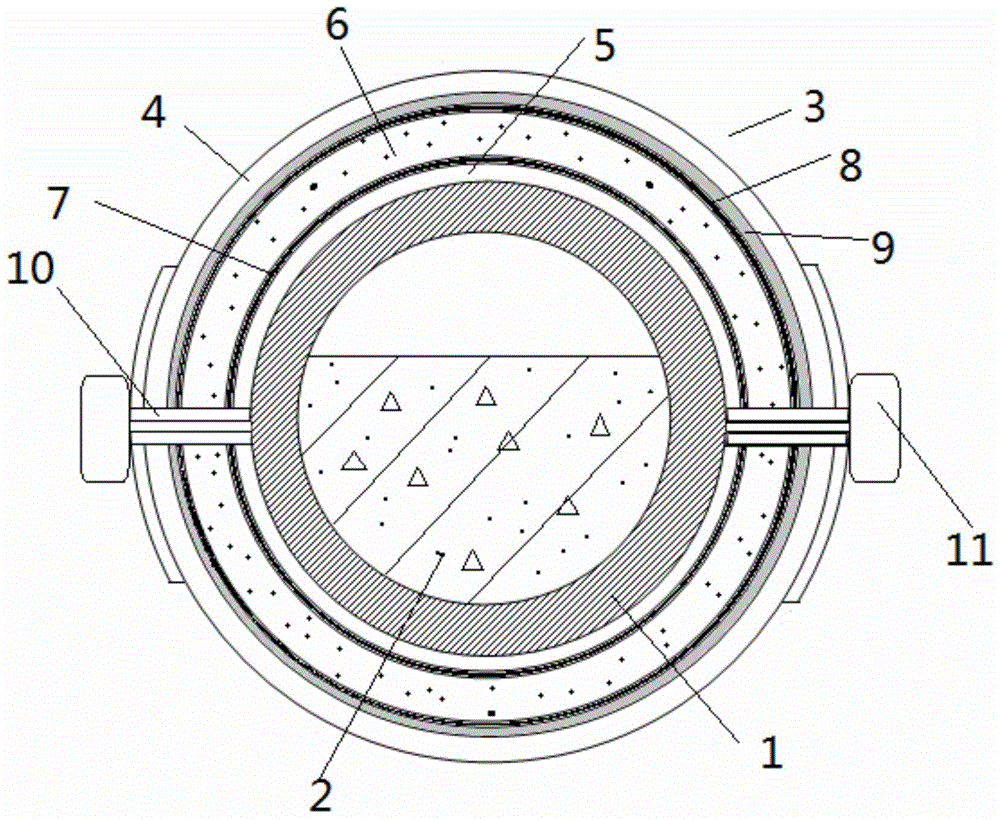

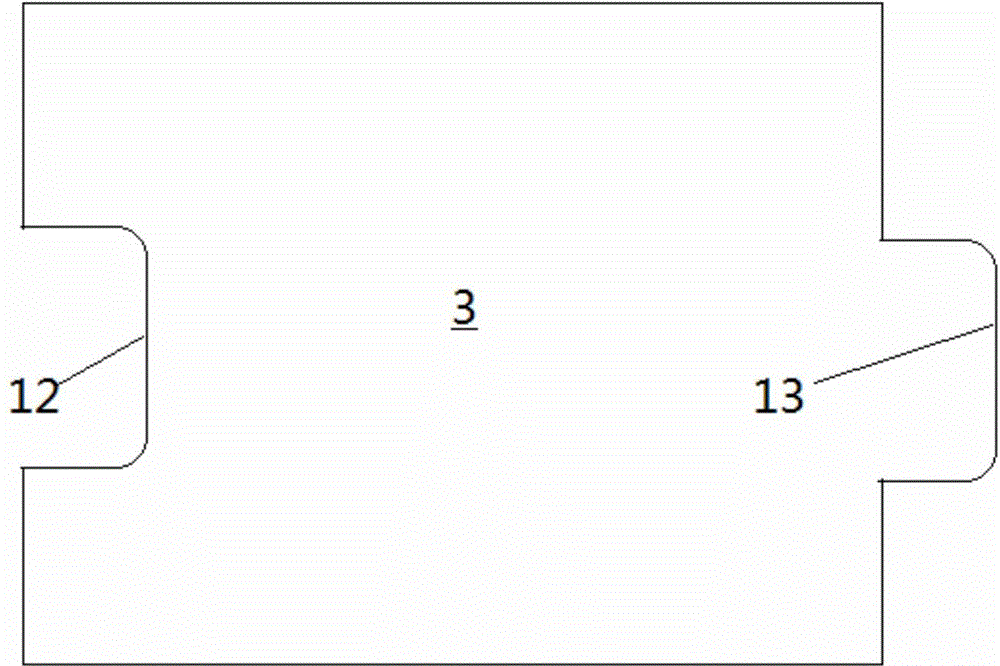

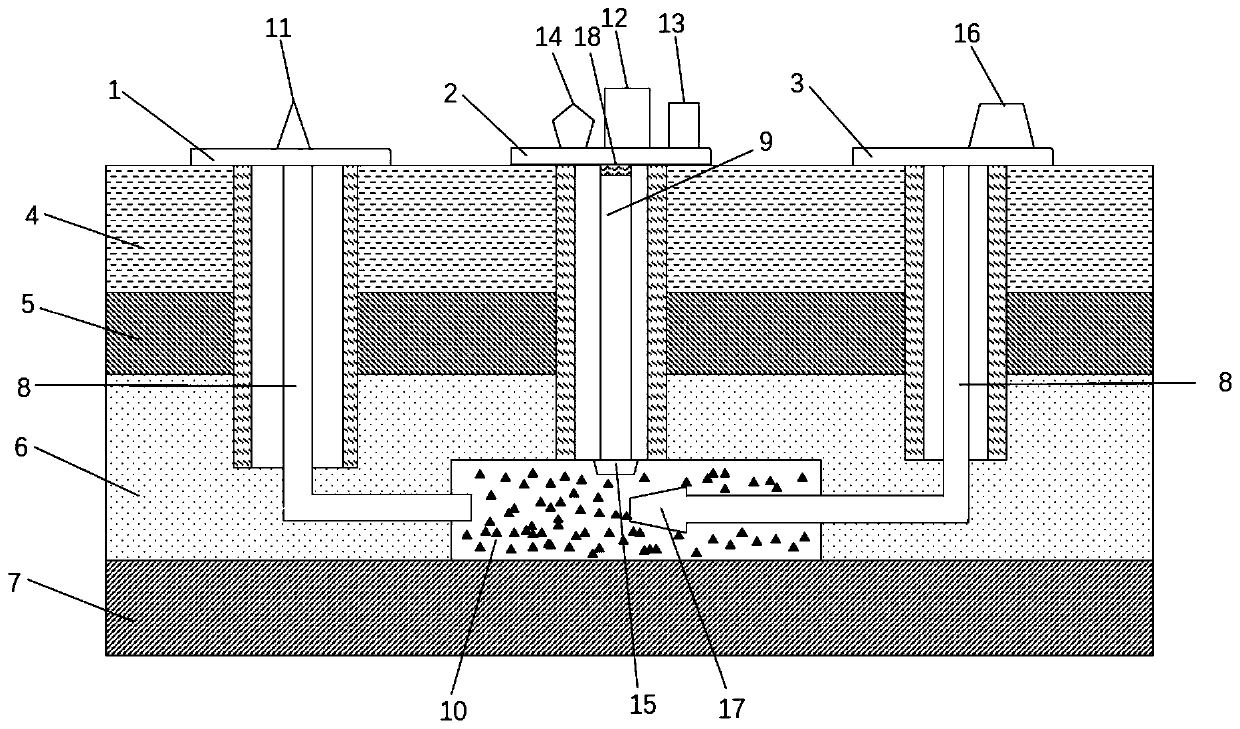

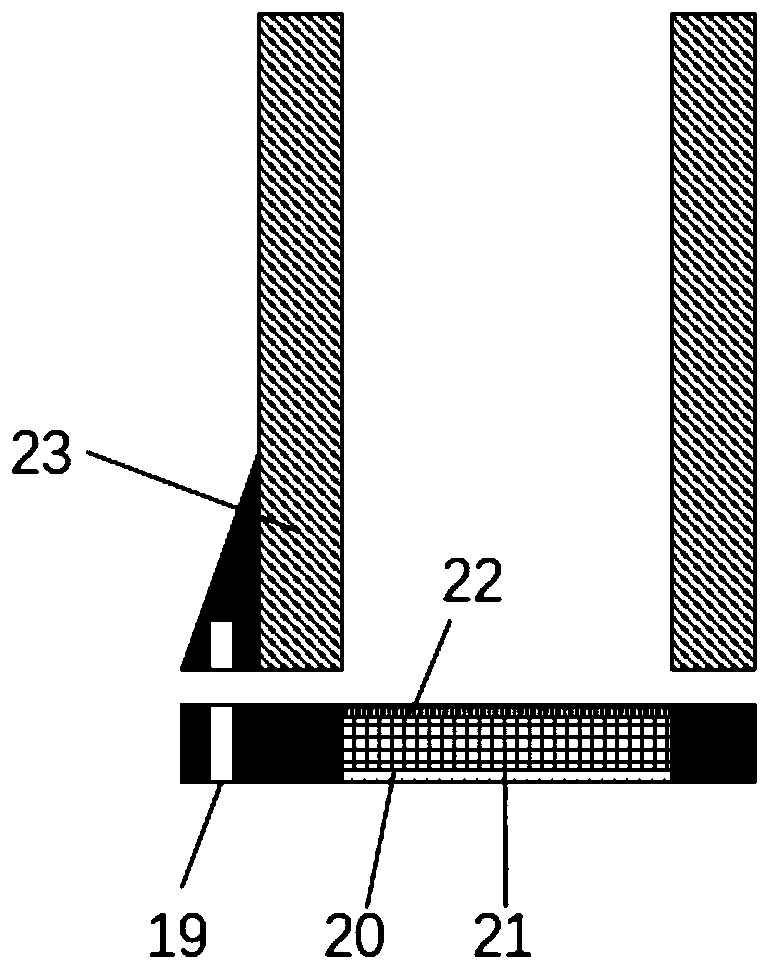

Conveying pipe sleeve for pumping concrete construction

ActiveCN104818852AAvoid pipe cloggingSimple structureBuilding material handlingElectric heatingEngineering

The invention relates to a conveying pipe sleeve for a pumping concrete construction. The conveying pipe sleeve is in cup joint at the outer side of a conveying pipe (1), and is spliced by multiple sections of pipe sleeve units in a length direction of the conveying pipe; each section of the pipe sleeve unit is spliced by more than two pipe piece units; the pipe piece units are sealed cavities consisting of outer walls (4), inner walls (5), upper bottom surfaces, lower bottom surfaces and two side sealing plates (10); phase change materials (6) are filled in the sealed cavities; electric heating devices (7) are arranged at the inner sides of the inner walls, and temperature sensors connected with temperature control devices of the electric heating devices are embedded at the outer sides; and the inner sides of the outer walls are provided with reflective film layers (8) and heat insulating layers (9) in sequence from top to bottom. The multiple pipe piece units are clamped and fastened on the outer surface of the conveying pipe through connecting parts (11); the multiple sections of the pipe sleeve units are longitudinally spliced; and the upper and lower bottom surfaces of the adjacent pipe piece units are respectively provided with concave parts (12) and convex parts (13) with matched shapes. The pipe sleeve is simple in structure and convenient to be disassembled, prevents the blockage caused by low temperature, and improves the energy utilization rate.

Owner:张鑫浩

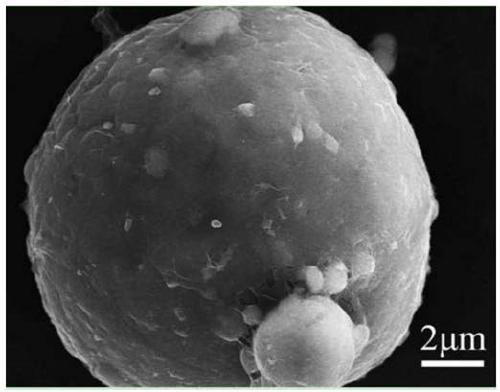

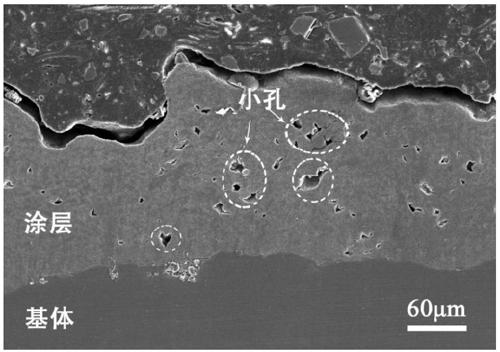

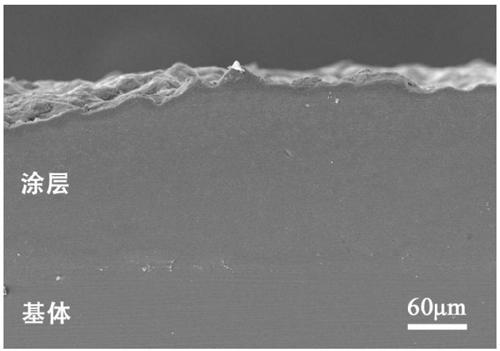

Graphene-coated aluminum composite coating, preparation method and application thereof

ActiveCN109440098AMake up for localized corrosionMake up for the characteristics of easy localized corrosionTransportation and packagingMetal-working apparatusAluminium powderHardness

The invention belongs to the technical field of metal surface treatment, and discloses a graphene-coated aluminum composite coating, a preparation method and application thereof. The preparation method comprises the steps that aluminium powders are put into a graphene oxide aqueous solution and are subjected to a mixing reaction, and thus graphene-coated aluminium powders are obtained; a metal surface is subjected to roughness fabrication adopting a method of mechanical treatment, and the metal surface with roughness is obtained after being cleaned and dried; a cold spraying device is started,and the graphene-coated aluminium powder is put into a specified powder feeding tube; and the metal surface with roughness is installed on a specific fixture, a cold spraying technological parameteris set, and the spraying device is started to deposit the composite graphene-coated aluminium powders on the metal surface with roughness, and the preparation of the graphene-coated aluminum compositecoating is carried out. According to the aluminium powders coated through the preparation method, the surface hardness is improved, the fluidity is better, and the phenomenon of tube plugging duringspraying is avoided, and thus the spraying efficiency is improved. The structure of the graphene-coated aluminum composite coating has high compactness, can efficiently insulate eroding ions, has higher corrosion resistance and can be used in the field of corrosion prevention.

Owner:GUANGDONG UNIV OF TECH

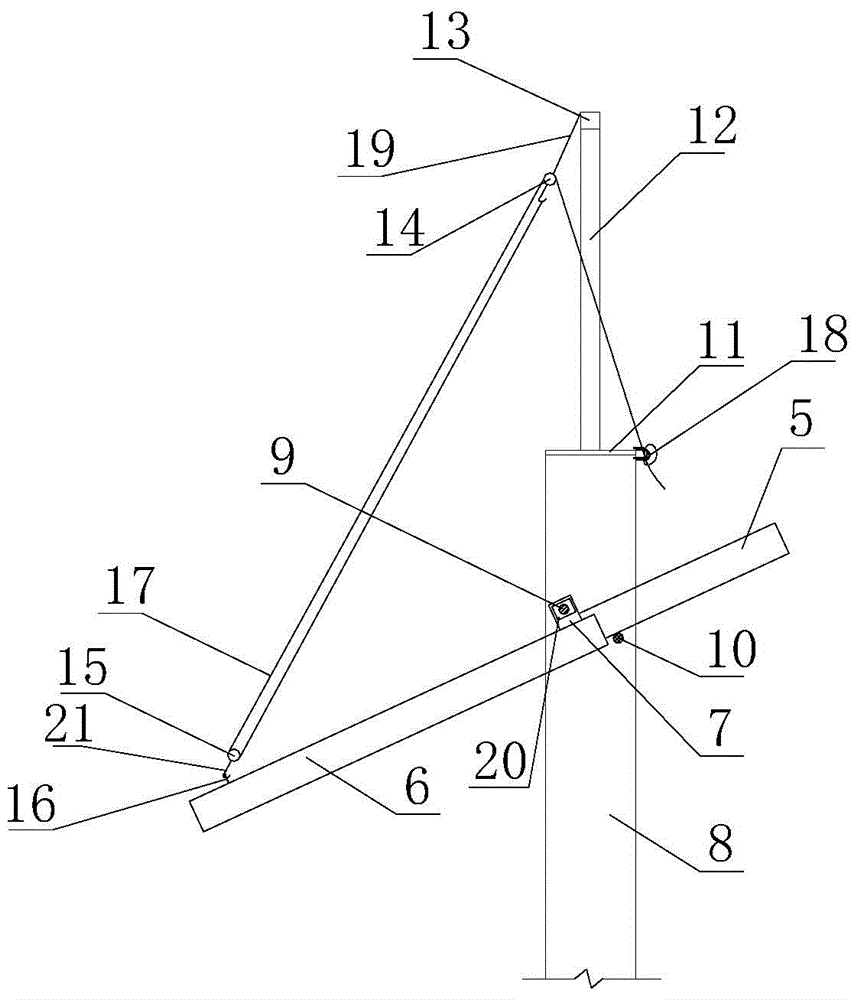

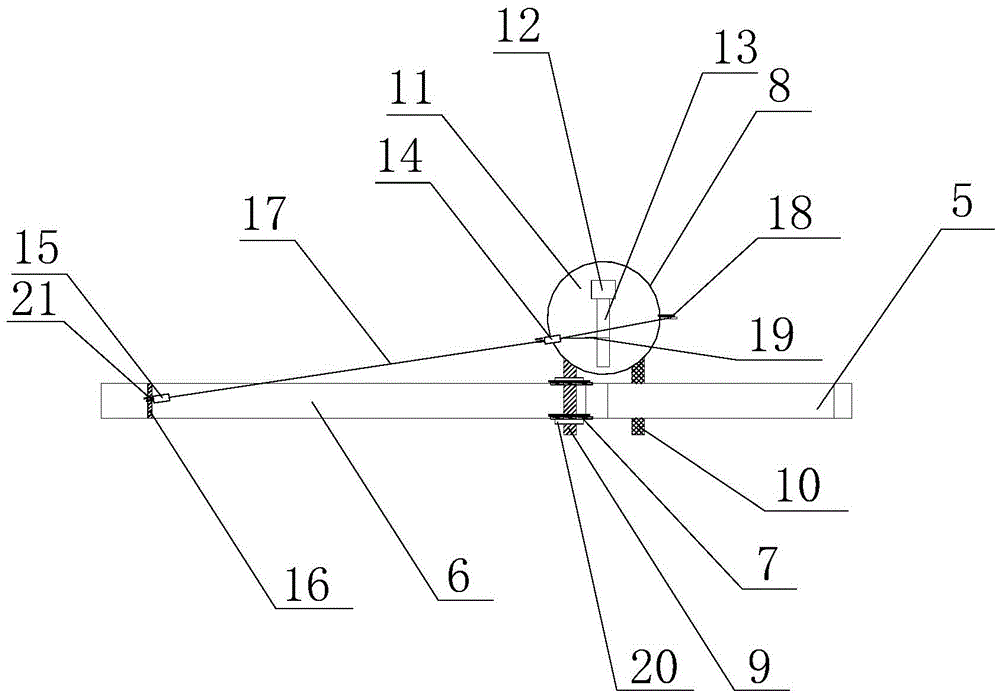

Concrete transfer device

ActiveCN104649039AReduce disturbanceNo change in performanceLoading/unloadingStructural engineeringEngineering

The invention discloses a concrete transfer device. The concrete transfer device comprises a steel pipe pile and a sliding chute, wherein an upright post is fixedly arranged on the top of the steel pipe pile, and a cross rod is fixedly arranged on the top of the upright post; one end of the sliding chute is put on the corner of a wharf, and the other end of the sliding chute extends downwards slantly and is connected with the cross rod through a suspension device. When the concrete transfer device is used, a concrete tank car positioned on the wharf is used for discharging concrete inside the upper section of the sliding chute, the concrete flows towards the lower section of the sliding chute along the upper section of the sliding chute and finally flows in the cabin of a transport ship, and after the cabin is filled with the concrete, the transport ship can drive away from the transfer device. The concrete is transported to the transport ship by adopting the sliding chute, the disturbance on the concrete is little, the performance of the concrete is not changed, the phenomenon of pipe blockage can further be avoided, the device is free of hoisting operation, the safety is guaranteed, and the concrete transfer device is simple in structure and convenient in operation and has great promotional value.

Owner:CCCC SECOND HARBOR ENG

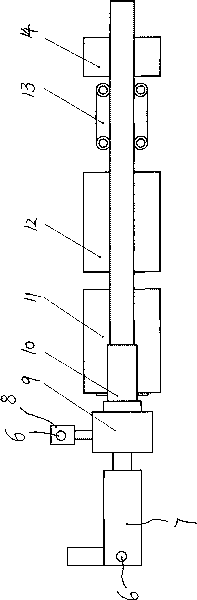

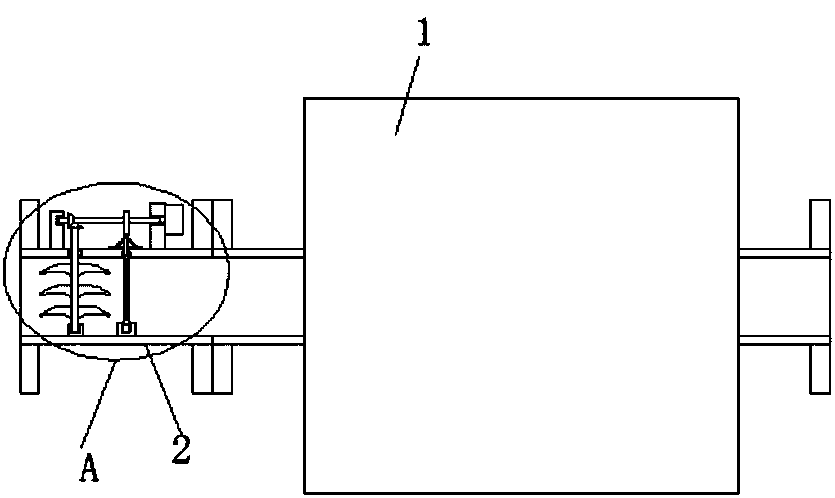

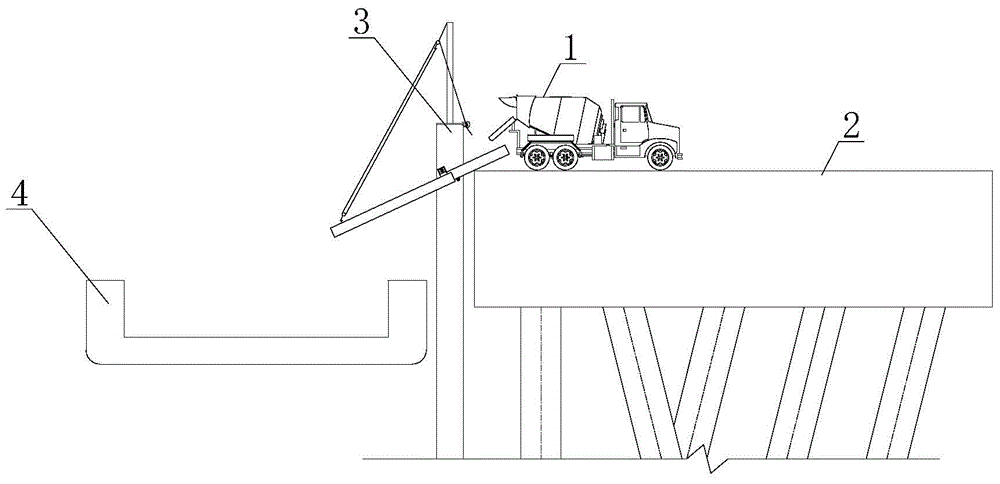

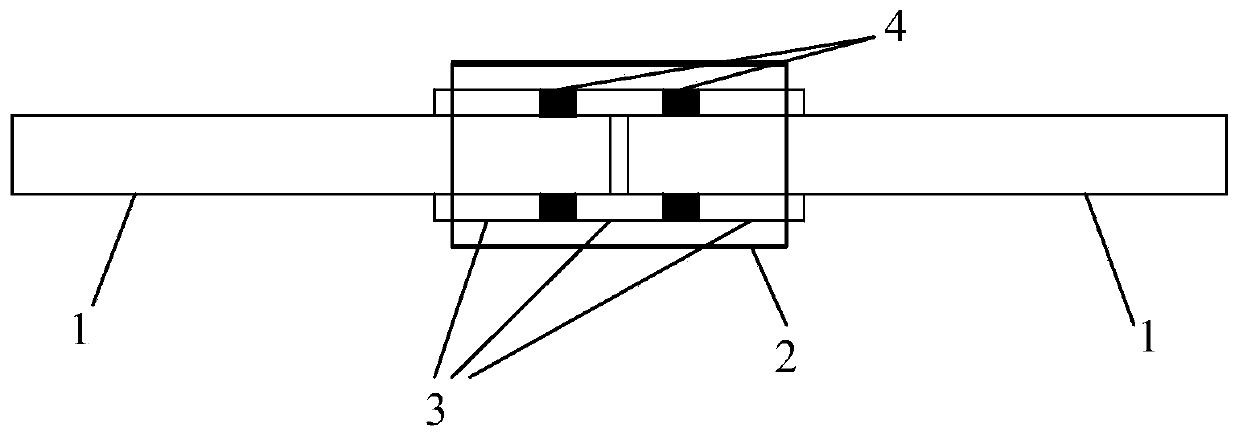

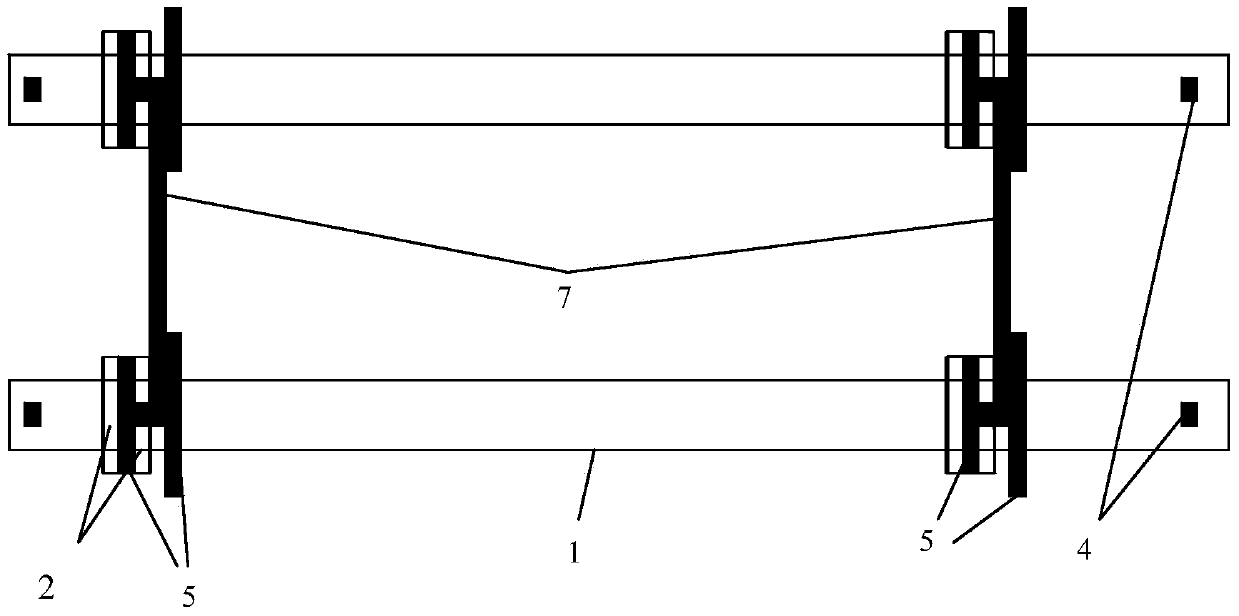

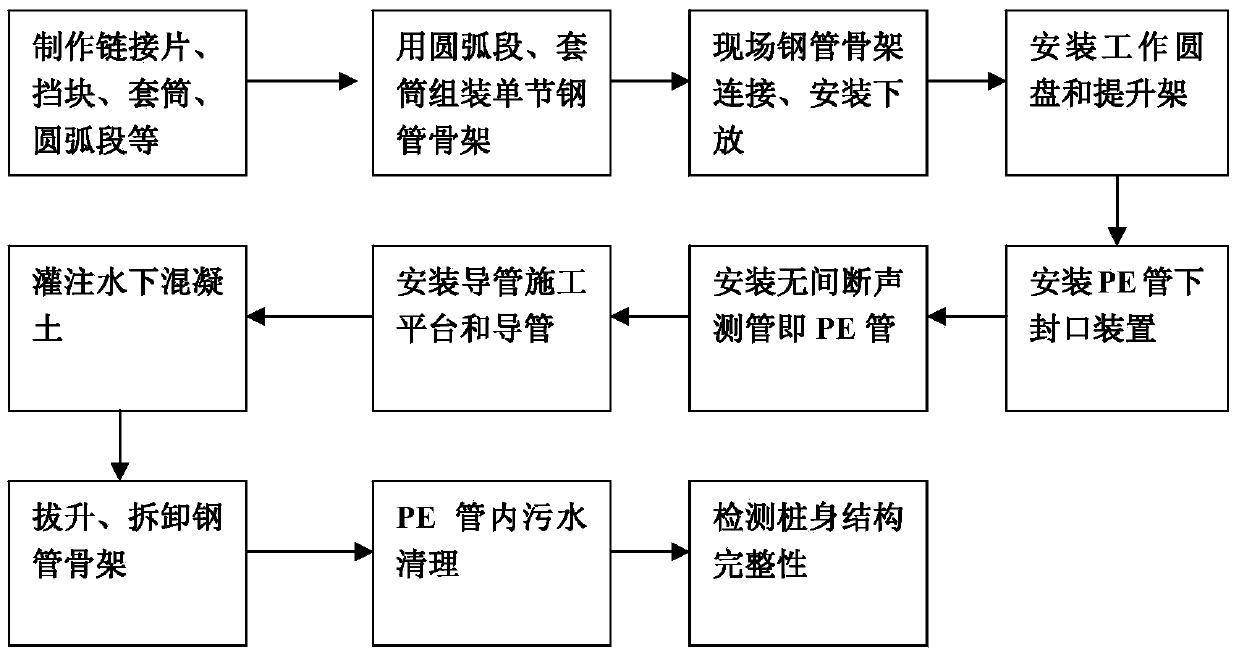

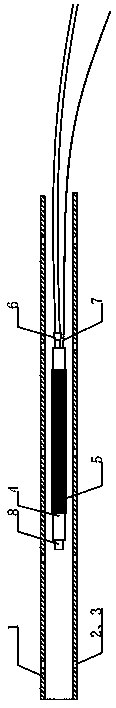

Continuous sounding pipe installation method and device for detecting concrete filling pile

InactiveCN104196062AAvoid clogging pipesImprove work efficiencyFoundation testingAcoustic transmissionEconomic benefits

The invention discloses a continuous sounding pipe installation method for detecting a concrete filling pile through an acoustic transmission method. The method comprises the steps that firstly, a steel pipe framework is put to the bottom of the pile axuilairily; a continuous sounding pipe is installed at one time through a sounding pipe passage formed by the installed steel pipe framework, and the bottom of the pipe is sealed when the continuous sounding pipe is put to the bottom of the pile; concrete is injected, the steel pipe framework is pulled out section by section in the injecting process, and the continuous sounding pipe is left in concrete to become a passage to defect the completeness of a pile body structure through the acoustic transmission method; the completeness of the pile body structure is detected through the acoustic transmission method. The continuous sounding pipe installation method and device for detecting the concrete filling pile largely improve work efficiency, save a large number of steel materials, reduce the construction cost, improve economic benefits and have great application prospects in pile foundation construction of railways, highways, airports and the like.

Owner:陈默

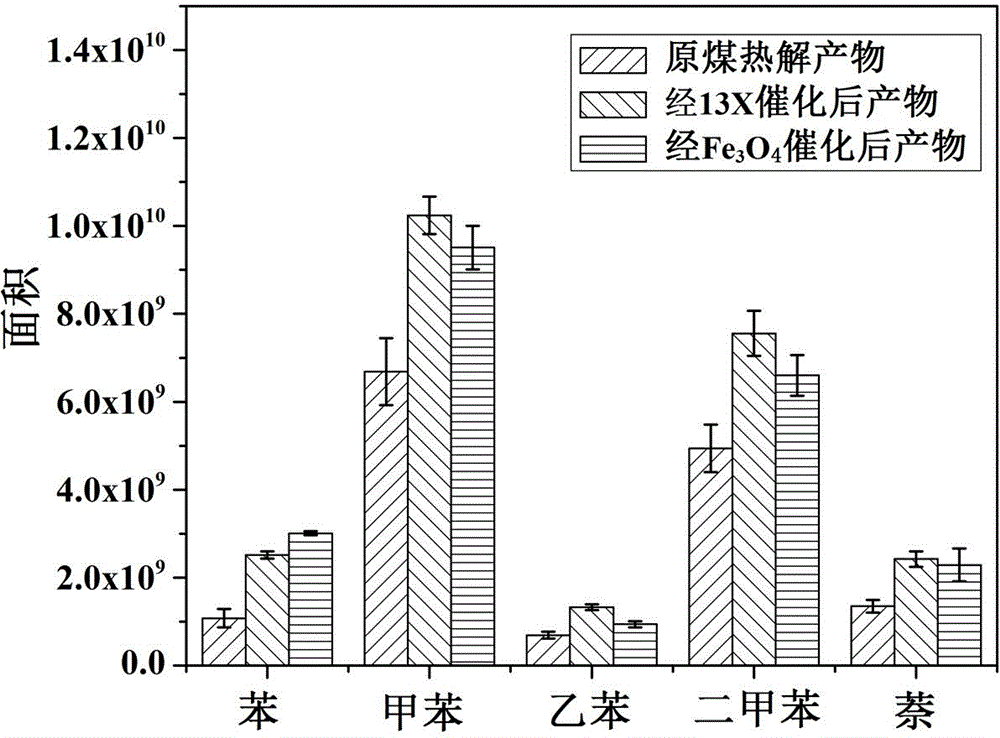

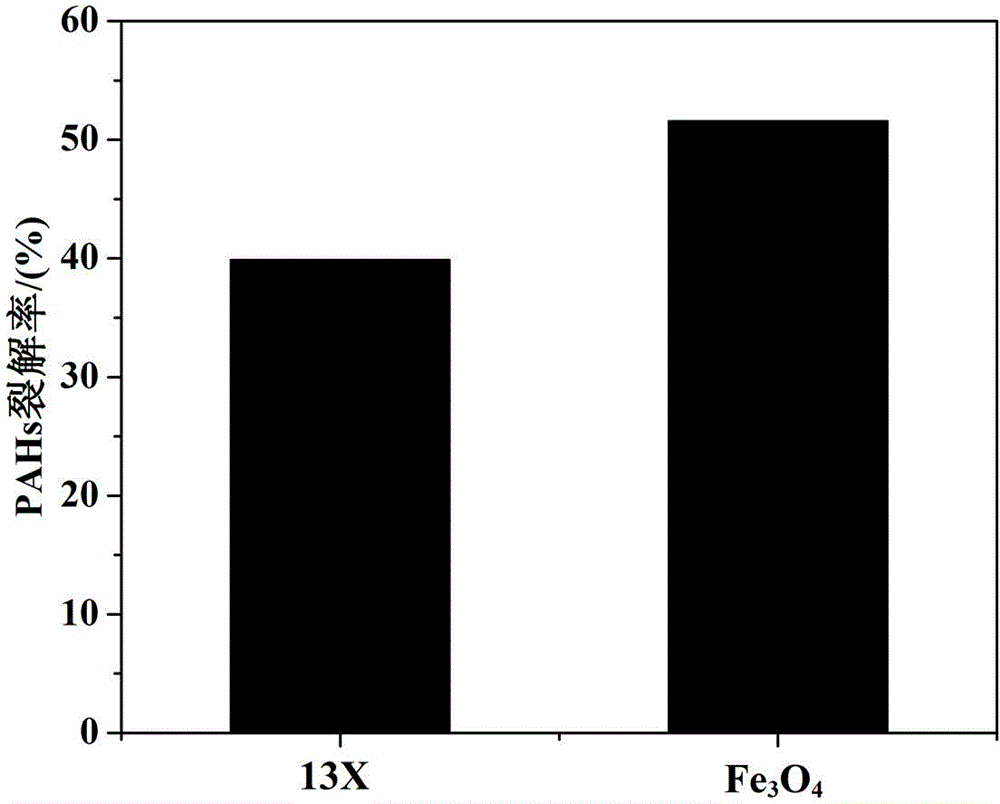

Coal tar catalytic upgrading method

InactiveCN104130799AReduce the content of heavy componentsImprove utilization efficiencyHydrocarbon oil crackingEconomic benefitsChemical products

The invention discloses a coal tar catalytic upgrading method which is as follows: a catalytic segment is added into the coal coking process, a catalyst is put into the catalytic segment, the catalytic segment is arranged between a coke oven coal pyrolysis crude coal gas outlet and an ammonia cooling section, 650 to 800 DEG C discharged crude coal gas from a coke oven directly enters into the catalytic segment to fully contact with the catalyst in the catalytic segment for catalytic cracking of heavy components in coal tar, and then enters into the ammonia cooling section for ammonia condensation. The method can effectively reduce the heavy component content in tar, promote low polycyclic aromatic compound formation, improve the yield of chemical products, increase the tar utilization efficiency and avoid the pipeline blocking problem caused by heavy tar condensation for the reason of systematic temperature change, reduces heavy subsequent purification processing work, and has the good application prospect and economic benefit.

Owner:TAIYUAN UNIV OF TECH

Sewage discharge and deodorization device for municipal engineering sewage pipeline

ActiveCN109797840AAvoid blockingCreate pollutionSewerage structuresSewer pipelinesRubber ringTurbine blade

The invention discloses a sewage discharge and deodorization device for a municipal engineering sewage pipeline. The sewage discharge and deodorization device comprises a wall, an anti-fall cover, a rotary turbine and a cylinder and is characterized in that a sewer is reserved at the bottom of the wall, a prefabricated well is mounted in the middle of the wall in an embedded manner, a fixing ringis fixed to the inner wall of the prefabricated well, a slide groove is formed in the inner wall of the fixing ring, one end of a slide support is fixedly connected to the bottom edge of the anti-fallcover, a support rod is fixedly mounted on the lateral side of the slide support at the bottom of the anti-fall cover, turbine blades are welded to the top edge of the anti-fall cover, the rotary turbine is fixedly mounted on a fixing seat, a guide cylinder is in through connection with the bottom of the cylinder, and a sealing rubber ring is embedded into the edge of the inner wall of a flow sealing plate. The sewage discharge and deodorization device has the advantages that odor in the sewer can be isolated, municipal environment pollution caused by odor spreading is avoided, pedestrian safety can be protected when a well lid is damaged, and silt accumulation, which causes pipeline blocking, in the pipeline is avoided.

Owner:RIZHAO POLYTECHNIC

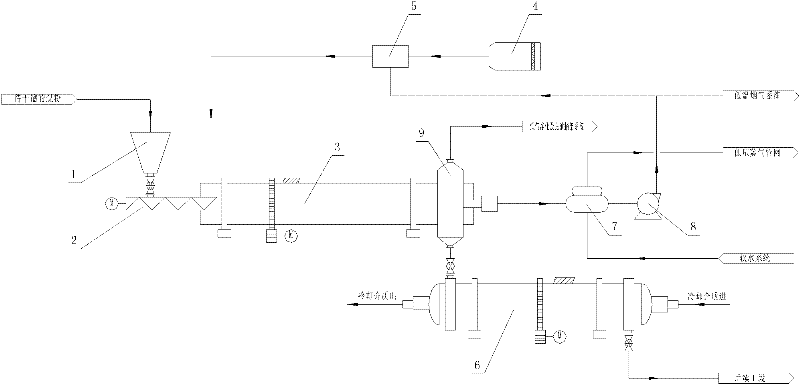

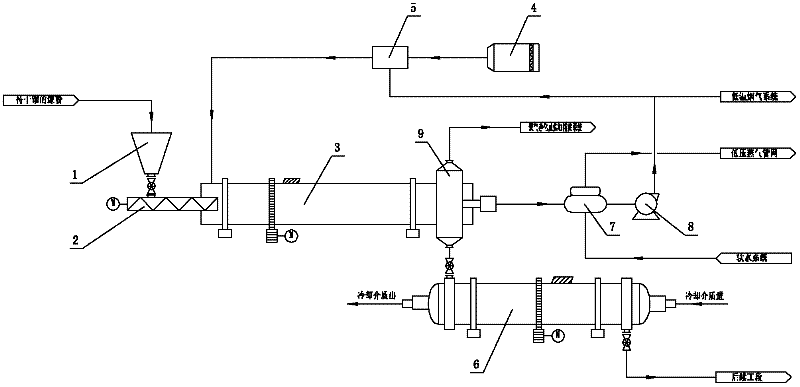

Multi-pipe revolving low-temperature dry distillation technology of fine coal

InactiveCN102492445ACloth is convenientRequirements for cylinder insulation are reducedEnergy inputIndirect heating destructive distillationThermal insulationTar

The invention discloses a multi-pipe revolving low-temperature dry distillation technology of fine coal. The technology comprises steps that: (1) fine coal requiring dry distillation is distributed into a cylinder of a multi-pipe revolving dry distillation machine; flue gas mixed and regulated in an air mixing chamber is delivered into a plurality of heat exchange tubes arranged in the cylinder of the multi-pipe revolving dry distillation machine; and fine coal in the cylinder is heated; (2) when heat is absorbed by the fine coal in the cylinder, the fine coal is pyrolyzed, such that hot semi-coke and dry distillation gas are produced; (3) the hot semi-coke is cooled in a coke cooling machine, the semi-coke is delivered to a next process, and is collected and stored; a next section is proceeded; (4) the dry distillation gas is delivered into a coal gas cooling, cool gas purifying, and tar collecting system; (5) the flue gas discharged after the heat exchanging process is delivered into a waste heat boiler for producing low-pressure vapor; a part of the low-temperature flue gas which leaves the waste heat boiler is refluxed for regulating the temperature of the flue gas, and another part of the low-temperature flue gas is delivered into a low-temperature flue gas system where the heat of the flue gas is recycled. According to the invention, the fine coal passes through a shell pass, and the flue gas passes through a tube pass. Therefore, problems of difficult material distribution, high requirements on cylinder thermal insulation and easily blocked pipe of the multi-pipe revolving dry distillation machine are solved.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

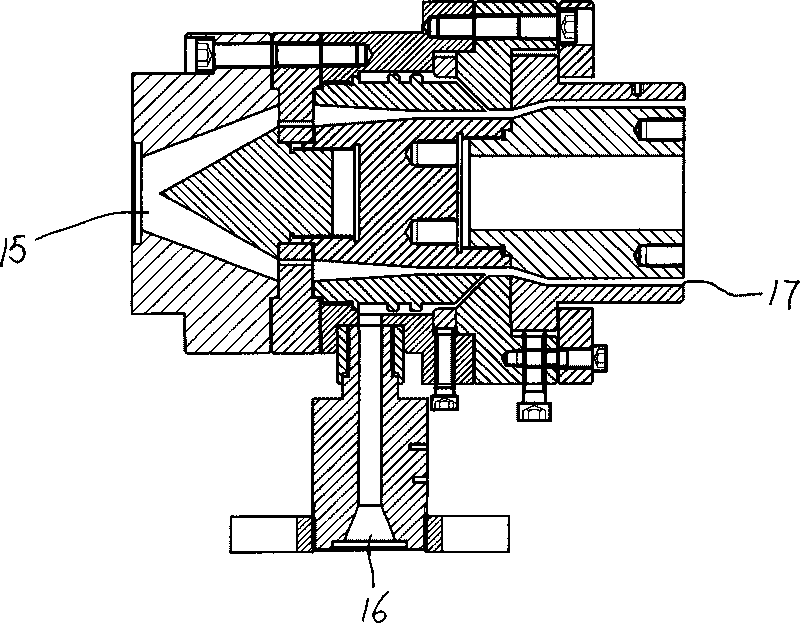

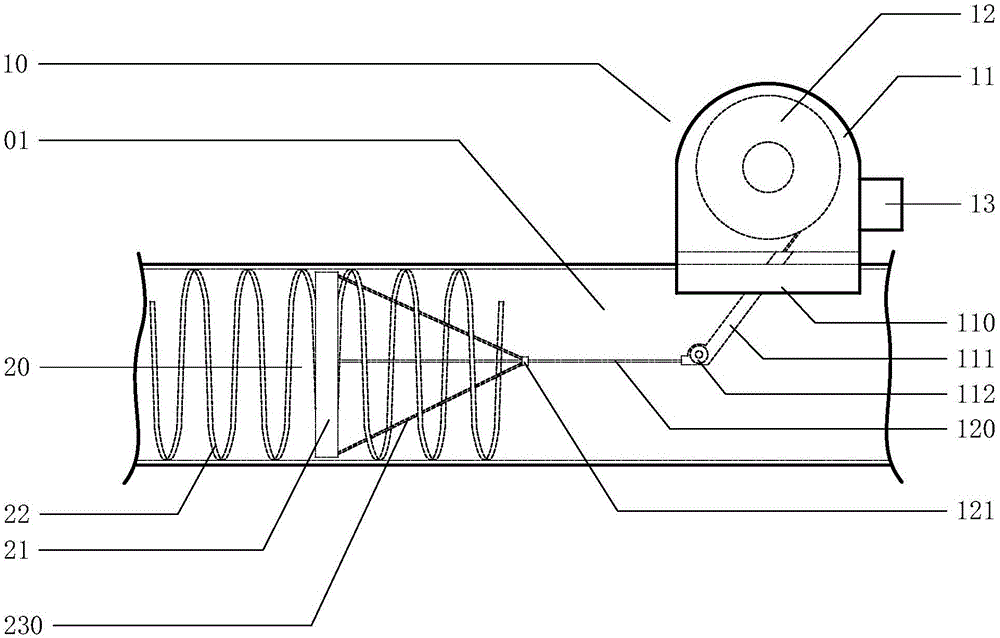

Ash remover for inner wall of mortar pipe

An ash remover for the inner wall of a mortar pipe comprises an external winding and unwinding machine and an internal ash scrapping frame. The external winding and unwinding machine comprises a pipe clamping machine box, a pull rope winch and an inflating pressurization machine; the pipe clamping machine box is of a closed box structure, the bottom of pipe clamping machine box is provided with a pipe clamping support and a pull rope guide pipe, the pull rope winch is installed in an inner cavity of the pipe clamping machine box and provided with a winding-unwinding pull rope, and the internal ash scrapping frame is installed in an inner cavity of the mortar pipe and comprises a casing pipe transverse moving frame and a screw-type ash scrapping rod. According to the ash remover, the internal ash scrapping frame slides to the outlet end of the mortar pipe through the action of water flow and slides to the water inlet end of the mortar pipe through the pulling force of the external winding and unwinding machine, the screw-type ash scrapping rod removes coal ash adsorbed on the inner wall of the mortar pipe in the process of sliding back and forth, and the problems that the coal ash forms ash fouling and a pipeline is blocked are prevented. Accordingly, the ash remover for the inner wall of the mortar pipe is reasonable in structure, convenient to assemble and capable of enabling the mortar pipe to smoothly convey mortar.

Owner:SUZHOU YUNSHOU SOFTWARE TECH CO LTD

Natural gas hydrate compound exploitation method

ActiveCN111255419AImprove protectionIncrease the reaction contact areaOther gas emission reduction technologiesFluid removalInjection wellCarbon dioxide

The invention discloses a natural gas hydrate compound exploitation method. The natural gas hydrate compound exploitation method comprises the following steps that an exploited well, an injection wellA and an injection well B are arranged at a stratum position of a natural gas hydrate to be exploited, and the injection well A and an injection well B are arranged on the two sides of the exploitedwell; a solid-state crushing drill rig and auxiliary equipment are lowered into a natural gas hydrate storage layer through the injection well B, after the storage layer is drilled, a drill hole is parallel to a horizontal line to continue to drill to crush the storage layer; the exploited well is closed, a carbon dioxide control platform is controlled, and carbon dioxide is injected into the natural gas hydrate storage layer through the injection well A; a drilling liquid control platform is controlled, and drilling liquid is injected into the natural gas hydrate storage layer through the injection well B; and the exploited well is opened, and natural gas generated in the storage layer is extracted to an offshore platform. According to the natural gas hydrate compound exploitation method,the advantage of good stability of the carbon dioxide hydrate is used, the stability of the stratum is ensured, geological disasters and mass decomposition of the hydrate are avoided, and meanwhile,the yield of the natural gas hydrate is effectively improved through favorable reaction conditions provided by the drilling liquid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

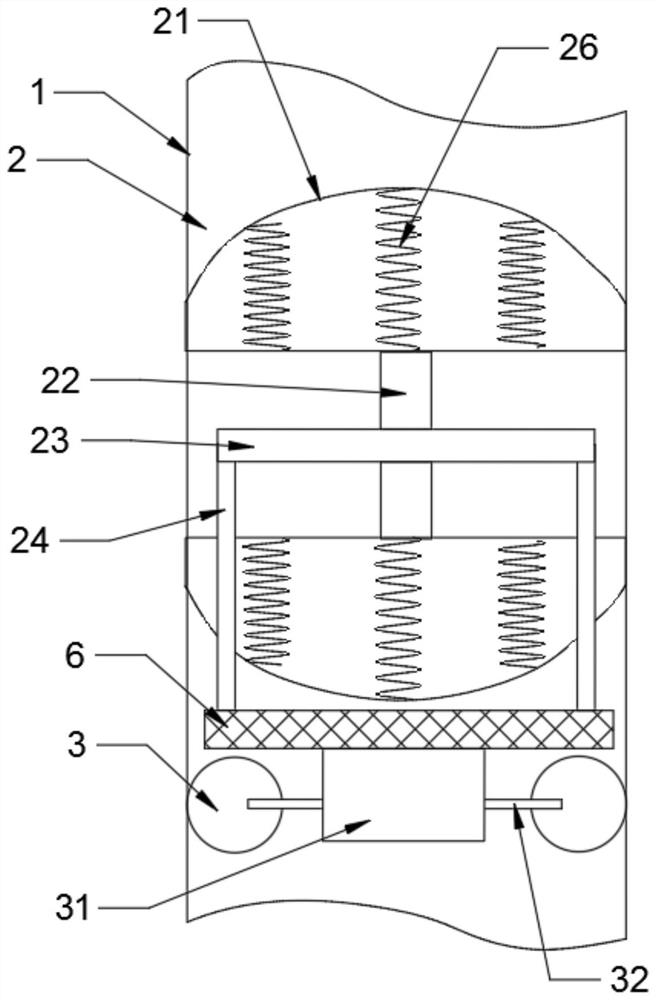

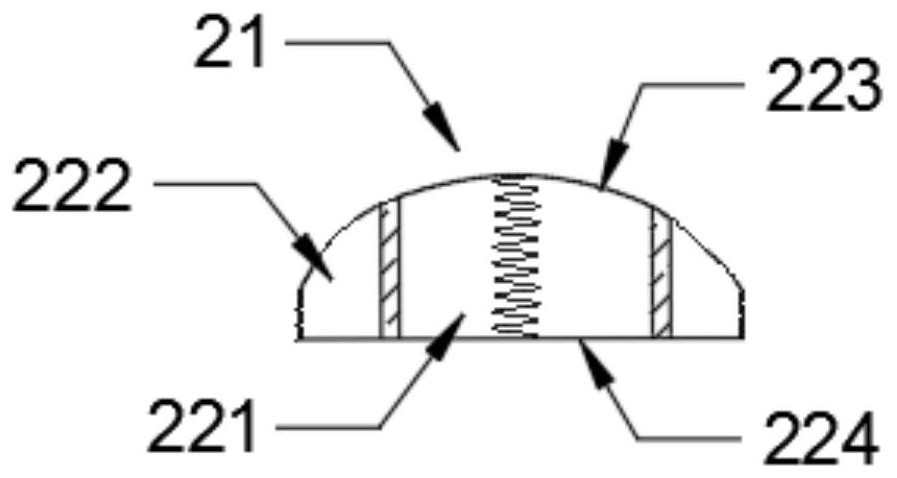

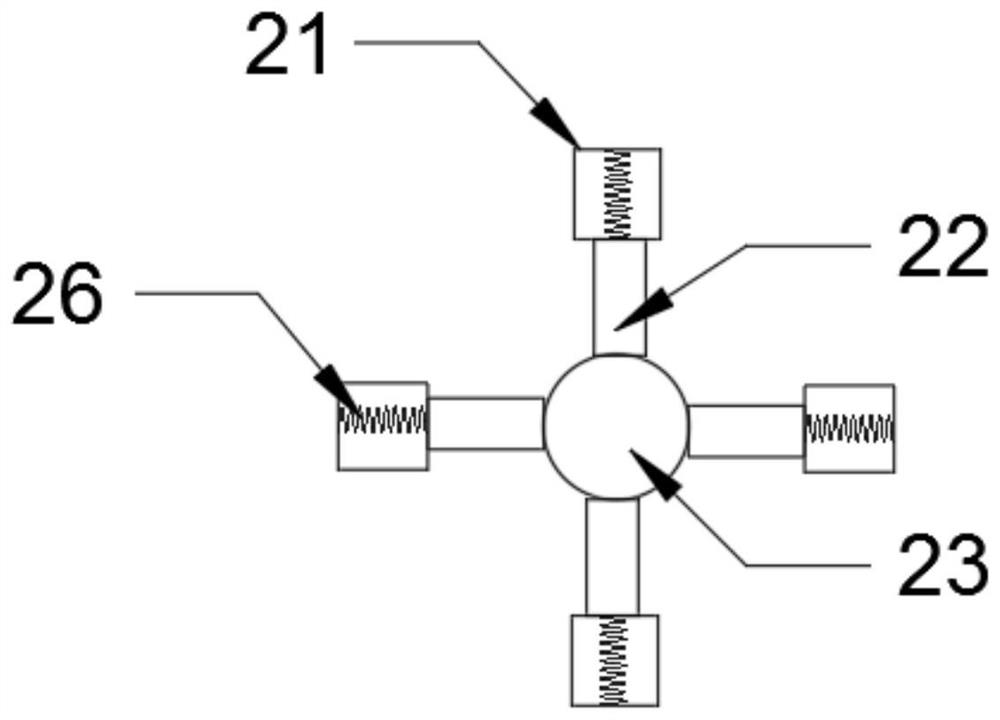

Municipal engineering pipeline drainage dredging device

The invention discloses a municipal engineering pipeline drainage dredging device. The municipal engineering pipeline drainage dredging device comprises a pipeline, wherein a scraping assembly is arranged in the pipeline, the scraping assembly moves in the pipeline through rollers, the scraping assembly is used for scraping sludge on the inner wall of the pipeline, a dredging assembly is further arranged in the pipeline, and the dredging assembly is used for dredging a blocked part in the pipeline. The municipal engineering pipeline drainage dredging device is scientific and reasonable in structure and safe and convenient to use, a first supporting rod can be pushed to rotate by utilizing the impact of water flow in the pipeline, so that a scraping plate rotates in the pipeline, the function of scraping the sludge on the inner wall of the pipeline in all directions by the scraping plate is realized, the sludge is not attached to the inner wall of the pipeline any more, the sludge can be effectively prevented from being accumulated more and more, the scraped sludge freely falls, and the separation or cleaning of the sludge in the later period is facilitated.

Owner:青岛西海岸城市建设集团有限公司

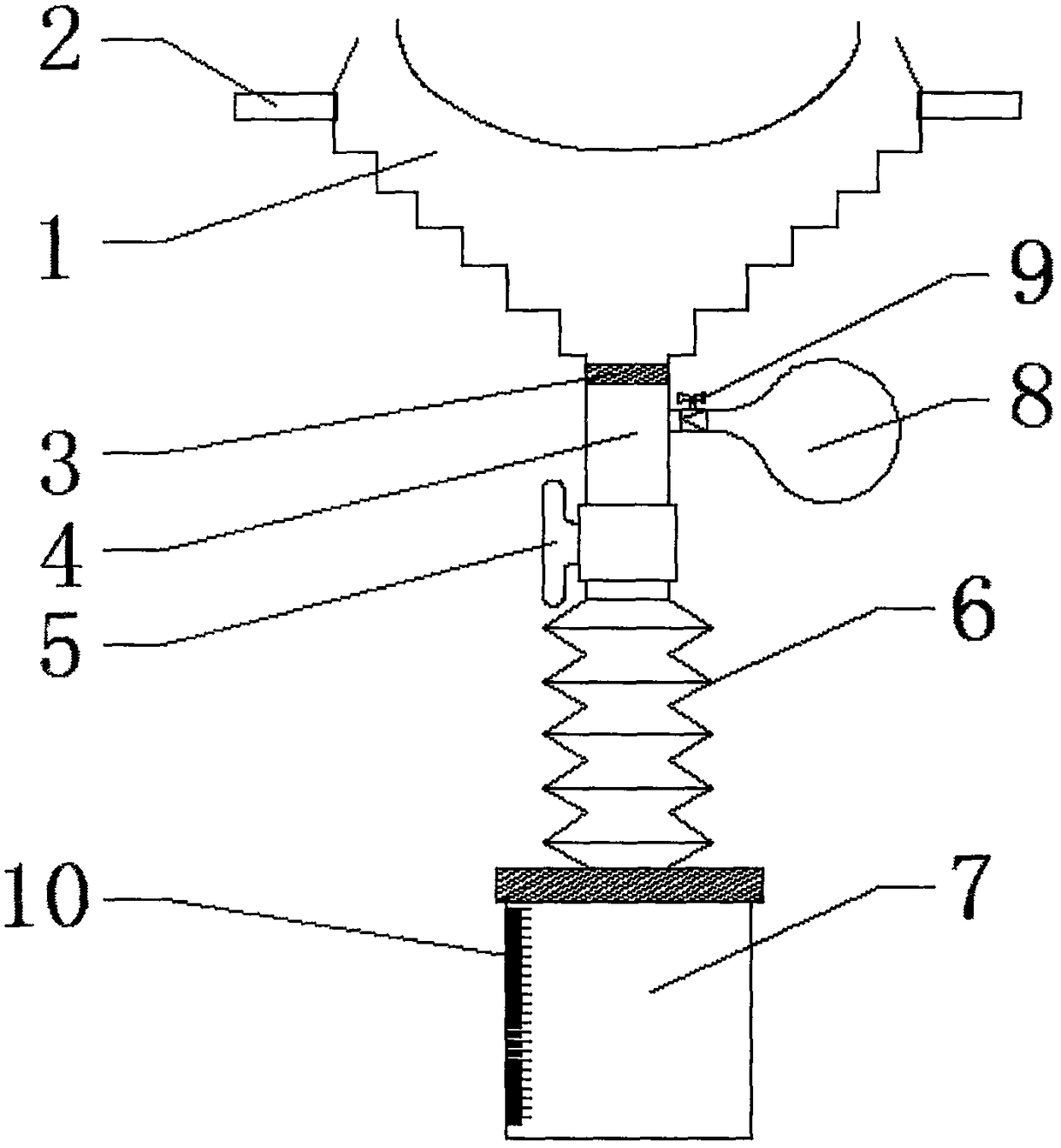

Disposable sealed midstream urine collecting device

InactiveCN108433746AAvoid spillingPrevents clogged pipesSurgeryVaccination/ovulation diagnosticsScrew threadUrine sample

The invention discloses a disposable sealed midstream urine collecting device, which comprises a funnel. The funnel is fixedly connected to a pipeline via a threaded connector; a two-way valve is arranged on the pipeline; the pipeline is fixedly connected to a telescopic corrugated pipe via a screw thread; a telescopic corrugated pipe communicates with a urine storage container; and an anti-blocking inflating device is connected to one side of the pipeline. By adopting the device, midstream urine of a patient with urinary incontinence can be conveniently collected, so that complex operating steps can be reduced; in addition, the container can be kept sealed in a urine collecting process, so that possibility that a urine sample is polluted can be reduced, secondary pollution can be avoided,the truthfulness of a detection result can be guaranteed and the existing problem that the container cannot be held easily can be avoided; and meanwhile, a bed sheet can be also prevented from getting contaminated.

Owner:上海康叮医药科技有限公司

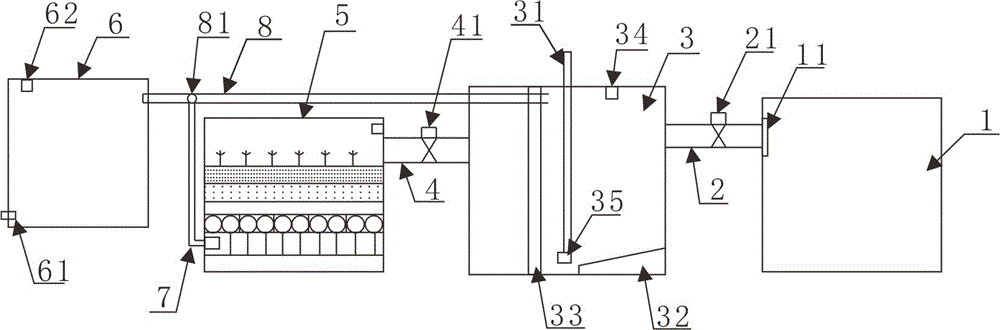

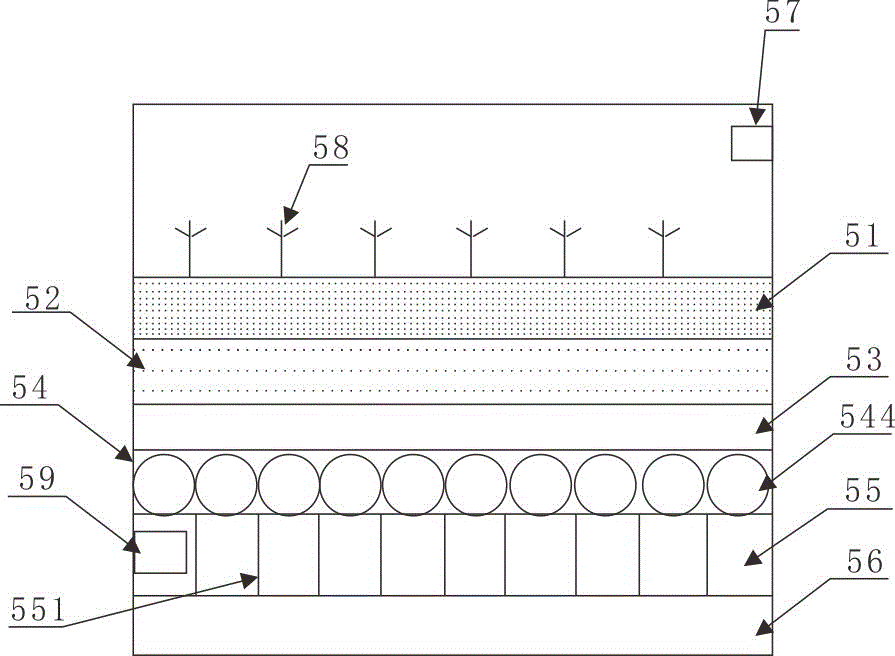

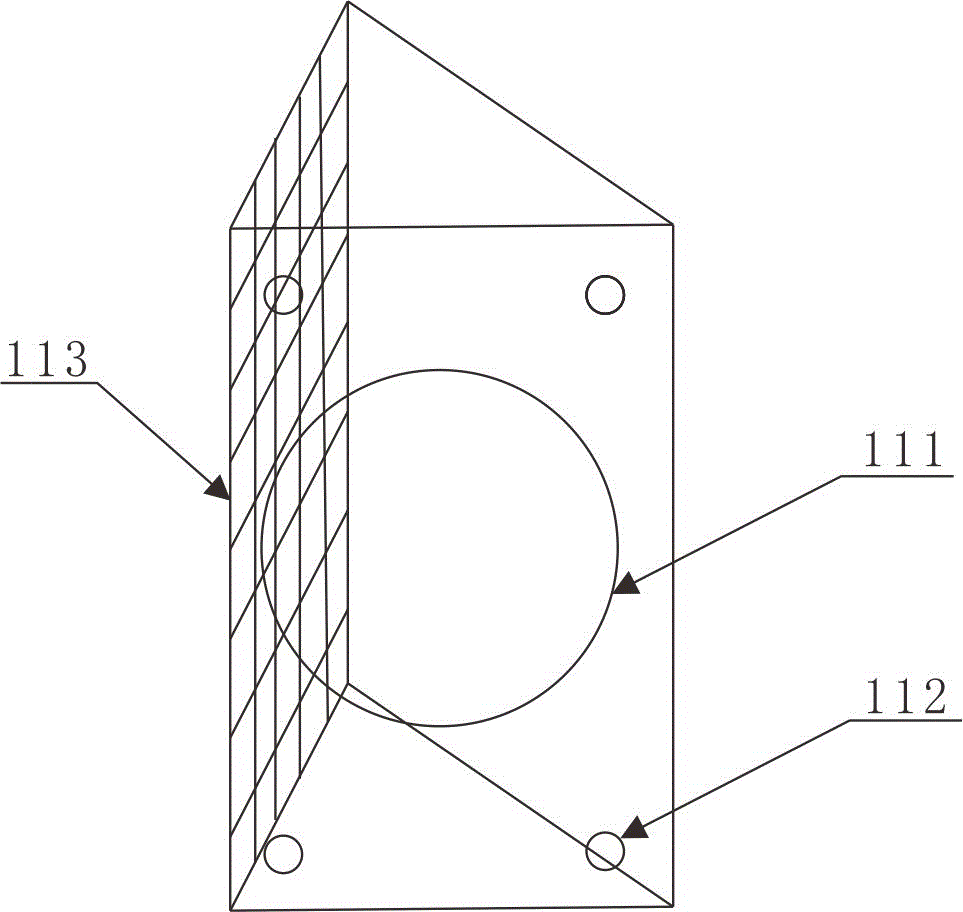

Water seepage and flood drainage system based on sponge city

ActiveCN106337484AMitigate flood discharge capacityImprove permeabilityTreatment involving filtrationMultistage water/sewage treatmentConstructed wetlandWater storage

The invention discloses a water seepage and flood drainage system based on a sponge city. The water seepage and flood drainage system comprises an artificial wetland, wherein the artificial wetland is connected with a buffer tank by virtue of a second water pipe, and the buffer tank is connected with a river by virtue of a first water pipe; the artificial wetland is successively provided with a sterilizing layer, a first isolation layer, a water storage layer and a planting layer from bottom to top; soil is arranged in the planting layer, and emergent aquatic plants are planted on the planting layer; coarse sand is arranged in the water storage layer; a mud separation plate for blocking mud and sand is arranged in the first isolation layer, and the mud separation plate is wrapped with geotechnical cloth; and a plurality of volcanic rocks are arranged in the sterilizing layer. The water seepage and flood drainage system based on the sponge city solves the problem that the rainy and flood water is difficult to seep and accumulate for use; and meanwhile, the system can effectively alleviate the flood leak pressure of a river, can improve the convenience of the municipal water application and can realize a function of seeping, collecting, purifying, storing and utilizing the river water and rainy water.

Owner:天津沃佰艾斯科技有限公司 +1

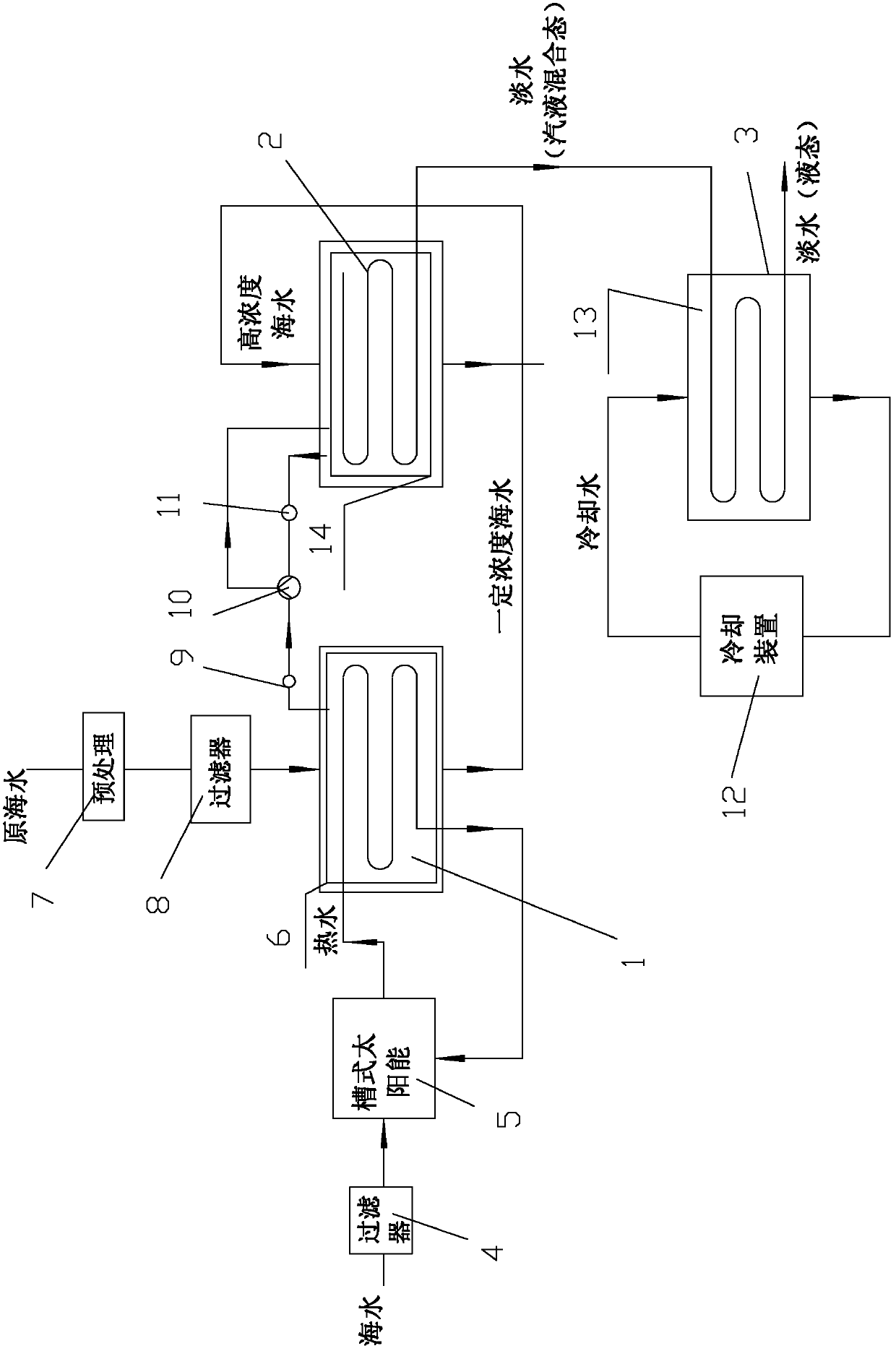

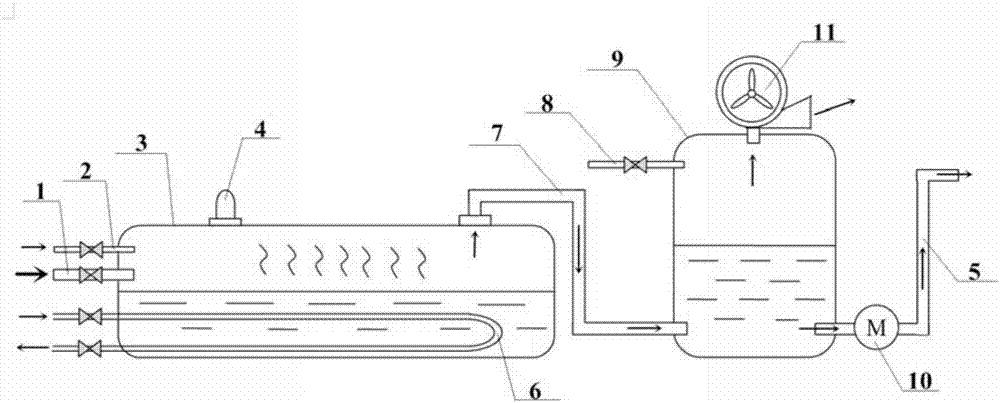

Seawater desalinating device

ActiveCN103288157AIncrease water productionAvoid cloggingGeneral water supply conservationSeawater treatmentDesalinationEngineering

The invention discloses a seawater desalinating device, relating to equipment with a small falling film evaporator and particularly relating to a device which carries out transverse-tube falling film evaporation by using solar energy. The seawater desalinating device comprises a seawater pretreatment system, an evaporator, a self-excited transverse-tube falling film evaporation-condensation device, a condenser, a grooved solar device and the like, wherein heat collected by the grooved solar device is transferred to the evaporator through heat exchange so as to supply a power source to the whole device. According to the seawater desalinating device, a pressure regulating device is arranged, so that the problem of control on difference of pressure inside the evaporator and the self-excited transverse-tube falling film evaporation-condensation device is solved; pretreated seawater is subjected to further filtering, so that the problem of pipeline blockage caused by seawater subjected to falling film is solved; and desalinated water collection tanks which are simple in structure and convenient in use are provided, so that the problem of low water yield caused by the fact that steam is condensed on an interior wall is solved. Compared with the prior art, the seawater desalinating device has the advantages that the effect on reducing the steam waste caused by wall condensation can be achieved, so that the water yield is increased.

Owner:GREE ELECTRIC APPLIANCES INC

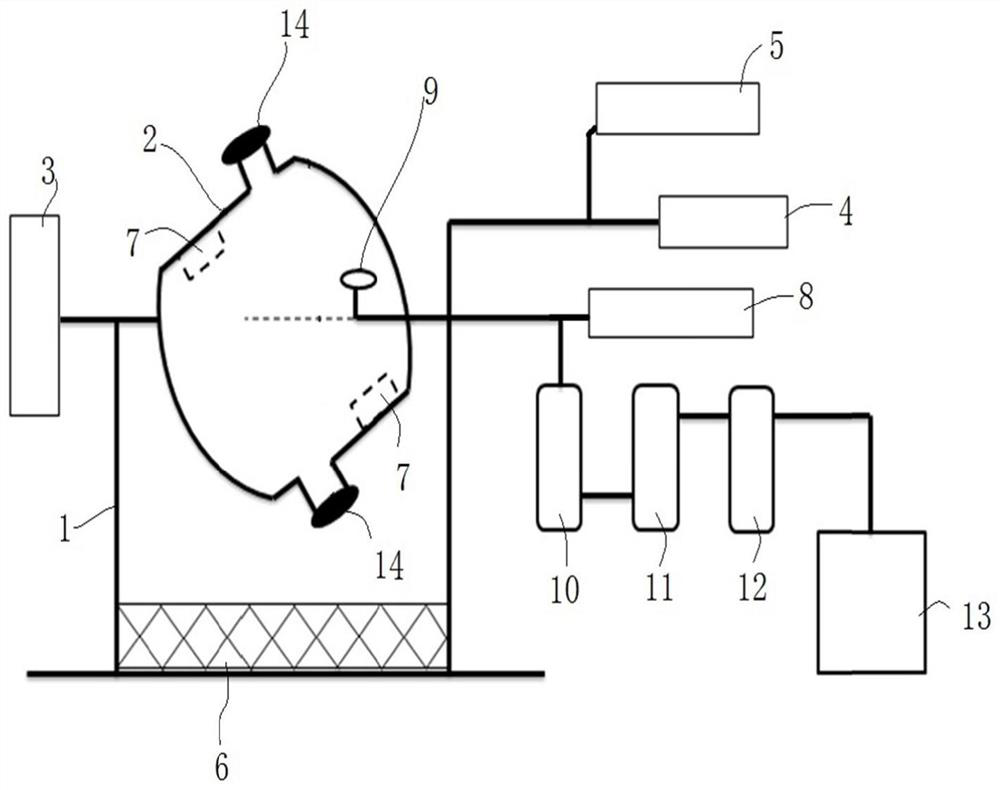

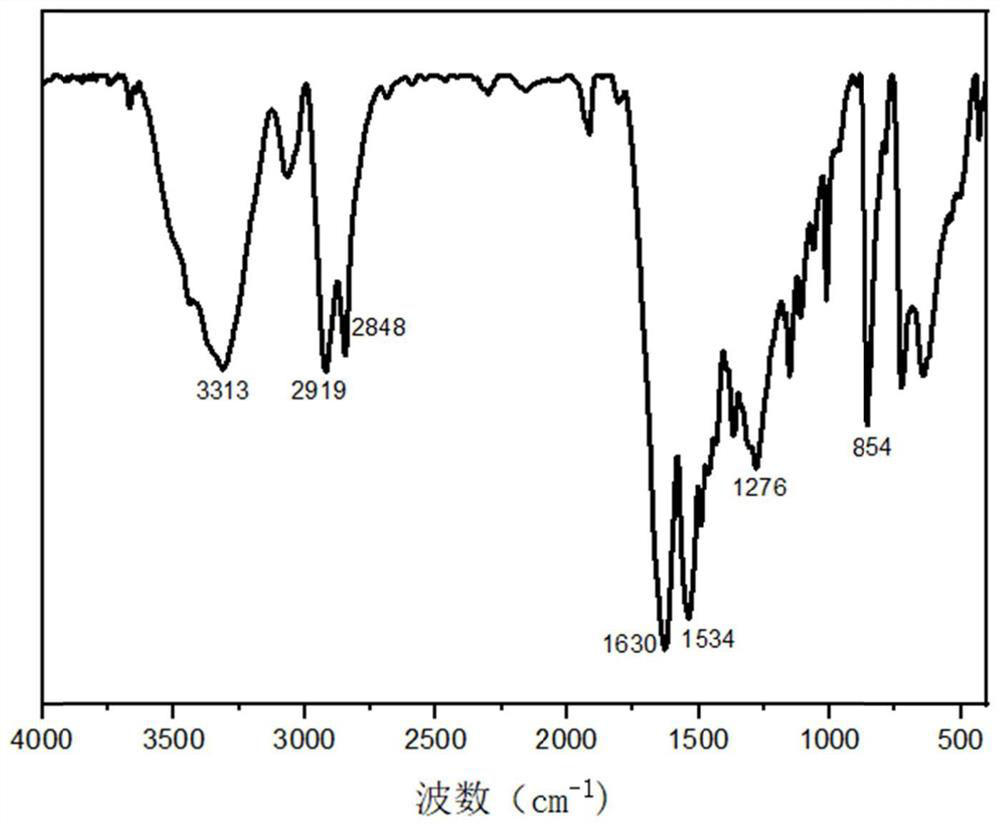

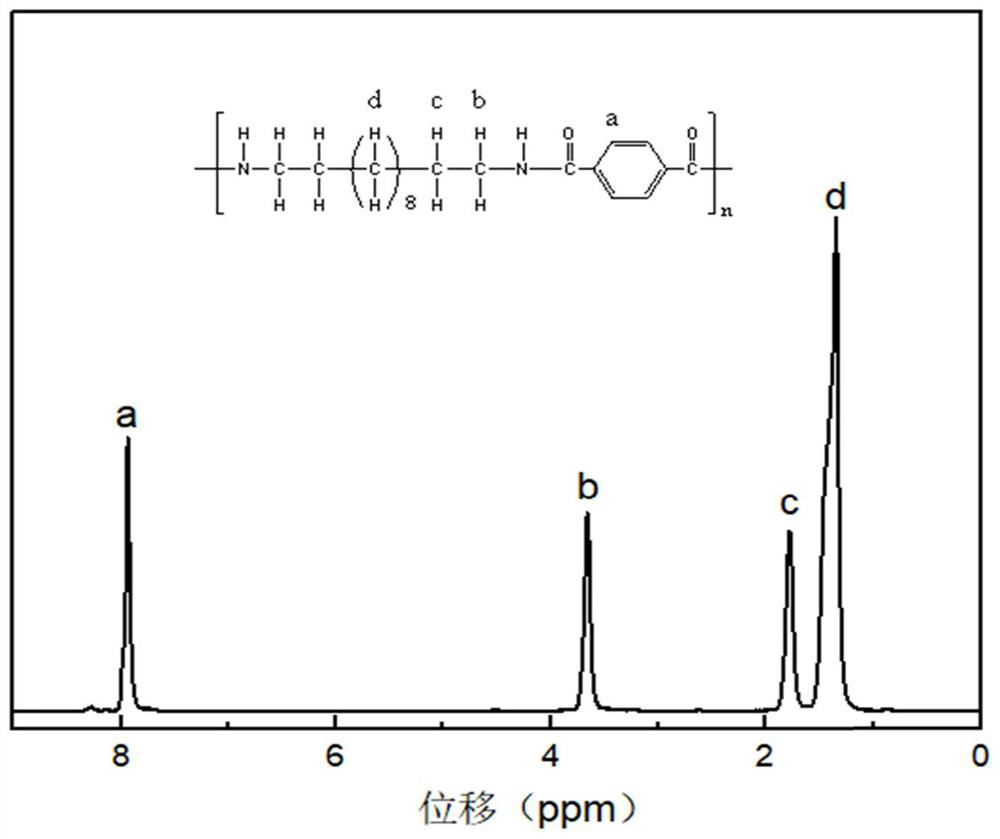

Synthesis method of long-carbon-chain semi-aromatic nylon

The invention relates to the field of synthesis of semi-aromatic nylon, in particular to a synthesis method of long-carbon-chain semi-aromatic nylon. The synthesis method comprises the following stepsof mixing a wet powdery nylon salt, an antioxidant, a catalyst, a surfactant and pellets, and carrying out one-step solid-phase polymerization in a dynamic mixing state to obtain powdery nylon, underdynamic mixing, enabling the small pellets to promote material stirring and mixing and reducing material adhesion to the wall, wherein the one-step solid-phase polymerization comprises solid-phase pre-polymerization and solid-phase post-polymerization, in the solid-phase pre-polymerization process, ensuring nylon salt and a pre-polymerization product not to be molten, in the solid-phase post-polymerization process, gradually reducing the system pressure to vacuum, and keeping the system pressure in a vacuum state for at least 1 hour, wherein the temperature of the solid-phase post-polymerization is not lower than the termination temperature of the solid-phase pre-polymerization. The synthesis method is a practical industrial large-scale production scheme, the product is non-sticky to thewall, the apparent shape of the product is white powdery nylon, the product can be directly used for molding processing without further granulation, and the overall quality of the product is very good.

Owner:ZHENGZHOU UNIV

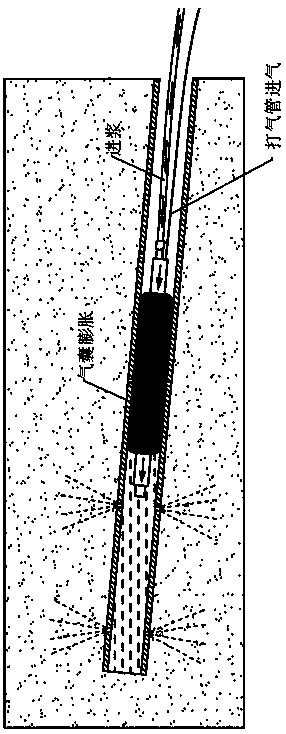

Airbag grout-block valve pipe assembly for conveniently perforating and slip casting construction

PendingCN108180024ADense fill effectGood non-return effectUnderground chambersFoundation engineeringBlocked valvesSlurry

The invention discloses an airbag grout-block valve pipe assembly for conveniently perforating and slip casting construction. The airbag grout-block valve pipe assembly includes a slip casting drill pipe, a rod body grout-block valve, a rod body grout-out hole, a slip casting valve pipe body, a grout-block airbag, a slip casting pipe, an inflating pipe and a slip casting gun; the slip casting drill pipe is provided with the rod body grout-out hole which is provided with the rod body grout-block valve, the slip casting drill pipe is provided with the slip casting pipe body which is provided with the grout-block airbag, and the grout-block airbag forms an integral whole on the slip casting valve pipe body; and the front portion of the slip casting valve pipe body is connecting with the slipcasting gun, the tail portion of the slip casting valve pipe body is connected with the slip casting pipe, and the grout-block airbag is connected with the inflating pipe. According to the airbag grout-block valve pipe assembly for the conveniently perforating and slip casting construction, the slip casting efficiency is greatly improved, compared with existing slip casting valve pipe products, the airbag grout-block valve pipe assembly has the advantages of higher grout-out speed and grout-out pressure, wider slip casting semi-diameter, denser grout liquid filling effect and better grout liquid non-return performance under the same slip casting pressure, and the phenomenon of pipe plugging due to use of the grout liquid with quick set and early strength can be effectively prevented.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

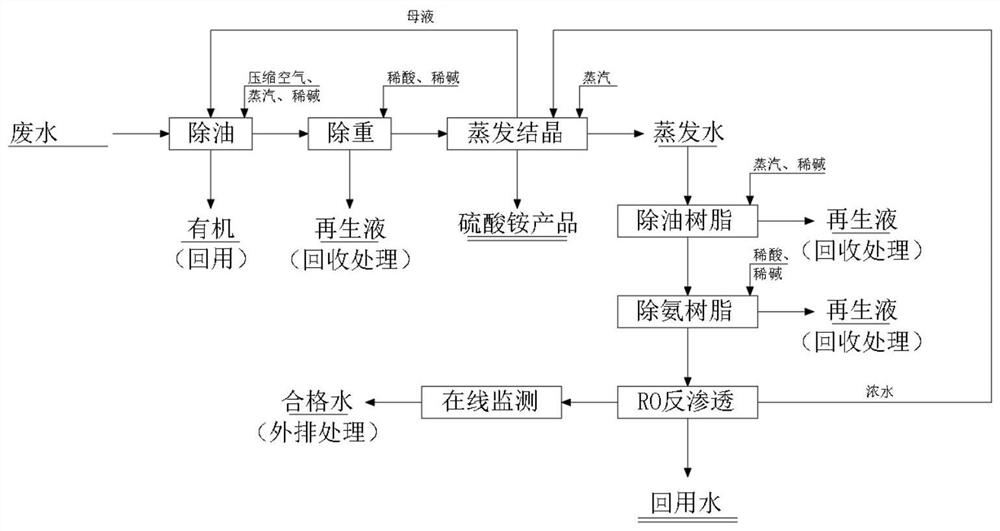

Treatment process of high-salinity wastewater

PendingCN113716779ASave waterImprove qualityWater contaminantsWater/sewage treatment by ion-exchangeWater useIon exchange

The invention relates to a treatment process of high-salinity wastewater, and belongs to the technical field of wastewater. The treatment process of the high-salinity wastewater comprises the following steps: S1, recovering oil in extraction wastewater by adopting an oil removal method of adsorption resin adsorption, and conducting filtering to obtain oil-removed wastewater; and S2, adding metal ion exchange resin into the oil-removed wastewater to remove heavy metals. Metal ion exchange resin is used for adsorbing heavy metals, resource recycling of heavy metal ions and ammonium sulfate is performed after adsorption treatment, and evaporated water after wastewater treatment can be returned to each water use process for use, so that high-salinity wastewater can be subjected to resource utilization and harmless treatment, a large amount of water resources can be saved, moreover, the resource utilization of the wastewater is a new benefit growth point, and the method has important significance in realizing water conservation and emission reduction.

Urea hydrolytic and pyrolytic compound ammonia preparation system for denitration in thermal power plant

PendingCN107188198AAvoid cloggingAvoid clogging pipesAmmonia preparation/separationAmmoniaWater pipe

The invention discloses a urea hydrolytic and pyrolytic compound ammonia preparation system for the denitration in a thermal power plant. The urea hydrolytic and pyrolytic compound ammonia preparation system comprises a urea solution inlet pipe, a hydrolytic reactor, a decarbonization tank, a desalted water pipe and an exhaust fan, wherein the urea solution inlet pipe is communicated with an inlet in the side surface of the hydrolytic reactor; the bottom of the hydrolytic reactor is provided with a steam heater for heating a urea solution in the hydrolytic reactor; a top outlet of the hydrolytic reactor is communicated with a bottom inlet of the decarbonization tank; a desalted water inlet in the side surface of the decarbonization tank is communicated with the desalted water pipe; the exhaust fan is located at a top opening of the decarbonization tank; a bottom outlet of the decarbonization tank is communicated with an ammonia water pipe. The system is low in energy consumption; a product cannot block a pipeline; moreover, the cost is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

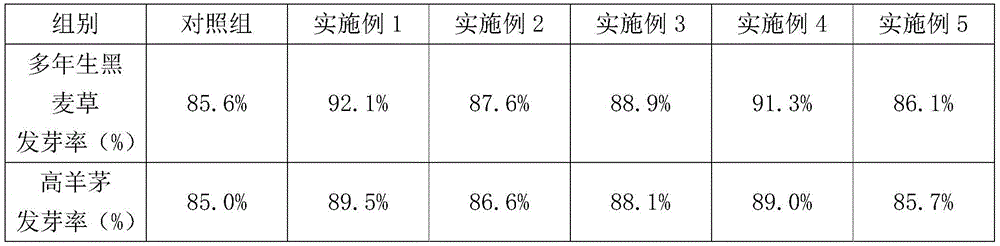

Method for preventing pipeline from being blocked by too-wet dressing soil in slope dressing soil dry-spraying operation

ActiveCN105484273AAvoid clogging pipesGuaranteed greening effectClimate change adaptationAfforestationVegetable matterSoil science

The invention discloses a method for preventing a pipeline from being blocked by too-wet dressing soil in slope dressing soil dry-spraying operation. The method includes the following steps that firstly, improved dressing soil is prepared, wherein a sand material and vegetable matter are added to the water-contained dressing soil to be stirred and evenly mixed; and secondly, the improved dressing soil is sprayed to a mountain slope beside a road through a dressing soil dry-spraying process. By the adoption of the method, a dressing soil ratio improving method is adopted, bonded particles are effectively scattered, the matrix wall bonding phenomenon is effectively avoided, viscosity is reduced, and the aggregation phenomenon is reduced; the wall bonding phenomenon is reduced; and the pipeline blocking phenomenon generated in dry-spraying operation can be effectively prevented, smooth construction is guaranteed, waste is used, cost is reduced, the soil is evenly sprayed to the slope face of the slope, the construction progress is guaranteed, and the afforesting effect of the slope can be guaranteed.

Owner:TIANJIN RES INST OF BUILDING SCI

Denitration agentcapsule and preparation method and application thereof

PendingCN113617218ATo achieve the effect of denitrificationPrevent escapeGas treatmentDispersed particle separationPhysical chemistryMass fraction

The invention provides a denitration agent capsule and a preparation method and application thereof. The denitration agentcapsule comprises a capsule shell and a denitration agent wrapped in the capsule shell; the denitration agent is prepared by mixing effective agent components and a binder; the mass fraction of the effective agent component is 91-99 wt% of that of the denitration agent, and the mass fraction of the binder is 1-9 wt% of that of the denitration agent; the total mass percentage of the effective agent component and the binder is 100 wt% of the denitration agent. The denitration agent capsule can smoothly reach the interior of a rotary kiln, a shaft kiln, a Maerz kiln, a sleeve kiln or a melt separation furnace, so that the denitration agent capsule is completely mixed with raw materials, the denitration agent capsule is conveyed to the optimal temperature area of denitration agent reaction through a feeding system, the internal denitration agent is released after the capsule shell is melted, and the denitration effect in combustion is achieved.

Owner:唐山鑫联环保科技有限公司

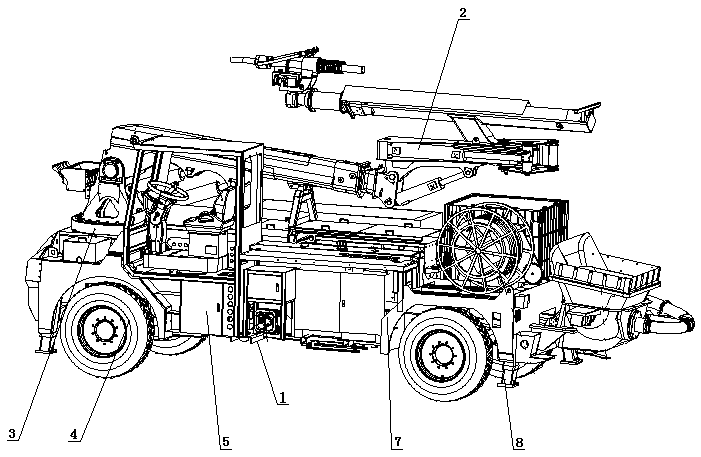

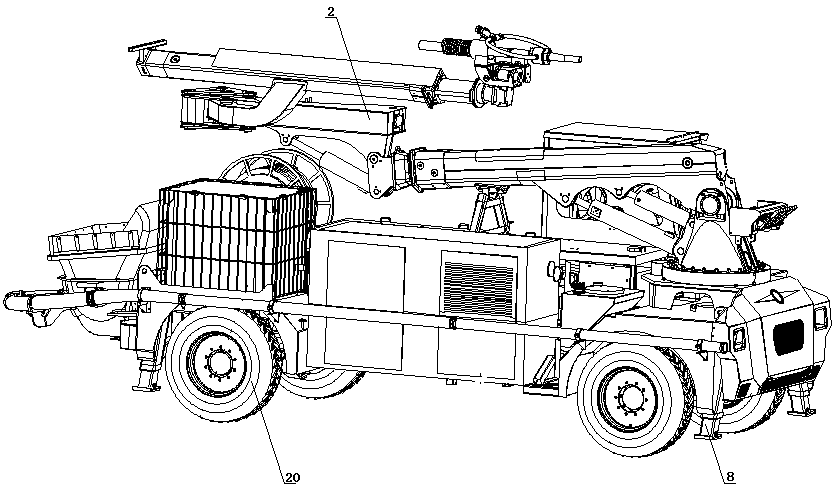

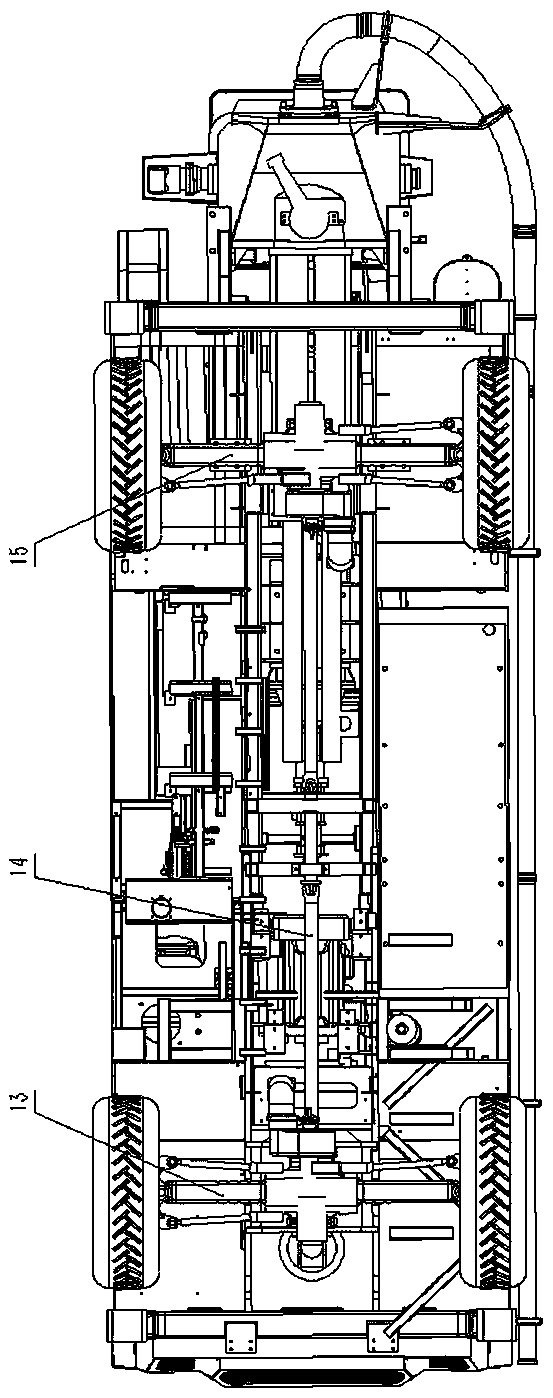

Concrete wet spraying machine chassis and concrete wet spraying machine

PendingCN109372549AStable torqueImprove stability and securityUnderground chambersTunnel liningAgricultural engineeringTransmission system

The invention relates to a concrete wet spraying machine chassis, which comprises a bearing chassis body and a travelling system. The travelling system comprises a front axle, a transmission shaft, arear axle and a hydraulic transmission system; the front axle and the rear axle are fixed to the front and rear parts of the bottom of the bearing chassis body, and connected through the transmissionshaft; the transmission shaft comprises a front transmission shaft, an intermediate transmission shaft and a rear transmission shaft; the hydraulic transmission system comprises an engine, and furthercomprises a travelling pump and a steering brake pump which are arranged on the engine, a travelling motor and an electromagnetic directional valve, the output end of the steering brake pump is connected with the electromagnetic directional valve, the electromagnetic directional valve is connected with a steering oil cylinder, the travelling pump is connected with the travelling motor in a transmission mode, the output end of the traveling motor is connected with a gearbox, the gearbox is connected with a main reducer of the front axle and the transmission shaft, and the transmission shaft isconnected with a main reducer of the rear axle. The invention further relates a concrete wet spraying machine. According to the concrete wet spraying machine chassis and the concrete wet spraying machine, the operation efficiency is high, the labor intensity is low, the passability is good, and the turning radius is small.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com