Conveying pipe sleeve for pumping concrete construction

A technology for pumping concrete and conveying pipes, applied in the field of conveying pipe sleeves, which can solve the problems of cumbersome heat preservation methods and poor heat preservation effects of conveying pipes, and achieve the effects of simple structure, convenient disassembly and assembly, and prevention of pipe clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

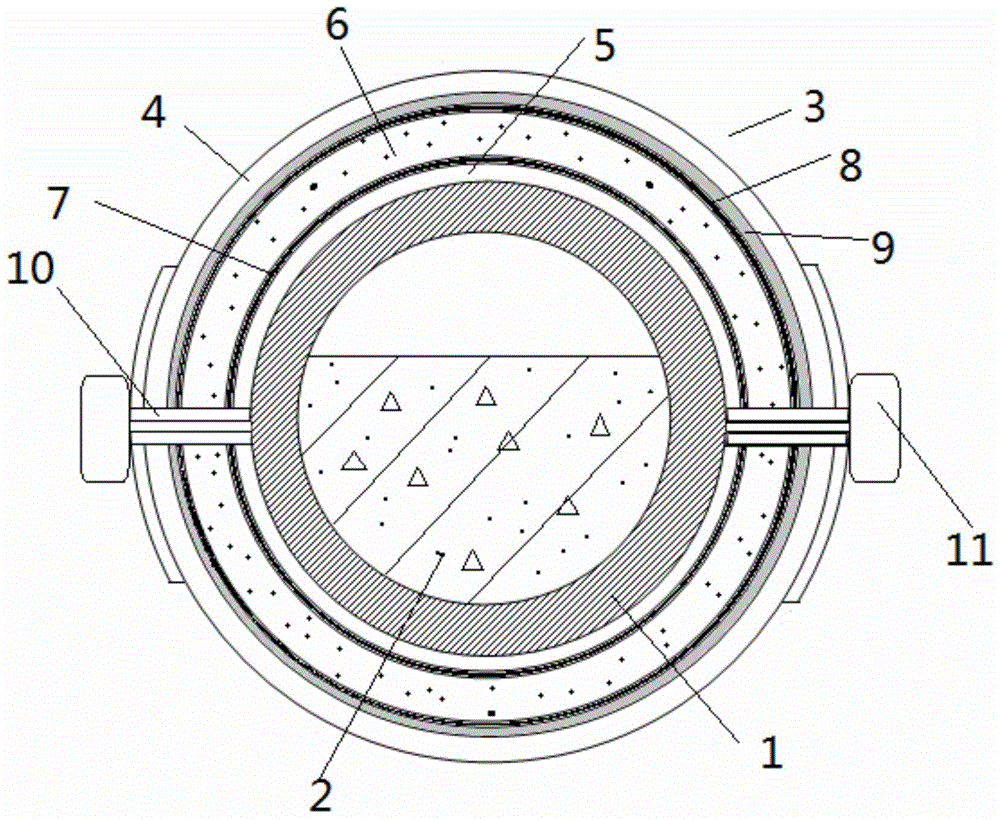

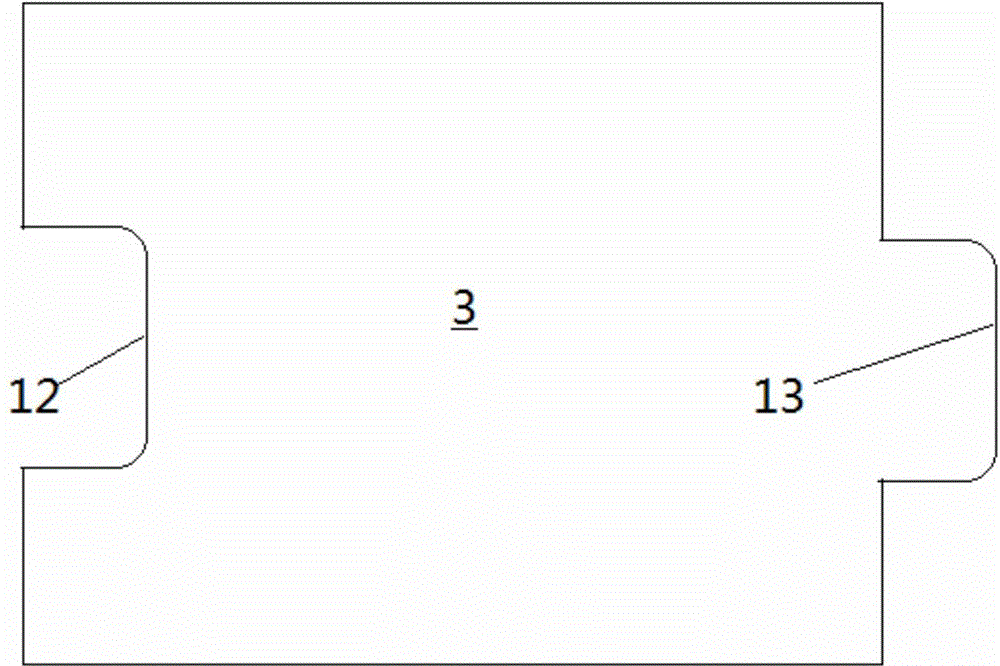

[0033] Such as figure 1 , figure 2 As shown, a delivery pipe sleeve 3 for pumping concrete construction, the sleeve 3 is sleeved on the outside of the delivery pipe 1 of the pumped concrete 2, and the inner diameter of the sleeve 3 is compatible with the outer diameter of the delivery pipe 1 , so that the pipe sleeve 3 can be sleeved outside the delivery pipe 1; along the length direction of the delivery pipe 1, the pipe sleeve 3 is formed by splicing multiple sections of pipe sleeve units. Each segment of pipe sleeve unit is spliced by more than two segment units, and each segment unit is a sealed cavity composed of an outer wall 4 , an inner wall 5 , an upper bottom surface, a lower bottom surface and two side sealing plates 10 . The phase change material 6 is filled in the closed cavity, and the phase change material 6 is an organic phase change material or an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com