Graphene-coated aluminum composite coating, preparation method and application thereof

A graphene coating, aluminum composite technology, applied in transportation and packaging, metal processing equipment, pressure inorganic powder coating and other directions, can solve problems such as accelerated corrosion of magnesium alloy substrates, avoid pipe blockage, compensate for local corrosion, improve The effect of spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

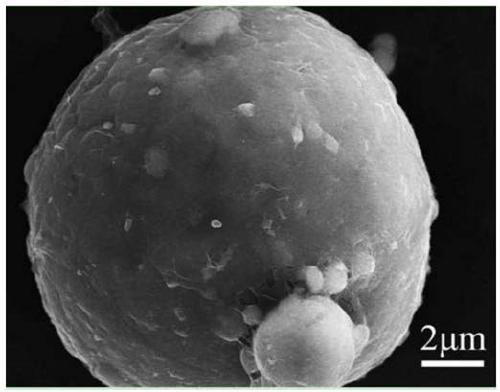

[0032] 1. Coating of aluminum powder: weigh 0.02g graphene oxide, put into 100mL deionized water and disperse to a clear and transparent solution, and obtain a graphene oxide aqueous solution with a concentration of 0.2g / L; weigh 20g aluminum powder (10 ~40μm) into the dispersed graphene oxide aqueous solution with a concentration of 0.2g / L and magnetically stirred. After reacting for 300s, filter off the excess water and wash the above-mentioned graphene-coated powder with alcohol and filter again. Bake it down for 18 hours to obtain a graphene-coated aluminum powder with a graphene mass fraction of 0.1 wt%.

[0033] 2. Surface roughening of the substrate: use YT-9060 sandblasting machine to sandblast the surface of the magnesium alloy. After sanding and sanding, the surface roughness is 5-10Ra.

[0034] 3. Surface cleaning: Put the substrate treated in step 2 into alcohol and ultrasonically clean it for 20 minutes to remove oil and impurities, and dry it for later use.

[...

Embodiment 2

[0044] The aluminum powder coating process and the coating preparation steps are the same as in Example 1, the difference being that the graphene oxide weighed is 0.03g, the concentration of the graphene oxide aqueous solution is 0.3g / L, and the graphene mass fraction obtained is 0.15 Wt% graphene-coated aluminum powder; the reaction time of aluminum powder in the solution is 400s; the blasting gas pressure is 0.6MPa, the blasting angle is 85°, or polished with 200 mesh sandpaper; cold spraying process parameters: working pressure is 0.8Mpa, the gas temperature is 400°C, the moving speed of the nozzle relative to the sample is 100mm / min, the distance between the bottom of the nozzle and the surface of the sample is 20mm, and the powder feeding rate is 0.2g / s.

Embodiment 3

[0046] The aluminum powder coating process and the coating preparation steps are the same as in Example 1, the difference is that the weighed graphene oxide amount is 0.04g, the concentration of the graphene oxide aqueous solution is 0.4g / L, and the obtained graphene mass fraction is 0.2 Wt% graphene-coated aluminum powder; the reaction time of aluminum powder in the solution is 450s; the blasting gas pressure is 0.65MPa, the blasting angle is 80°, or polished with 400 mesh sandpaper; cold spraying process parameters: working pressure is 0.65Mpa, the gas temperature is 450°C, the moving speed of the nozzle relative to the sample is 200mm / min, the distance between the bottom of the nozzle and the surface of the sample is 10mm, and the powder feeding rate is 0.4g / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com