Patents

Literature

238results about How to "Obvious economic advantages" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

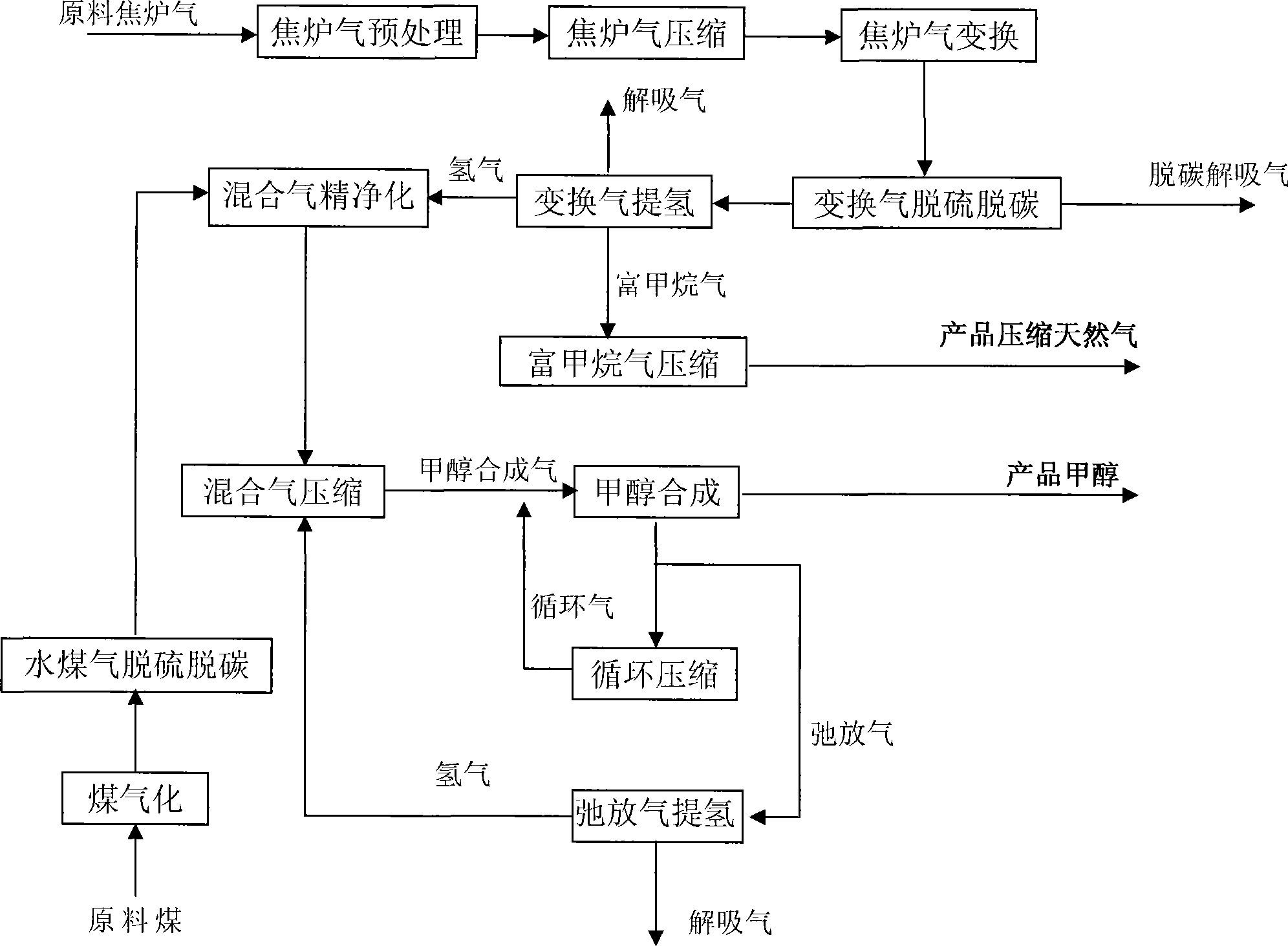

Method for preparing methyl alcohol synthesis gas and compressed natural gas from coke oven gas and coal

The invention discloses a method for producing methanol synthesis gas and compressed natural gas by taking coke oven gas and coal as raw materials, and the main steps comprise that purification treatment, transformation treatment, desulfurizing decarburization, pressure swing absorption separation of methane and hydrogen and methane-rich gas compression are carried out to the coke oven gas to prepare the compressed natural gas; and coal gasification reaction, purification treatment, mixing with the hydrogen and fine desulfurization treatment are carried out to the coal to obtain the methanol synthesis gas. The method is based on the characteristics of more hydrogen and less carbon in the coke oven gas and more carbon and less hydrogen in the coal-made methanol feed gas, transforms CO to H2 and CO2 by the transformation treatment after the effective pretreatment to the coke oven gas, and then the H2 and CH4 are separated effectively by a PSA technology so as to be used as the raw materials with higher values, and therefore the method achieves the purpose of comprehensively utilizing the coke oven gas and the coal as the raw materials for producing the methanol synthesis gas and the compressed natural gas, adopts the effective energy in the coke oven gas and the coal to maximum, saves energy, reduces emission and improves the economic benefits.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

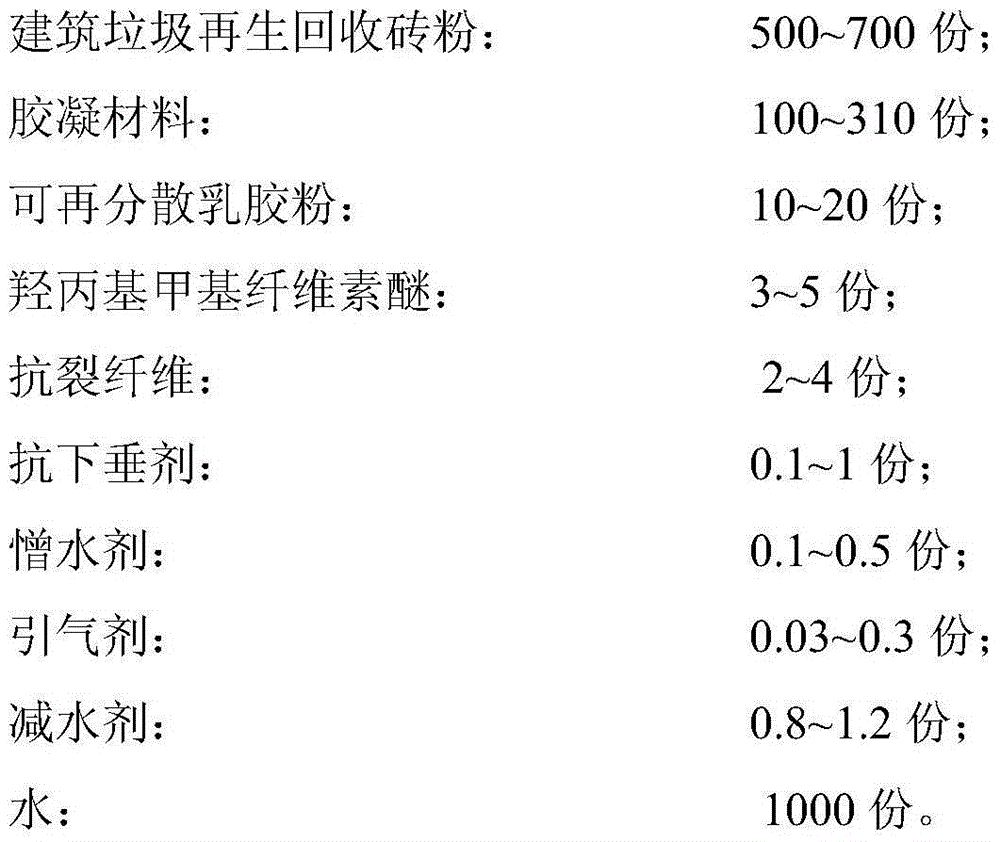

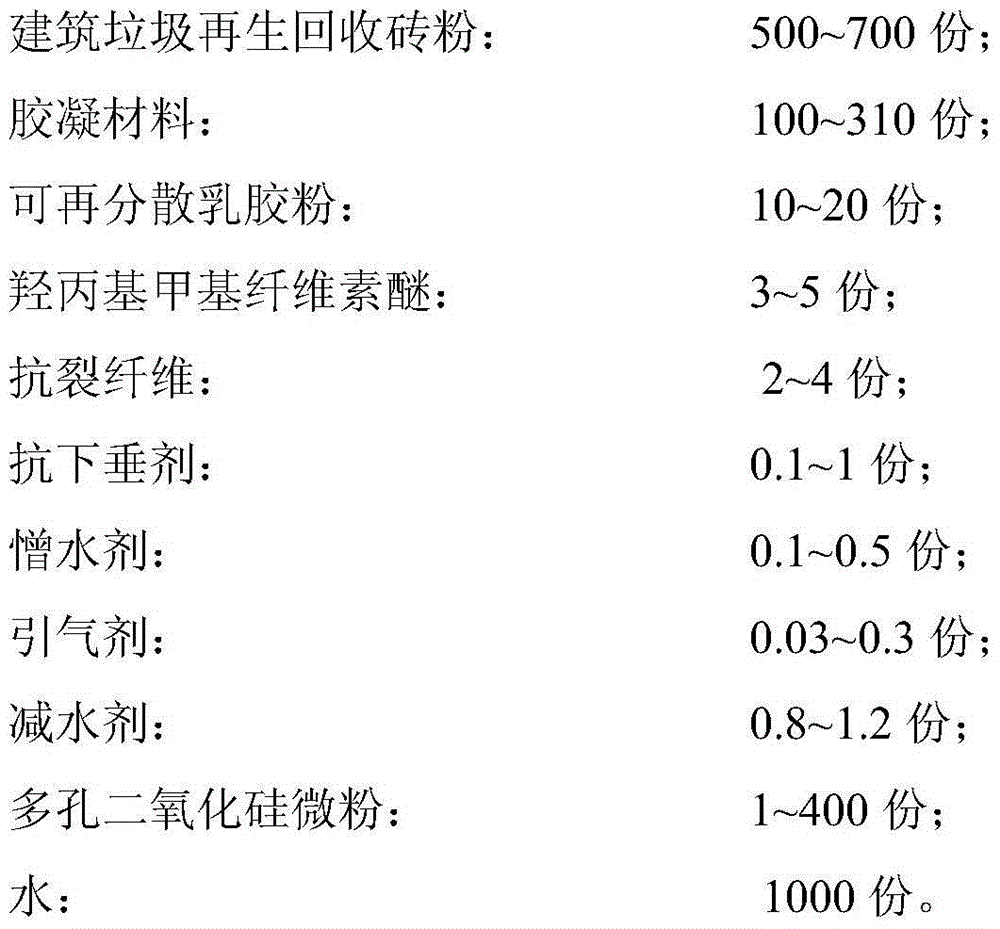

Construction waste reclaimed brick powder-containing spray construction heat insulation mortar

The invention discloses a construction waste reclaimed brick powder-containing spray construction heat insulation mortar. The mortar is prepared from, by weight, 500-700 parts of construction waste reclaimed brick powder, 100-310 parts of a gelling material, 10-20 parts of redispersible powder, 3-5 parts of hydroxypropyl methyl cellulose ether, 2-4 parts of a crack resistant fiber, 0.1-1 part of an anti-sagging agent, 0.1-0.5 parts of a water repellent, 0.03-0.3 parts of an air entraining agent, 0.8-1.2 parts of a water reducer and 1000 parts of water. The mortar has the characteristics of A grade flame retardation, good heat insulation performance, high compression and tensile strength, long life, environmental protection, waste recycling, easy mechanical spraying construction, construction energy consumption reduction, suitableness for internal and external wall heat insulation construction, simplicity, feasibility and low cost.

Owner:TONGJI UNIV

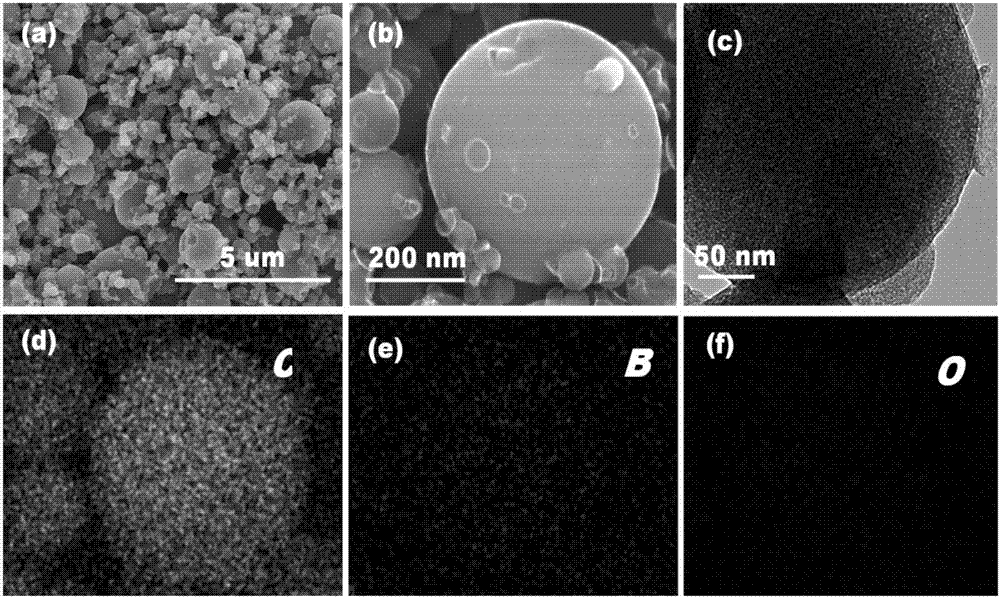

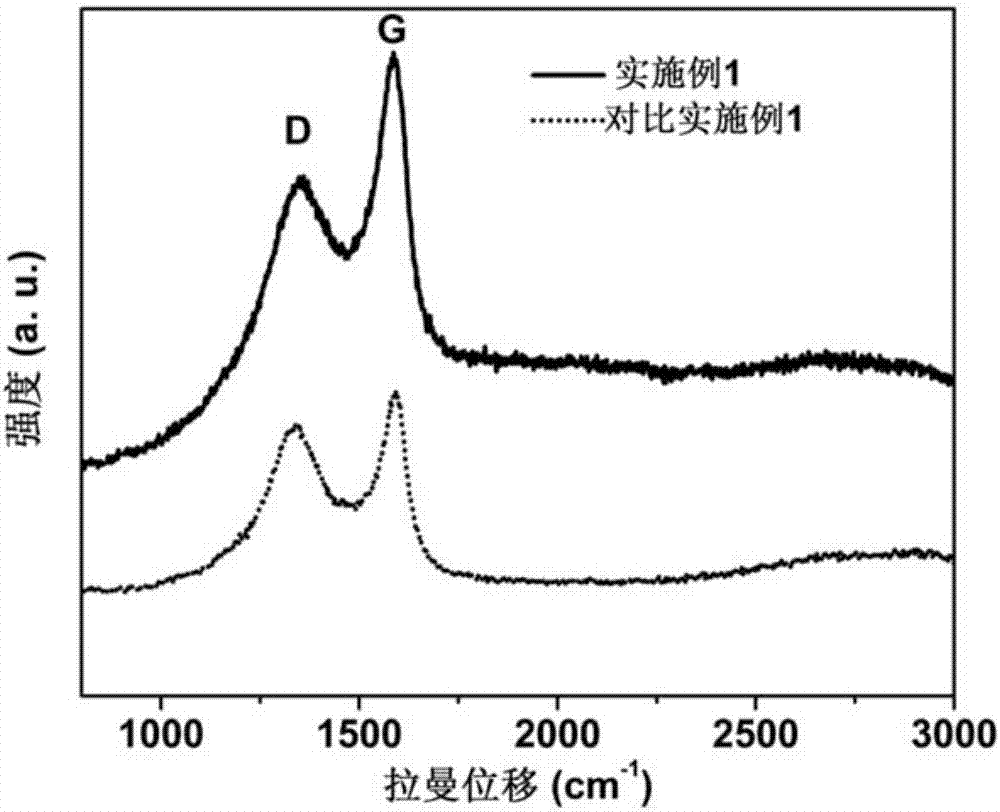

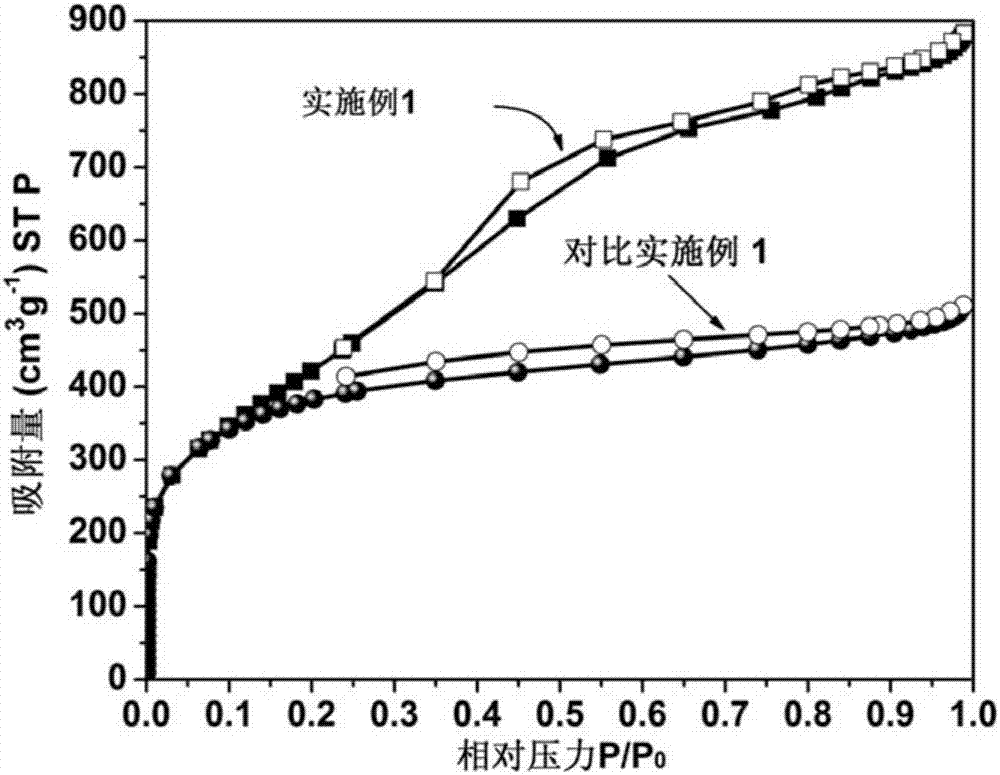

Method for preparing boron-doped porous carbon spheres

InactiveCN107346821ALow costSimple continuous production processSecondary cellsNegative electrodesPorous carbonBoron doped carbon

The invention relates to a method for preparing boron-doped porous carbon spheres. The method comprises the following steps: 1) dissolving a saccharide carbon source and boric acid in water, and carrying out mixing and stirring by a certain ratio, so as to obtain a transparent solution; 2) adding a silicon-based pore former so as to form a boron-doped porous carbon sphere precursor solution; 3) subjecting the obtained precursor solution to a (aerosol assisted) spray drying process, so as to obtain solid-state boron-doped carbon sphere precursor particles; 4) subjecting the obtained solid particles to pyrolysis in an inert atmosphere, so as to obtain a mixture, of which a pore template SiO2 is embedded in boron-doped carbon spheres; 5) removing the silicon-based pore former from the mixture, and carrying out drying, thereby obtaining the boron-doped porous carbon spheres. According to the method, the problems of the existing boron-doped carbon material technologies that the raw material cost is high, the preparation process is miscellaneous, the boron doped amount is low, and large-scale industrial production is difficult are solved, and an alternate material, which is superior to commercial graphite, of negative poles of lithium-ion batteries is provided.

Owner:卢云峰

Soil repairing agent used for fixing heavy metal element in polluted soil, preparation method and application thereof

ActiveCN104403675AAmendment of polluted soilImprove the ecological environmentAgriculture tools and machinesContaminated soil reclamationAdditive ingredientSorbent

The invention relates to a soil repairing agent used for fixing heavy metal element in polluted soil, a preparation method and an application thereof. The soil repairing agent is a solid granular product, and is prepared by uniformly mixing a soil heavy metal chemical fixing agent ingredient (A), a soil heavy metal adsorbent ingredient (B) and a soil conditioner ingredient (C); according to the mass percentage, the soil heavy metal chemical fixing agent (A) content in the soil repairing agent composition is 20-80%, soil heavy metal adsorbent (B) content is 10-20%, and soil conditioner (C) content is 10-60%. The soil repairing agent can be directly and mutually mixed with the soil polluted by the heavy metal element and then is placed, or the soil repairing agent is dispersed or dissolved in water, then is uniformly stirred and mixed by the soil polluted by the heavy metal element and is placed, so that heavy metal element can be fixed, and heavy metal fixing rate can reach more than 95%. Transportable concentration of the heavy metal element in soil can be greately reduced, soil heavy metal pollution problem can be effectively solved, and polluted soil can be treated and restored finally.

Owner:SHANGHAI RES INST OF CHEM IND

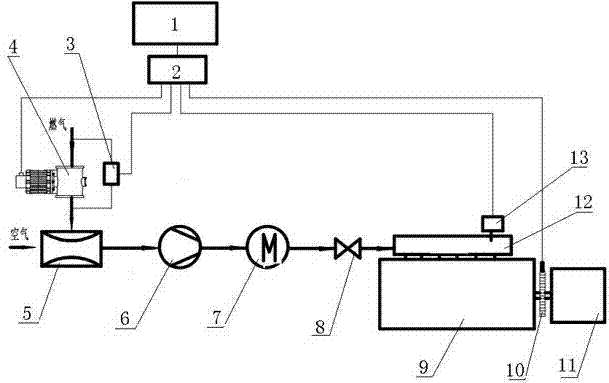

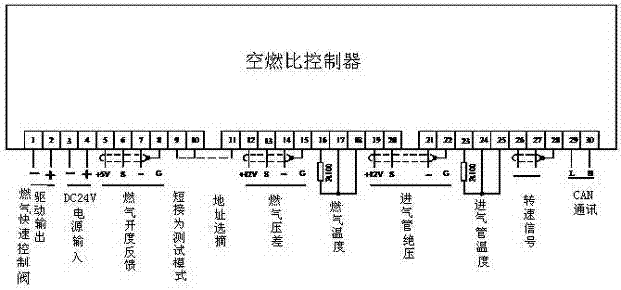

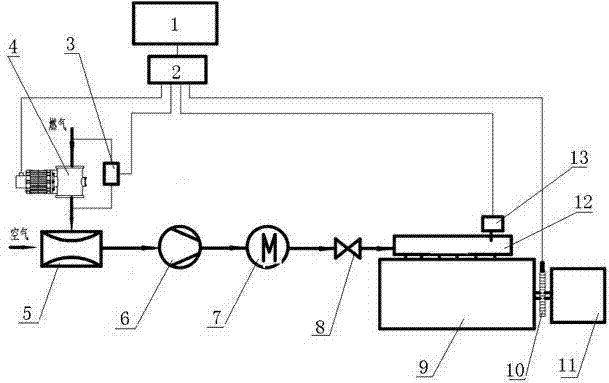

Air-fuel ratio rapid automatic adjusting system for gas generator set

InactiveCN102230425AReasonable air-fuel ratio control strategyEasy to startElectrical controlInternal combustion piston enginesDifferential pressureTurbocharger

The invention relates to an air-fuel ratio rapid automatic adjusting system for a gas generator set, which comprises a touch screen, a Venturi tube mixer, a turbosuperchager, an intercooler, a throttle valve, an engine, a rotating speed sensor, an generator, an intake manifold and a mixture gas absolute pressure / temperature measurement module, wherein one end of the Venturi tube mixer is respectively connected with the gas pressure difference / absolute pressure / temperature measurement module, a gas rapid control valve, an air-fuel ratio controller and the touch screen in sequence; the other end of the Venturi tube mixer is connected with the turbosuperchager, the intercooler, the throttle valve, the intake manifold, the engine, the rotating speed sensor and the engine in sequence; the gas rapid control valve and the gas pressure difference / absolute pressure / temperature measurement module are connected with the air-fuel ratio controller and the touch screen in sequence; the intake manifold is connected with the air-fuel ratio controller and the touch screen in sequence; and the air-fuel ratio of the engine is automatically adjusted rapidly according to the difference value of practical mass flow and theoretical mass flow of a mixture gas in the engine.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

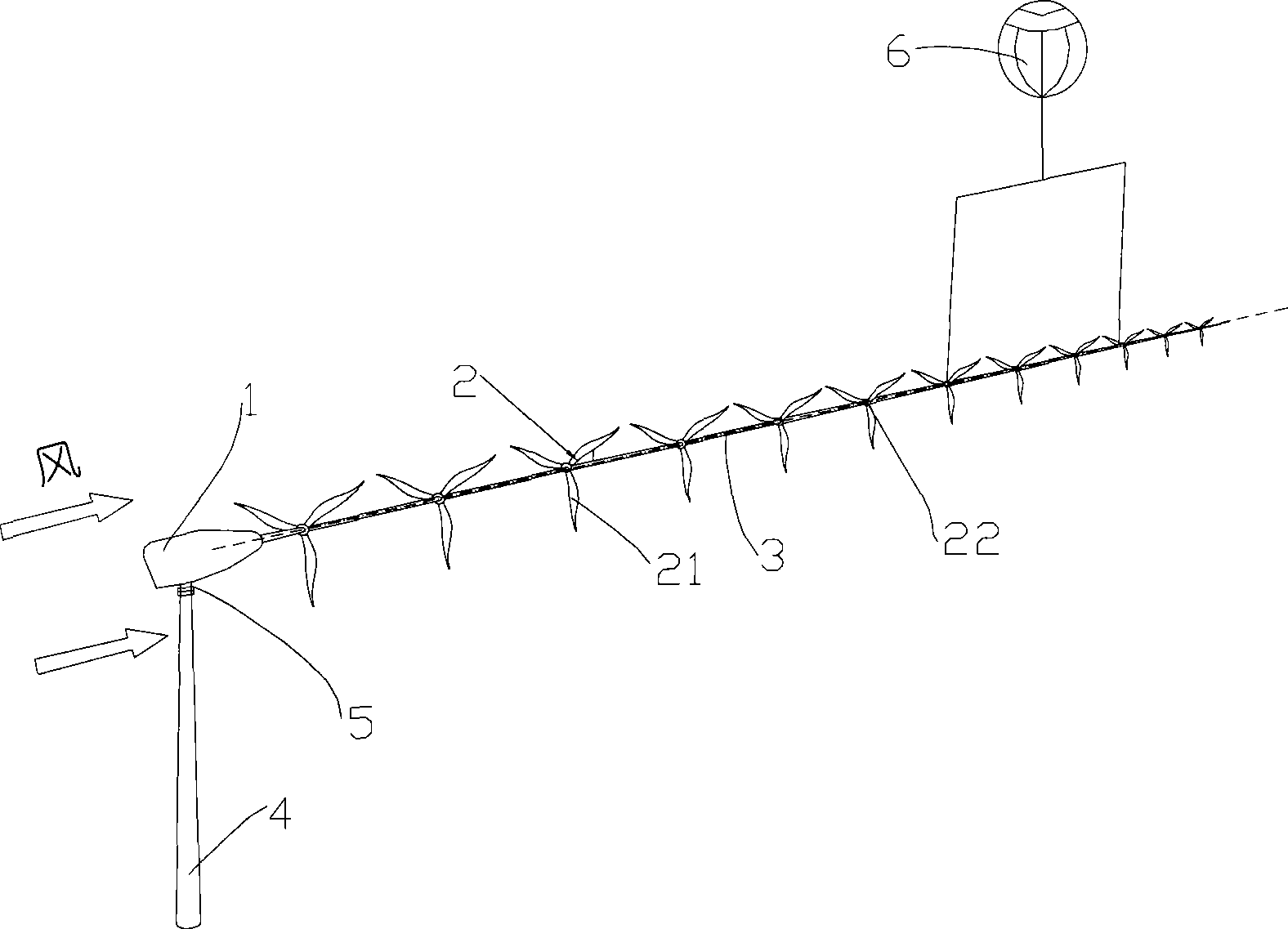

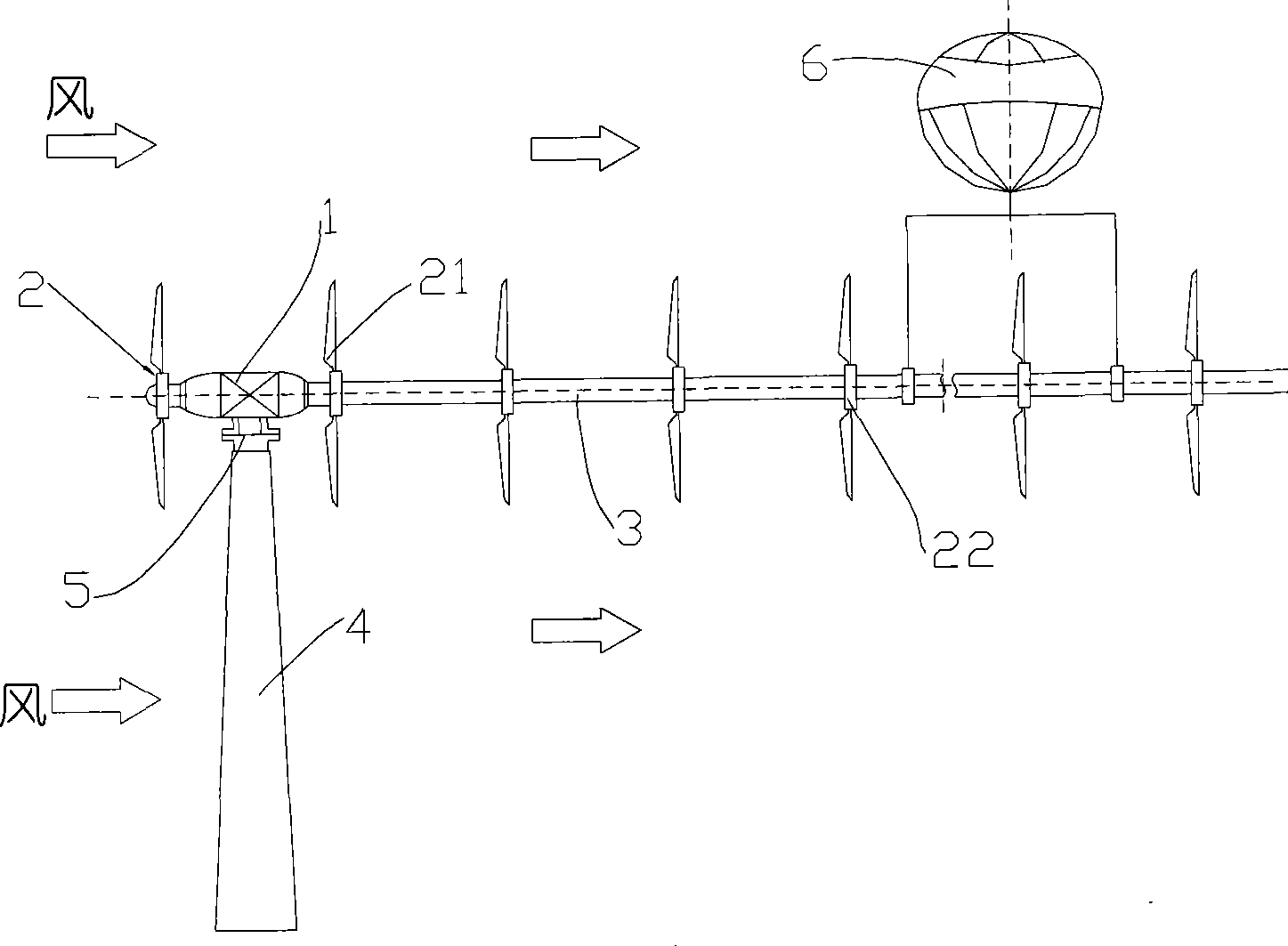

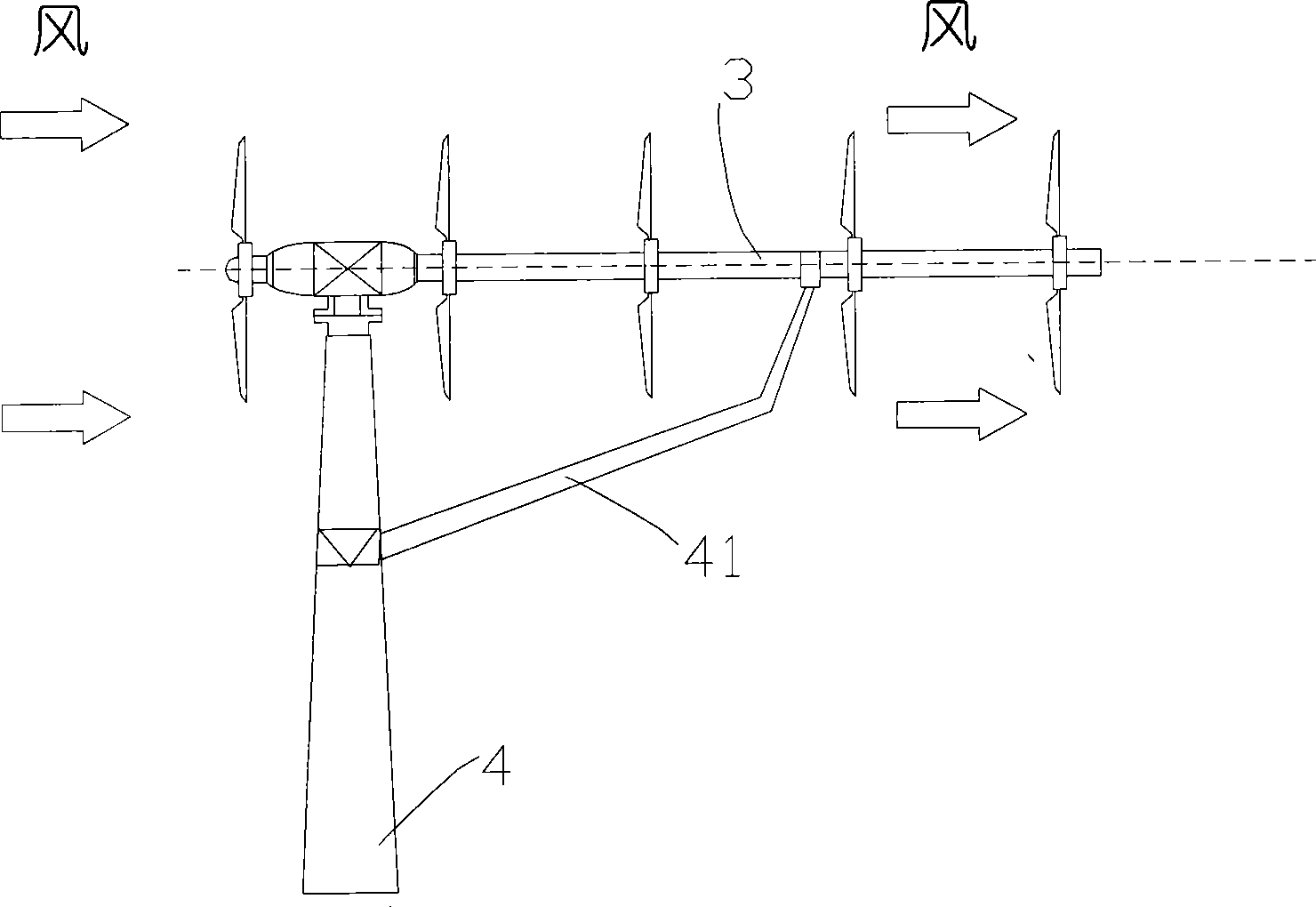

Wind generator system

InactiveCN101446270AImprove economyEase of mass productionFinal product manufactureWind motor supports/mountsDrive shaftTower

The invention discloses a wind generator system which comprises a tower, a generator assembly which is arranged on the tower, a transmission shaft which is connected with the generator assembly, and multi-stage wind wheels which are movably arranged and spaced along the axial direction of the transmission shaft. The multi-stage wind wheels with small blades are arranged on the same shaft to replace a single wind wheel with huge blades, thus overcoming various disadvantages which are caused by huge blades of the existing huge wind generator, enhancing wind energy utilization efficiency, and universality and economical efficiency of the application of the wind electric power generation. In addition, for the generators with the same power, decrease of diameter of the wind wheels causes corresponding increase of rotation speed of the wind wheels so that transmission ratio of a gear box is reduced, manufacturing and installation cost of the gear box is reduced, which can further enhance economical efficiency of the generator system. The system has the advantages of low cost, high wind energy utilization ratio, convenient and easy manufacture, installation and maintenance, wide application field range, and can greatly reduce the diameter and whole size of the wind wheels of the existing big and small wind generators to facilitate transportation.

Owner:刘运科

Process for preparing active carbon by co-decomposition of city sludge and agricultural wastes

A process for preparing activated carbon by co-pyrolysis of municipal sludge and agricultural waste comprises the steps of mixing the agricultural waste and the municipal sludge in a certain proportion to obtain a mixture; heating the mixture at a certain temperature under the condition of air isolation, keeping the temperature for a period of time, collecting a solid product, and cooling; and pulverizing the solid product to obtain the activated carbon product. In order to obtain an activated carbon with higher absorptive capacity, a certain amount of nitrate can be added into the mixture. Because the agricultural waste can make up the low heat value shortcoming of the sludge, while the municipal sludge can solve the problems with the agricultural waste that the pyrolysis solid product is easy to flow away and difficult to store, the inventive process can not only solve the high energy consumption and high cost problems of the prior sludge incineration, pyrolysis and other heat treatment methods, but also can be used for environmental treatment to save energy and reduce emission.

Owner:CHINA UNIV OF MINING & TECH

Rock asphalt composite modifier as well as preparation method and application thereof

InactiveCN102690522AImprove high temperature stabilityHigh softening pointBuilding insulationsNeedle penetrationRoad surface

The invention discloses a rock asphalt composite modifier as well as a preparation method and an application thereof. The rock asphalt composite modifier is prepared through the following steps: grinding 10-90% of rock asphalt and 10-90% of diatomite to be powder and then mixing the powder. The rock asphalt composite modifier can be used for mixing modified asphalt mixture and paved on the roads with the climatic features of high temperature, raininess and intense cold and / or the traffic conditions of heavy load, slow speed and canalization. After the rock asphalt composite modifier is added, the softening point of the composite modified asphalt is improved, the needle penetration is reduced and the high-temperature property of the mixed material is remarkably improved so as to obviously reduce the problems of tracking, pushing, upheaval and pit slots as a result of heavy-load traffic, high-temperature climate and canalization. The rock asphalt composite modifier can be used for remarkably enhancing the adhesive capacity between the asphalt and aggregate and improving the water damage resistance of the asphalt roads.

Owner:GUANGZHOU ZHONGGU BUILDING MATERIALS

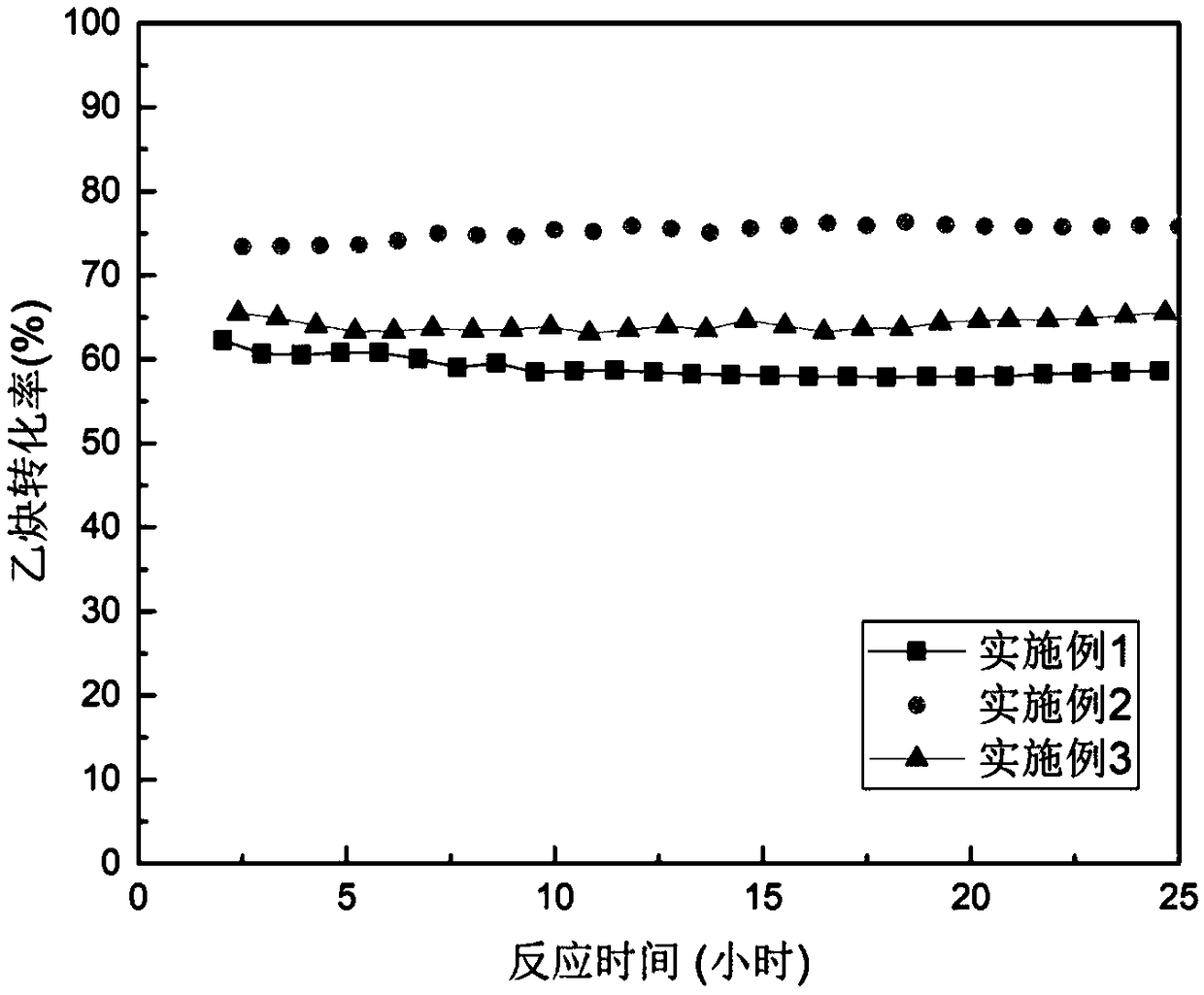

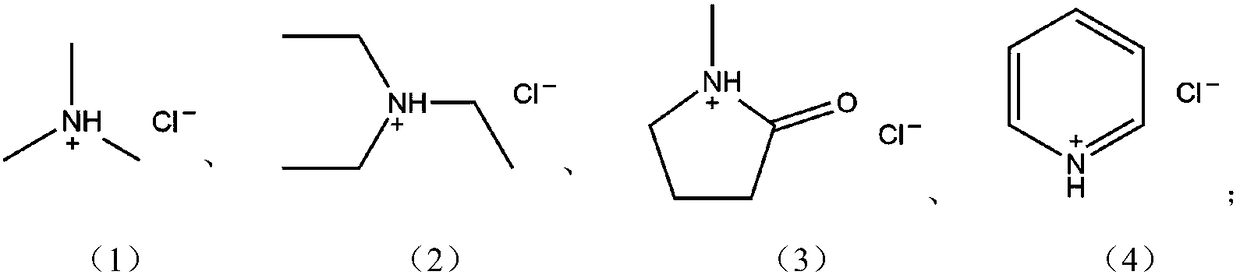

Metal halide acid radical ion liquid for catalyzing acetylene hydrochlorination as well as application method thereof

ActiveCN109158126AAvoid pollutionImprove thermal stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen halideSource material

The invention relates to metal halide acid radical ion liquid for catalyzing acetylene hydrochlorination as well as an application method thereof. The metal halide acid radical ion liquid takes one ofalkyl-containing amine hydrogen halide, alkyl monosubstituted pyrrolidone hydrogen halide and pyridine hydrogen halide as a cationic source material and takes one of halide of zinc, copper, iron andtin as an anionic source material, wherein the molar ratio of the cationic source material to the anionic source material is 1:(0.3-3.0). In a bubbling reactor, the metal halide acid radical ion liquid serves as a catalyst, the reaction raw material gas acetylene and hydrogen chloride are mixed, the mixture is introduced into the metal halide acid radical ion liquid to perform reaction, the reaction temperature is 120 to 200 DEG C, the volume velocity ratio of the acetylene to the hydrogen chloride is 1:(1.0-1.6), the volumetric space velocity of the acetylene is 10 to 100 h<-1>, and under thecondition of not using noble metal, the highest conversion rate of the acetylene can reach to above 90 percent and the selectivity of chloroethylene is still more than 99 percent.

Owner:TIANJIN UNIV +1

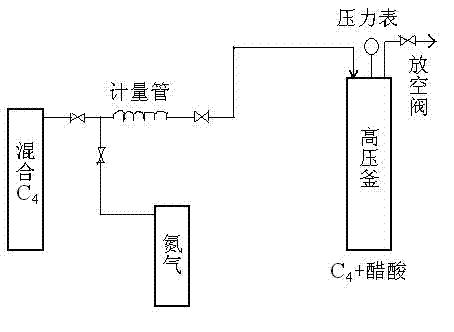

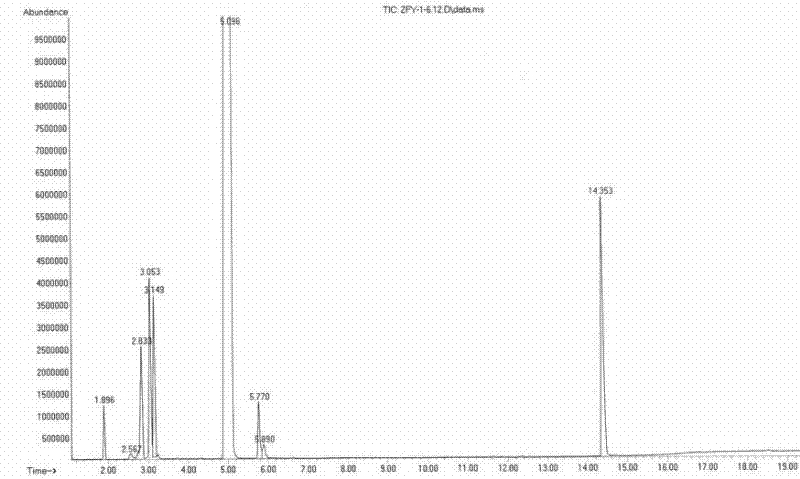

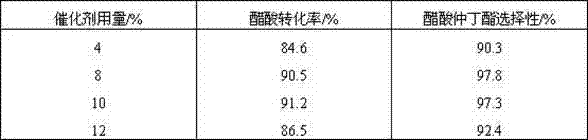

Method for producing sec-butyl acetate by synthesizing acetic acid and mixed C4

InactiveCN102344364AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationPtru catalystReaction temperature

The invention relates to a method for producing sec-butyl acetate by synthesizing acetic acid and mixed C4, which belongs to the chemical field. The invention aims to provide the method for producing the sec-butyl acetate by synthesizing the acetic acid and the mixed C4, which is used for fully and reasonably utilizing byproduct mixed C4 resources of petrochemical enterprises, broadening the way to comprehensively utilize C4 hydrocarbon, and producing fine chemical products with high added value. According to the invention, a kettle type batch reactor is adopted, strong-acid cation exchange resin is adopted as solid catalyst, the acetic acid and the mixed C4 are used as the raw materials to synthesize the sec-butyl acetate, the reaction pressure is 2.0-6.0MPa, the reaction temperature is 80-160 DEG C, the reaction time is 5-15h, the molar ratio of olefine acid is 0.2-1.5, and the catalyst amount is 4-12 percent of the acetic acid. According to the synthetic process of the sec-butyl acetate, the acetic acid and butane (refinery byproduct mixed C4 contains 1-butane and 2-butane) are adopted as the raw materials to be directly synthesized through addition reaction under the action of acid catalysts, an olefin resource is directly utilized, and ethanol is unnecessary to be an intermediate, so that the production cost of the sec-butyl acetate is reduced, the obvious economic advantage is achieved, the refinery mixed C4 resource is effectively utilized, and the method is an effective way to improve chemical utilization of C4 hydrocarbon.

Owner:CHANGCHUN UNIV OF TECH

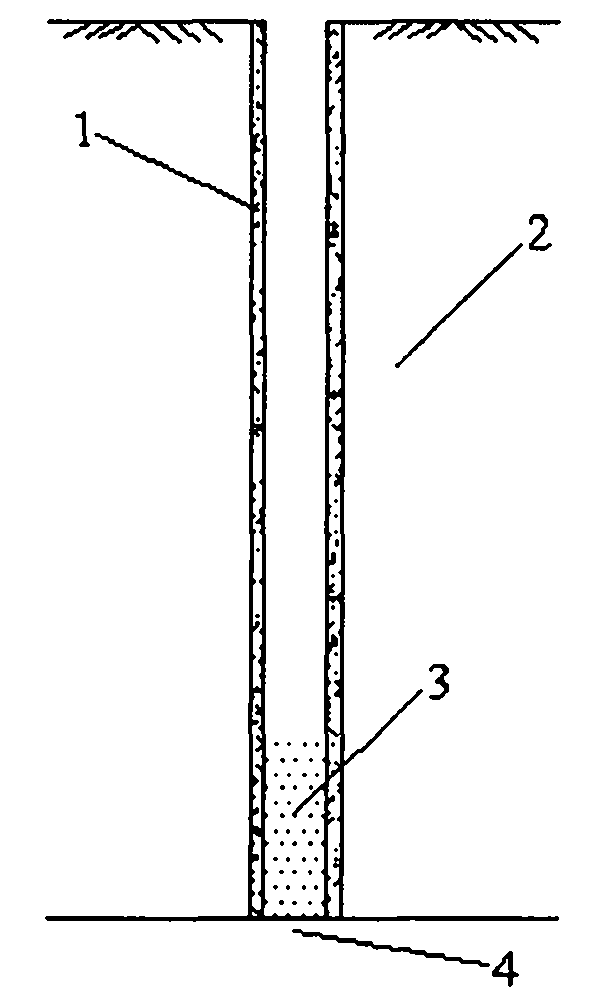

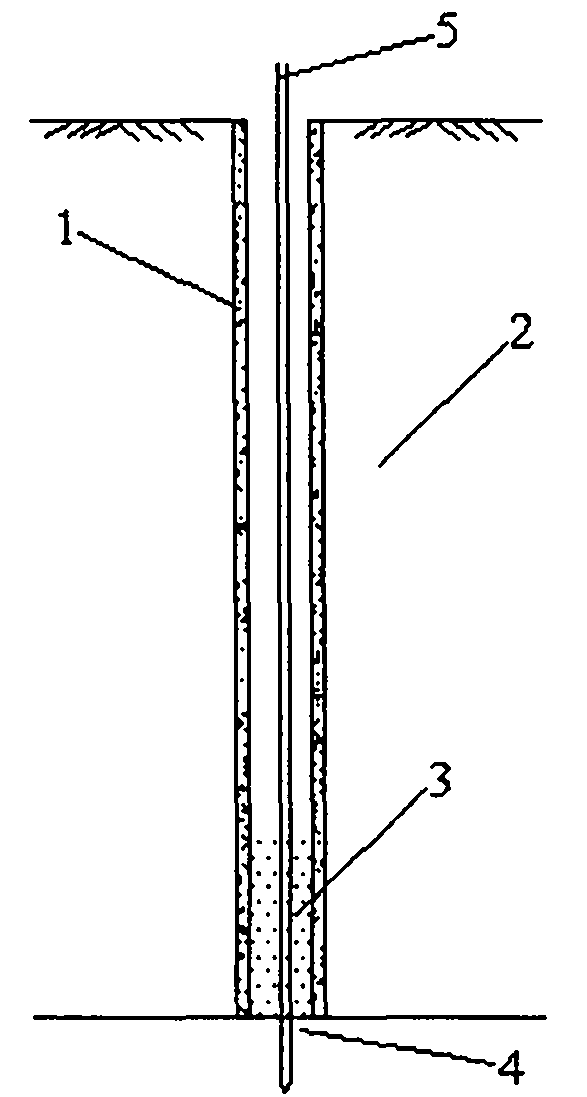

PHC pile-based multiple high jet pedestal pile construction method

The invention discloses a prestressed high-strength concrete (PHC) pile-based multiple high jet pedestal pile construction method, which comprises the following steps of: statically pressing a PHC pile to the designed depth of a soil layer, drilling to the depth below the bottom of the PHC pile through the hollow part of the PHC pile by a multiple high-pressure spiral jet drill rod, performing multiple tube construction at the bottom of the PHC pile to form an enlarged head cavity greater than the diameter of the PHC pile and in accordance with the design requirement, and then filling the enlarged head cavity to form an enlarged head. The method has obvious economic benefit; and compared with other pile types acquiring the same bearing capacity, the PHC pile-based multiple high jet pedestal pile has obvious economic advantage.

Owner:HENAN POLYTECHNIC UNIV

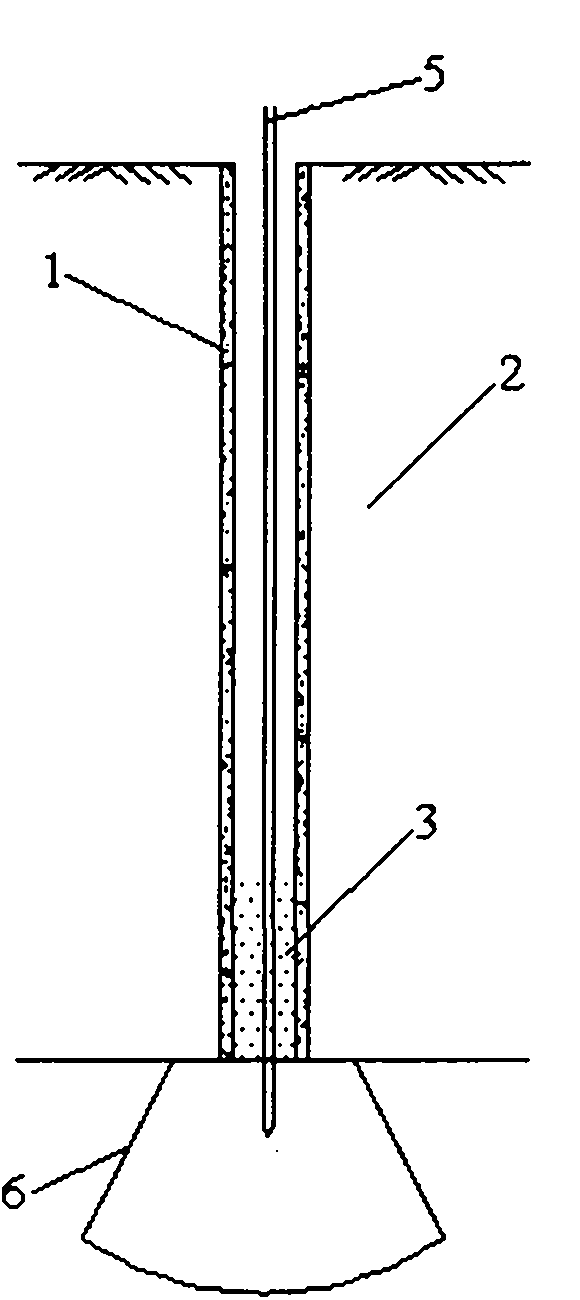

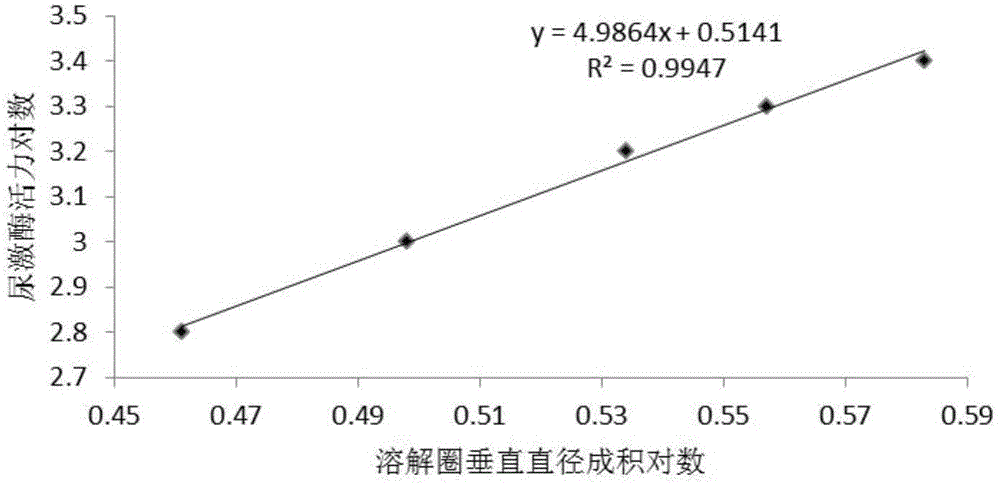

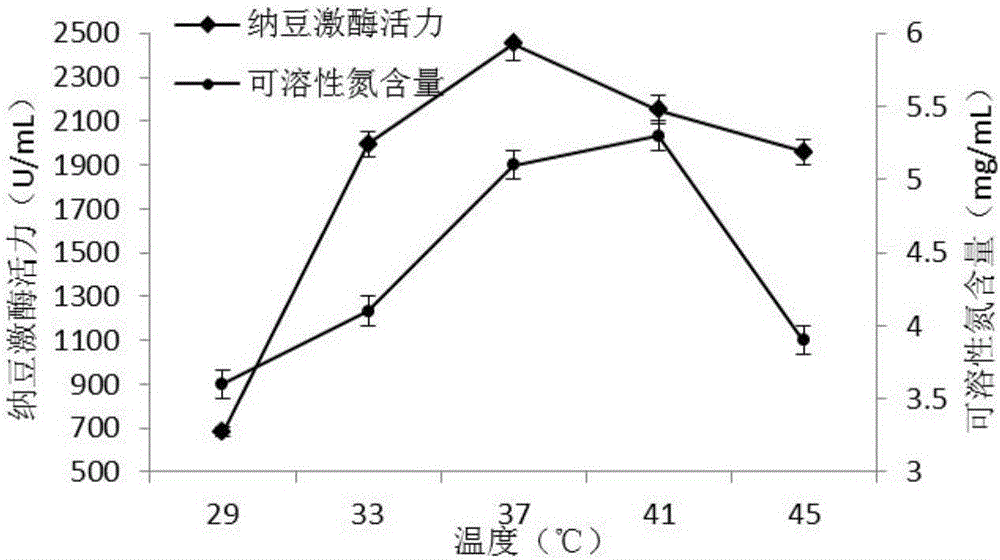

Method for preparing nattokinase through solid-state fermentation

ActiveCN106085991AIncrease added valueReduce manufacturing costHydrolasesMicroorganism based processesSaline waterBiotechnology

The invention belongs to the technical field of microorganism fermentation engineering and relates to a method for preparing nattokinase through solid-state fermentation. The method includes: respectively preparing a bevel culture medium, a seed solution culture medium and a fermentation culture medium; inoculating bacillus natto onto the bevel culture medium for culture to obtain activated bacillus natto, picking and placing 1-2 rings into the seed solution culture medium for oscillation culture to serve as a fermentation seed solution; sterilizing and then naturally cooling the fermentation culture medium, spraying the fermentation seed solution into the fermentation culture medium, adding water, and stirring well; paving a thin layer in a beaker, using gauze to seal, sequentially performing fermentation and after-ripening for 24 h, and adding normal saline; performing extraction and centrifuging to obtain supernate rich in nattokinase. The method is simple in process and convenient to operate, raw materials are easy to get and low in cost, and nattokinase prepared by the method is high in activity and has obvious economic benefit.

Owner:烟台泰禾电子科技有限公司

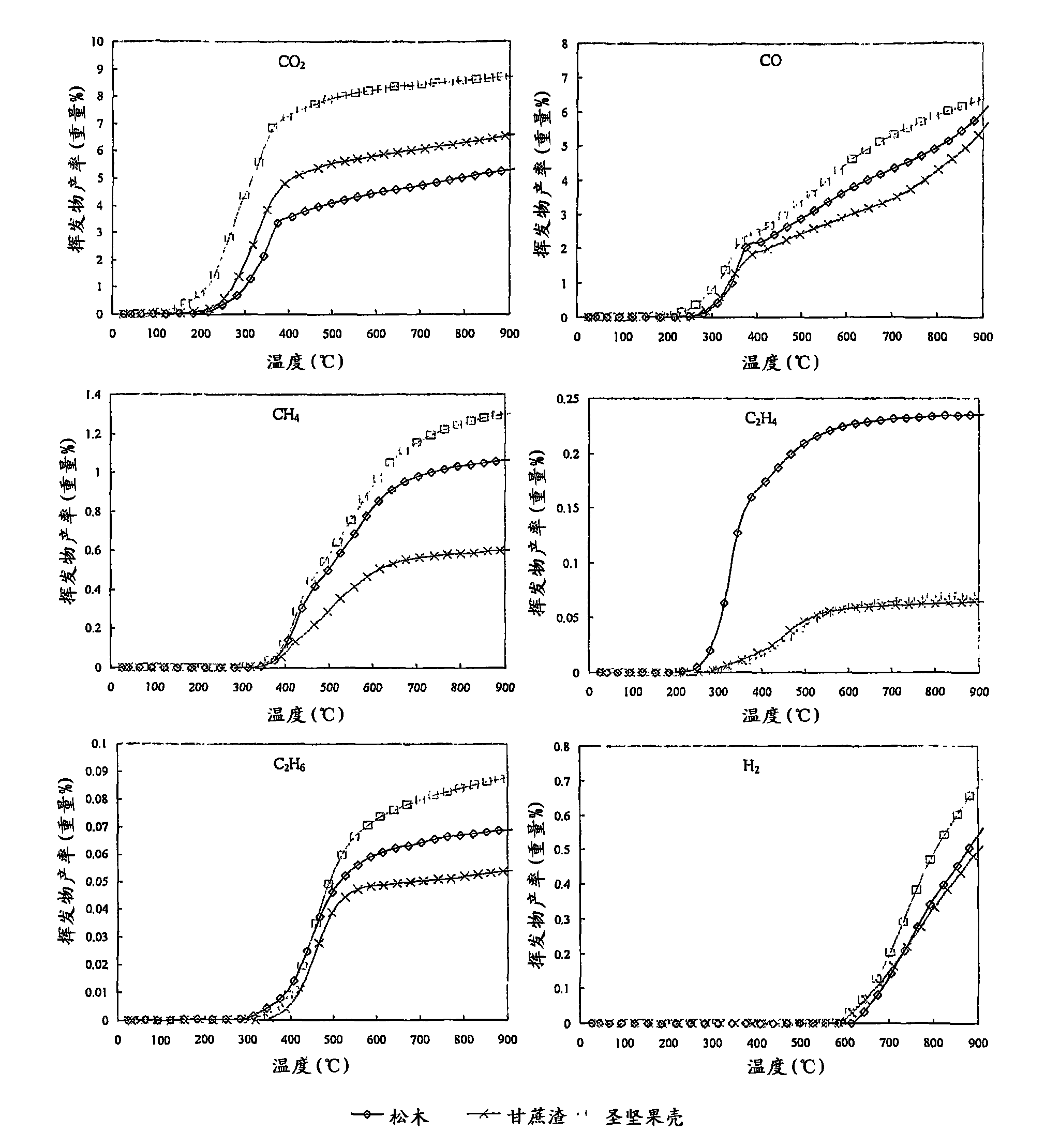

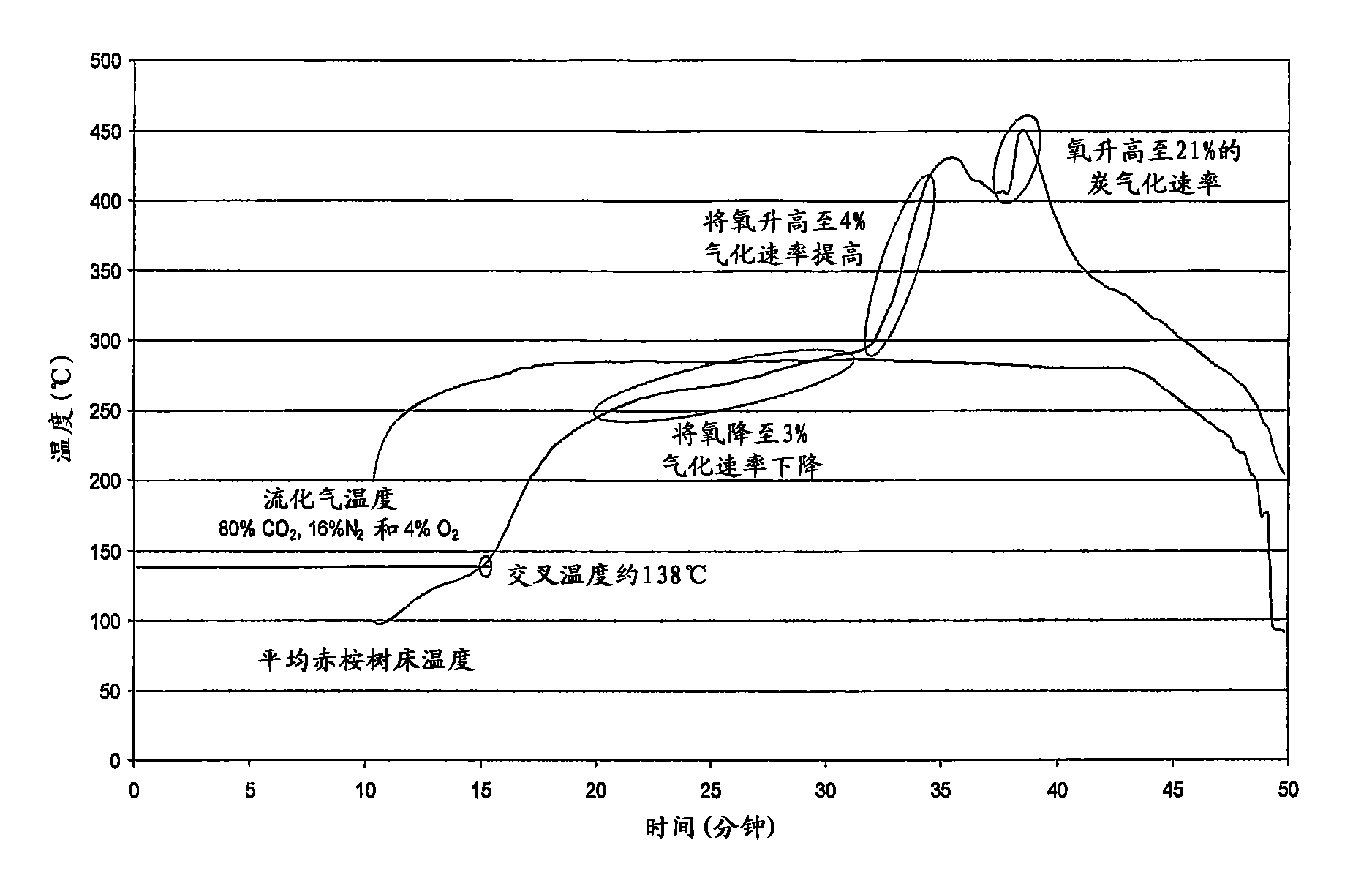

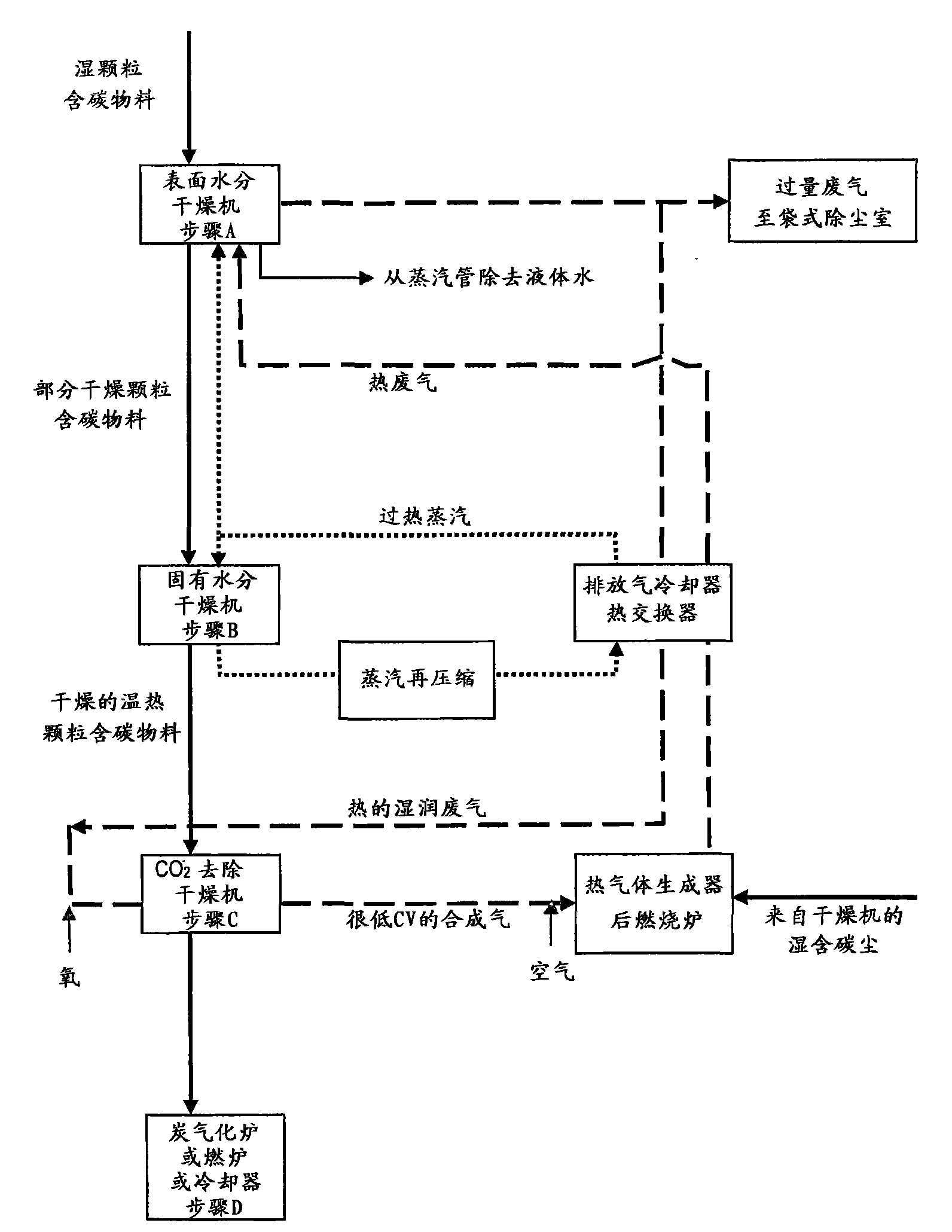

Drying and gasification process

InactiveCN101636473AModular scalabilityObvious economic advantagesCombined combustion mitigationCombustible gas productionSurface moistureSyngas

A process for producing syngas from a carbonaceous substance and / or treating a carbonaceous substance, the process including the following steps: a) reducing the surface moisture of the carbonaceous substance; b) reducing the inherent moisture of the carbonaceous substance; and, c) gasifying the carbonaceous substance to produce syngas, wherein at step a) the carbonaceous substance is directly contacted with a hot gas at a temperature of between 50 DEG C to 250 DEG C, and / or the carbonaceous substance is indirectly contacted with saturated steam at a temperature of between 105 DEG C and 250 DEG C.

Owner:CORKYS CARBON & COMBUSTION

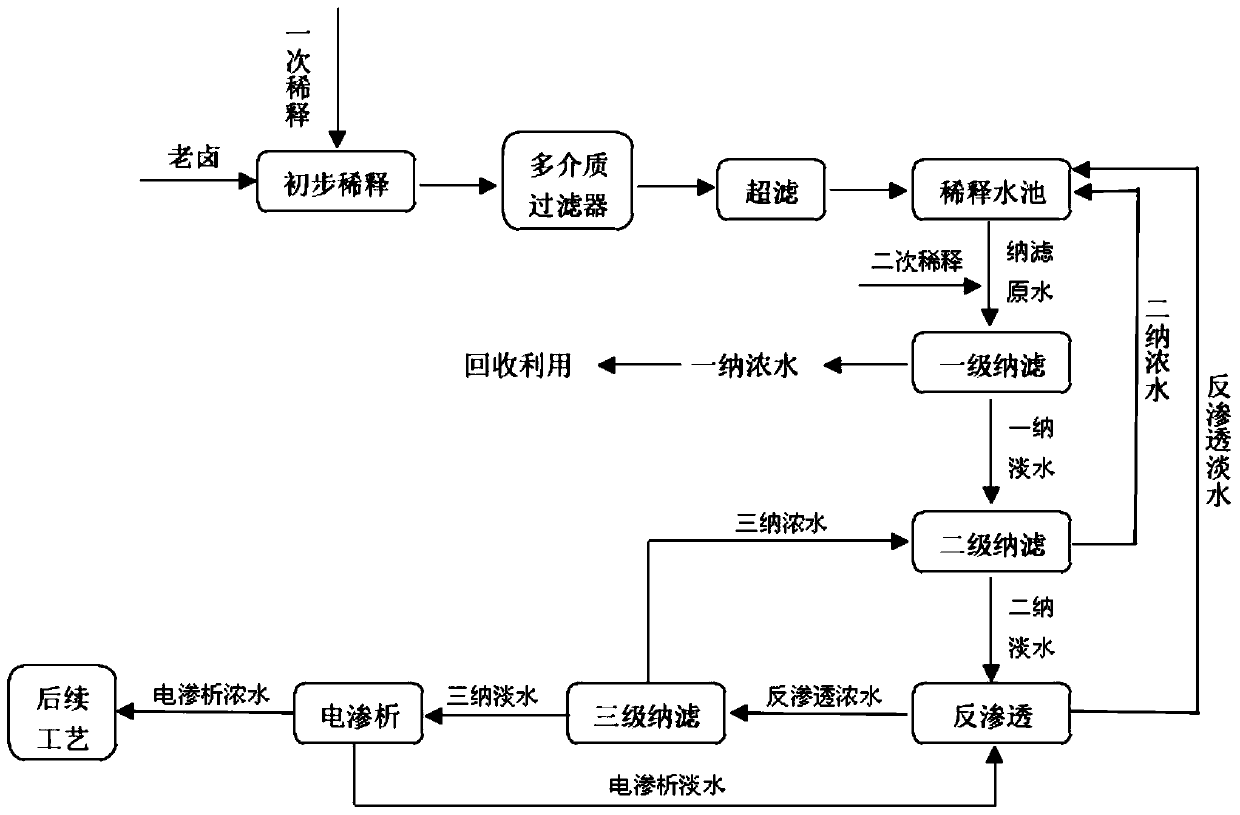

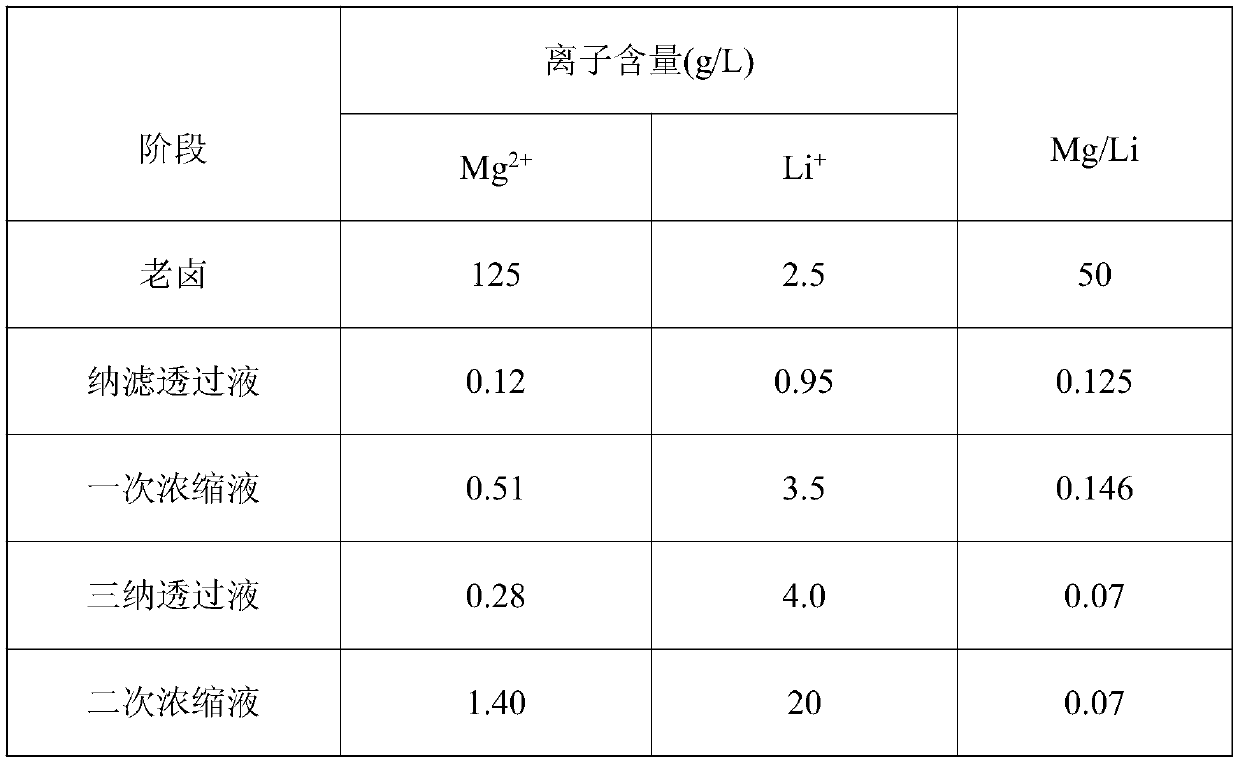

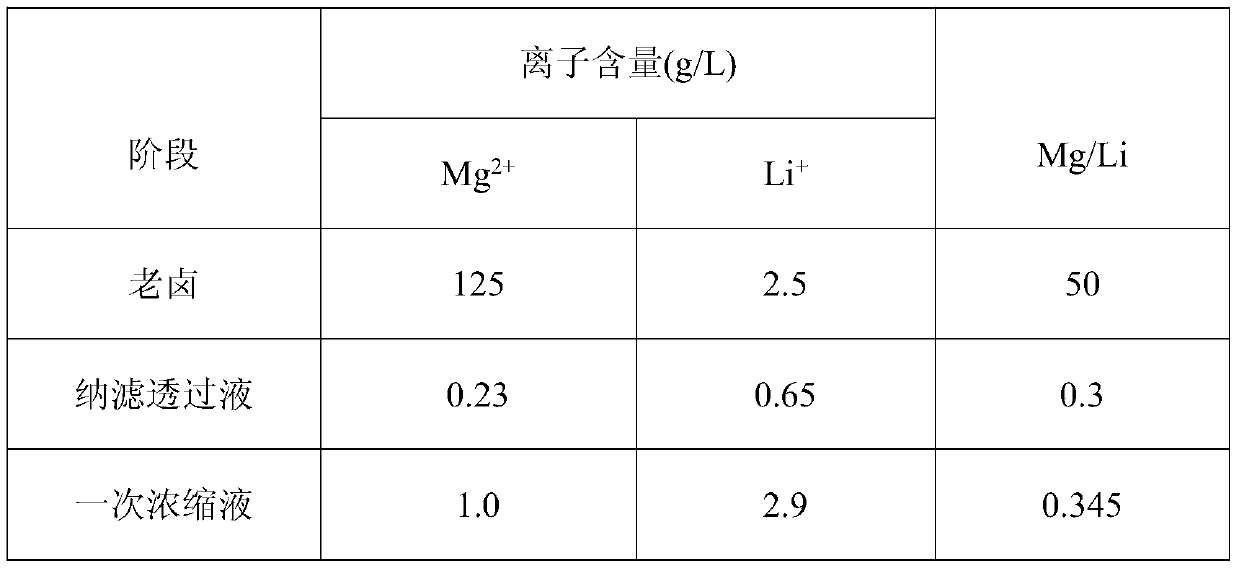

Method for separating and enriching lithium from magnesium lithium

The invention discloses a method for separating and enriching lithium from magnesium lithium. The method includes: diluting and filtering salt brine to obtain nanofiltration raw water; putting the nanofiltration raw water into a first nanofiltration separation device for magnesium and lithium separation to obtain first nanofiltration concentrated water and first nanofiltration fresh water; puttingthe first nanofiltration fresh water into a reverse osmosis device for first concentration to obtain reverse osmosis concentrated water and second nanofiltration fresh water; putting the second nanofiltration fresh water into an electrodialysis device for secondary concentration to obtain electrodialysis concentrated water and electrodialysis fresh water, wherein the electrodialysis concentratedwater is a solution enriched with lithium ions. In the method, four membrane separation technologies of ultrafiltration, nanofiltration, reverse osmosis and electrodialysis are coupled in a certain order, and high efficiency separation and enrichment of lithium in the salt brine can be achieved by making full use of the advantages of the various membrane separation technologies.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

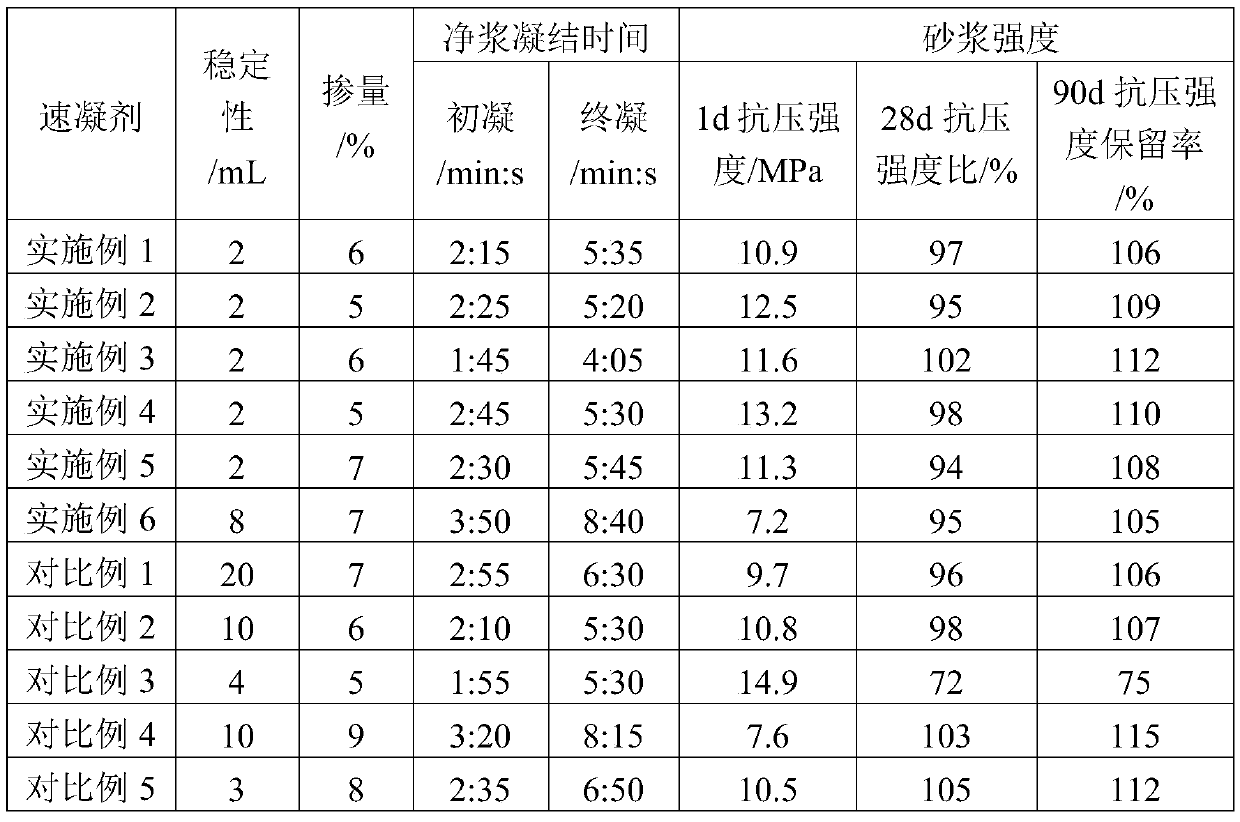

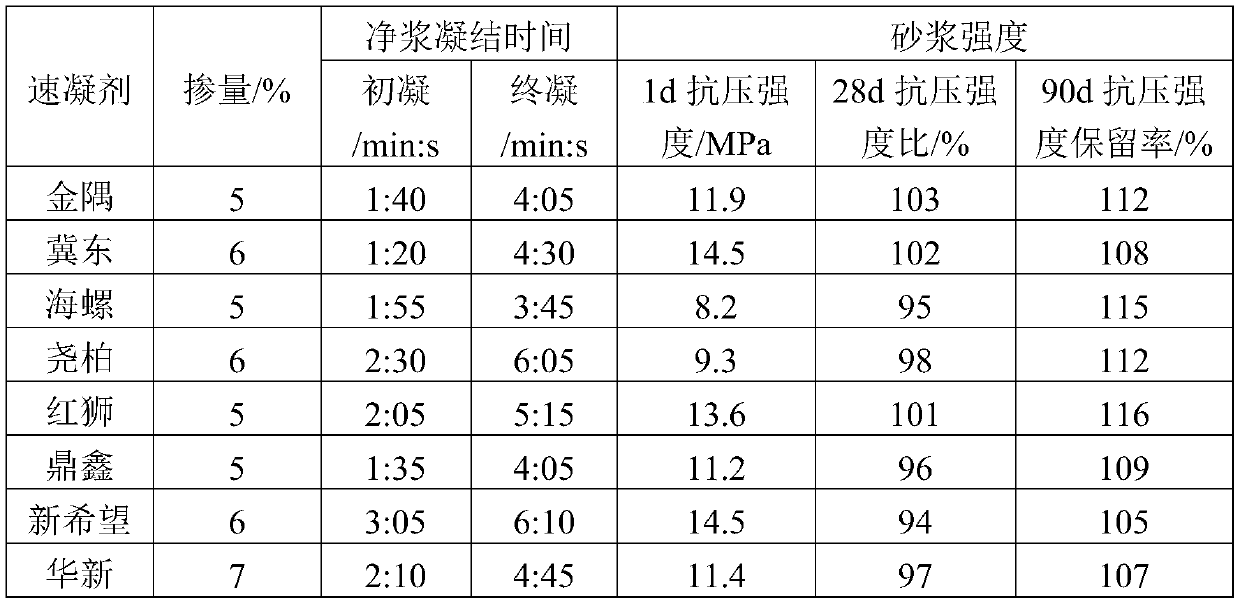

Liquid accelerator as well as preparation method and application thereof

The invention discloses a liquid accelerator and a preparation method thereof. The liquid accelerator is prepared from the following raw materials: a solution containing metaaluminate, aluminum sulfate, an inorganic acid solution, a complexing stabilizer, water, an optional anti-settling agent and an optional acidity neutralizer. The liquid low-alkali accelerator provided by the invention has theadvantages of rapid cement setting and hardening, rapid development of early strength of sprayed concrete, basically no loss of later strength and the like at a relatively low mixing amount, has widecement adaptability, and can still provide excellent rapid hardening and early strength properties for cement with low C3A content; the liquid accelerator has the advantages of no (low) corrosion, stable long-term storage performance, simple production process, easily controlled conditions, good economic benefit and wide application prospect.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

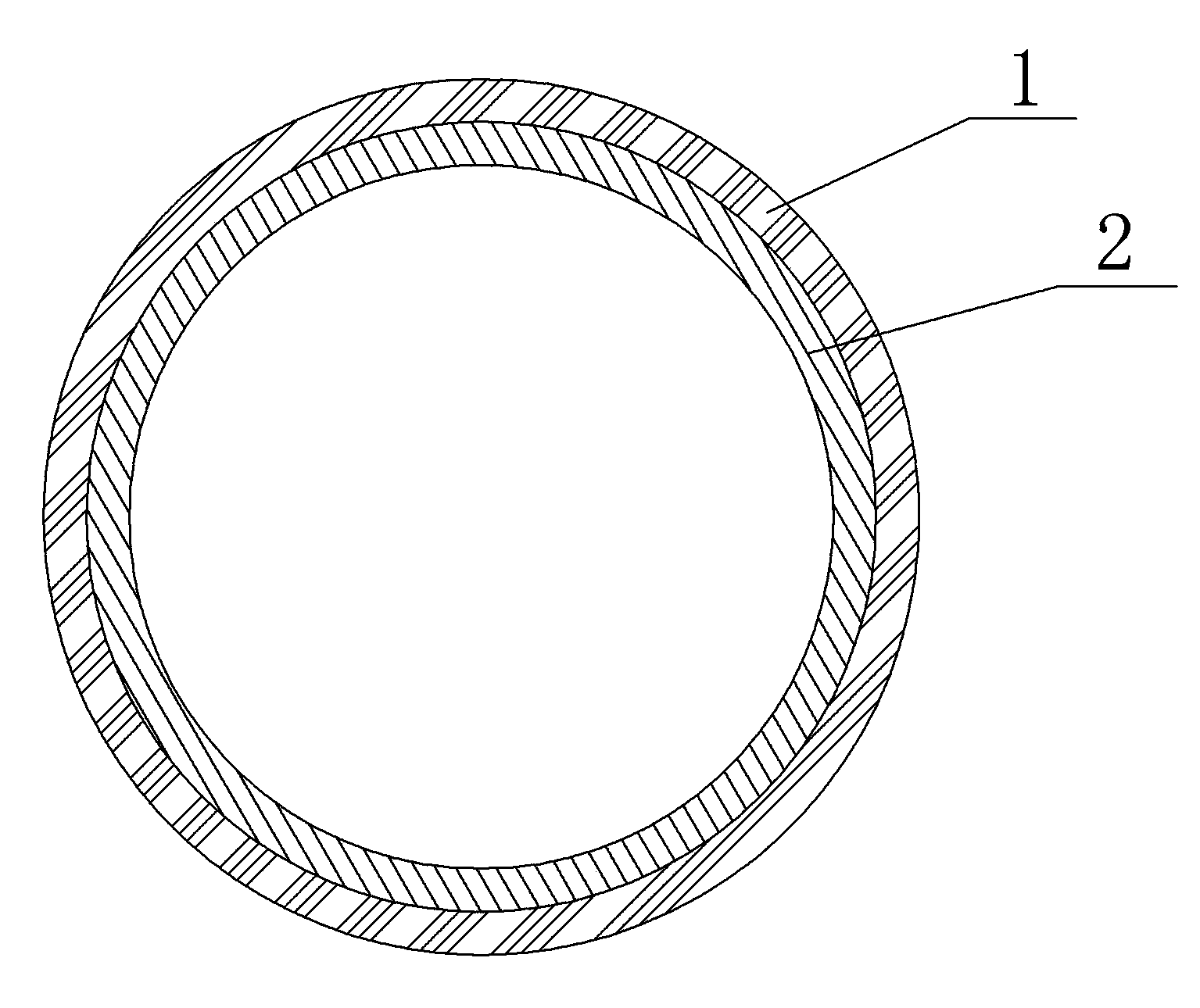

Double-layer composite tube and manufacturing method thereof

ActiveCN104019298AImprove stress resistanceFlow fastFlexible pipesLow-density polyethyleneWater quality

The invention discloses a double-layer composite tube and a manufacturing method thereof. The double-layer composite tube and the manufacturing method aim to solve the technical problems that black pigment is added into traditional HDPE tubes, accordingly inner walls are not smooth, water scale is prone to being generated, bacteria grow, and secondary pollution of water is caused. The double-layer composite tube comprises an inner layer and an outer layer, the inner layer is made of ultrahigh molecular weight polyethylene and ethylene-vinyl alcohol copolymers or low-density polyethylene, and the outer layer is made of high-density polyethylene, ethylene-vinyl alcohol copolymers and special melanin particles C of PE. The method includes the following steps of material proportioning and dehumidifying, material plastifying, material forming, vacuum sizing and spraying and cooling. The double-layer composite tube has the advantages of being good in toughness and flexibility, high in chemical stability, good in corrosion resistance, good in sealing performance, large in distribution power, long in service life, high in low temperature resistance, hygienic, free of toxin and the like. The manufacturing method is simple, easy to operate and capable of achieving integral production of the double-layer composite tube.

Owner:菏泽三垒塑业股份有限公司

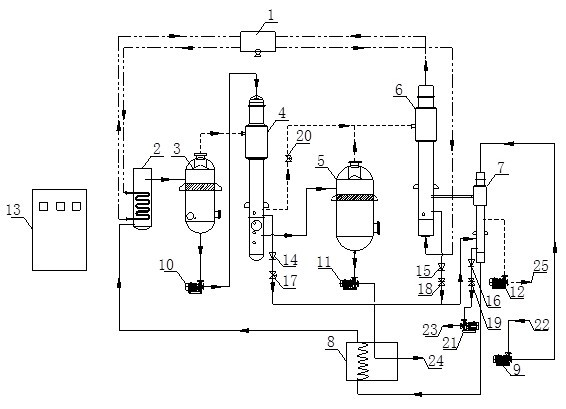

Free energy heat pump multiple-effect evaporation device and process

InactiveCN102527070AReduce work efficiencySimple equipment installationHeat pumpsMultiple-effect evaporationEngineeringOperating energy

The invention belongs to the technical field of energy conservation and environment friendliness, and relates to a free energy heat pump multiple-effect evaporation device which integrates a heat pump and a multiple-effect evaporation system, and a free energy heat pump multiple-effect evaporation process. The free energy heat pump multiple-effect evaporation device comprises the heat pump and the multiple-effect evaporation system which is integrated with the heat pump, wherein the heat pump is a medium- and high- temperature heat pump and is driven by a power supply system; the multiple-effect evaporation system comprises a vertical heat exchanger, a multiple-effect separator, a multiple-effect evaporator, a condenser, a heat exchanger, a delivery pump and a vacuum pump; and the medium-and high- temperature heat pump is communicated with the vertical heat exchanger and the condenser by a process pipeline. According to the free energy heat pump multiple-effect evaporation device and the free energy heat pump multiple-effect evaporation process, the running of the heat pump is adopted, and a cold source and a heat source are utilized organically, so that the aim of energy conservation can be fulfilled in the first-effect or second-effect operating state, operating energy consumption is reduced, and the simplification of equipment and the reduction of fixed investments are facilitated; and the free energy heat pump multiple-effect evaporation device can operate under the condition of lack of steam, the number of laying of steam pipelines can be reduced, a circulating cooling water system can be eliminated, and the waste heat discharge is reduced.

Owner:KESHENG ENVIRONMENTAL PROTECTION TECH CO LTD

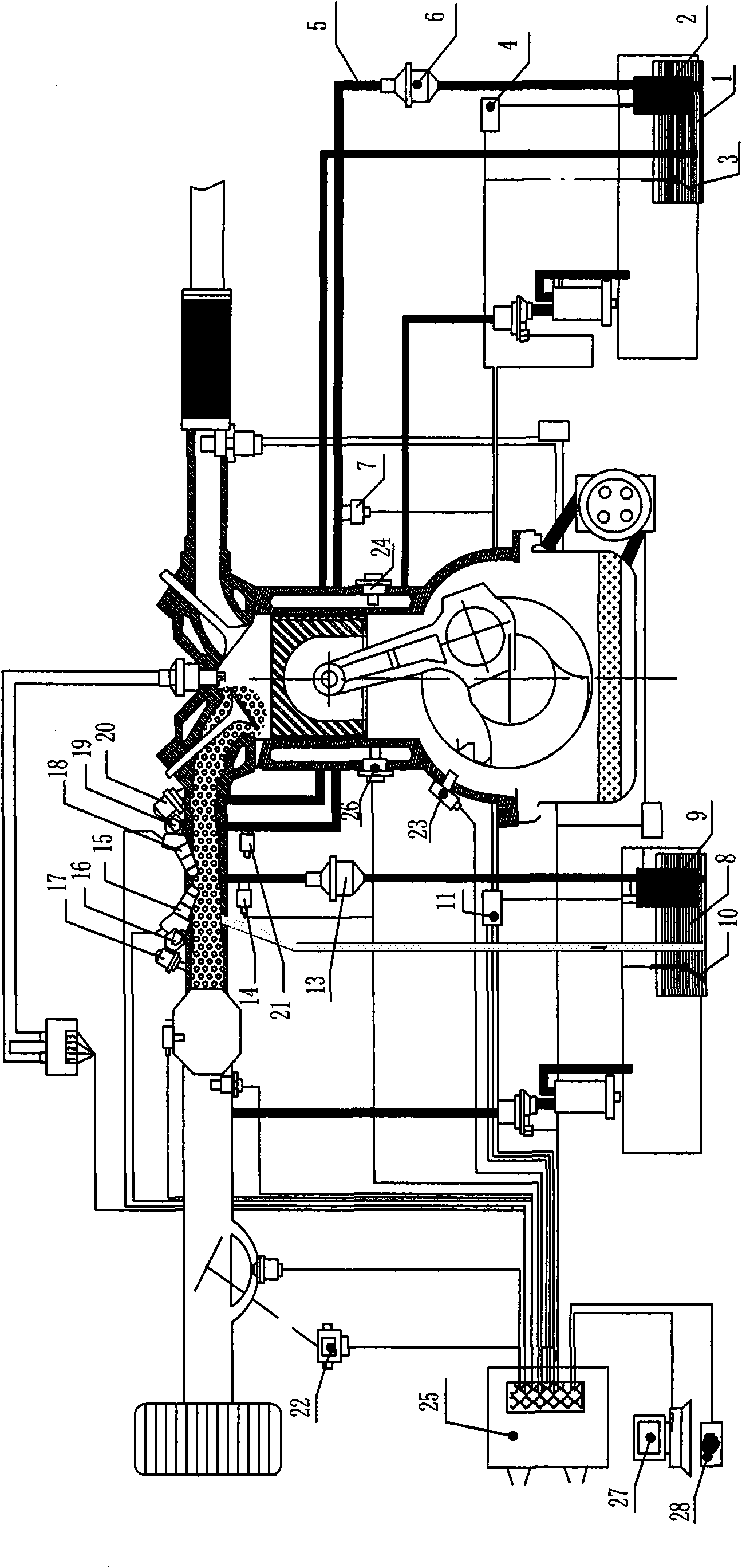

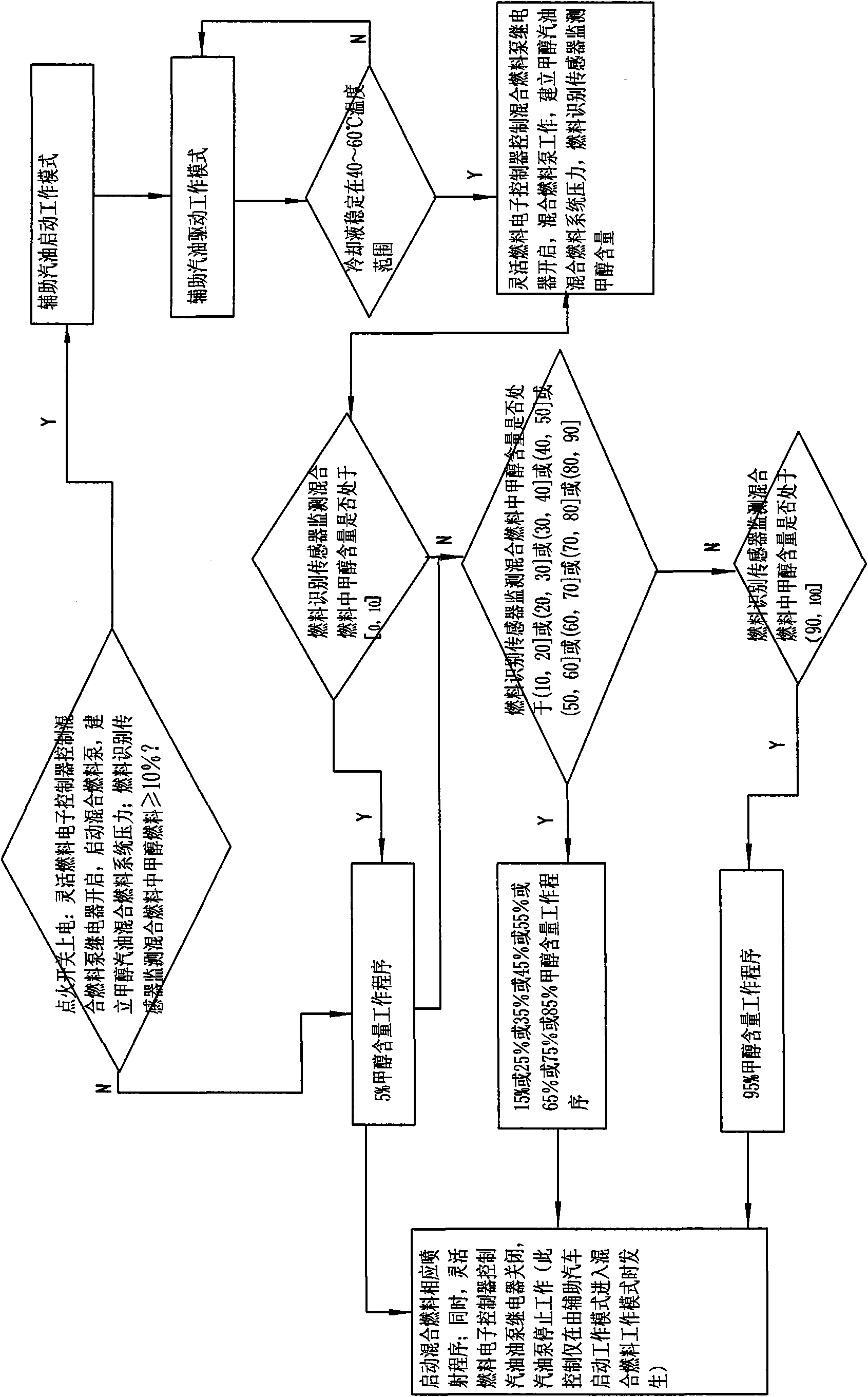

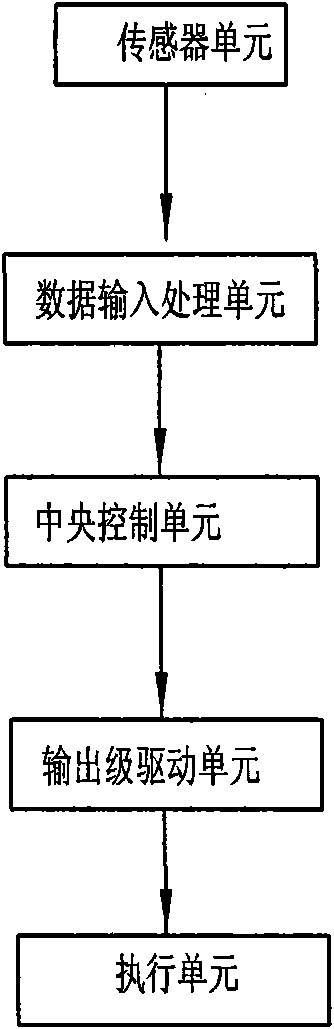

Control method of methyl alcohol flexible fuel vehicle and system thereof

ActiveCN101655037AGive full play to the high-efficiency combustion characteristicsBurn fullyElectrical controlMachines/enginesAlcohol contentElectronic control system

The invention relates to a control method of methyl alcohol flexible fuel vehicle and a system thereof. The system comprises a mixed fuel feeding system, an electronic control system and an engine, wherein, mixed fuel in a mixed fuel box comprises methyl alcohol and auxiliary fuel as the balance. A fuel recognition sensor is used for recognizing methyl alcohol content in fuel, corresponding data is transmitted to a data processing unit, the data processing unit analyzes the data and transmits a result to a central control unit, and the central control unit chooses a corresponding working module to adjust the corresponding control parameter, which ensures that the engine works at the optimum state. The invention mainly provides a control system of a methyl alcohol flexible fuel vehicle, which can add mixed fuel at any ratio to the mixed fuel box, needs no additives, has favorable starting performance and high dynamic property and discharges cleanly. The invention solves the technical problems that the fuel supply is out of control because of methyl alcohol-petrol mixed fuel delamination and vehicle starting performance is lowered in the prior art.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

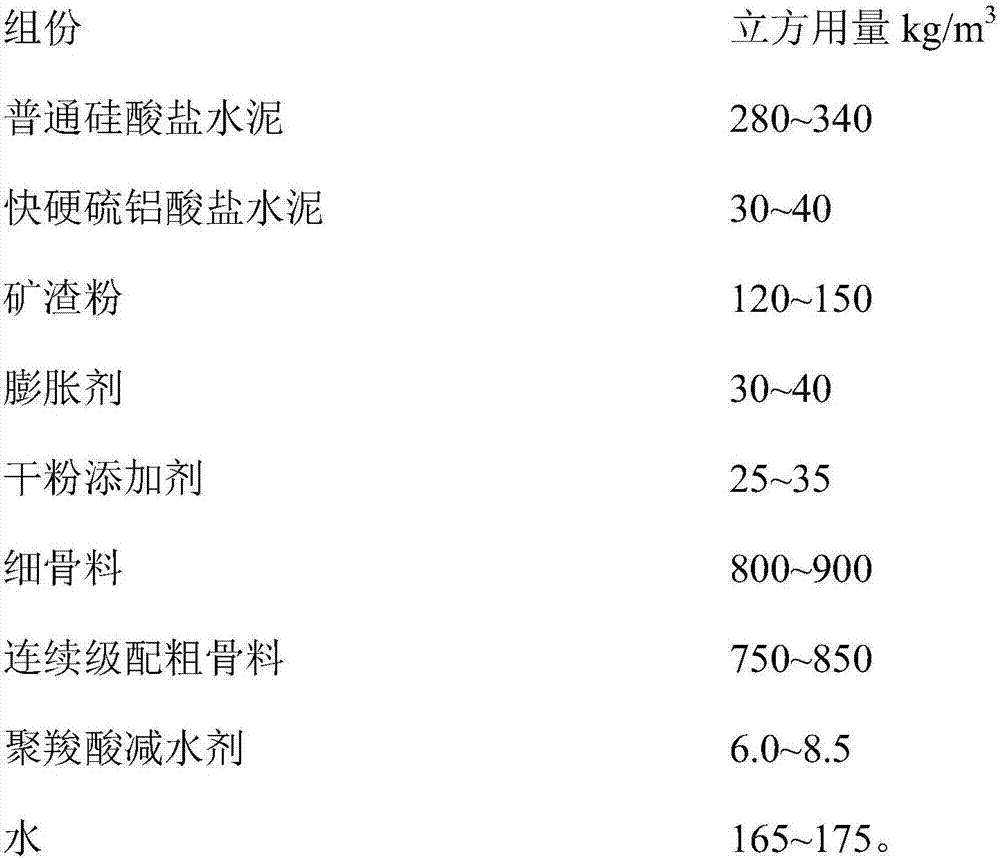

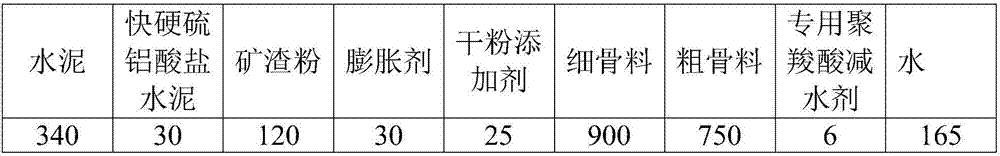

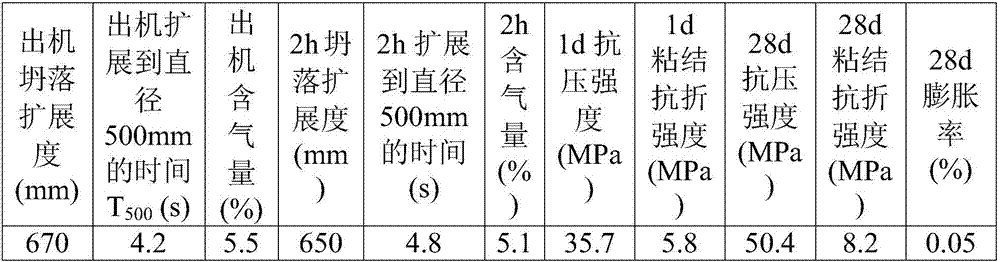

Self-compacting concrete for concrete repairing and preparation method of self-compacting concrete for concrete repairing

The invention discloses self-compacting concrete for concrete repairing and a preparation method of the self-compacting concrete for concrete repairing. Per cubic meter of the concrete is prepared from 280-340kg of ordinary Portland cement, 30-40kg of quick-hardening sulfate aluminum cement, 120-150kg of slag powder, 30-40kg of an expanding agent, 25-35kg of a dry powder additive, 800-900kg of fine aggregate, 750-850kg of continuously graded aggregate, 6.0-8.5kg of a special polycarboxylate superplasticizer and 165-175kg of water. The self-compacting concrete for concrete repairing is preparedby well mixing of ordinary Portland cement, quick-hardening sulfate aluminum cement, slag powder, the expanding agent, the dry powder additive, fine aggregate and coarse aggregate according to a certain stirring process. The self-compacting concrete for concrete repairing is high in strength of bonding to old concrete, high in early strength, capable of slightly expanding and especially applicable to repairing of dense reinforcement cement concrete structures and CRTS III type slab ballastless track filling layers by self-compacting concrete filling layers.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

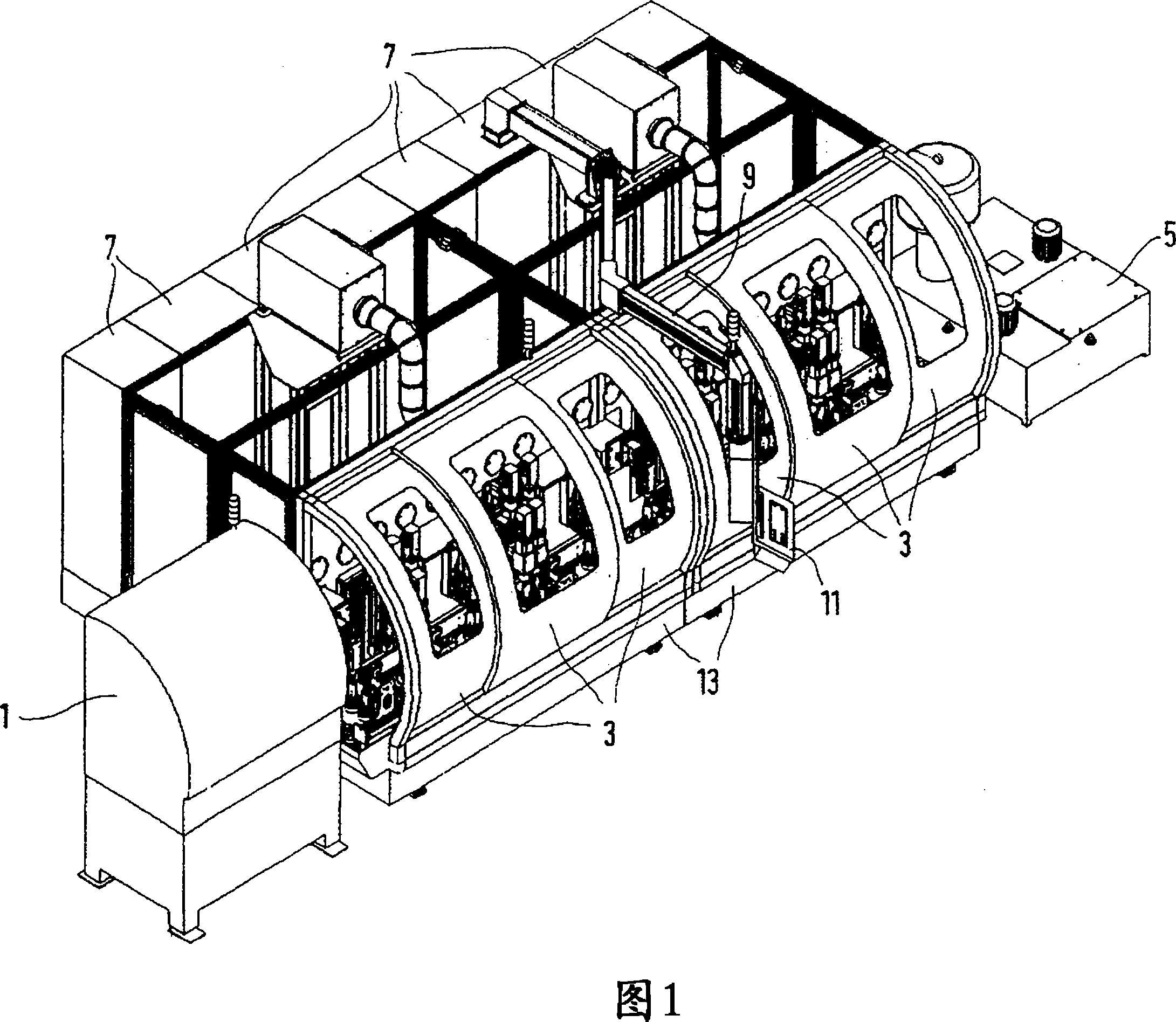

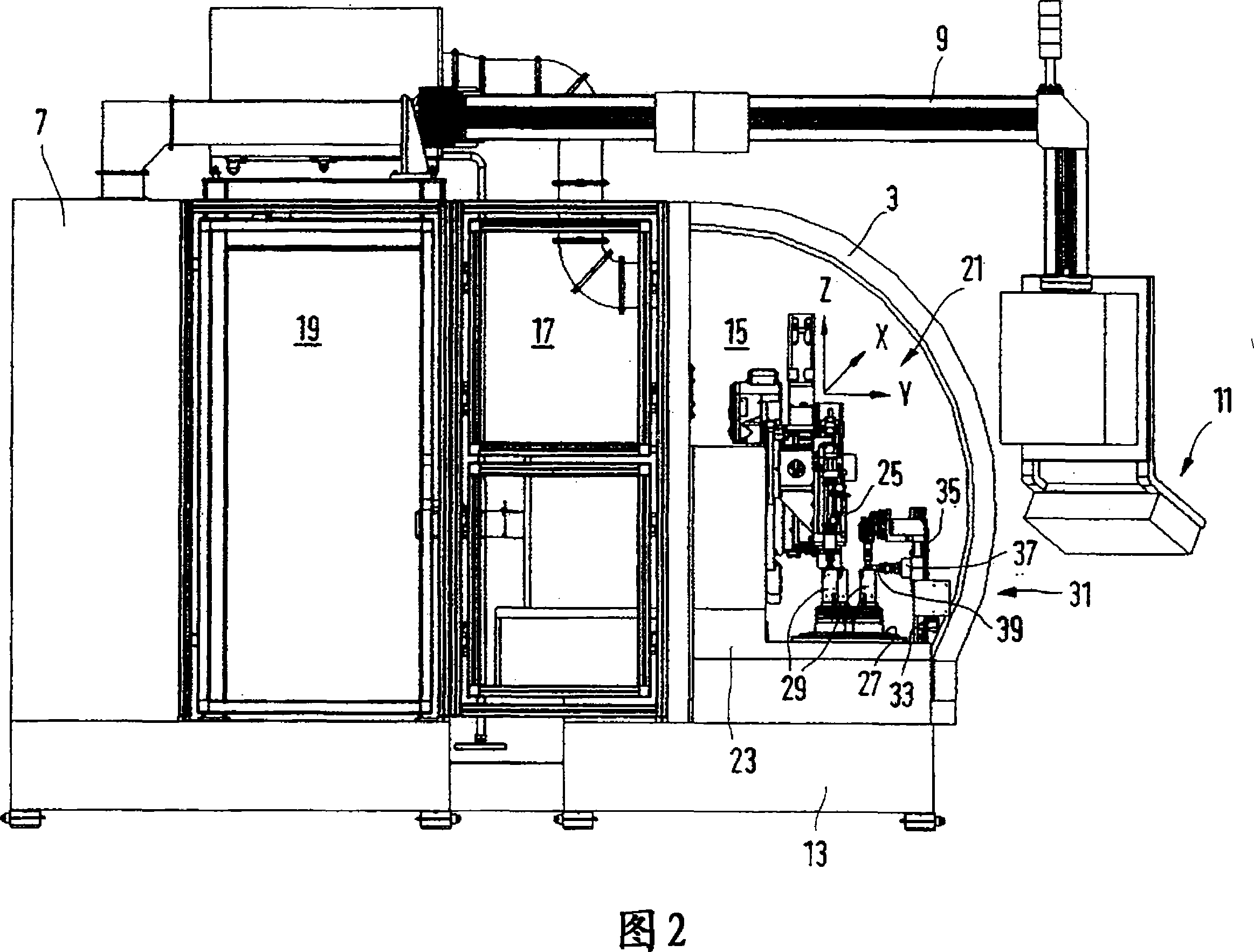

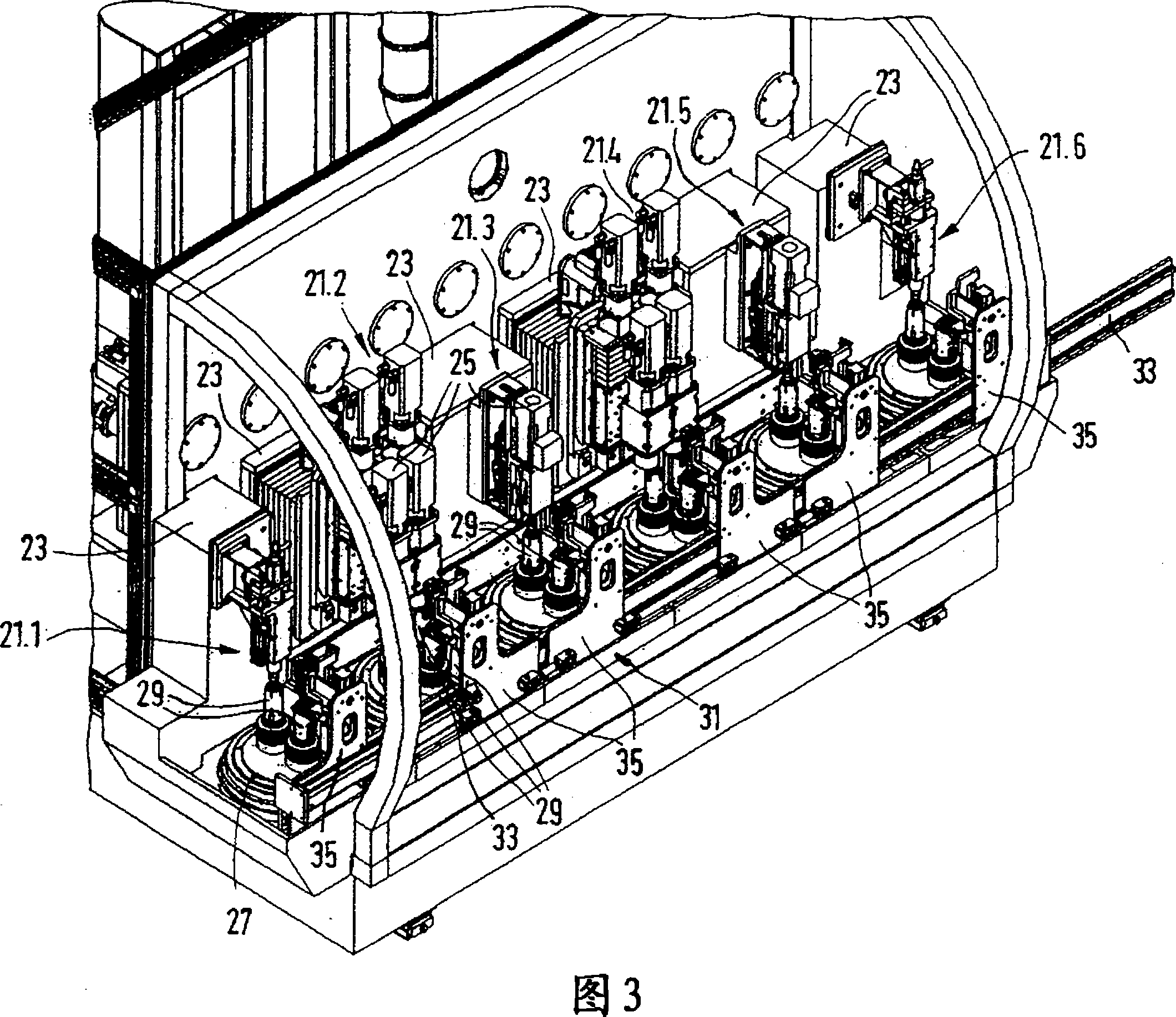

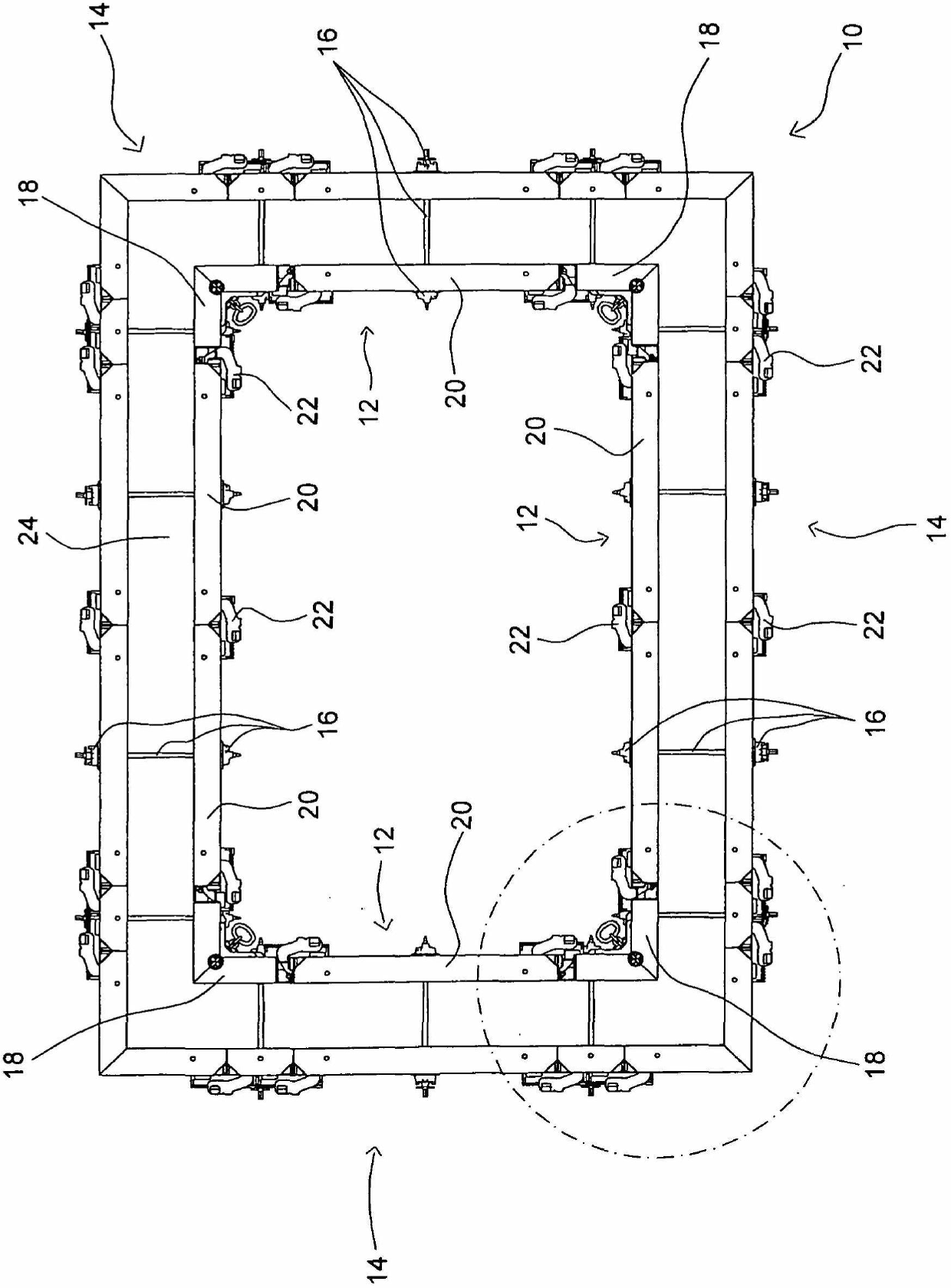

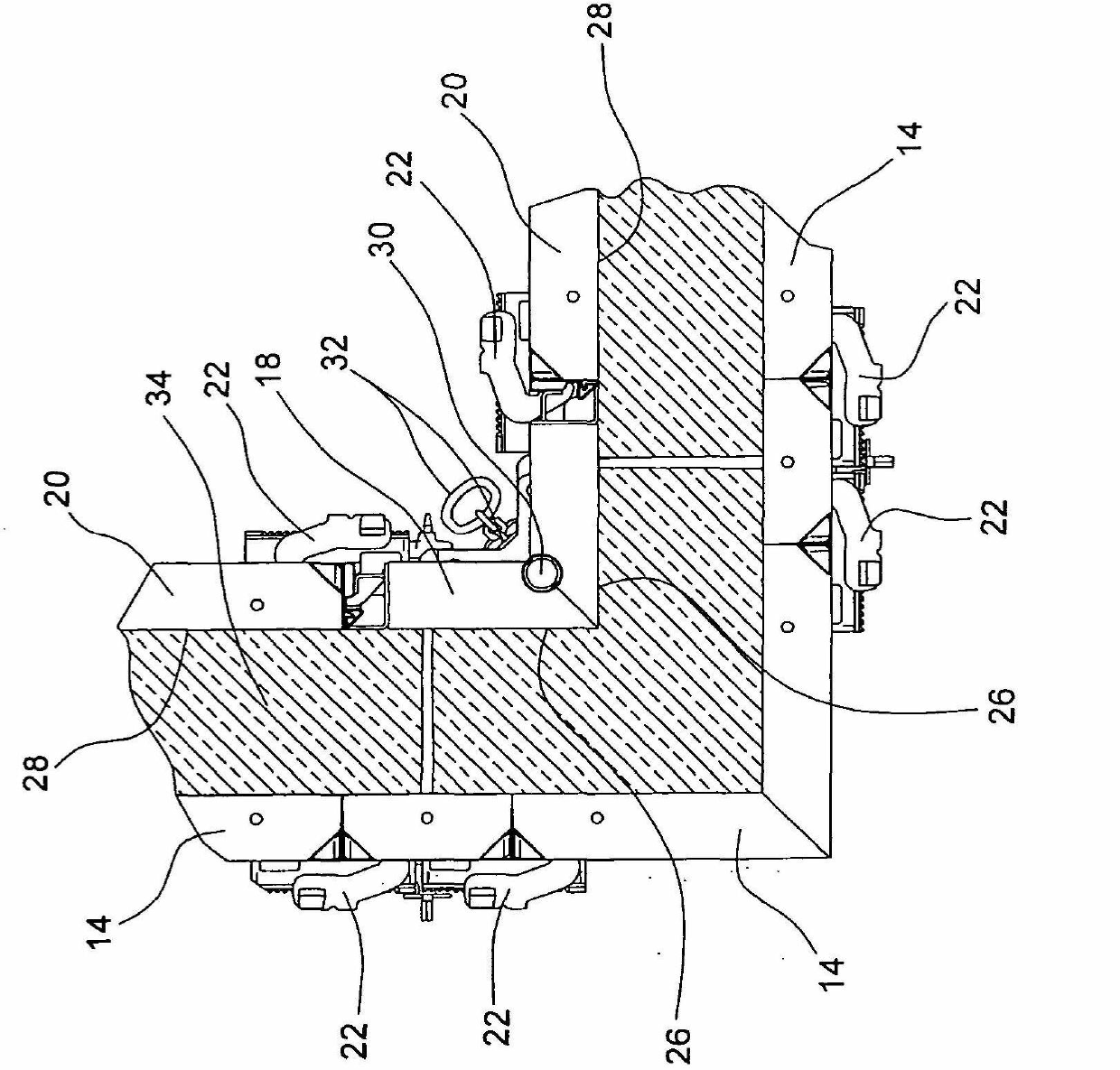

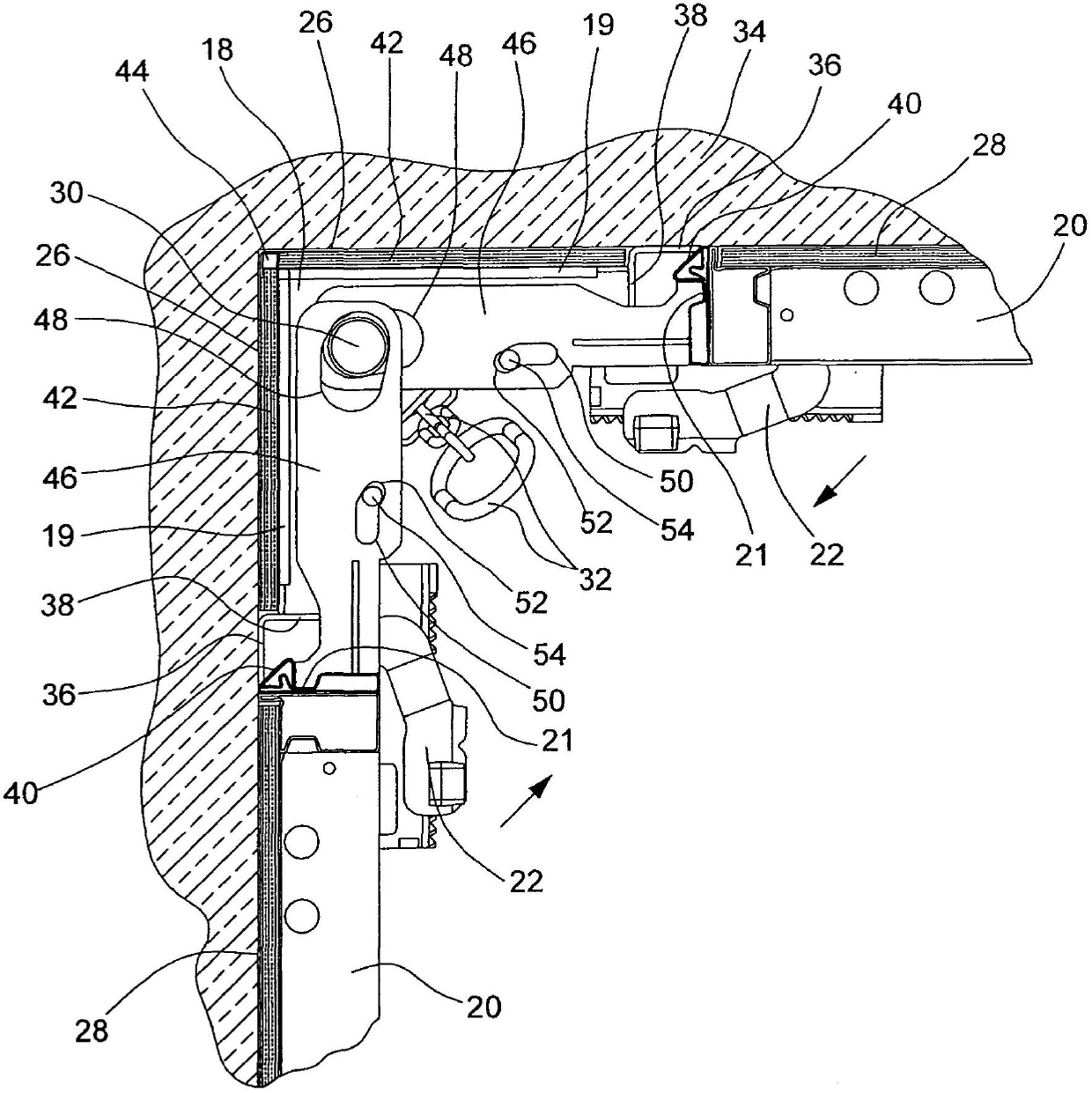

Production line for flexibly machining workpieces

InactiveCN101198440ABest loadDouble the outputAssembly machinesMetal working apparatusProduction lineEngineering

The inventive production line for producing workpieces comprises several machining cells (21) which are positioned in row side by side and a transport device (31) for transporting the workpiece(s) to be machined to the machining cells (21) or for removing them therefrom, wherein all machining cells (21) of the production line are arranged on a base module (13), the transport means (31) comprises a guide rail (33) extending along at least the entire length of the base module (13) and at least one transport slide (35) is placed on the guide rail (33).

Owner:SUPFINA GRIESHABER GMBH & CO KG

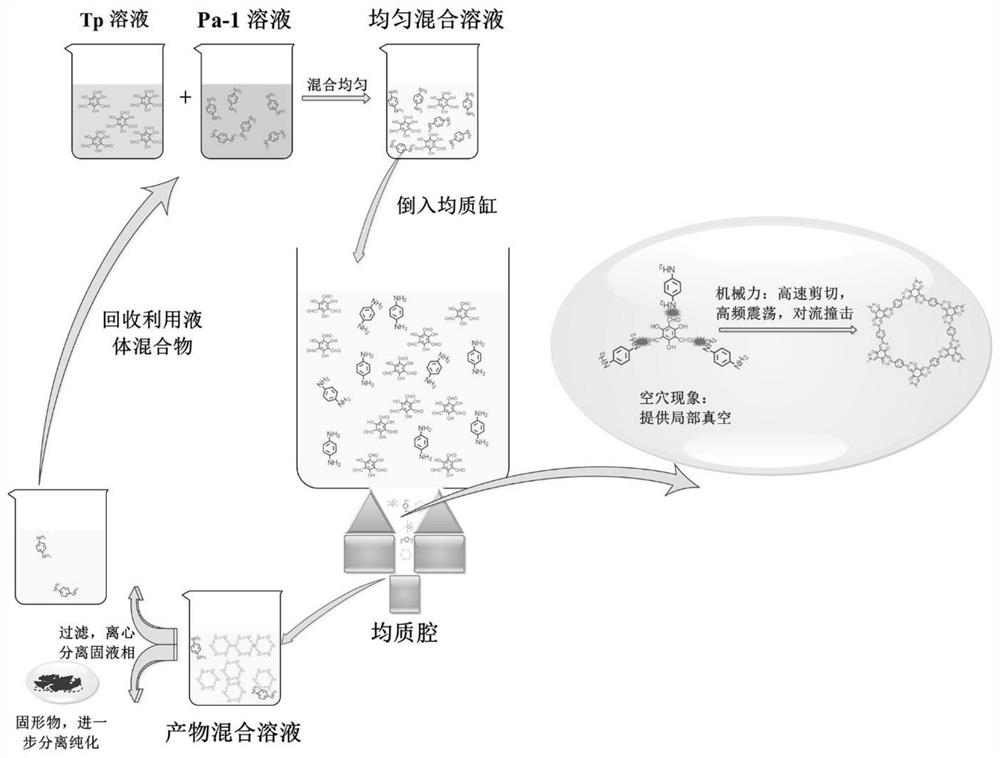

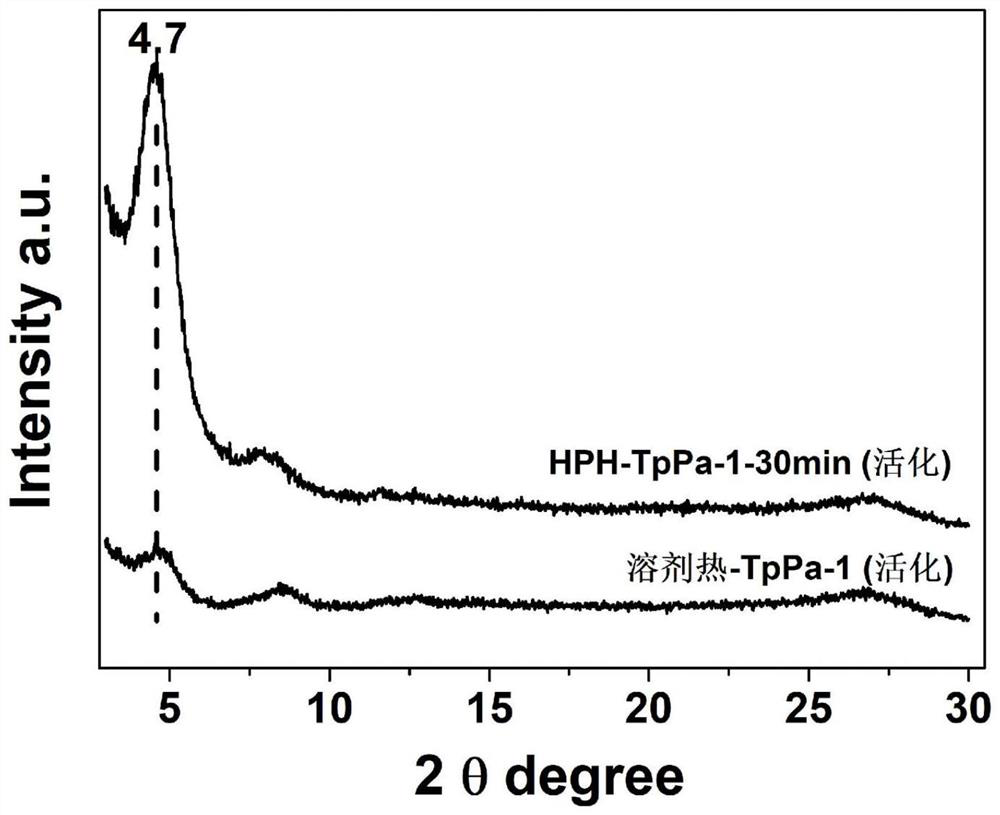

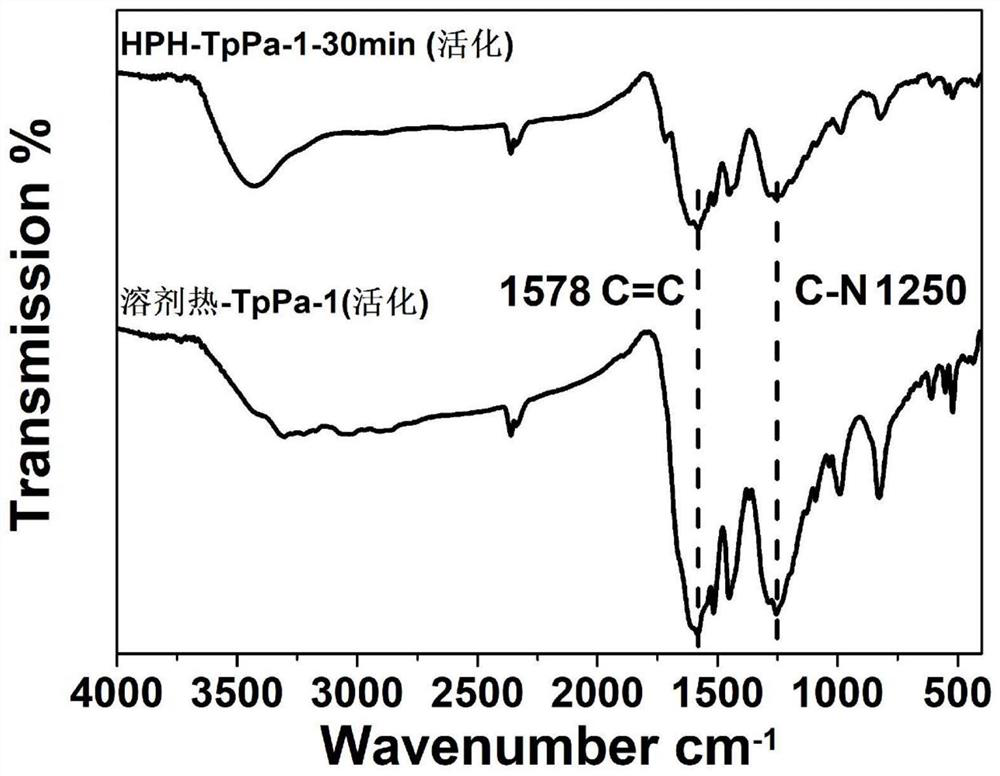

Method for preparing covalent organic framework material by high-pressure homogenization

ActiveCN113024828AShort reaction timeEasy to operateOther chemical processesPtru catalystEthylic acid

The invention relates to a method for preparing a covalent organic framework material by high-pressure homogenization. According to the synthesis method, at normal temperature and normal pressure, a common organic ligand is used as a raw material, water or an organic reagent is used as a solvent and a template agent, organic acid and inorganic acid are used as catalysts, and the corresponding COFs are obtained by homogenizing for a certain time through a high-pressure homogenizer. The method comprises the following steps of: adding 2, 4, 6-trihydroxy-1, 3, 5-benzenetricarboxaldehyde and p-phenylenediamine into a beaker, adding a proper amount of water and acetic acid, uniformly mixing, adding the mixture into a high-pressure homogenizer, and homogenizing for a certain time; and carrying out suction filtration on the product powder after the homogenizing reaction, recycling the filtrate, washing the product powder, and carrying out vacuum drying to obtain the covalent organic framework material HPH-Tp-Pa-1. Compared with other COFs preparation methods, the method provided by the invention has the advantages of continuous reaction, simple operation, low cost, high yield, environmental protection, energy saving, short reaction time and the like, has the potential of large-scale production, and can greatly promote the industrial production process of the COFs material.

Owner:NANKAI UNIV

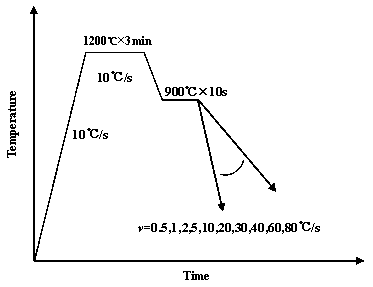

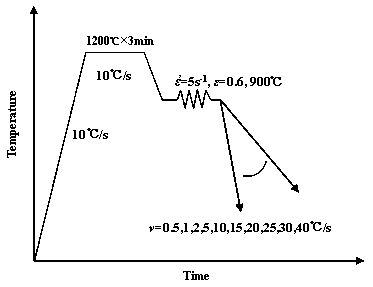

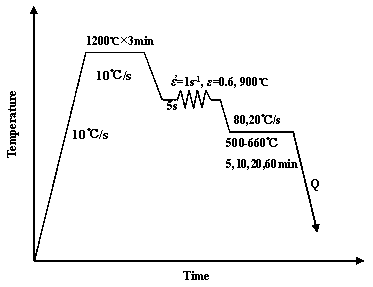

Dispersion nanometer reinforced 690 steel and manufacturing method thereof

The invention discloses dispersion nanometer reinforced 690 steel and a manufacturing method thereof. The manufacturing method comprises the steps of casting, heating, rolling and heat treatment. Thesteel comprises the following chemical components of, in percentage by mass, 0.02%-0.30% of C, 0.50-2.0% of Mn, 0.04-0.10% of Al, 0.002-0.013% of V, 0.01-0.3% of Nb, 0.005-0.3% of Ti, 0.001-0.010% ofN, and the balance Fe and inevitable impurities. The manufacturing method comprises the casting process and the TMCP process. By adjusting and optimizing the ratio of the alloy elements in the steel,the hardenability of the steel is improved by virtue of the trace alloy elements, and meanwhile carbon nitride nano-scale second-phase particles are formed; and meanwhile, the TMCP process is adopted,and the precipitation behavior of the micro-alloy elements as well as the precipitation amount, size and distribution of grains are controlled, so that the grains are refined, the strength and toughness of the steel are improved, and good formability and corrosion resistance are obtained.

Owner:INSTITUTE OF SCIENCE & TECHNOLOGY INNOVATION DONGGUAN UNIVERSITY OF TECHNOLOGY

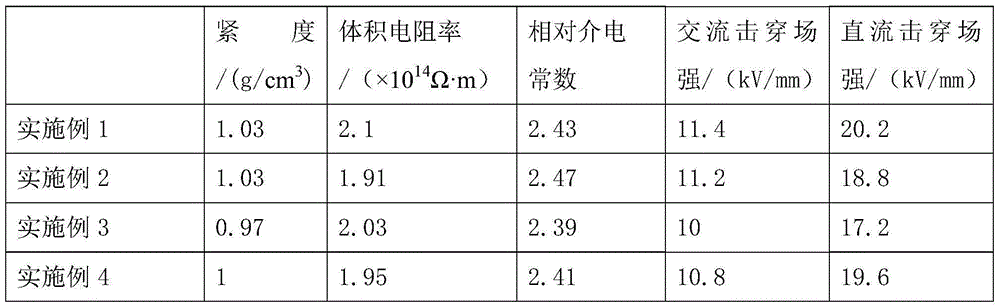

Method for preparing electrical insulating papers containing broadleaf wood fibers

InactiveCN104863022AEasy to operateLow pricePlastic/resin/waxes insulatorsTextiles and paperFiberElectrical performance

The invention relates to a method for preparing electrical insulating papers containing broadleaf wood fibers, which belongs to the technical field of electrical insulating papers, wherein needle-point leaf wood pulp dry pulp boards and broadleaf wood pulp dry pulp boards are immersed in deionized water to soak firstly, and are respectively or commonly defibered and beaten by utilizing a beating machine after being soak, and then two kinds of pulps are mixed and uniformly stirred to obtain paper pulp suspension liquid. The paper pulp suspension liquid is put into a paper page forming device to dehydrate and form, and obtains electrical insulating papers. Wet insulating paper pages are autoclaved to obtain finished electrical insulating papers after being autoclaved and dried. The finished electrical insulating papers are placed in constant temperature and constant humidity environment to store and reserve, the temperature of the constant temperature and constant humidity environment is 25 EDG C, and the relative humidity of the constant temperature and constant humidity environment is 50%. The method for preparing the electrical insulating papers containing the broadleaf wood fibers adds certain proportion of broadleaf wood fibers into needle-point leaf wood insulating papers, is simple in process and easy to operate, has lower price compared with needle-point leaf wood pulps, is obvious in economic advantages, and can effectively reduce production cost under the premise that electrical performance of insulating papers is guaranteed.

Owner:TSINGHUA UNIV

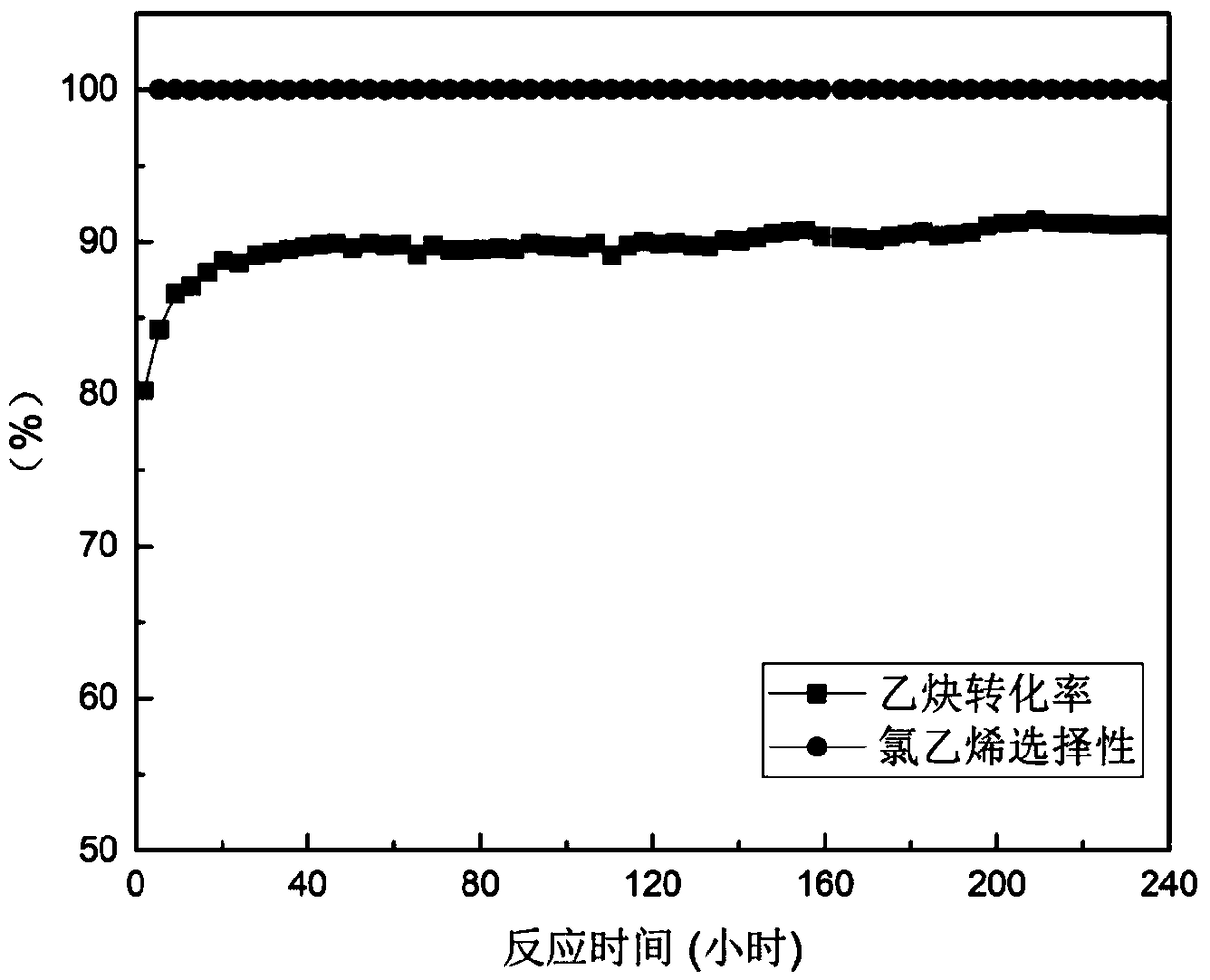

Method for preparing vinyl chloride by taking azacyclo-protonic acid ionic liquid as medium through acetylene hydrochlorination

ActiveCN104086351AAvoid local overheatingAvoid catalytic carbon depositionPreparation by halogen halide additionNitrogenHydrogen chloride

The invention discloses a method for preparing vinyl chloride by taking an azacyclo-protonic acid ionic liquid as a medium through acetylene hydrochlorination. The method comprises the following steps: by taking the azacyclo-protonic acid ionic liquid which is synthesized by taking an azacycle compound as a raw material as the medium, mixing with a non-mercury catalyst to prepare a catalysis system, feeding the catalysis system into an acetylene hydrochlorination catalysis system firstly, and subsequently feeding acetylene and hydrogen chloride for reaction. The method adopts the ionic liquid as the reaction medium and the non-mercury metal compound as the catalyst, green and environment-friendly liquid phase reaction of acetylene hydrochlorination is achieved, and moreover the azacyclo-protonic acid ionic liquid is simple to prepare, economic and good in application prospect.

Owner:ZHEJIANG UNIV

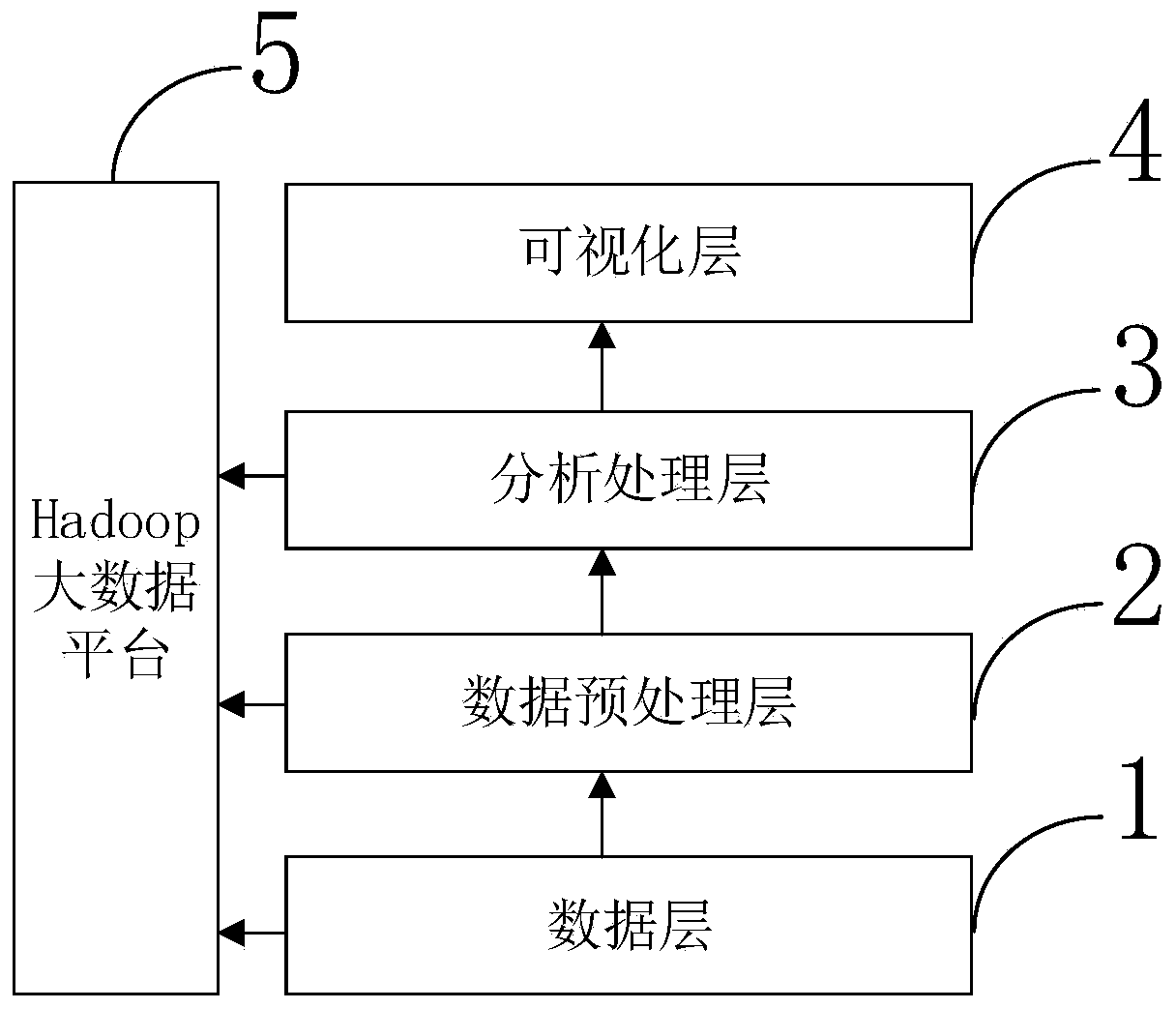

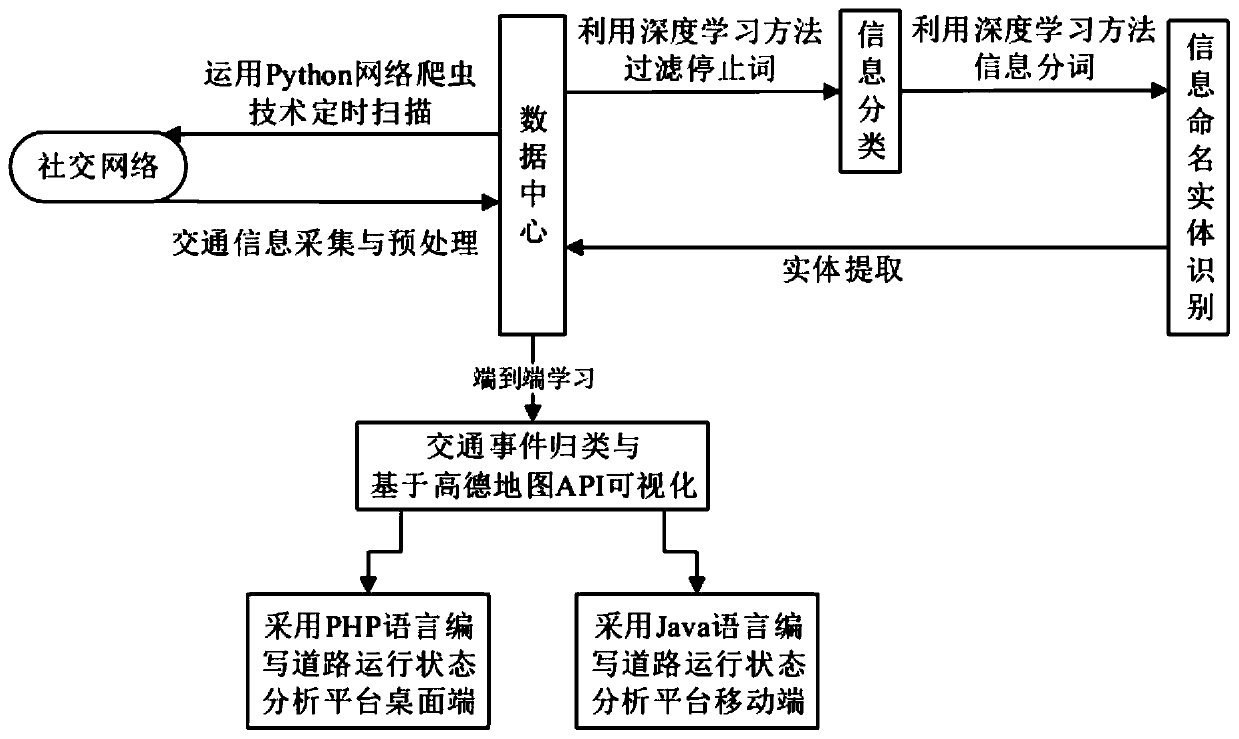

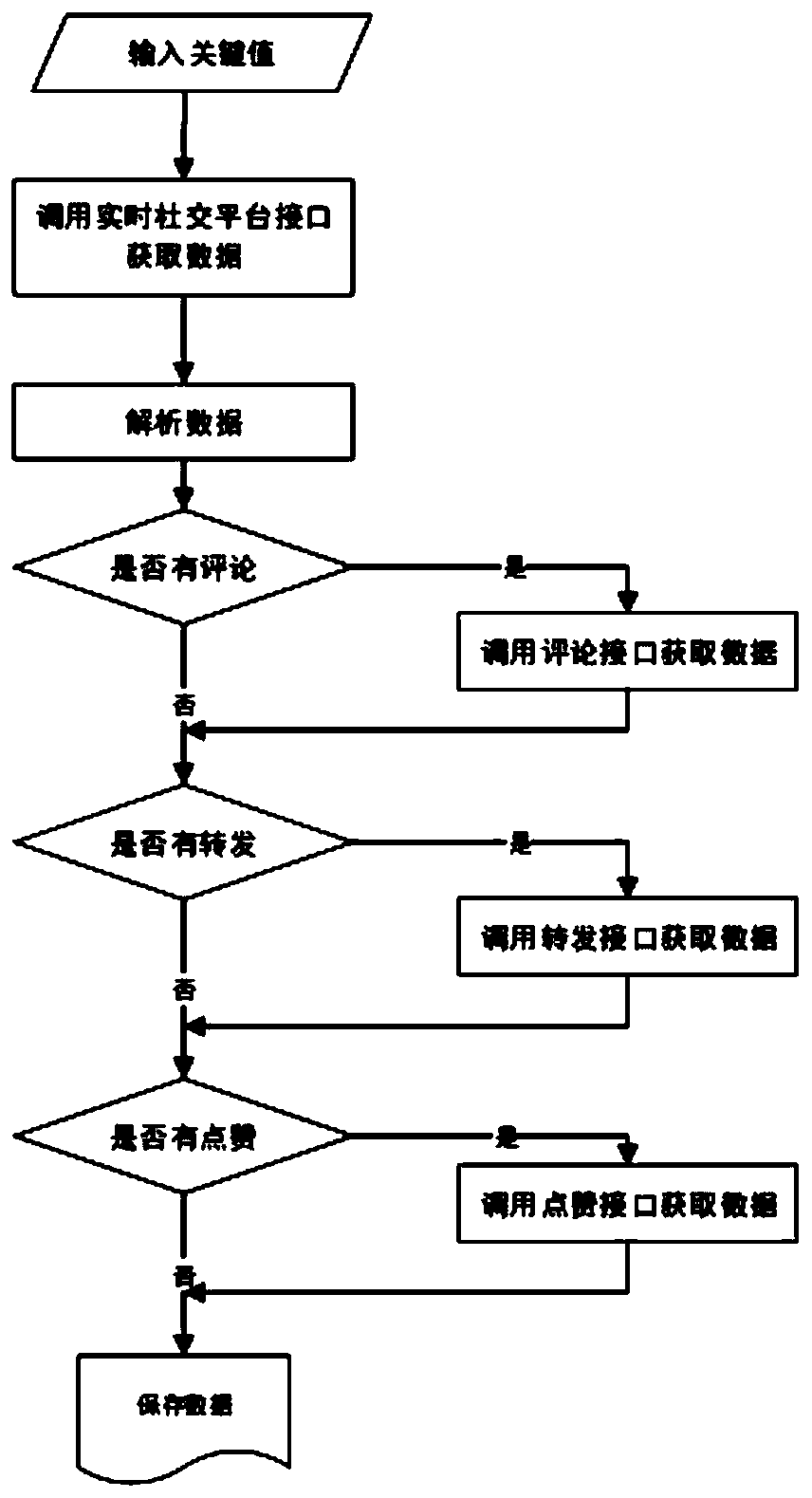

Road traffic operation state real-time sensing method based on social network information

ActiveCN110555568ASpatial distribution is not limitedObvious economic advantagesVisual data miningStructured data browsingSimulationAir traffic control

The invention belongs to the technical field of road traffic operation state real-time sensing and discloses a road traffic running state real-time sensing method based on social network information,which comprises the following steps of automatically acquiring, classifying and extracting multi-angle effective traffic information in a social network platform by using a web crawler technology, screening, analyzing and predicting, establishing an end-to-end self-learning model, and performing visual labeling on a map; learning and predicting future data from past data based on deep learning, and feeding back the predicted future data to a social network for users to share traffic information in real time. The system is not limited in spatial distribution, does not need to arrange and maintain ground sensing equipment, has obvious economic advantages, can effectively capture sudden traffic incidents, traffic incidents at specific places, temporary traffic control, newly added traffic restrictions and traffic environment information, provides quick response signals for related management departments, and provides travel decision basis for residents.

Owner:CHONGQING JIAOTONG UNIVERSITY

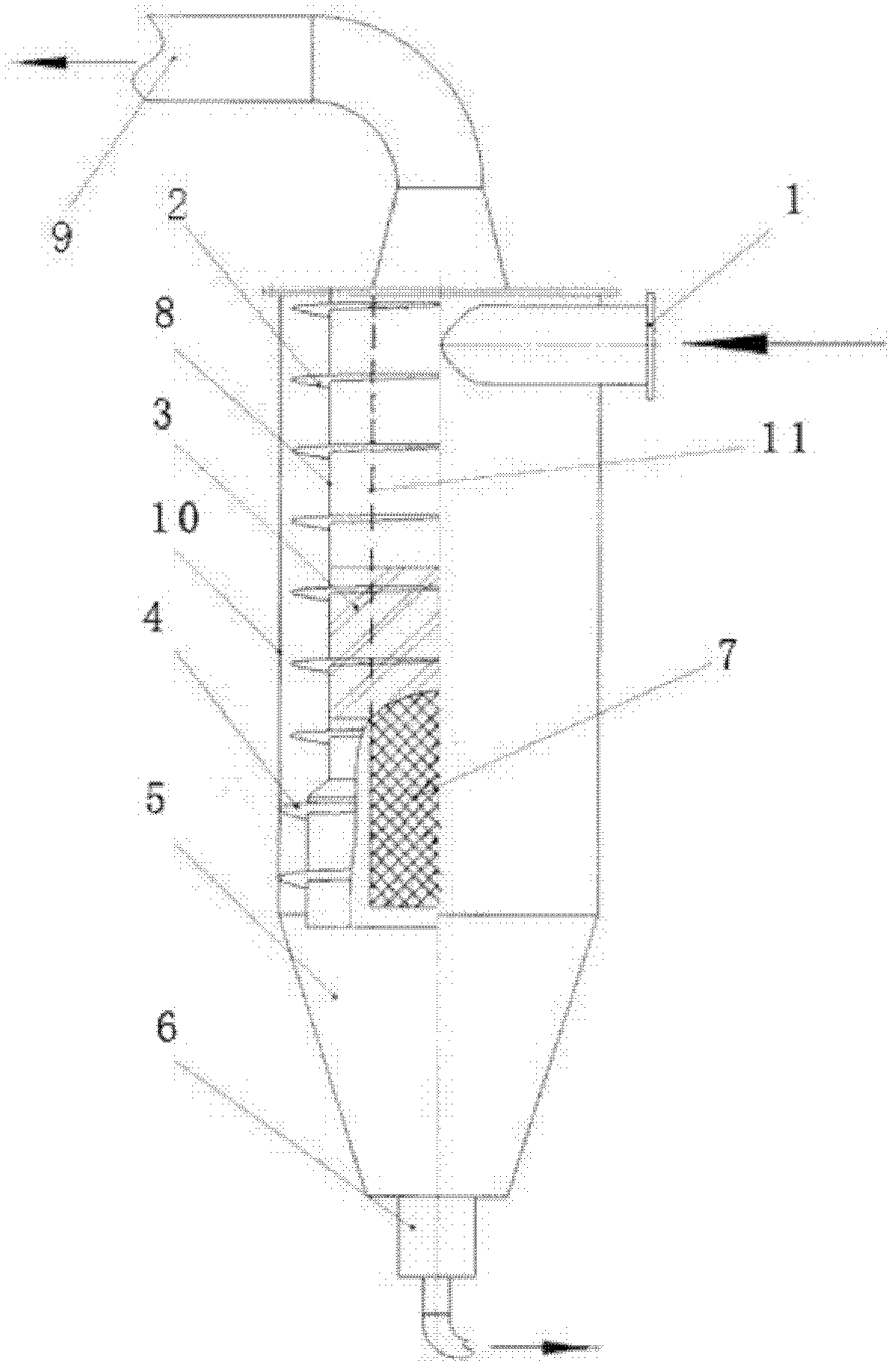

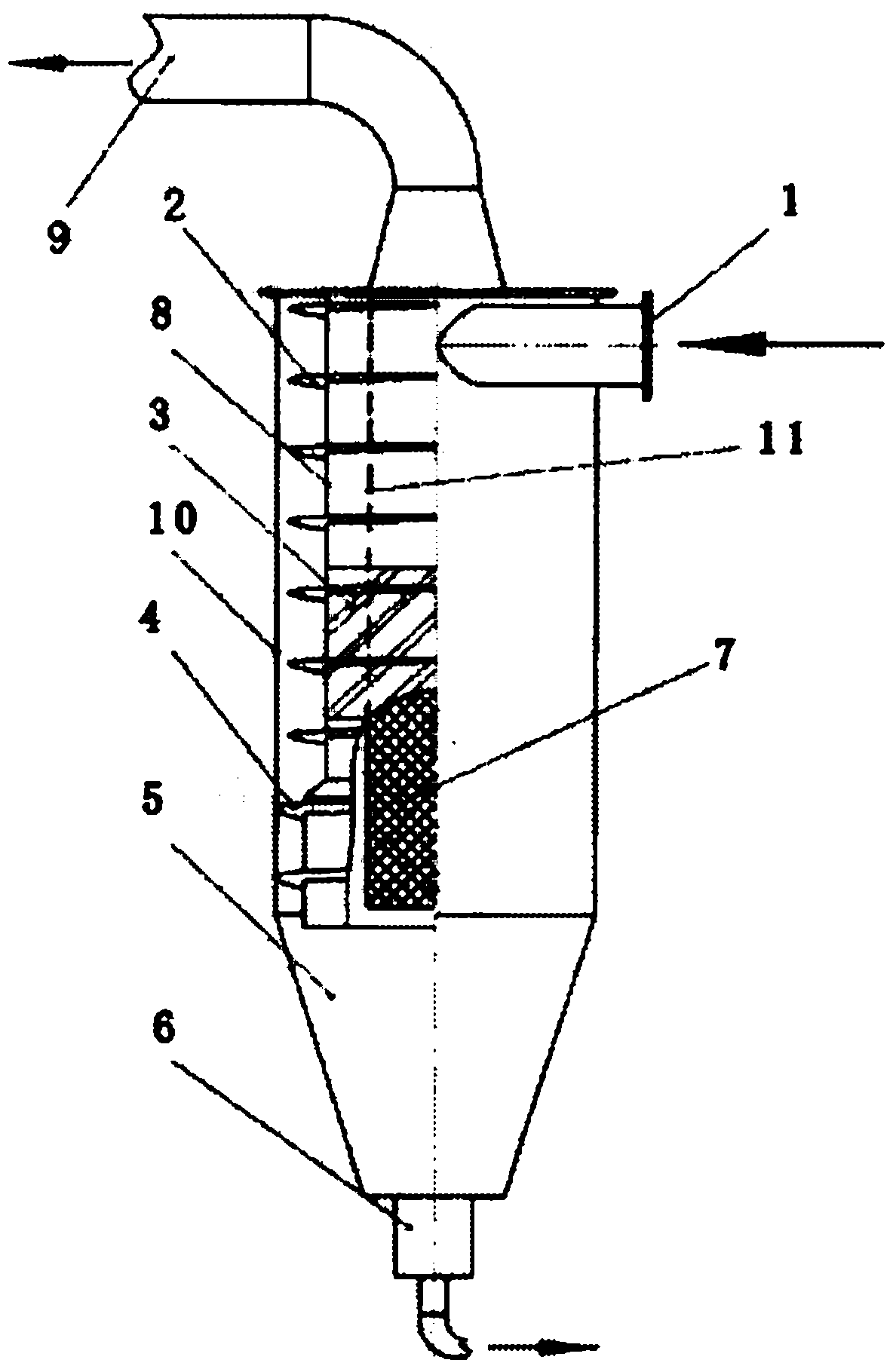

Dual-swirl water purifier

InactiveCN102614711AReach the standard of recyclingRealize the function of filtration and purificationFiltration circuitsWater resourcesOblique cutting

The invention belongs to the field of water treatment equipment and discloses a dual-swirl water purifier, which can perform tertiary sewage treatment without extra power. The dual-swirl water purifier is formed by sleeving three layers of pipe sleeves with different diameters, wherein the upper part of an outer sleeve is provided with a water inlet which is communicated with a primary swirl cavity; a sewage collecting and settling area and a sewage outlet are formed on the lower part in the outer sleeve; a water inlet oblique cut is formed on the surface of a middle section of a middle sleeve along the tangential direction; the outer surface is wound with spiral swirl vanes and spiral swirl lower vanes; gaps are reserved between the vanes and the outer sleeve; a gap is not reserved between the lower vanes and the outer sleeve; and a filtering net is arranged on an outer surface of an inner meshed pipe framework and is communicated with a purified water outlet. Three filtering and purifying functions, namely primary filtering, middle precision filtering and final filtering are realized, and the invention has the characteristics that the water purifier is small in size, compact in structure and high in sewage treatment amount, a recycling ratio of water is improved, and the water resources are saved.

Owner:北京五一环保科技股份有限公司

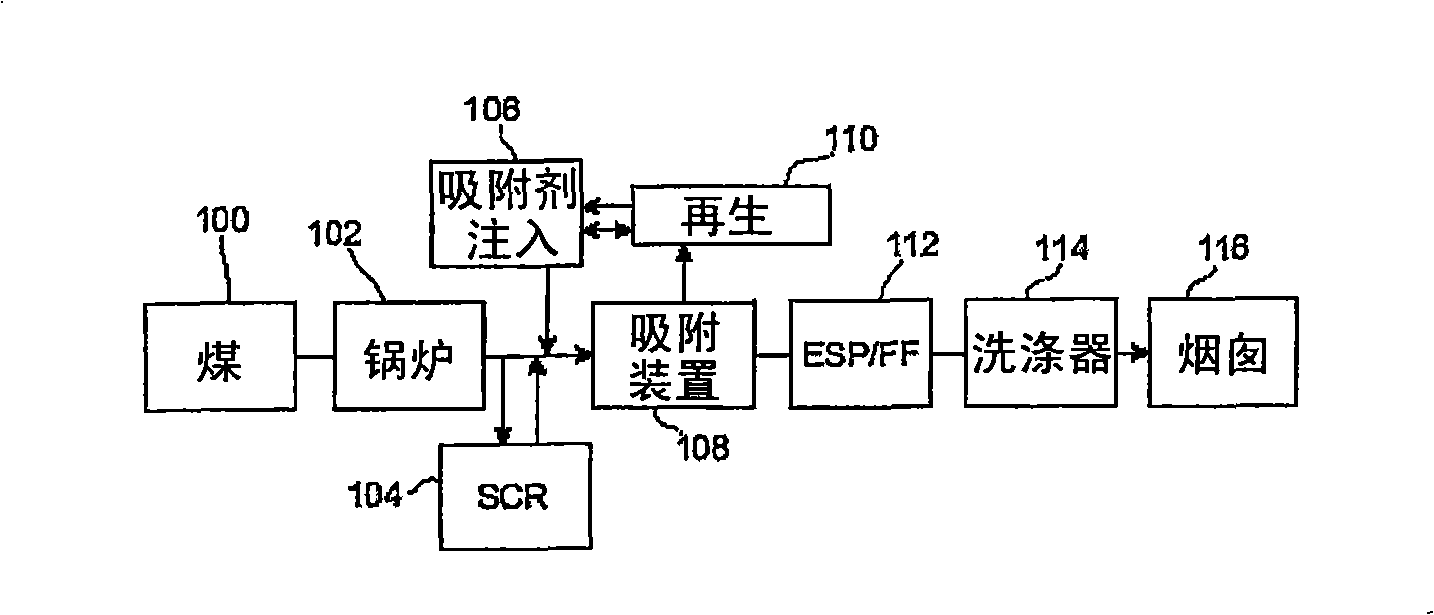

Method to remove an agent using a magnetic carrier

InactiveCN101309739AFunction increaseGood dispersionGas treatmentDispersed particle separationProcess systemsSorbent

The subject of the invention is a process for removal or separation of agents from dynamic process systems, particularly when the agent may be hazardous. Its primary embodiment lies in the removal of mercury from the exhaust from fossil fired heating systems, however, it can be seen as also applicable to many other types of separation processes. The process uses a regenerable and recyclable magnetic substrate having a sorbent attached thereto. The combination of the magnetic substrate and sorbent is referred to as a magnetic carrier.

Owner:STEWARD ENVIRONMENTAL SOLUTIONS

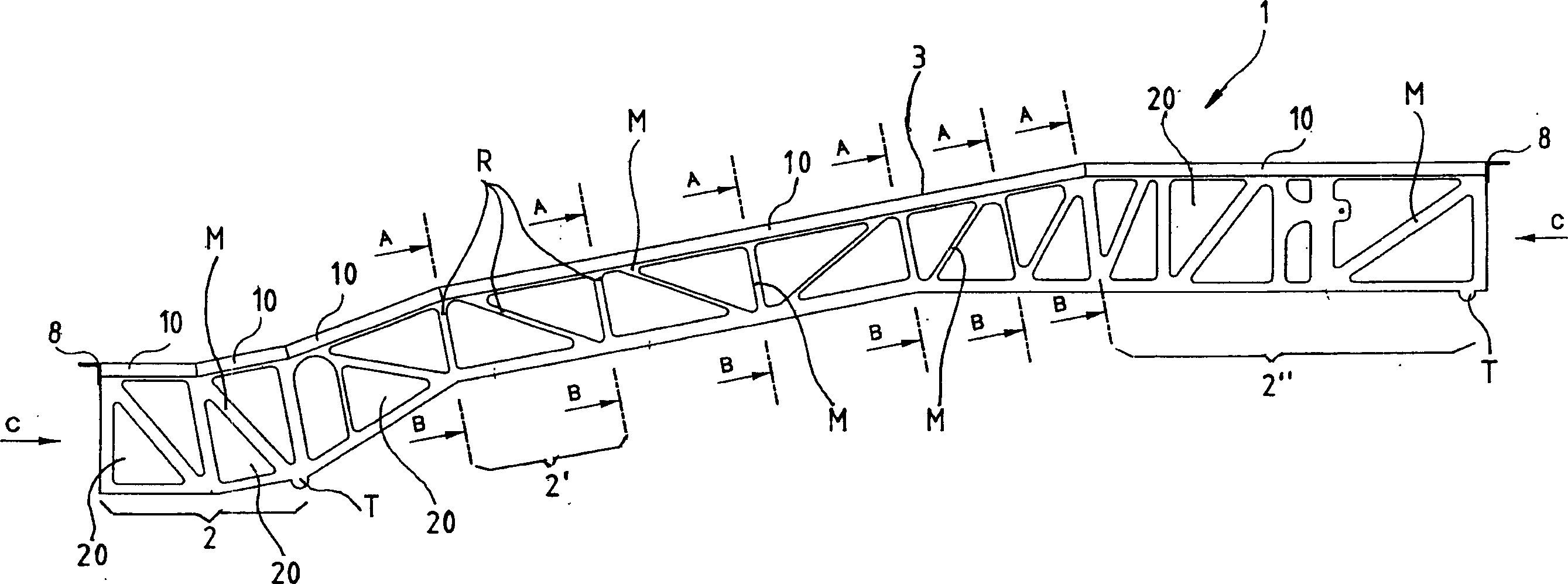

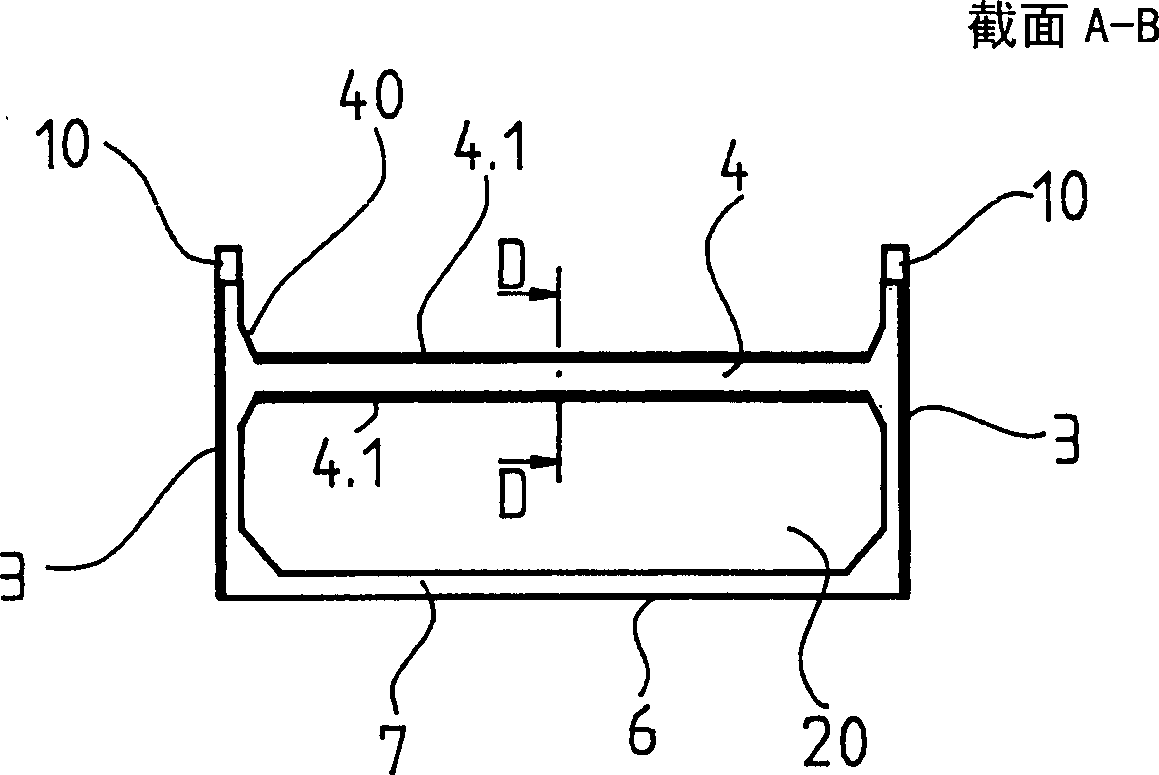

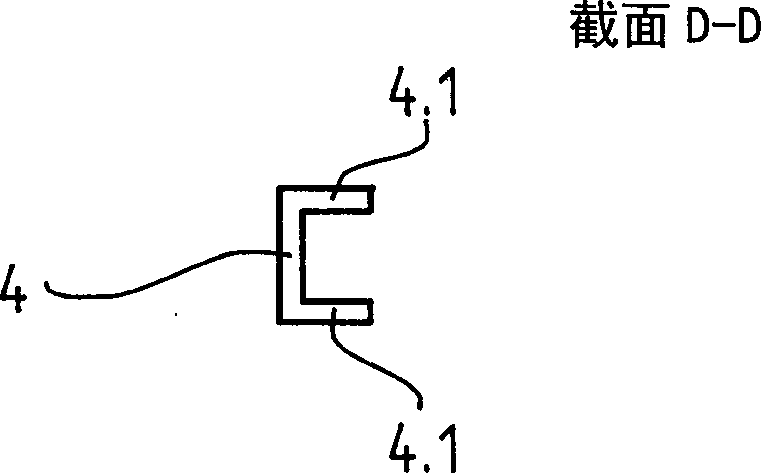

Supporting structure

InactiveCN1426955AEasy to produceImprove utilizationEscalatorsArchitectural engineeringBuilding construction

The invention relates to a support construction for an escalator or moving walkway, which comprises at least one framework element (2), wherein the framework element (2) is integrally constructed as an areal, non-profiled, cut plate. By virtue of the simple structure of the support construction without very much welding work, production time is substantially reduced.

Owner:INVENTIO AG

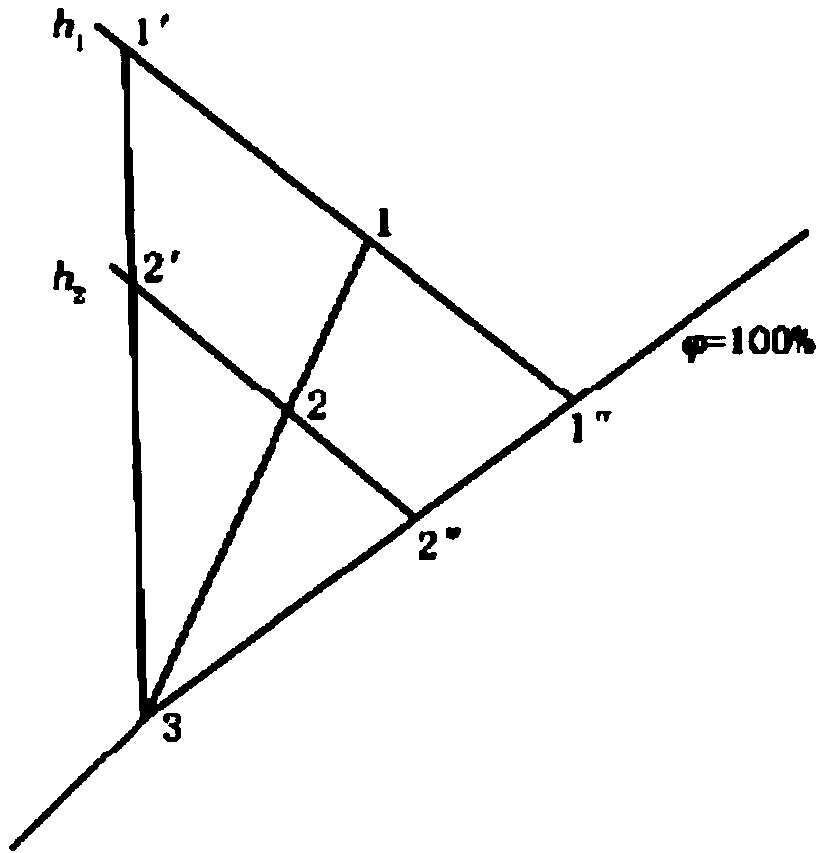

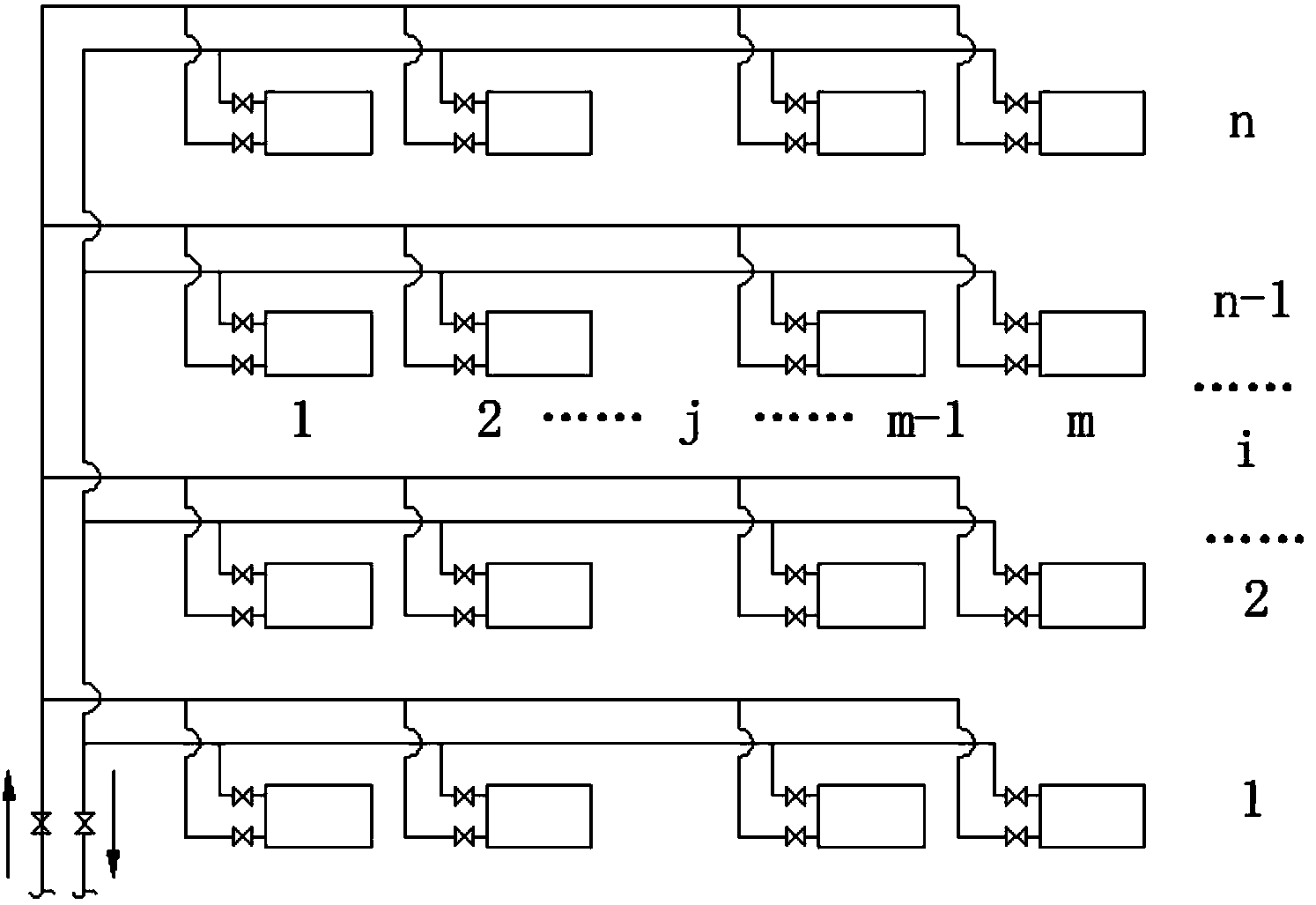

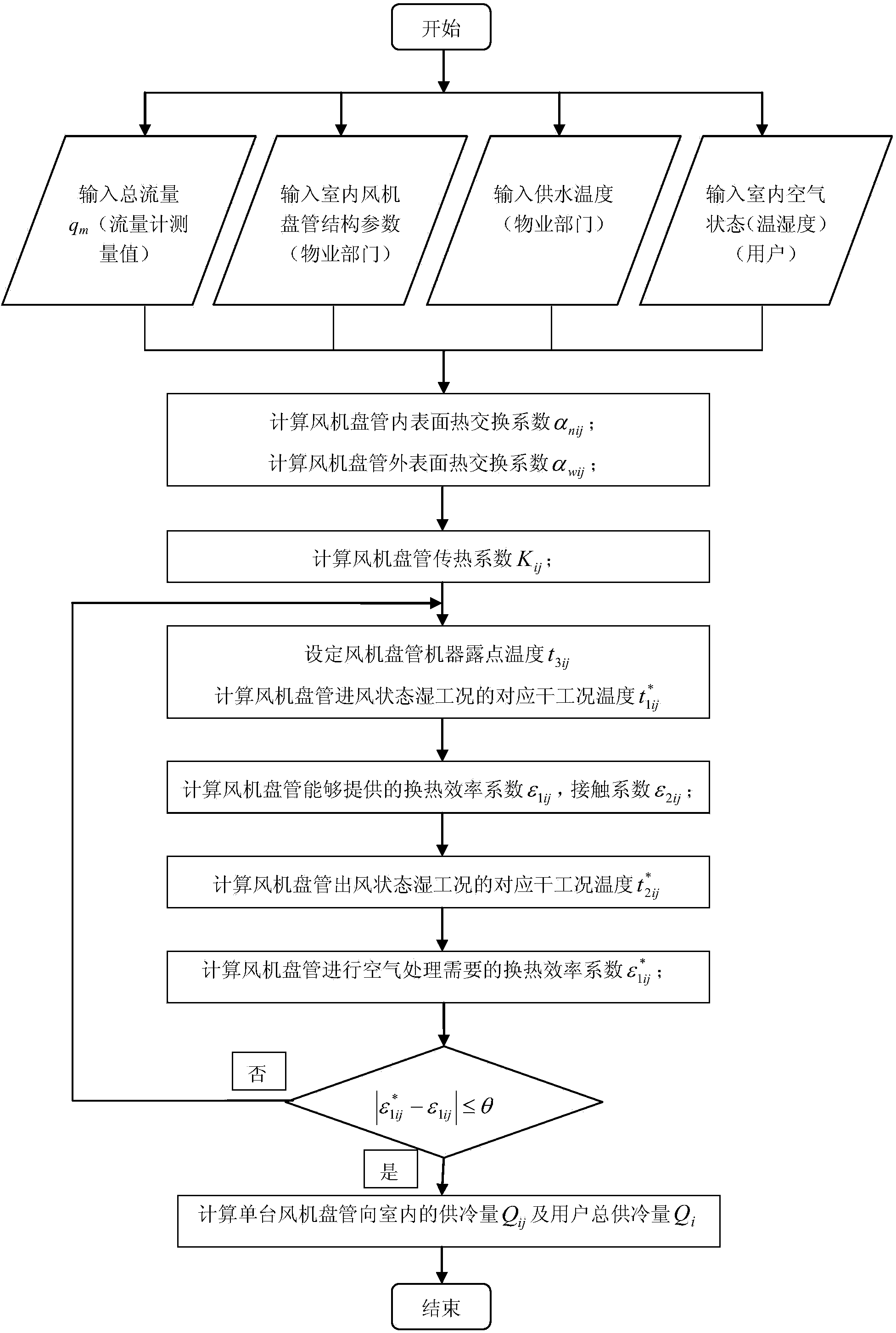

Fan coil cold measuring method based on flow-cold relation model

InactiveCN104298888ALess investmentMeet the accuracySpecial data processing applicationsData validationRelational model

The invention discloses a fan coil cold measuring method based on a flow-cold relation model. According to a fan coil structure, air supply volume and water supply flow, an inside-outside surface heat exchange coefficient is determined, a heat transfer coefficient is determined, dew temperature of a fan coil is set according to water supply temperature, a heat exchange efficiency coefficient and a contact coefficient which the fan coil can provide are determined, dry condition corresponding to wet condition of inlet air of the fan coil is determined, a heat exchange efficiency coefficient which the fan coil requires to treat the air is determined, dry condition corresponding to wet condition of outlet air of the fan coil is determined, and finally, cold supply volume of the cold supply tail of the fan coil after flow measurement is acquired according to the principle of energy conservation. The method has the advantages that measuring a temperature difference between supplied heat and supplied backwater is not required, the operating process is simpler accordingly, equipment failure rate is low, mounting is more convenient, energy saving is favored, reliability is high, and field measurement data shows that the method is higher in accuracy.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Formwork-stripping device

InactiveCN102667031AEasy to operateAvoiding the danger of fallingMouldsForms/shuttering/falseworksCouplingEngineering

The invention relates to a formwork-stripping device with a corner formwork element (18) which can be connected on both sides to in each case a further formwork element (20), wherein a vertically movable pull rod (30) is provided in the corner formwork element for moving the further formwork elements relative to the corner formwork element. The pull rod has an engagement surface, which can be moved together with it, for a lever and / or a coupling region (32), which can be moved together with it, for a pull chain.

Owner:PERI GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com