Liquid accelerator as well as preparation method and application thereof

A technology of accelerator and liquid, which is applied in the field of liquid accelerator and its preparation, and can solve problems affecting solution stability, high energy consumption, aggregation and thickening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

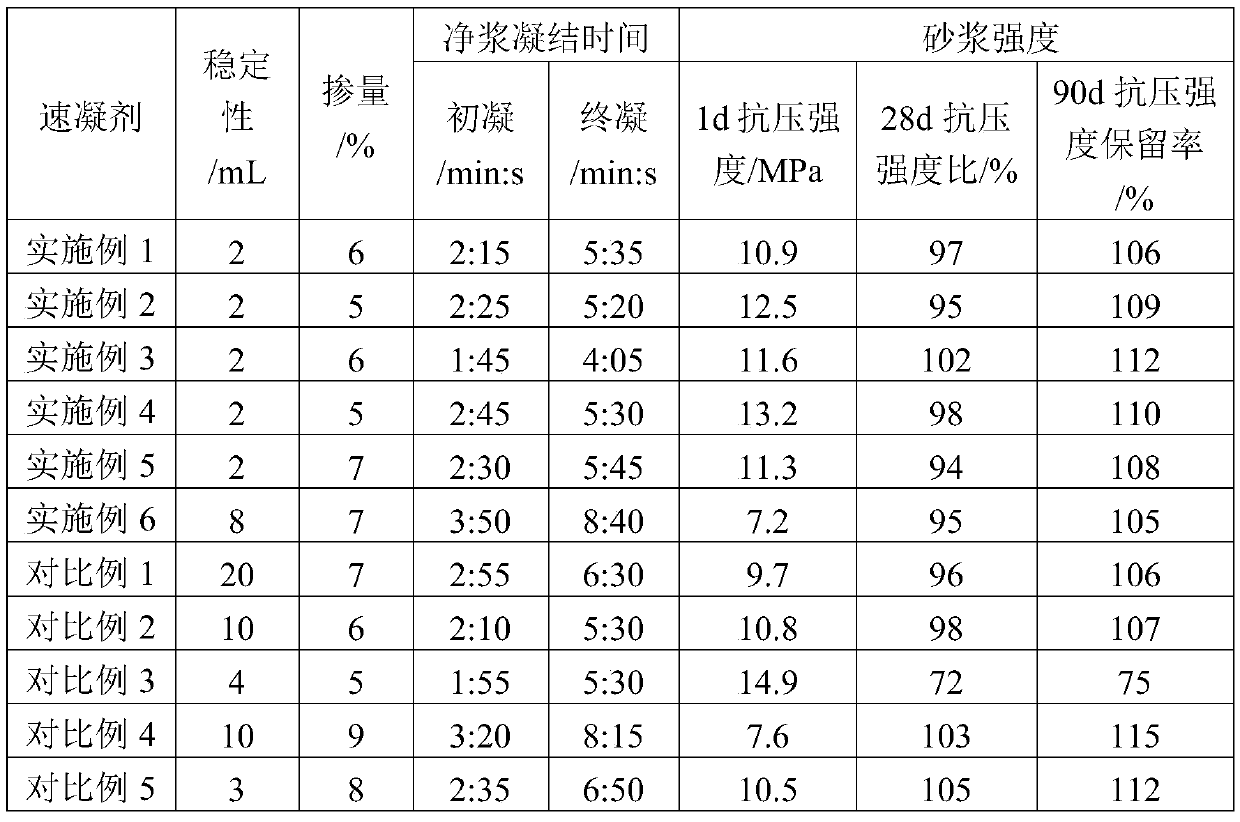

Examples

Embodiment 1

[0069] Step 1. Mix 44 parts by weight of sodium hydroxide and 96 parts by weight of deionized water, heat to 100°C, add 60 parts by weight of aluminum hydroxide, and react for 3 hours to obtain a solution containing sodium metaaluminate;

[0070] Step 2, sequentially add 210 parts by weight of deionized water and 200 parts by weight of the solution containing sodium metaaluminate obtained in step 1 into the reactor equipped with a stirrer, stir evenly, and add 420 parts by weight of industrial sulfuric acid in 3 times Aluminum (adding 140 parts by weight each time), mixing and stirring for 15 minutes after adding each time, after adding all the industrial aluminum sulfate, mixing and stirring for 20 minutes to obtain the first mixed solution;

[0071] Step 3, adding 20 parts by weight of citric acid into the first mixed solution obtained in step 2, stirring and reacting for 30 minutes, to obtain the second mixed solution;

[0072] Step 4. Add 125 parts by weight of inorganic a...

Embodiment 2

[0075] Step 1. Mix 62.5 parts by weight of sodium hydroxide and 100 parts by weight of deionized water, heat to 110°C, add 87.5 parts by weight of aluminum hydroxide, and react for 2 hours to obtain a solution containing sodium metaaluminate;

[0076] Step 2, sequentially add 140 parts by weight of deionized water and 250 parts by weight of the solution containing sodium metaaluminate obtained in step 1 into the reactor equipped with a stirrer, stir evenly, and add 400 parts by weight of industrial sulfuric acid in 4 times Aluminum (adding 100 parts by weight each time), mixing and stirring for 10 minutes after adding each time, after adding all the industrial aluminum sulfate, mixing and stirring for 15 minutes to obtain the first mixed solution;

[0077] Step 3, adding 20 parts by weight of diethanolamine into the first mixed solution obtained in step 2, stirring and reacting for 45 minutes, to obtain a second mixed solution;

[0078] Step 4. Add 180 parts by weight of inorg...

Embodiment 3

[0081] Step 1. Mix 62.1 parts by weight of sodium hydroxide and 121.5 parts by weight of deionized water, heat to 120°C, add 86.4 parts by weight of aluminum hydroxide, and react for 4 hours to obtain a solution containing sodium metaaluminate;

[0082] Step 2, sequentially add 50 parts by weight of deionized water and 270 parts by weight of the solution containing sodium metaaluminate obtained in step 1 into the reactor equipped with a stirrer, stir evenly, and add 350 parts by weight of industrial sulfuric acid in 2 times Aluminum (adding 175 parts by weight each time), mixing and stirring for 15 minutes after adding each time, after adding all the industrial aluminum sulfate, mixing and stirring for 20 minutes to obtain the first mixed solution;

[0083]Step 3, adding 15 parts by weight of triethanolamine into the first mixed solution obtained in step 2, stirring and reacting for 30 minutes, to obtain a second mixed solution;

[0084] Step 4. Add 300 parts by weight of inor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com