Lightly-calcined-dolomite sandwich composite partition wall plate and manufacturing method thereof

A technology of lightly burning dolomite and lightly burning dolomite powder, which is applied in the direction of building structure, building components, climate change adaptation, etc., can solve the problems of consuming magnesite resources, difficult to popularize and apply, etc., and achieves the promotion of resource utilization and comprehensive utilization. , expand the scope of application, improve the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of manufacturing method of lightly burned dolomite sandwich composite partition wall board, comprises the following steps successively:

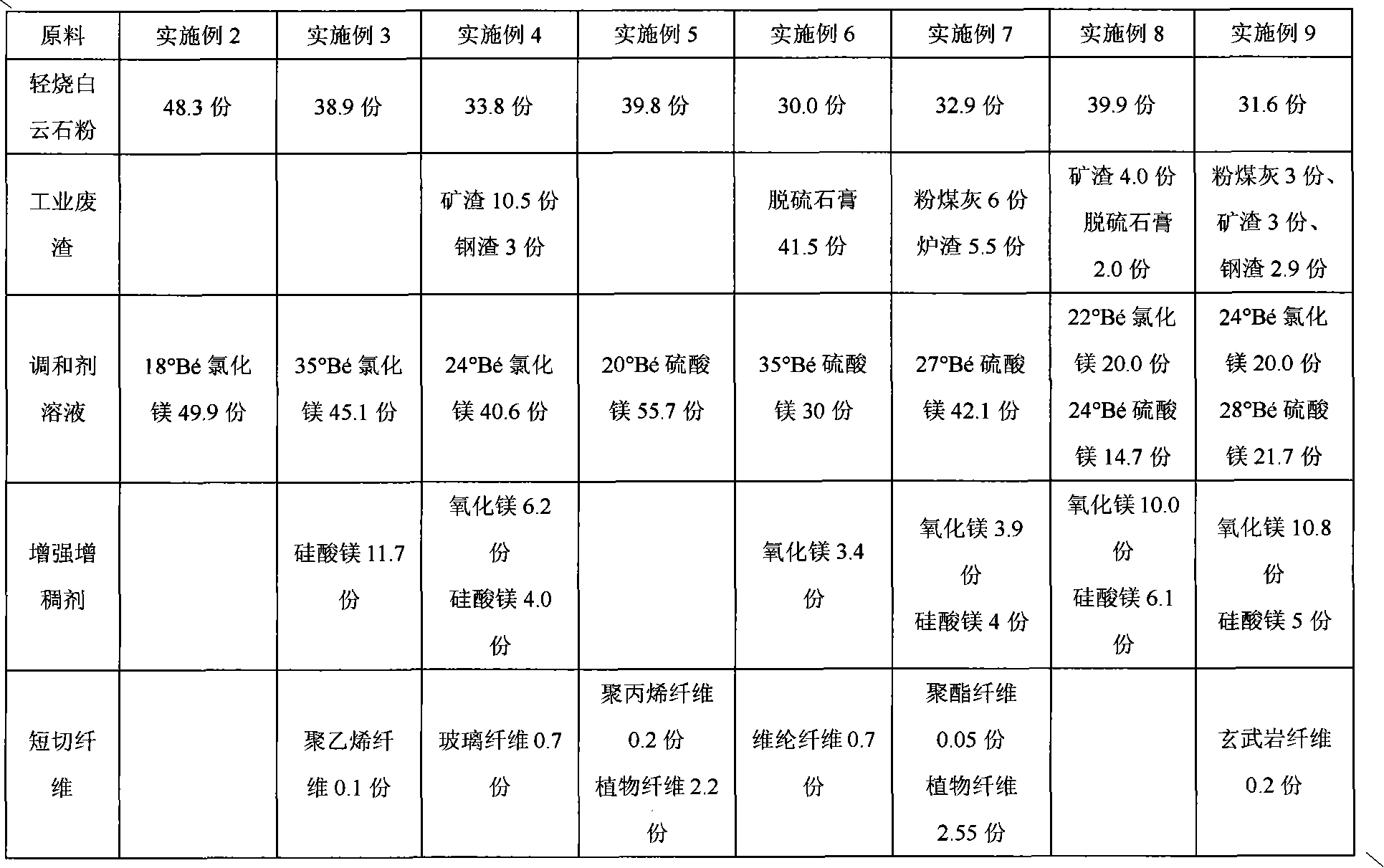

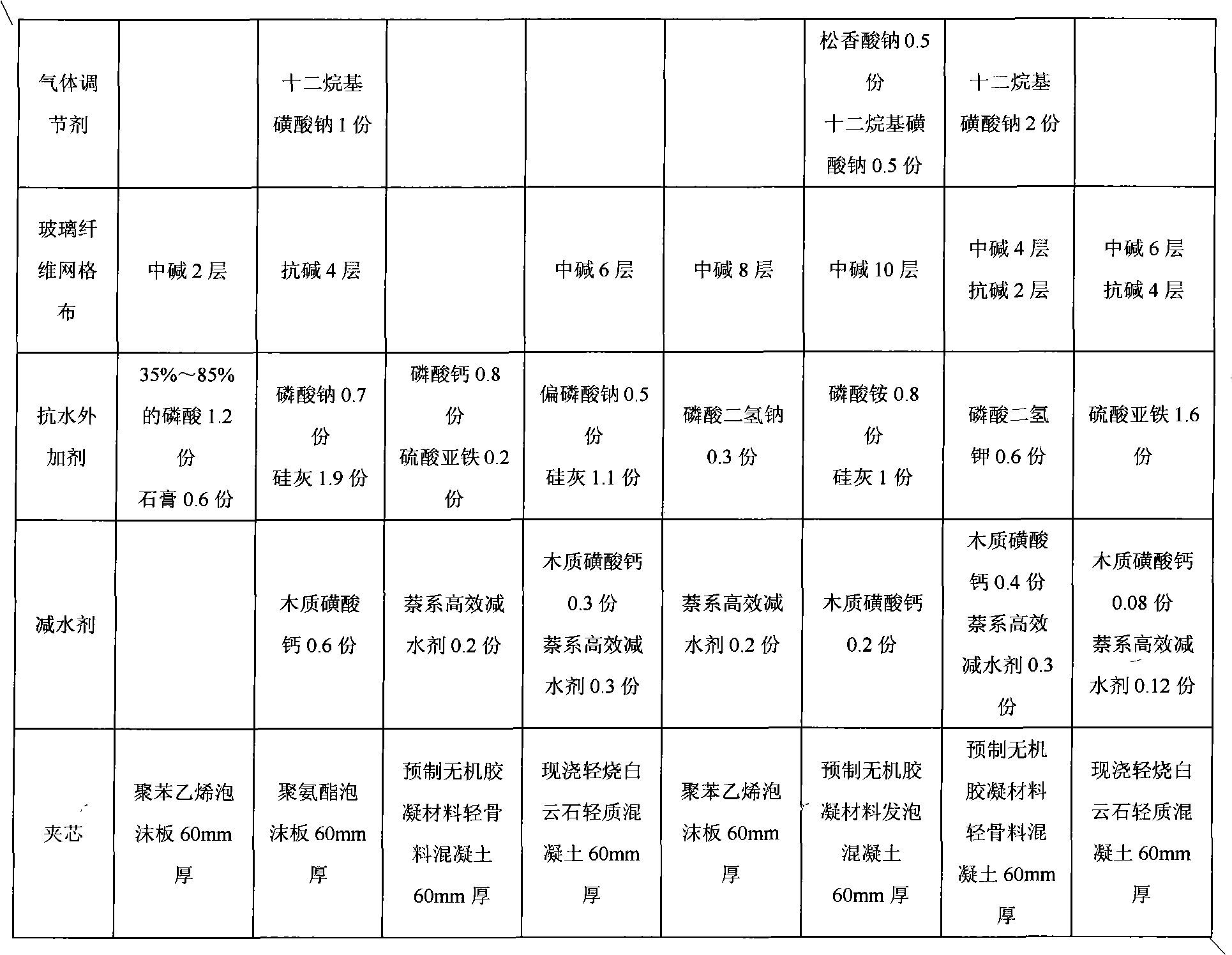

[0038] (1) With lightly burned dolomite powder, industrial waste slag, blending agent solution, reinforcing thickener, chopped fiber, gas regulator, water-resistant additive and water reducing agent as raw materials, according to the mixing ratio of embodiment 2-9, Measured separately, mixed and stirred to make light burnt dolomite mixture;

[0039] (2) pouring a lightly burned dolomite mixture with a thickness of 2 to 5 mm on the bottom surface of the mold;

[0040] (3) Spread glass fiber mesh cloth;

[0041] (4) Pouring a lightly burned dolomite mixture with a thickness of 2 to 5mm;

[0042] (5) Place or pour the insulation sandwich layer;

[0043] (6) Pouring light-burned dolomite mixture around and on the surface of the thermal insulation sandwich layer, the thickness of the surface mixture is 2-5mm;

[00...

Embodiment 18

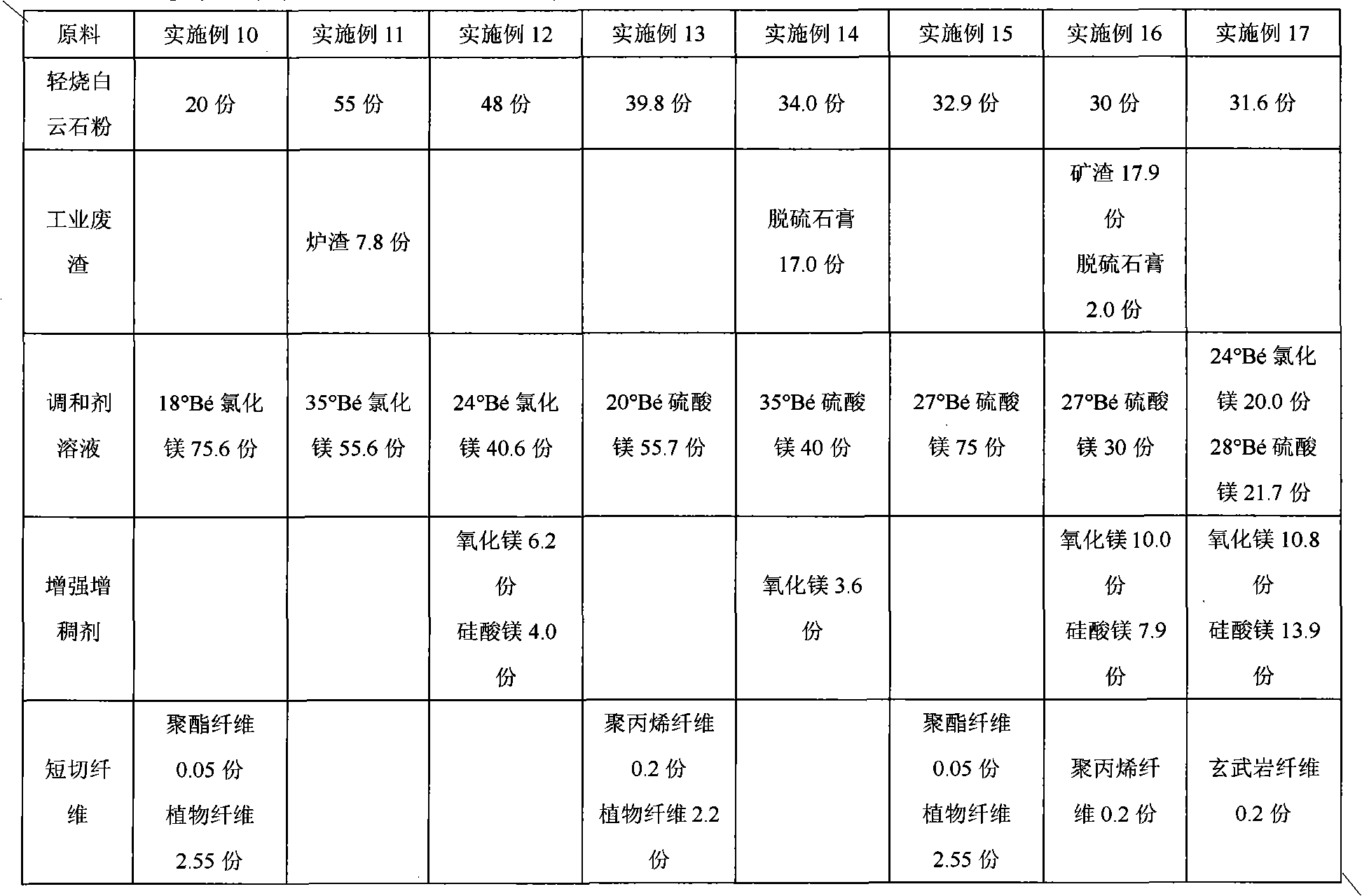

[0056] Example 18: The performance of the lightly burned dolomite sandwich composite partition wall panel prepared by the formula of Examples 2-17 was tested, and the results are shown in Table 3.

[0057] Table 3: Performance test table of the lightly burned dolomite sandwich composite partition wall board prepared by the formula of Example 2-17

[0058]

[0059]

[0060] It can be seen from Table 3 that the present invention has the characteristics of light weight, high strength, water resistance, frost resistance, impact resistance, and environmental protection requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com