Light irradiation device and inkjet printer

一种光照射、光线的技术,应用在折射器、反射器、打印装置等方向,能够解决均匀度不良等问题,达到影响程度减低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

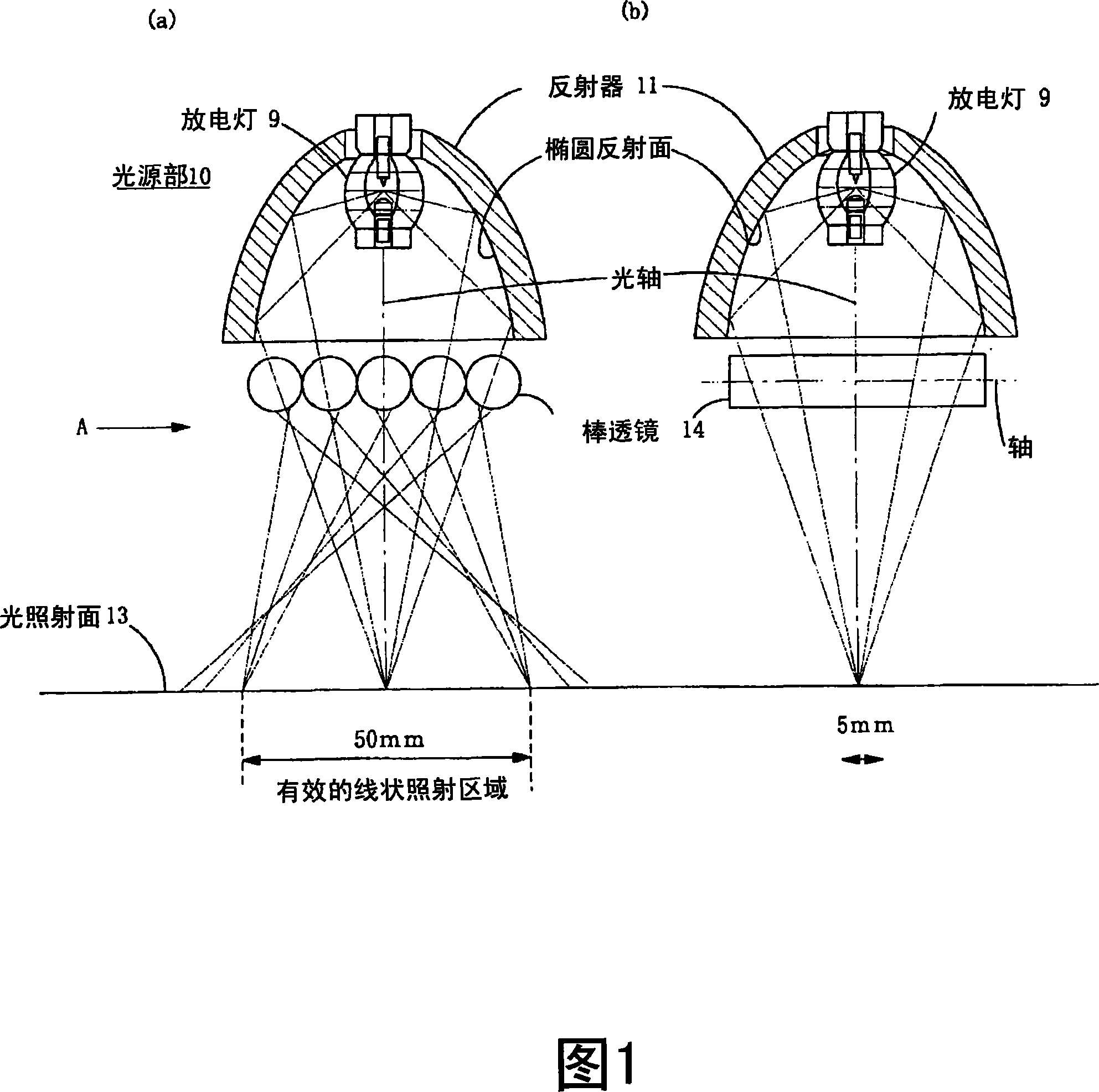

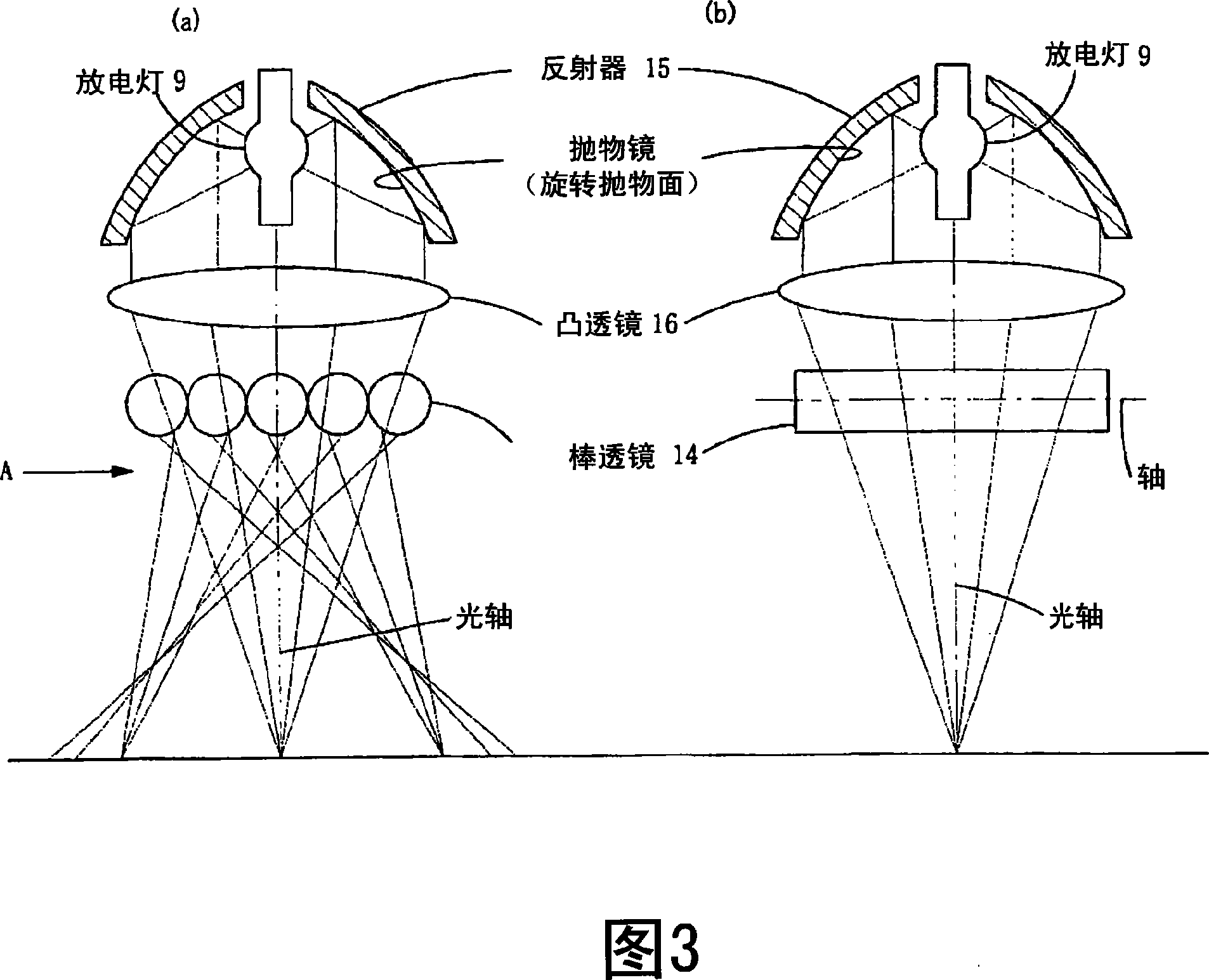

[0121] Using the light irradiator of the first embodiment shown in FIG. 1 , the number of rod lenses was changed, and the illuminance distribution of the light irradiation area on the light irradiation surface W where light was collected linearly was measured.

[0122] Fig. 4 shows the results. The coaxial vertical axis is the integrated light quantity (relative value), and the horizontal axis is the irradiation width (length) (mm).

[0123] Each curve in Fig. 4 represents the number of rod lenses arranged on the light exit side of the reflector respectively, for (A) no rod lens, (B) 1 rod lens, (C) 2 rod lenses, (D) Seven rod lens cases.

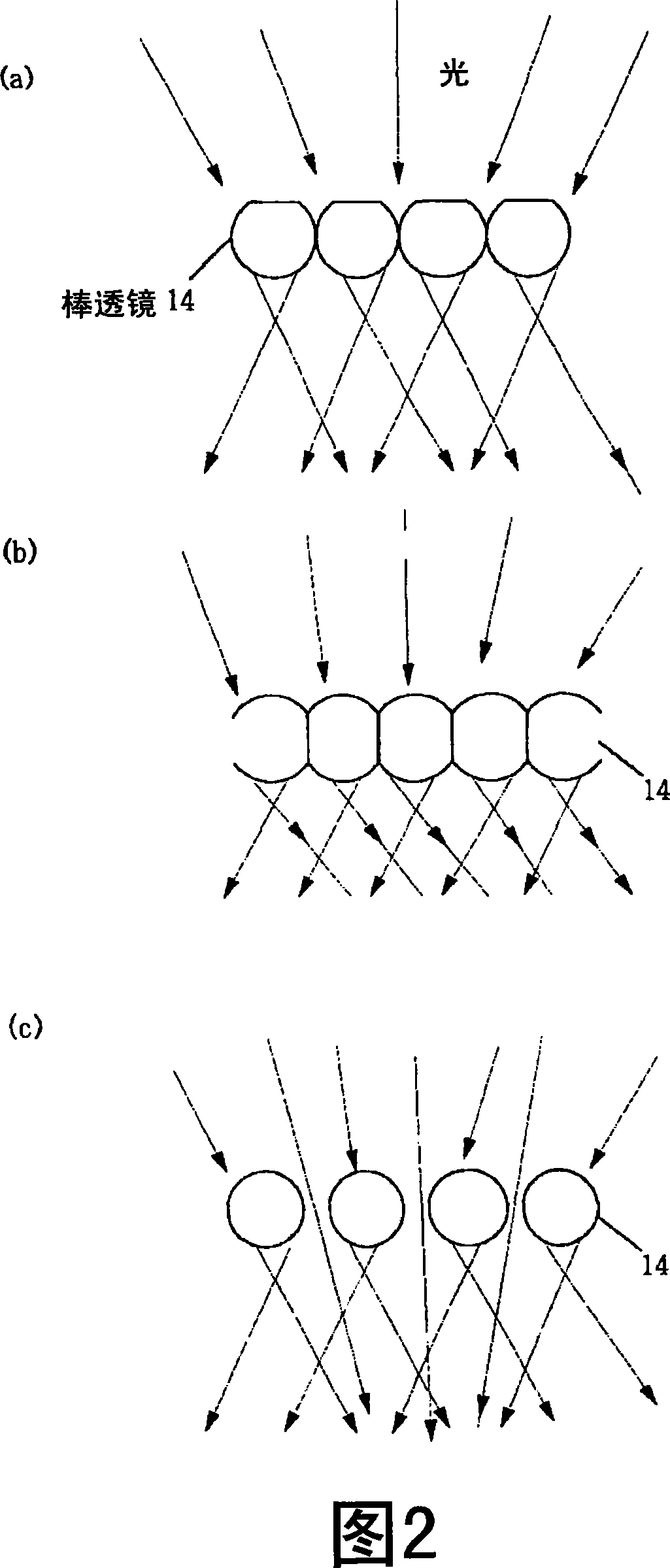

[0124] Furthermore, as shown in FIG. 5, the rod lens 14 provided on the light emitting side of the reflector 11 changes the size so that the light reflected by the reflector can enter the rod lens.

[0125] That is, when there is one rod lens, the diameter R of the rod lens is made equal to or slightly larger than the diameter of the opti...

no. 2 Embodiment

[0131] Fig. 6 is a diagram showing a second embodiment of the present invention configured to obtain a longer linear light irradiation area. 6 shows a light irradiator capable of obtaining a long-line light irradiation region using two sets of light source units 10 shown in FIG. 1 , but two sets of light irradiators shown in FIG. 3 above may be used.

[0132] In FIG. 6, the light source parts 101 and 102 have the same structure as the light source part 10 shown in FIG. The spheroidal reflective surface centered on its optical axis, the light-emitting part of the discharge lamp 9 (for example, the bright spot of the arc), is located at the first focal point of the reflector 11 having the spheroidal reflective surface.

[0133] In each light source unit 101, 102, the light from the discharge lamp 9 is reflected by the reflector 11, and enters the rod lens 14. A linear spotlight extending in a direction.

[0134] In the embodiment shown in FIG. 6 , each light source unit 101, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com