Power conversion device and wind power generation system

A technology of power conversion device and wind power generation system, which is applied in the direction of wind power generation, irreversible DC power input conversion to AC power output, etc., which can solve the problem of height increase and achieve the effect of improving maintenance workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

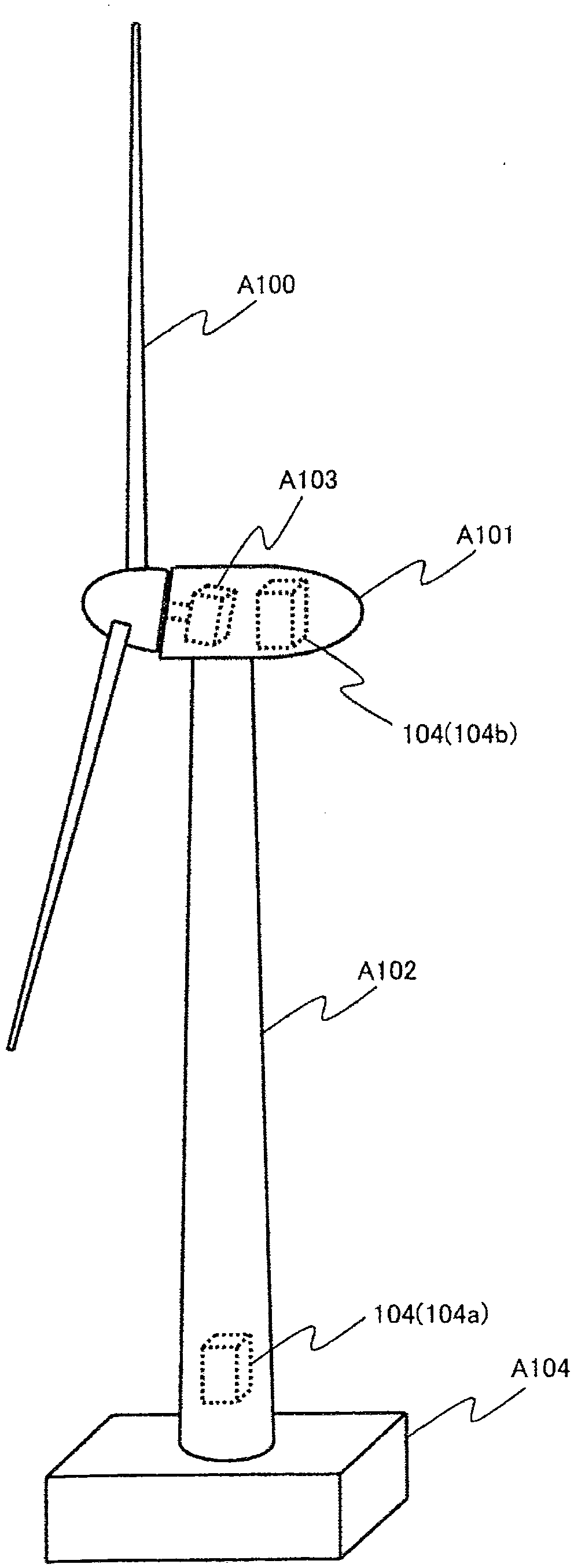

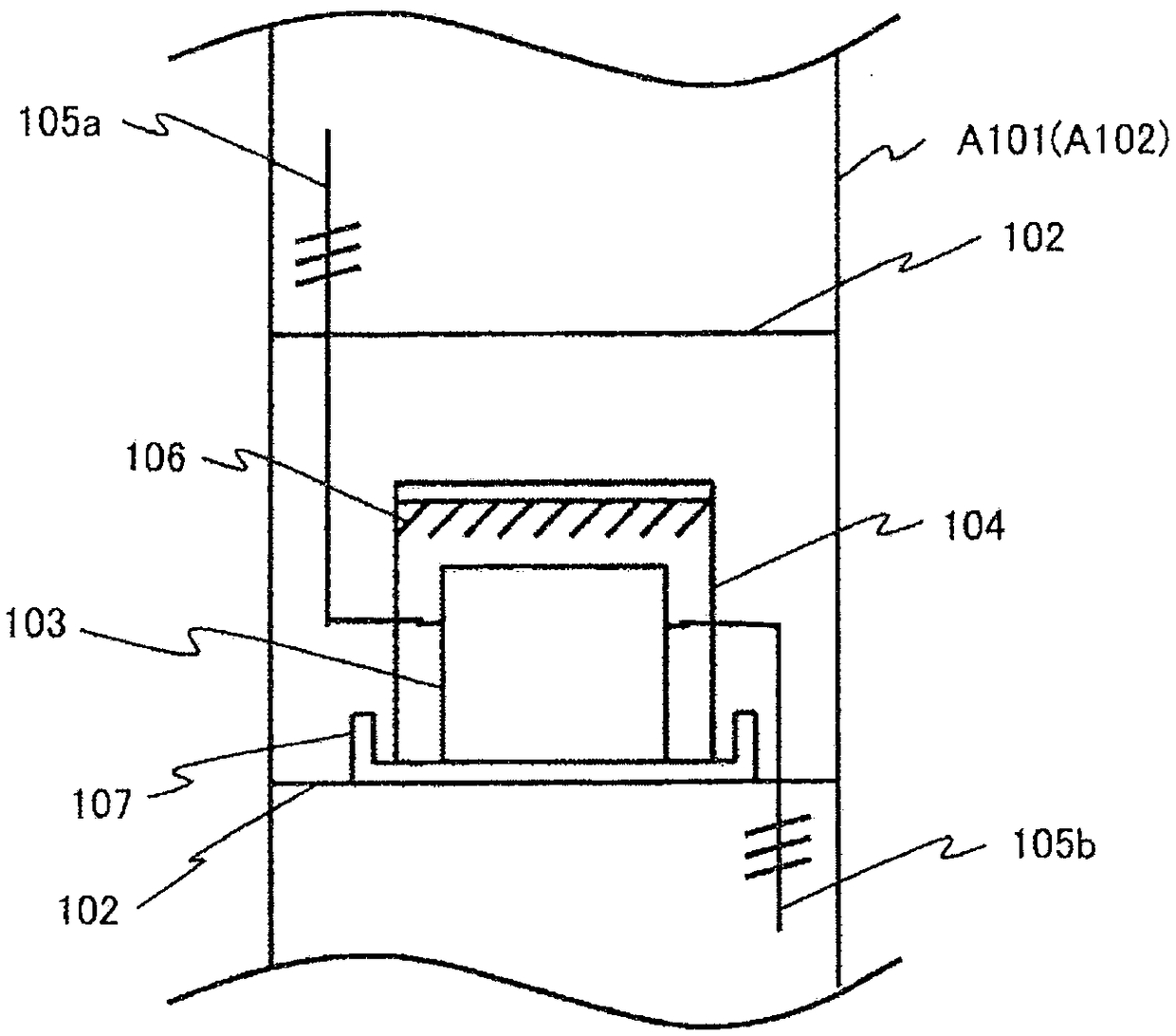

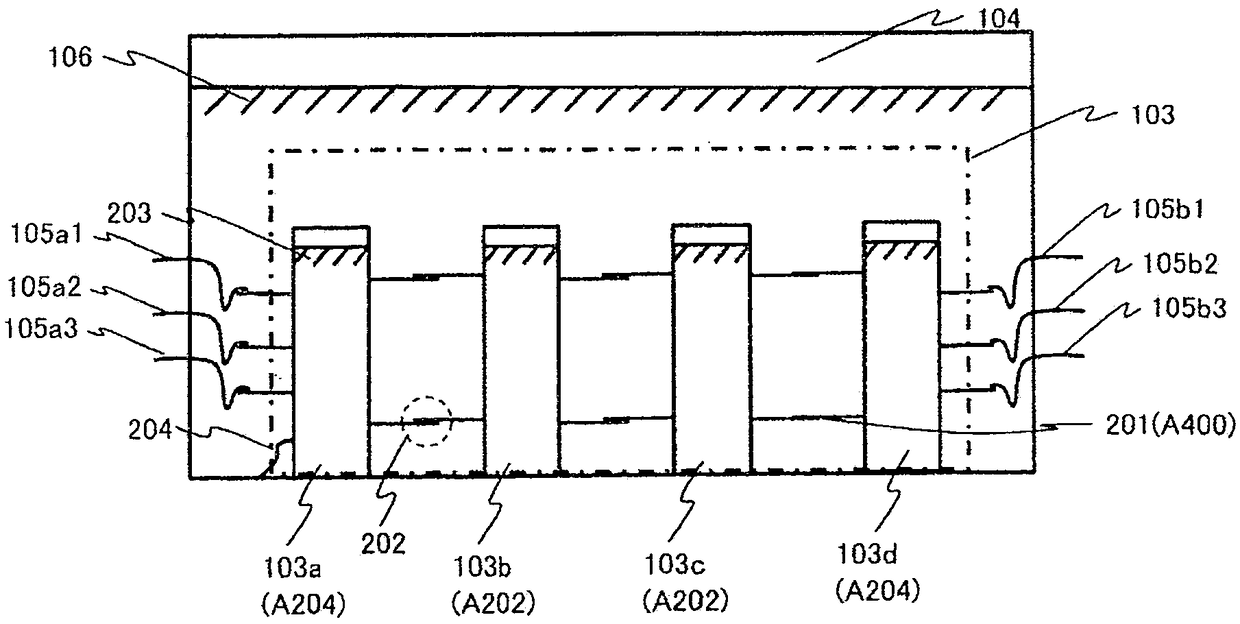

[0028] Hereinafter, an example of application to a wind power generation system will be described. figure 1 A schematic diagram showing a power converter (also referred to as a power conversion device) mounted on a wind power generation facility is shown. The wind power generation equipment is mainly composed of a base (A104), a tower (A102), a dome (A101) and blades (A100), and the generator mounted in the dome (A101) (A103) Power generation. exist figure 1 In the above, the rotating shaft of the blade (A100) is directly connected to the generator (A103), but the same applies to the case where the speed increaser and the gear are mounted on the rotating shaft. During the power generation process of the generator (A103), the rotation of the blades (A100) is dependent on the wind force and the rotational speed fluctuates, so the voltage supplied to the excitation of the generator (A103) or the The output voltage is controlled by power conversion by power converters (104a to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com