Holding member for fuel injection valve

A fuel injection valve and retaining component technology, applied in the directions of low pressure fuel injection, low pressure fuel injection, fuel injection device, etc., can solve problems such as damage to the reliability of the liquid tightness of the fuel injection valve, achieve easy loading and unloading, avoid deformation, The effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

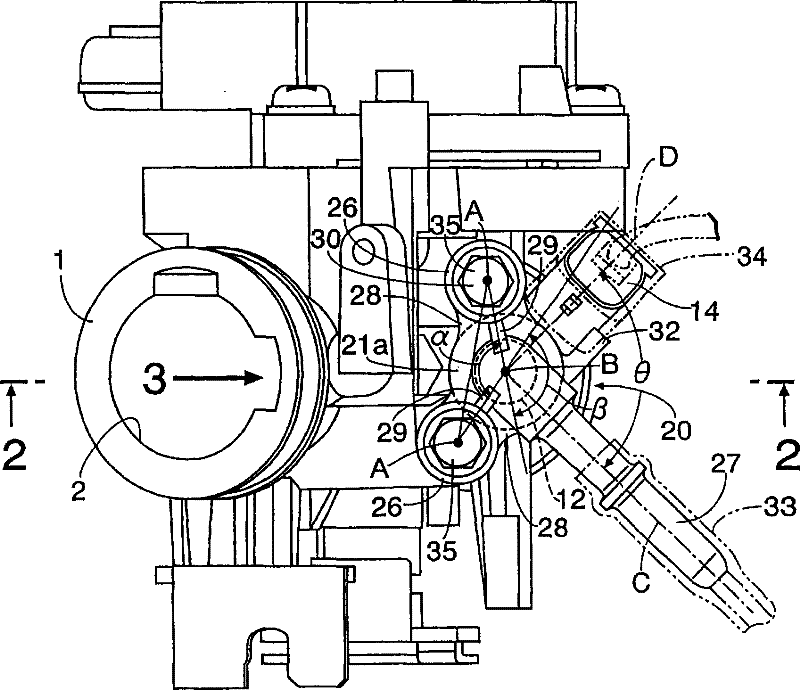

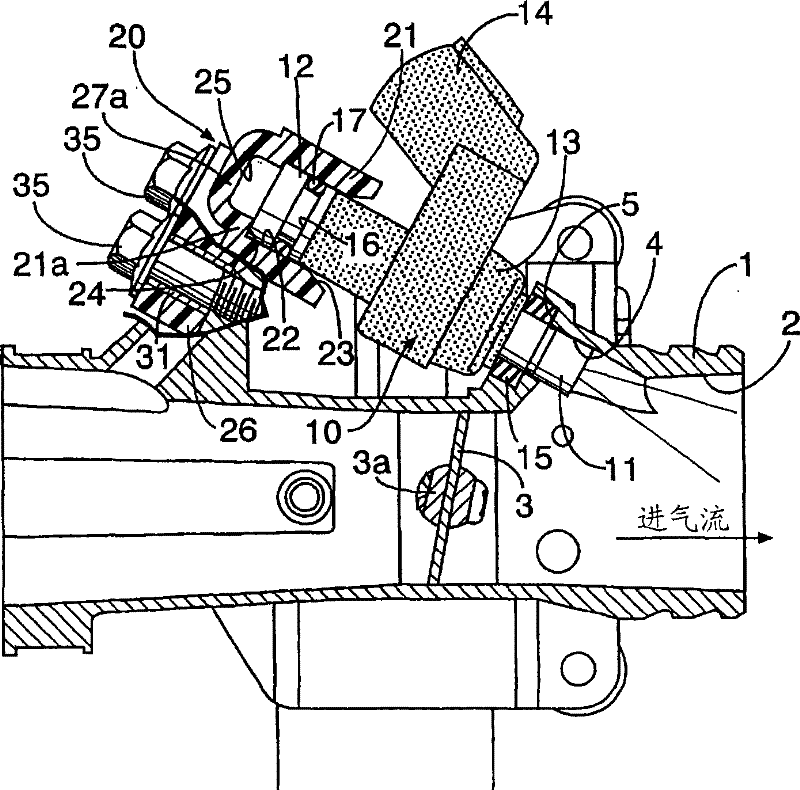

[0055] exist Figure 1 ~ Figure 3 Among them, the throttle valve body 1, which is an intake passage part of the engine, has an intake passage 2 connected to the intake port of the engine not shown in the figure, and opens and closes the intake passage 2 to adjust the intake air volume of the engine. The valve shaft 3 a of the butterfly throttle valve 3 is rotatably supported on the throttle body 1 . On the side wall of the throttle valve body 1 on the downstream side of the throttle valve 3, a mounting hole 4 and a mounting seat 5 are formed. The mounting hole 4 expands radially from the peripheral edge of the outer end.

[0056] On the other hand, an electromagnetic fuel injection valve 10 mounted on the throttle body 1 has a fuel injection portion 11 at one end, and a fuel inlet portion 12 at the other end, and formed on the outer peripheries of their intermediate portions. The casing 13 made of synthetic resin is molded so as to embed the coil portion inside the package, ...

Embodiment 2

[0076] next to Figure 7 A second embodiment of the invention is shown for illustration.

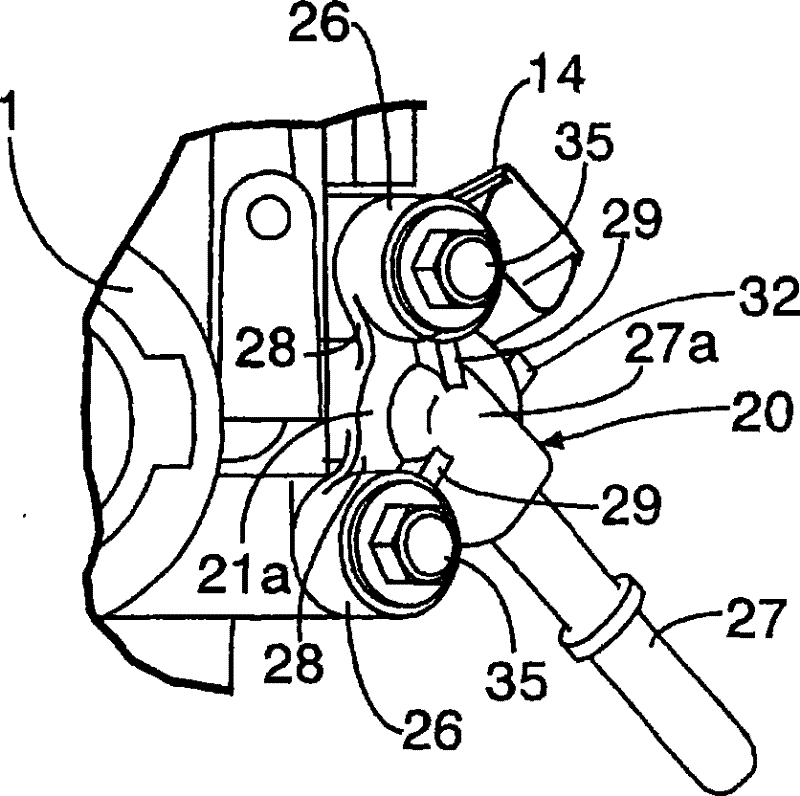

[0077] In the second embodiment, in the holding member 20 made of synthetic resin, on the peripheral edge of the opening of the guide surface 23 of the cover 21 , a pair of mounting protrusions are connected via a connecting portion 28 ′ whose thickness is thinner than that of the cover 21 . The platform parts 26, 26, and these mounting boss parts 26, 26 are arranged on the side of the cover part 21 with a small gap. The other structures are the same as those of the above-mentioned embodiment 1, so in the figure, the parts corresponding to the above-mentioned embodiment are marked with the same reference numerals, and repeated explanations are omitted.

[0078] In this second embodiment, even if the mounting bosses 26, 26 thermally shrink when the holding member 20 is molded with synthetic resin, the heat of the mounting bosses 26, 26 can be blocked by the thin connection portion 28'. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com